Cooling Towers

A cooling tower is an enclosed structure that removes heat from water (or other fluids) used in industrial plants and processes. There are different designs, types, shapes, and sizes of cooling towers. The basic working process is the same, however, and is based on evaporative cooling. Heat from water is transferred to the air through the process of evaporation, which lowers the temperature of the water. A cooling tower is sometimes called an evaporative condenser or a fluid cooler.

Evaporative cooling depends on wet bulb temperature, which is the lowest temperature to which the water can be cooled in the plant, process, or system. The rate of heat transfer needed for the evaporation of water into the air reveals how well the cooling tower is performing. The wet bulb temperature of the air entering the tower is a primary measure of the effectiveness of a cooling tower. The American Society of Mechanical Engineers (ASME) and the Cooling Technology Institute (CTI), an industry association that provides technical and educational services for its members, recommend that towers be sized and tested based on entering wet-bulb temperatures. Note: Wet-bulb temperatures are taken with a psychrometer.

Quick links to Cooling Towers Information

A Brief History of Cooling Towers

In Ancient Greece, Rome, and the Middle East, porous water pots and ponds were used with the concept of evaporation to gain relief from the heat. It wasn’t until the 1800s and the advent of the industrial age, though, that mechanical apparatuses to cool the air by evaporation of water were invented. A British patent from 1819 was one of the first for an evaporative cooler to cool liquids. Early cooling towers coincided with the invention of condensers built for steam engines, which needed cool water to operate. One US patent from 1899 describes a water cooling tower to cool "large quantities of condensing-water . . . [t]he same water is used continuously . . . with peculiar efficiency and economy."

By the early 20th century, there were numerous US patents for inventions variously called "wet boxes, desert coolers, drip coolers, and then swamp coolers." One of the earliest of these direct coolers was a wooden frame wrapped with wet burlap, which utilized fans to force air into the area being cooled. A 1906 patent describes a water cooling-tower apparatus with nozzles, sprayers, and troughs used to "repeatedly distribute the water with great uniformity over the whole horizontal sectional area of the tower." The technology evolved into modern designs as circulating and integrated motor and fan units were incorporated and new materials and plastics were invented.

Applications of Cooling Towers

Heat dissipation is a common and often necessary process in any industrial plant. Towers to cool industrial recycled process water are used in almost all heavy industries, including in steel mills, food and beverage manufacturing, oil and gas refining, pulp and paper mills, chemical processing, and cement plants. They also provide cooled water for power plants that generate excess heat during electricity production, thus providing a consistent supply of liquid for their heat exchange systems. At power plants, chimney-designed cooling towers release excess heat as a water vapor plume, which consists of condensed steam being released to the atmosphere.

As part of large commercial, medical, and industrial HVAC (heating, ventilation, and air conditioning) systems, cooling towers are a standard in the new construction of office buildings, airports, convention centers, hospitals, high-rises, hotels, and manufacturing facilities. HVAC cooling towers impact comfort levels and, as a consequence, the health and productivity of the people inside buildings. Because they are large structures (larger than typical HVAC units) and require a lot of space, they are located outside on the roof or in out-of-the-way places on a building’s grounds.

How Cooling Towers Work

In an evaporative cooling tower, warm water is pumped or sprayed through the top of the tower where it meets cooling air inside the tower (which is fresh air drawn in from the atmosphere). The air forces the water to evaporate and the evaporation removes heat from the water. When the water reaches a lower temperature, the cooled water exits at the base and is returned or recycled back to the machinery or the process. The water again gathers heat from the industrial or machine process and is recirculated to the top of the cooling tower.

Although the idea is to recirculate water so it can be used again, there is water loss in the process due to evaporation, blowdown (removal of water with dissolved solid content or sediment), drift, and even leaks in the system. To compensate for that loss and improve the water-use efficiency, “make-up water” is added during operation.

