Pulverizers

Pulverizers are used to reduce the size of materials through grinding and crushing. Size reduction is an important part of a wide variety of industrial processes. Pulverizer manufacturers provide pulverizers that can be used on many different material types, including brick, shale, coal, concrete, limestone, wood, and even plastic materials. Because there are so many uses of pulverizers, and because they are used to process such a wide range of materials, an equally wide range of pulverizer configurations is necessary to accommodate them.

Quick links to Pulverizers Information

The History of Pulverizers

The concepts of grinding, crushing and pulverizing have been present for time immemorial. Modern pulverizing machines, on the other hand, have been in use since for a much shorter period of time.

Before pulverizing technology, people crushed coal and other mined materials using hand hammers or water powered trip hammers in small, charcoal-fired iron works and smithies. This was common from the Renaissance to the mid-Industrial Revolution. After the discovery of explosives, this gave way to the use of crushers, first found in foundries, then moved to coal breaker facilities. Coal mining only became more popular as time went on and people began using chimneys. In 1824, Sadi Carnot published a theory on the thermodynamic cycle of the heat engine, which he applied to the development of an engine that relied on pulverized coal.

While coal was one of the first focuses of pulverizing equipment, it soon diversified. In the United States in the late 1800s, several people received patents for various machines designed to pulverize or crush soil. At this time, most of these patents were designed for use on the farm. In 1886, for example, Fred Hepworth and Lou Satany of Aurora, Illinois received a patent for a "soil pulverizer." In 1892, Frederick Meier of Battle Creek, Michigan received a patent for a "clod crusher."

During the 1900s, engineers and manufacturers continued to develop new and improved pulverizer equipment. In 1954, for example, engineers developed a jet pulverizer that pulverized materials like coal at a high speed. In addition, mills, which were once powered by hand, are now generally powered by electricity. Pulverizers of today are also often assisted by CNC technology, which helps manufacturers pulverize with more precision and control. Another endeavor of modern pulverizer service providers is the search for more sustainable and energy efficient practices.

Advantages and Disadvantages of Pulverizers

It is important to explore the safety regulations associated with the material being reduced. Because of the immense force and pressure used in industrial pulverizers, the risk of employee injury can be high if proper safety precautions are not taken. Safety items such as guard rails, shields, sensors and auto shut-off controls decrease the likelihood of accidents. When properly installed, maintained, and operated by trained professionals, pulverizers are invaluable assets to many operations.

Design of Pulverizers

Every coal pulverizer is designed with a particular fuel grinding capacity, or throughput, at a certain Hardgrove grindability index (HGI), based on moisture content, a defined raw coal size, and desired fineness level. These factors must all be considered and are significant in discussions of pulverizer capacity. A well-performing pulverizer requires good fuel fineness and optimum airflows to achieve optimum combustion for your boiler.

Pulverizer machines can be used to pulverize or granulate and simultaneously air classify materials such as:

- Chemicals

- Minerals

- Limestone

- Phosphate Rock

- Pigments

- Tobacco

- Clay

- Barite

Characteristics of Pulverizers

Some pulverizers are capable of processing materials continuously, while other pulverizers process materials in batches. Single-batch pulverizers shut off once the desired time duration has transpired in order to achieve appropriate particle size. Usually more dense materials such as plastic or wood are processed in single batch pulverizers, whereas concrete or coal can be continuously fed into a pulverizer via a conveyor or other automated system.

Pulverizers are available in carbon, stainless steel and other materials depending on their intended use, since certain materials may be more suited for use in different applications and industries such as in food or other industries that require sanitary materials.