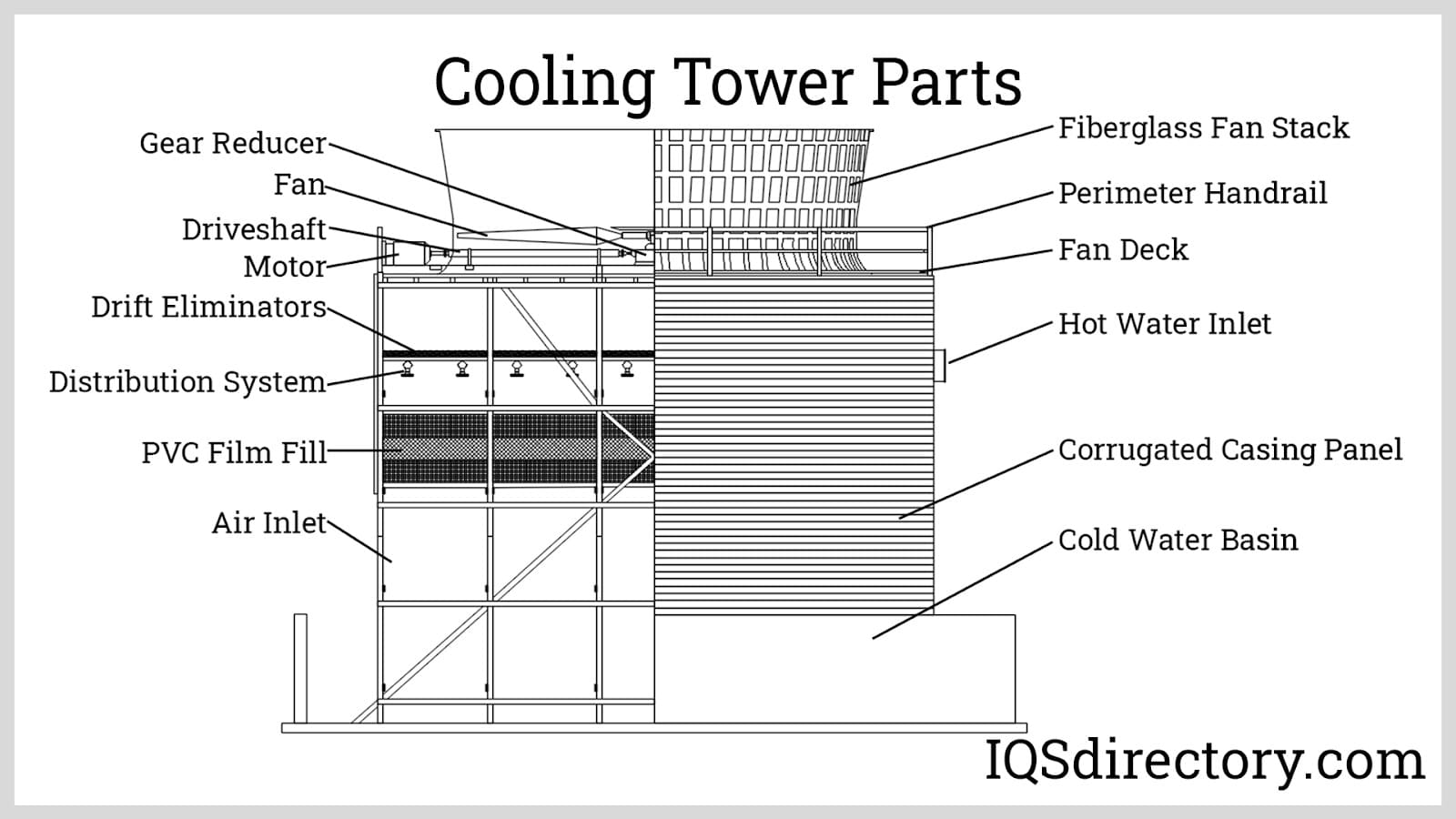

Main Components of Cooling Towers

- Fill Material

- This thermal component is the main area available for transferring heat from hot water to cool air. Fill is usually honeycombed or corrugated in pattern, which maximizes the water surface area. It is usually made of PVC (polyvinyl chloride), PP (polypropylene) material, or stainless steel.

- Water Distribution Deck (or Wet Deck)

- This component is usually a set of nozzles that uniformly sprays water to wet the fill material as it is being cooled. This maximizes heat transfer.

- Air Inlet and Air Outlet

- These are the points where cool air enters and warm air exits the tower. The air inlet may be on one side of the tower (in a cross-flow design) or it may be located near the bottom (in a counter-flow design).

- Intake Louvers

- These equalize airflow into the fill and keep water inside the tower.

- Drift Eliminators

- These are placed next to the fill to capture water droplets in the air stream that would otherwise be lost to the environment as vapor.

- Cool Water Basin

- This is located at the bottom of the tower beneath the fill. It collects the cooled water from the tower and may also serve as the foundation for the main structure.

- Mechanical Components and Instrumentation

- Fans, pumps, and motor drive mechanisms (e.g., gearboxes, driveshaft) move air and deliver the desired airflow. Sensors, sensor connectors, and cables may be mounted to detect vibration, high-frequency gear, and bearing faults. Instrumentation is also needed for measuring hot and cold water temperatures and measuring the flow of make-up water and the blowdown rate. All of these components impact energy efficiency and the amount of maintenance required.

- Casing or Shell

- This is the enclosure, which can be made of chemically treated wood, aluminum, hot dip galvanized steel, ceramic, or reinforced plastics (e.g., glass fiber material to reinforce plastic or other resins). The casing contains the water as it recirculates through the cool tower and provides structural support for the tower fan system and other internal components. The structure may need to be resistant to vibration, high wind load, and corrosion.

Cooling Tower Design and Customization Considerations

Cooling towers are categorized according to how air flows within the tower, by both the direction of airflow (counter-flow or cross-flow) and the type of draft (mechanical or natural). Equipment is also manufactured in a round or bottle shape, a rectangular shape, or hyperboloid (an identifying feature of power plants). Each design has its advantages and disadvantages. The final design choice is determined by many factors, including the user's requirements and application, economics, and even the location and the average weather conditions where the tower is built. The efficiency of evaporative cooling is affected by outside temperature, relative humidity, and wind velocity.

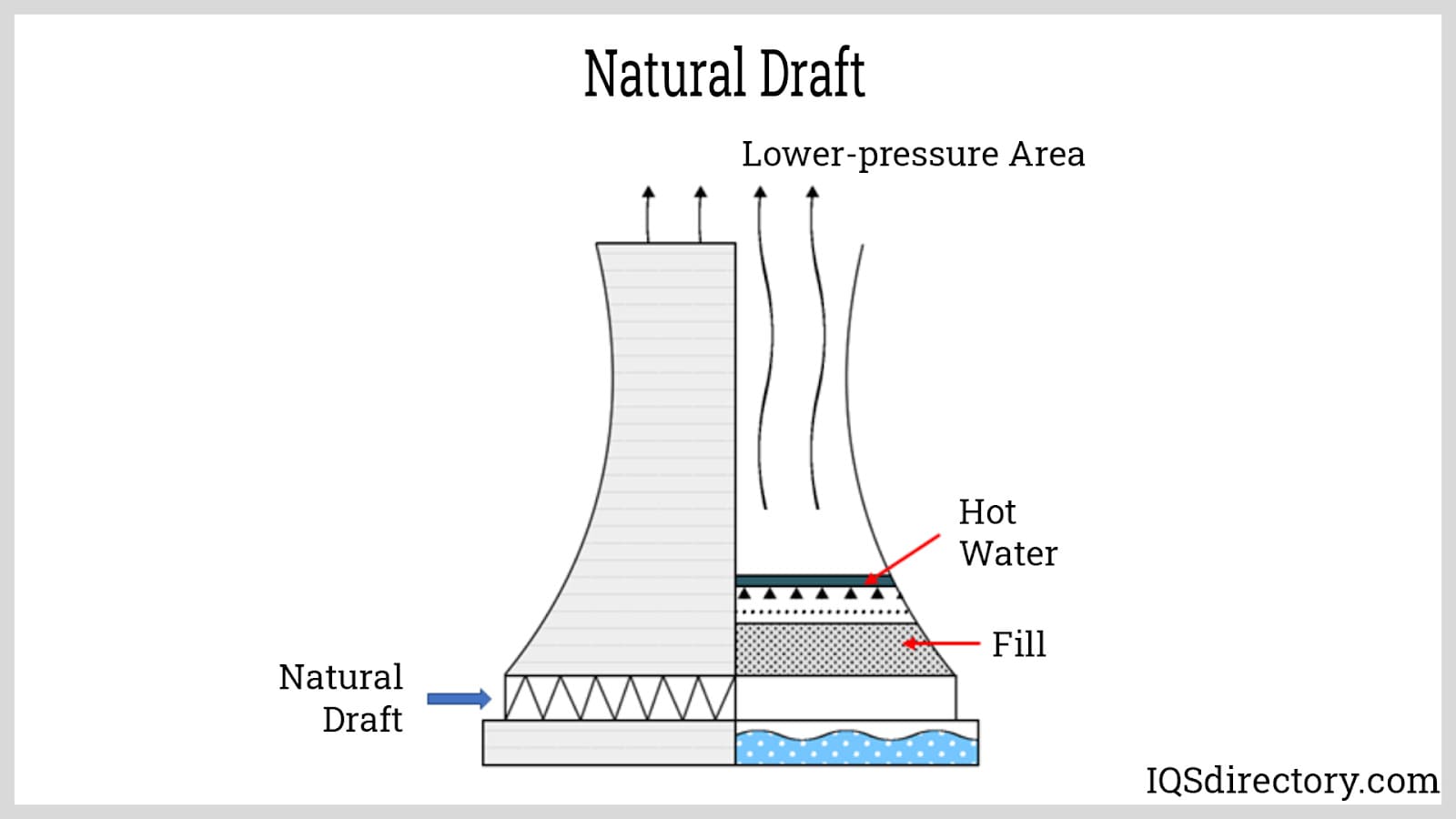

Natural draft towers use a chimney design and rely on the difference in pressure and temperature between the air outside (cool) and the air inside the tower. The tall chimney in which the air rises provides the updraft, without the need for a tower fan. Natural draft towers are best suited for open areas because performance depends on wind direction and velocity. This design is rarely used in HVAC cooling towers. Hyperboloid-designed towers at nuclear power and large coal-fired plants are natural draft designs that handle large water capacity requirements.