Pulverizer Images, Diagrams and Visual Concepts

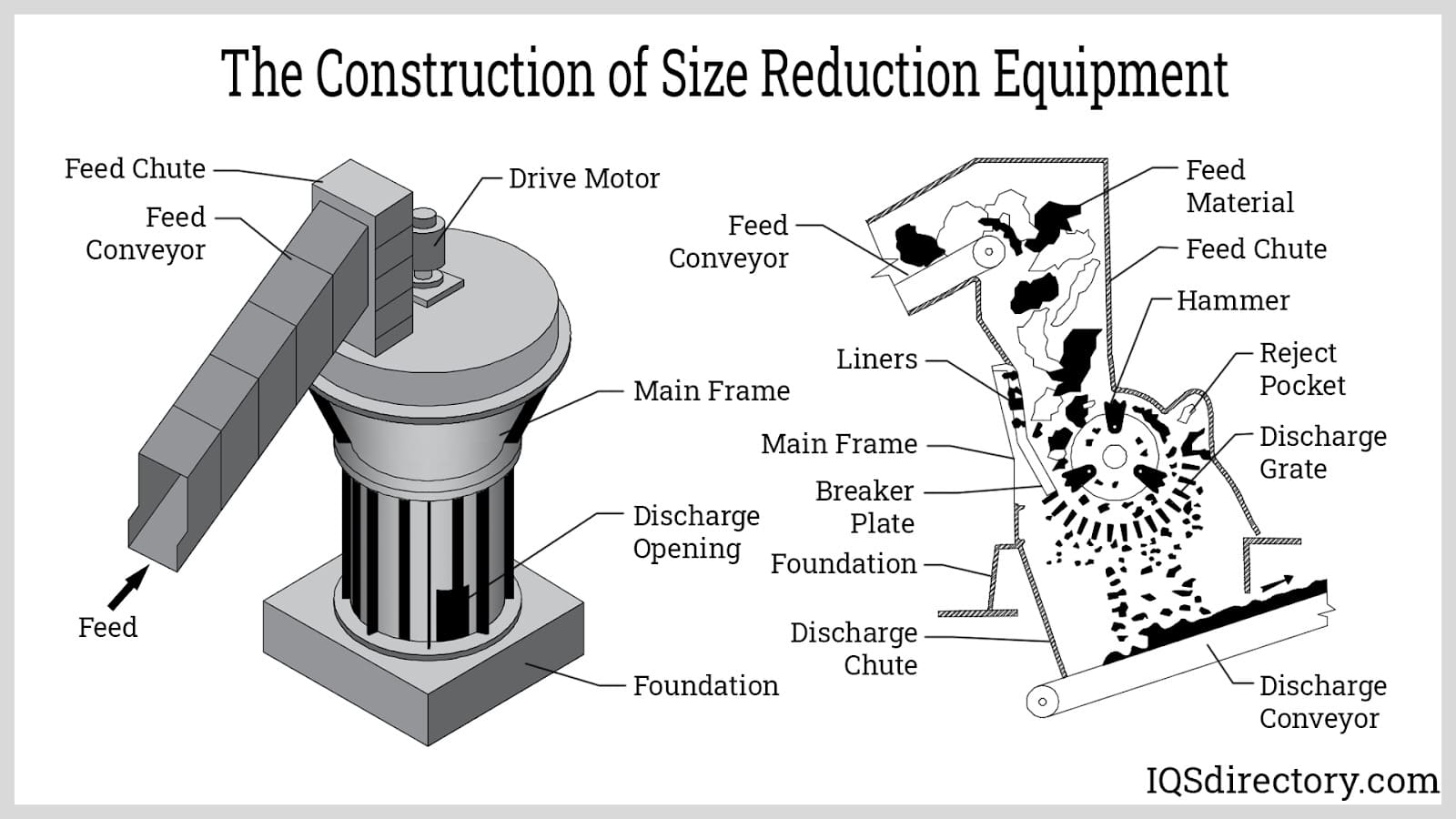

Every machine is designed for a certain throughput capacity or grinding capacity.

Every machine is designed for a certain throughput capacity or grinding capacity.