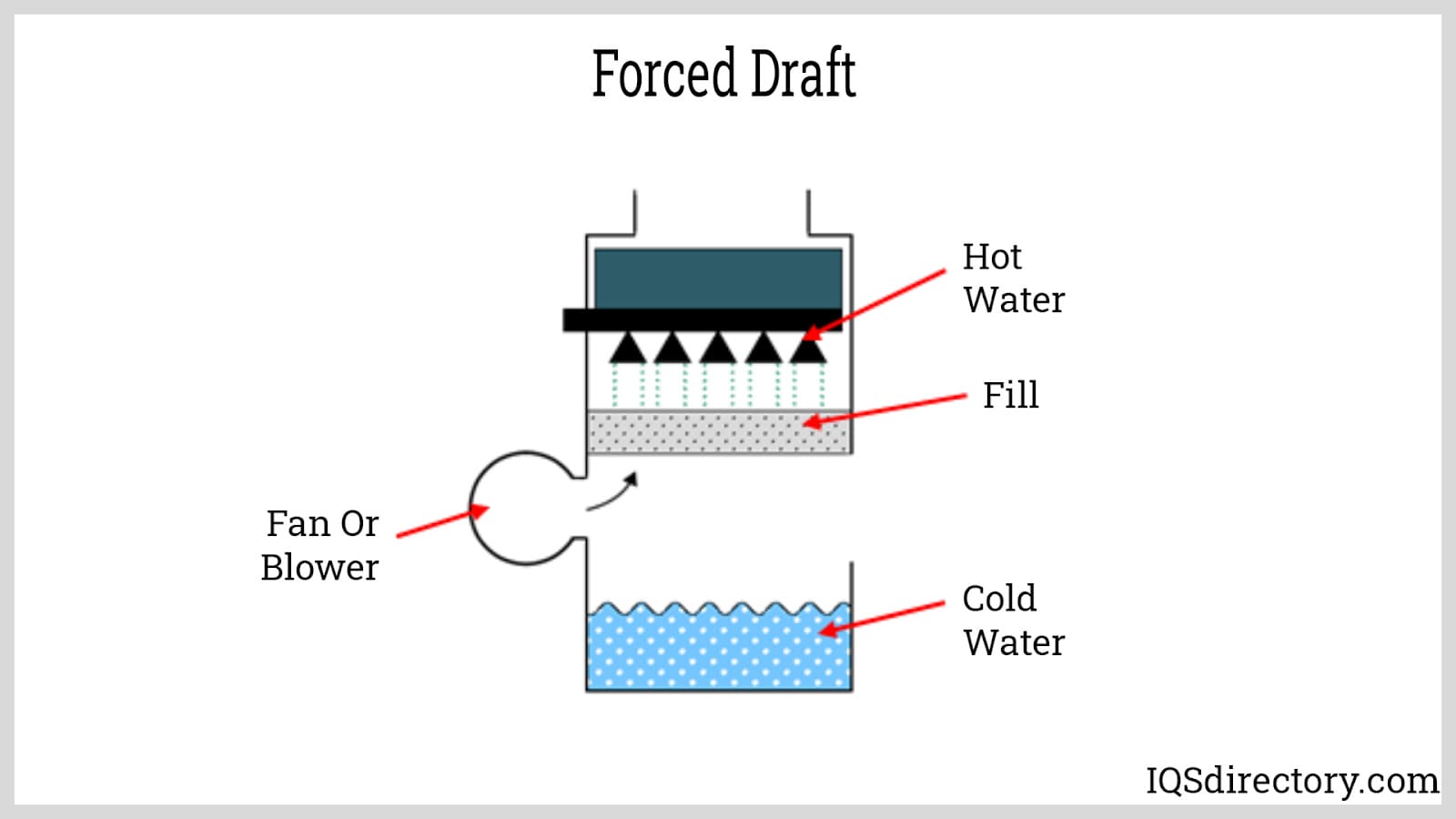

Mechanical draft towers use electric-powered fans to force air through the structure and may use cross-flow (in which air flows perpendicular to water flow) or counter-flow (in which air flows opposite to the water flow) designs. Counter-flow towers may be built with a smaller footprint because they are more compact than cross-flow towers in which the air flows horizontally. Mechanical draft towers can be costlier to operate because of the mechanical components needed to circulate air in the tower. They are easier to locate on or near buildings, though, so they are used in HVAC and refrigeration applications.

A round or bottle shape is a popular design for cooling towers in industrial processes because it allows for maximum cooling space and minimal area. These towers are available in many capacities and can be factory-built or erected on site. Rectangular shape cooling towers are common in air-conditioning plants.

There are user-defined design considerations as well, such as safety, noise abatement, erosion resistance, and chemical resistance.

Here are some examples of towers designed with user-defined considerations:

- Towers made of wood are susceptible to fire and rot because of the constant wet cooling environment; chemically treated wood is falling out of favor because it poses certain environmental and health risks.

- Towers made of fiber-reinforced polyester and hot dip galvanized steel are rigid in structure and can resist rot and rust and withstand many years of operation. However, pre-fabricated steel is heavy to transport and expensive to construct, requiring highly skilled workers. Plastic, on the other hand, is high strength but lightweight and easier to customize and transport than steel.

- Cooling towers can be noisy. In communities or buildings (e.g., schools, hospitals) where noise may be a special concern, a cooling tower may need to be acoustically engineered.

Cooling Tower Safety and Maintenance Considerations

Warm, moist environments are a breeding ground for microorganisms and biofilms that can cause operational and mechanical problems with cooling equipment, as well as human health issues. Cooling towers and evaporative condensers that use fans to move air through a recirculated water system and introduce large amounts of water vapor into the environment require frequent maintenance and cleaning, the addition of biocides, and inspection for growth of harmful Legionella bacteria (associated with pneumonia-like Legionnaires disease), in accordance with regulations in certain cities and states. Water quality assurance testing of the make-up water source (e.g., groundwater or surface water) is another consideration for the safe operation of a cooling tower.

Under the Clean Air Act Amendments of 1990, the Environmental Protection Agency (EPA) has rules to reduce emissions of air toxins with health effects from industrial process cooling towers.

There are safety code standards (NFPA 214) that apply to fire protection for field-erected and factory-assembled cooling towers; both for the combustibility of the construction materials and the fill.

Choosing a Cooling Tower Manufacturer

Many companies make or sell cooling tower equipment. Most are small companies. There may be fewer than a dozen large, global manufacturers. Companies compete with each other based on their products’ key properties. For a cooling tower, these key properties are psychrometric properties, energy efficiencies, and cost (including lifetime/maintenance costs).

There is a difference between a good manufacturer and the right manufacturer. The right manufacturer suits the customer’s needs. To select a manufacturer, customers should know whether the manufacturer provides its cooling towers as fully engineered equipment that the company sells or if it works with partner OEMs (original equipment manufacturers). Evaluate whether the company can supply replacement or spare-part products directly to customers and their facilities and if it offers good maintenance and quality assurance service (product and/or parts warranties) and a selection of reliable mechanical components. An easy way to find a Cooling Tower Manufacturer is to visit the company directory at the top of this page.

When cooling tower equipment is properly designed and maintained, it should be able to last for approximately 20 years and provide water to a plant, process, or system at a specified water temperature and flow rate and keep the entire cooling process performing optimally and energy efficiently. Connect with designers of cooling towers who can ensure you will receive an ideal system for your needs here on IQS Directory.

Cooling Tower Images, Diagrams and Visual Concepts

How a cooling tower exchanges heat by transfering the tempature between the air and water.

How a cooling tower exchanges heat by transfering the tempature between the air and water.

Cooling tower are broken down into structural (static equipment), mechanical (rotating equipment), and electrical parts.

Cooling tower are broken down into structural (static equipment), mechanical (rotating equipment), and electrical parts.

Natural draft cooling towers utilize no mechanical drivers or fans to create air flow through the cooling tower.

Natural draft cooling towers utilize no mechanical drivers or fans to create air flow through the cooling tower.

Forced draft cooling towers uses fans or blowers to force air into the cooling tower.

Forced draft cooling towers uses fans or blowers to force air into the cooling tower.