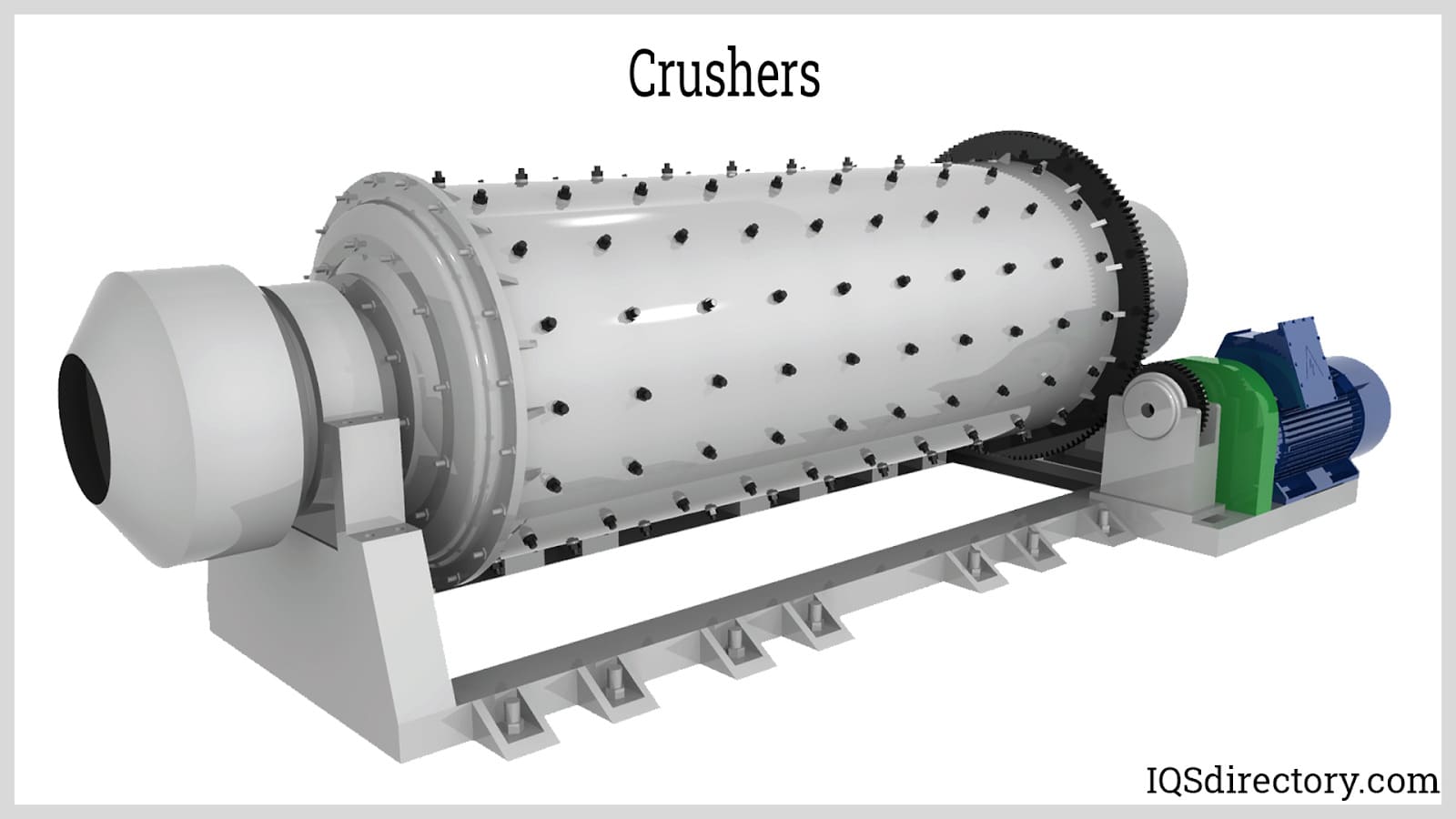

Crushers are tools to reduce big waste materials for easy recycling or disposal.

Crushers are tools to reduce big waste materials for easy recycling or disposal.

Grinding mills, tools to break huge quantities of solid objects into small particles using varying methods.

Grinding mills, tools to break huge quantities of solid objects into small particles using varying methods.