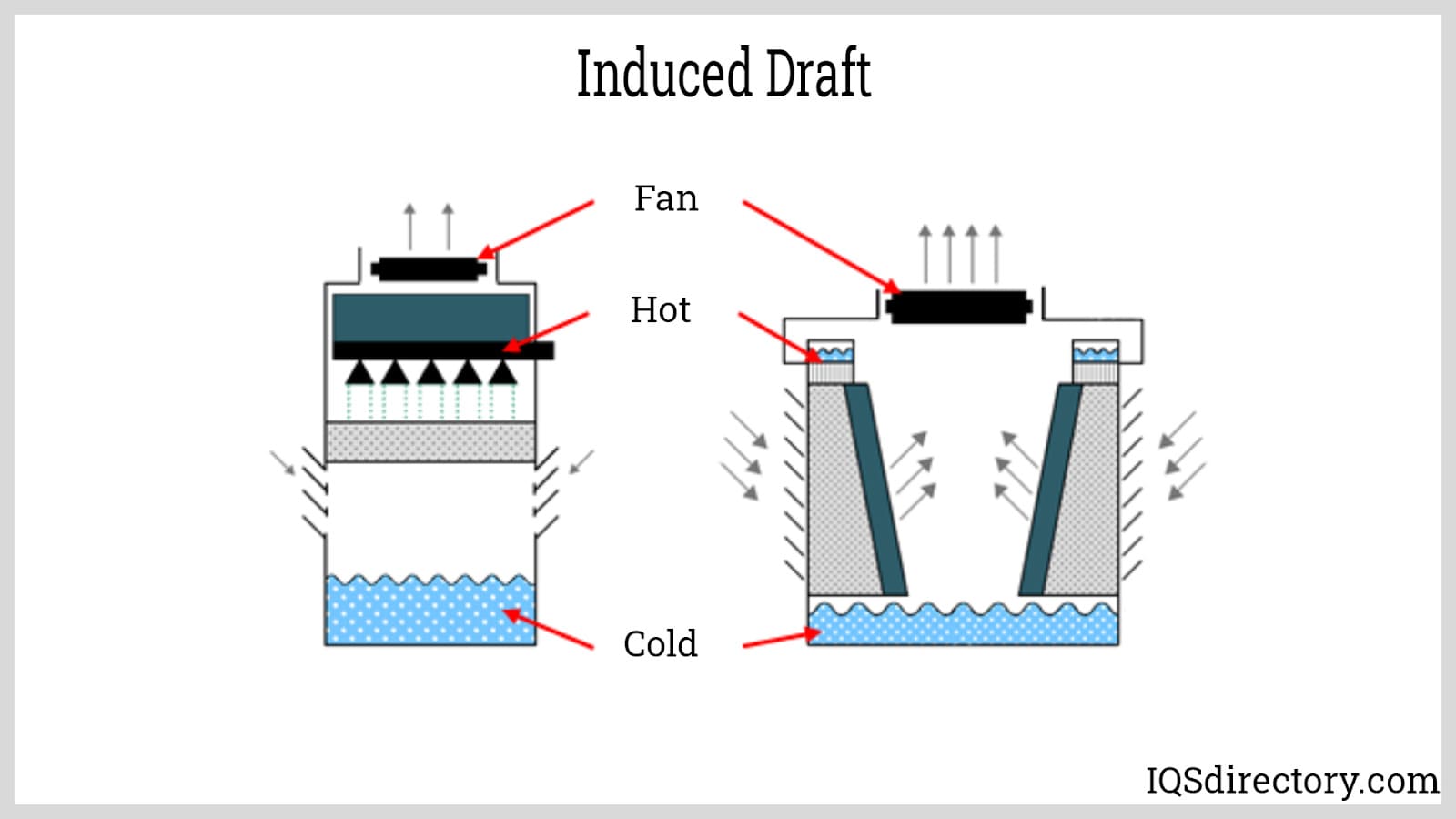

Induced Draft cooling towers have fans located at the top that draws air from the air intake louvers at the bottom or sides of the tower.

Induced Draft cooling towers have fans located at the top that draws air from the air intake louvers at the bottom or sides of the tower.

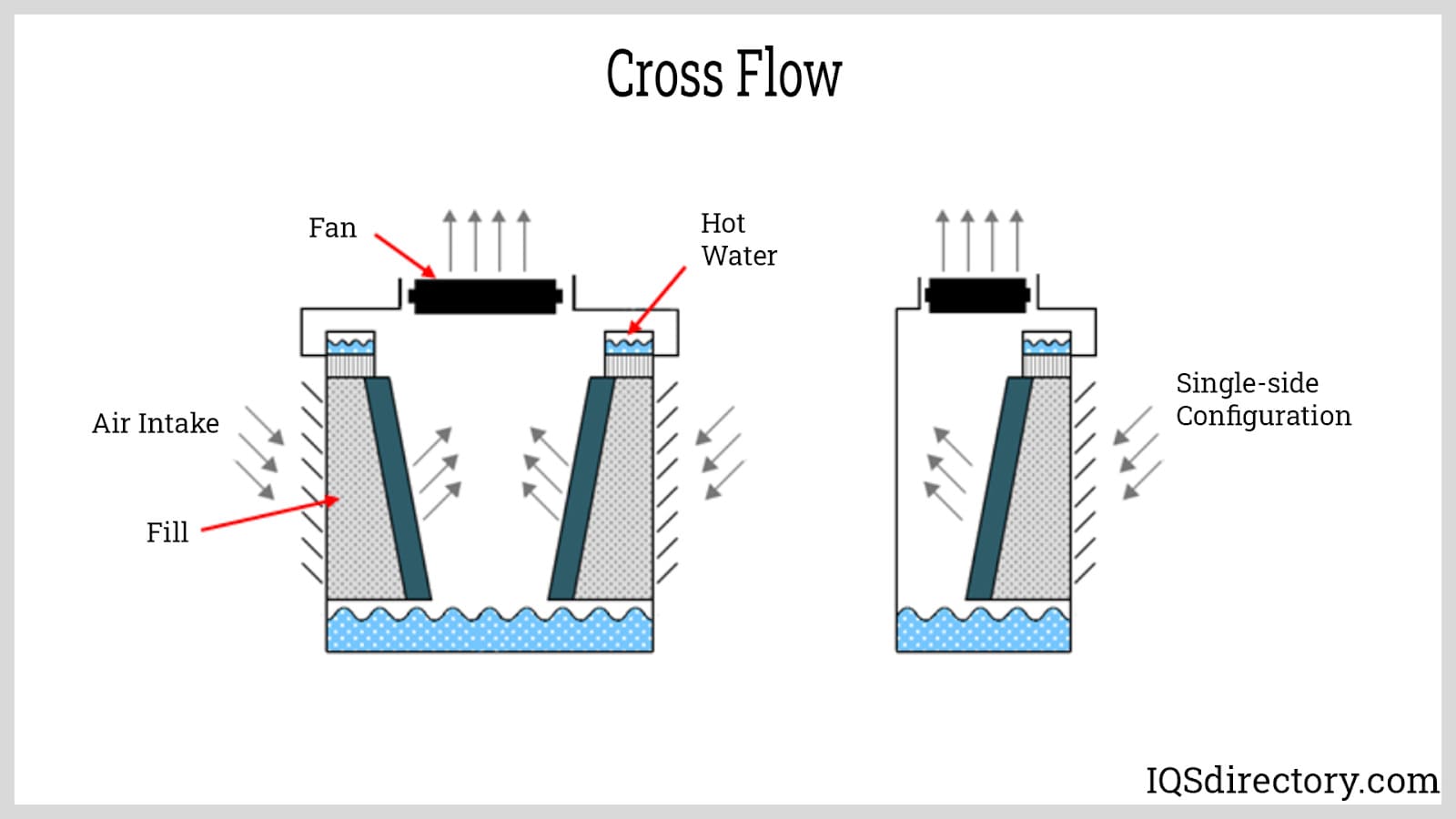

Cross-flow configuration, air flows horizontally through the fills across the downward fall of water.

Cross-flow configuration, air flows horizontally through the fills across the downward fall of water.

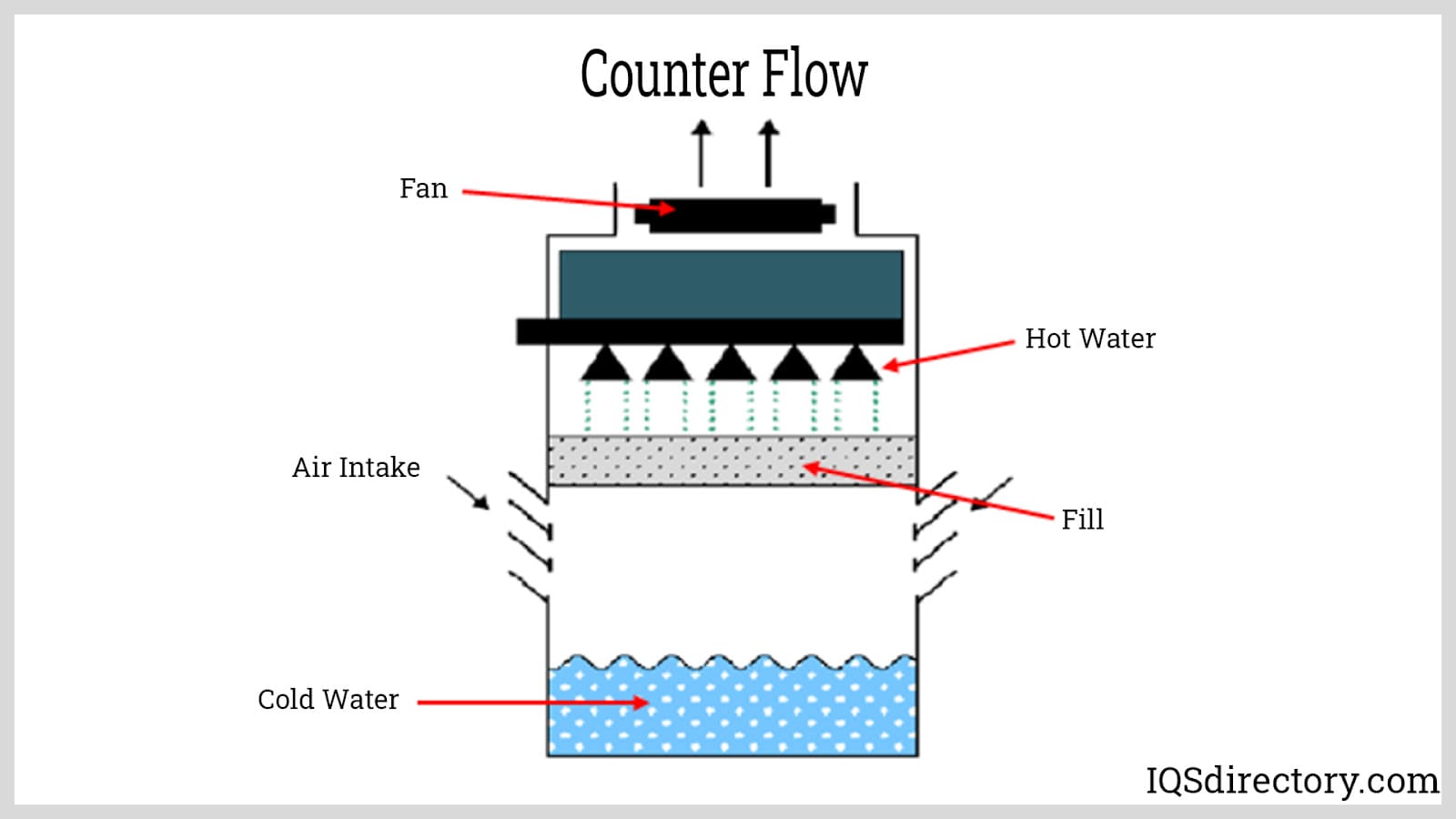

Counter-flow cooling towers has air flows parallel but opposite to the fall of water, with a pressurized-spray distribution system.

Counter-flow cooling towers has air flows parallel but opposite to the fall of water, with a pressurized-spray distribution system.

Cooling Tower Types

- Air Conditioner Cooling Towers

- Provide air conditioning and are fiberglass structures that cool larger buildings like hospitals, schools, and some offices.

- Ceramic Cooling Towers

- Have an attractive appearance but are usually more expensive than other cooling towers.

- Chillers Cooling Towers

- Supplementary means of eliminating waste heat that is a byproduct of many processes which require the use of air and liquid chiller systems.

- Closed Loop Cooling Towers

- Cooling towers in which the air and cooled water or other fluid do not have direct contact.

- Cooling Tower Design

- Determines the cost, performance, and efficiency of a cooling tower.

- Cooling Tower Manufacturers

- Companies that make units that cool fluids.

- Cooling Tower Systems

- Sometimes referred to as heat rejection devices. They cool water and other fluids through the removal of heat from the fluid.