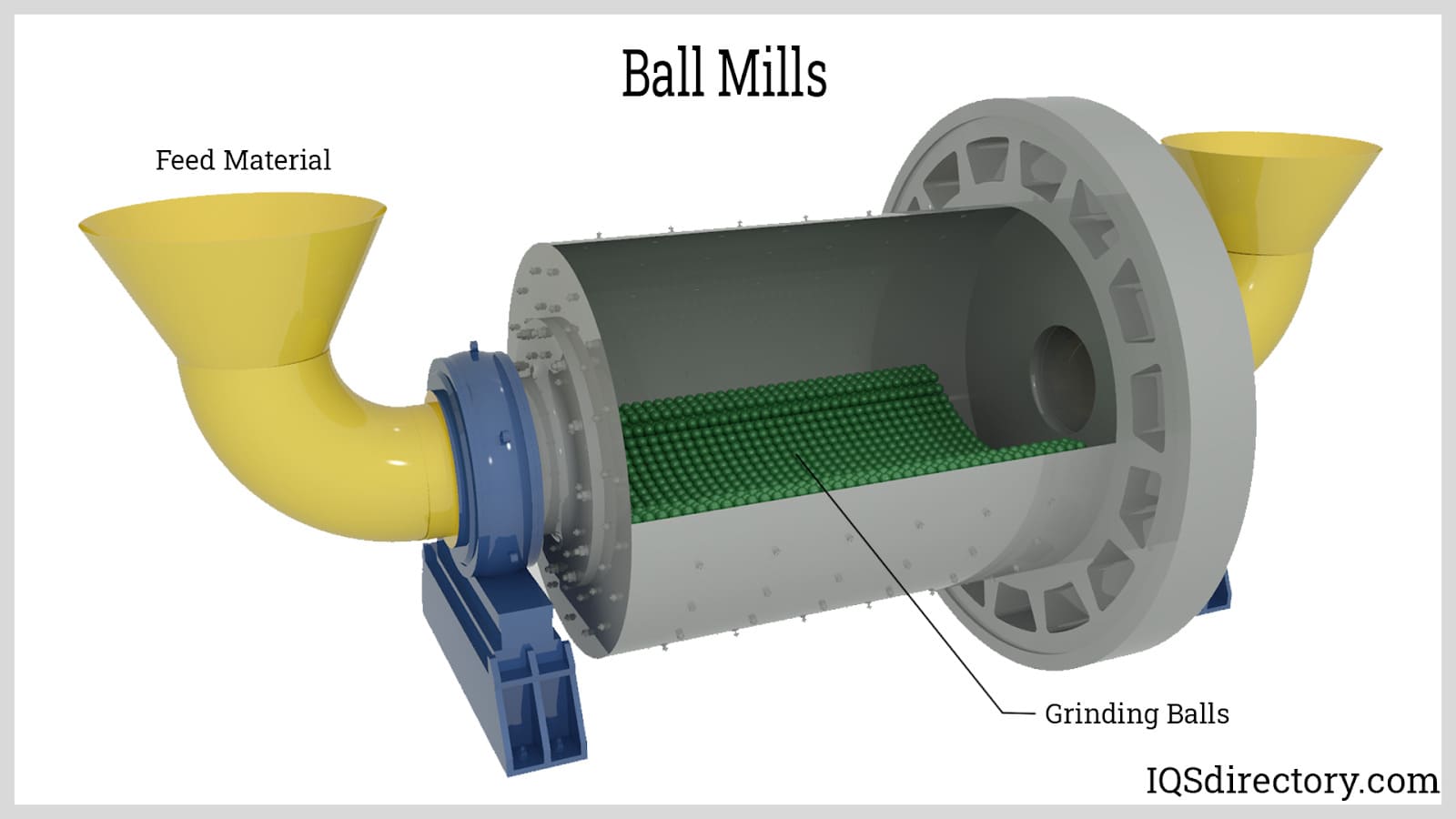

Ball mills, industrial crushing machines that are categorized by their usage of a loose crushing medium and size of reduction machine.

Ball mills, industrial crushing machines that are categorized by their usage of a loose crushing medium and size of reduction machine.

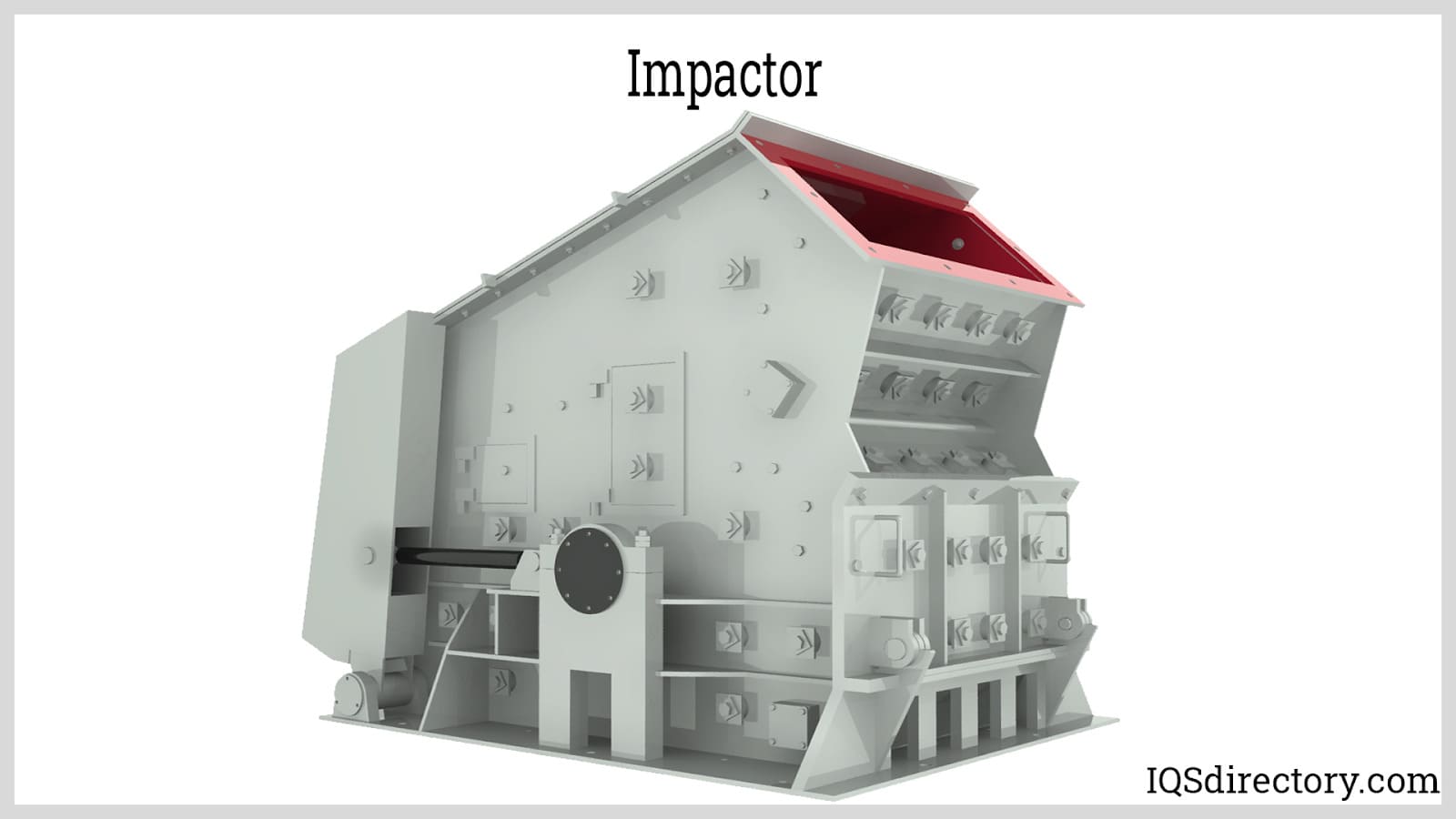

An impactor, a type of size reduction machine that uses a collision-fashioned force, rather then applying sheer pressure to break apart objects.

An impactor, a type of size reduction machine that uses a collision-fashioned force, rather then applying sheer pressure to break apart objects.