- Counterflow Cooling Towers

- Contain opposing air and water flows. The airflow moves up and the water flow moves downward.

- Cross Flow Cooling Towers

- Contain perpendicular air and water flows. The airflow is horizontal, and the water flows vertically downward.

- Disinfection Cooling Towers

- Used in drinking water and wastewater treatment facilities to assist in the elimination of bacteria, chemicals, and other impurities in the water.

- Evaporative Cooling Towers

- Heat extraction devices. They use the evaporation of a small amount of working fluid, typically water, to transfer heat into a moving air stream to cool the rest of the water stream close to the wet-bulb air temperature (which is a designed measurement of temperature reflecting the desired level of water vapor content of the cooling tower).

- Fiberglass Cooling Towers

- Have great weather resistance, which makes them useful in harsher environmental conditions. These cooling towers also provide good corrosion resistance, which is advantageous in applications such as water treatment, in which the tower will be exposed to chemicals.

- HVAC Cooling Towers

- Combine a water-cooled chiller, or condenser, with a cooling tower.

- Hyperbolic Cooling Towers

- Refers to a specific design and construction style for cooling towers. It utilizes hyperbolic structural planning, which creates a natural draft and employs evaporation to cool water and other fluids.

- Industrial Cooling Towers

- Heat rejection systems used for the cooling of water and other working fluids by removing process waste heat from the fluid and releasing it into the atmosphere.

- Mechanical Draft Cooling Towers

- Consist of forced draft towers. They contain side fans, which force the air through the system, and induced draft cooling towers, which contain overhead fans that pull the air through the system. Mechanical draft cooling towers are often used in smaller cooling tower systems.

- Natural Draft Cooling Towers

- Do not utilize fans but rely on exhaust air buoyancy and natural winds to move the air through the system. Natural draft cooling towers are used in applications involving large volumes of water, such as power generation plants.

- Open Circuit Cooling Towers

- Cooling towers in which water is internally distributed within the system and there is direct contact with the entering air.

- Water Cooling Towers

- Basic cooling systems used to cool water through contact with airflow. Applications utilizing water cooling towers include air conditioning and water/wastewater.

Cooling Tower Terms

- Ambient Temperature

- The DBT as measured by a thermometer.

- Axial Fans

- Fans in which the direction of the airflow does not change. Axial fan types include propeller, tubaxial, and vaneaxial.

- Blowdown

- Water removed from a cooling tower to prevent excessive buildup of impurities within the system. Impurities increase in concentration as water evaporates during the cooling process.

- Blow Out

- Water removed from a cooling tower through wind or splashing. Blow out is reduced or eliminated through the use of screens and other mechanisms.

- BTU (British Thermal Unit)

- The amount of heat gain or loss needed to change the temperature of one pound of water by one degree Fahrenheit.

- Drift

- Water droplets removed from a cooling tower along with the exhaust air. Drift must be controlled because, unlike the water vapor removed from the tower, drift often contains chemicals, debris, and other impurities that may negatively affect the environment.

- Drift Eliminator

- A mechanism in a cooling tower that prevents drift from leaving the tower by catching the drift as it flows through the eliminator while allowing the release of exhausted air through the eliminator and into the atmosphere.

- Dry Bulb Temperature (DBT)

- The temperature of the air entering the cooling tower, measured in degrees Fahrenheit.

- Entrainment

- Water in the air being brought into the cooling plumes as the liquid wastes are discharged.

- Exhaust Air

- The air removed from the cooling tower during the cooling process. Exhaust air also contains water vapor that has evaporated during the cooling process.

- Fill

- A labyrinth-like packing that provides a vastly expanded air-water interface. This allows heating of the air and evaporation to occur. Film fill consists of multiple, typically vertical, wetted surfaces upon which a thin covering of water spreads, while splash fill consists of many levels of horizontal splash elements that create a cascade of tiny droplets and have a large combined surface area.

- Fogging

- The foggy condensation of water vapor outside of a cooling tower resulting from the contact of saturated exhaust air emerging from the tower with cooler air outside of the tower.

- Induced Draft

- The process in which the fan of the cooling tower draws air from the bottom of the unit and passes it out through the top of the cooling tower.

- Noise

- Sound energy generated by the impact of falling water, movement of air by fans, and the movement of fan blades within the structure and the drive belts, gearboxes, and motors emitted by a cooling tower and recorded at a certain distance and direction.

- Nozzle

- A mechanism through which water flows into a cooling tower in either spray or stream form.

- Plume

- Exhaust air and water vapor emerging from a cooling tower. A plume may create fogging when introduced to air of a lower temperature.

- Psychrometer

- Mechanism used in a cooling tower system to measure the wet bulb temperature of the system.

- Recirculation

- The entrance into a cooling tower of previously discharged air that reenters the system along with fresh air.

- Thermal Capacity

- Cooling tower capacity representing the amount of liquid, measured in gallons per minute, that a cooling tower can process.

- Wet Bulb Temperature (WBT)

- The temperature within a cooling tower at which the air is saturated with water vapor, preventing the further occurrence of water evaporation.