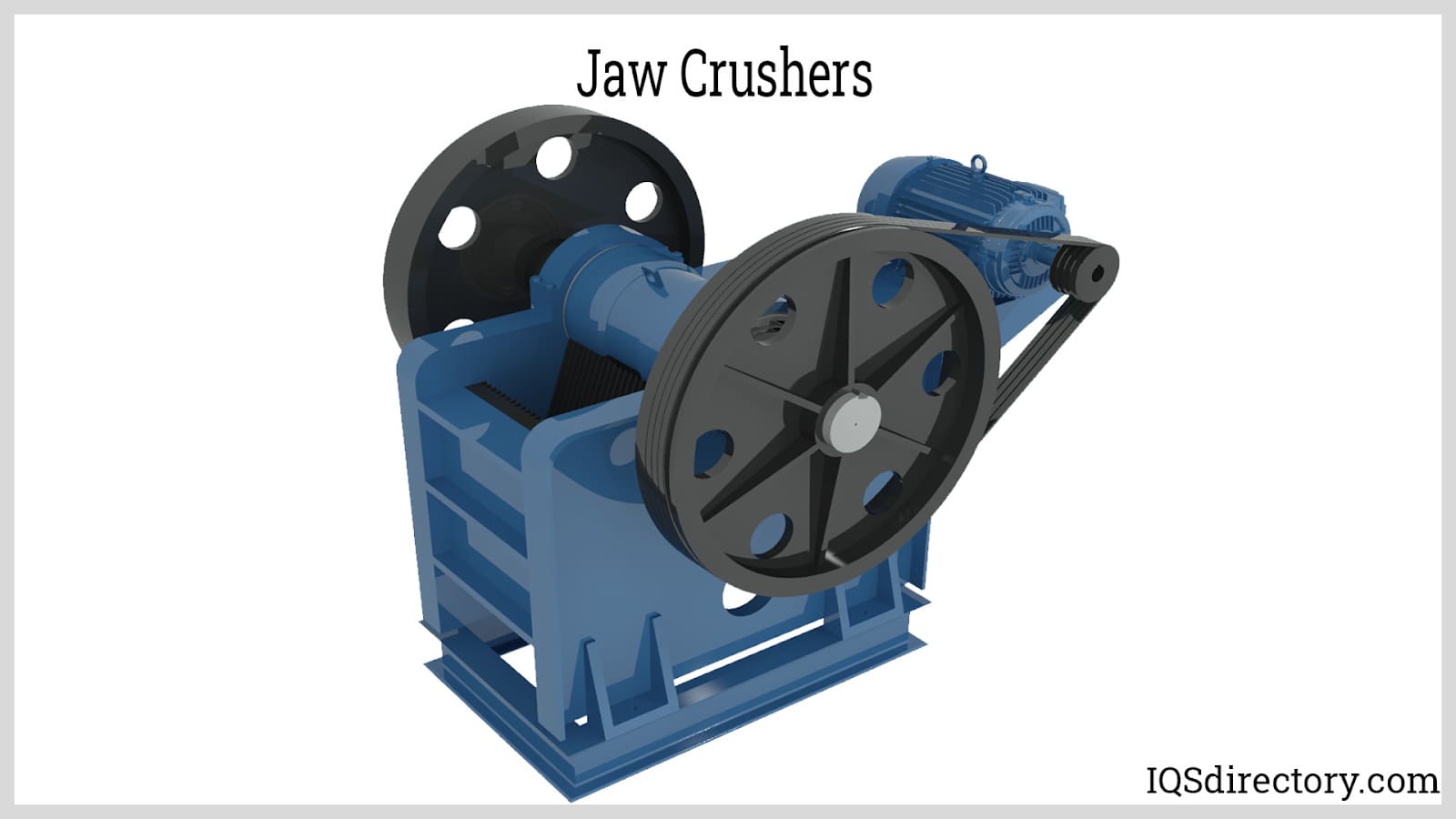

Jaw crushers are size reduction machines that use a blend of crushing jaws and gravity to pulverize materials.

Jaw crushers are size reduction machines that use a blend of crushing jaws and gravity to pulverize materials.

A stone crusher is a type of size reduction machine used to break apart a variety of large stones.

A stone crusher is a type of size reduction machine used to break apart a variety of large stones.

Types of Pulverizers

- Coal Pulverizers

- Coal mills grind coal into powder using heavy rollers. The rollers crush the coal into a powder.

- Low Speed Coal Pulverizers

- Ball and tube mills are low-speed machines that grind the coal with steel balls in a rotating horizontal cylinder. Due to its shape, it is called a tube mill and due to use of grinding balls for crushing, it is called a ball mill, or both terms as a ball tube mill.

- Medium Speed Coal Pulverizers

- Ring and ball mills consist of two types of rings separated by a series of large balls like a thrust bearing. The lower ring rotates, while the upper ring presses down on the balls via a set of spring and adjuster assemblies, or pressurized rams. Depending on the pulverizer design, the material to be pulverized. As the lower ring rotates, the balls orbit between the upper and lower rings, and balls roll over the bed of coal on the lower ring. The pulverized material is carried out of the mill by the flow of air moving through it. The size of the pulverized particles released from the grinding section of the mill is determined by a classifier separator. If the coal is fine enough to be picked up by the air, it is carried through the classifier. Coarser particles return to be further pulverized.

- High Speed Coal Pulverizers

- Attrition mill is a device for mechanically reducing solid particle size by intense agitation of a slurry of material being milled and coarse milling media.

- Crushers

- Designed to reduce the size of large, dense materials such as rock and stone to gravel or dust. Primarily, crushers are used for size reduction, easy disposal or recycling and to simplify differentiation of materials. One of the most common crusher designs is the jaw crusher, which has two jaws, one that is stationary and one that is mobile.

- Impactors

- Press and crush materials together. They are used often as a pre-pulverizing machine in a larger process.

- Impactors, also referred to as impact crushers, are very similar to crushers but differ in the manner of size reduction. Impaction is force that is transmitted through a collision or by striking one body against another, whereas crushing is the use of pressure created by two opposing forces. Crushing and impacting utilize pressure and collision-wrought force.

- Impact Crushers

- Utilize impaction to reduce the size of a range of materials. Impaction enables size reduction because it is a force that is transmitted through the striking of one body against another.

- Grinding Mills

- Use friction to break down materials. The friction in a grind mill is brought about as a result of grinding media, which can refer to many different coarse materials such as non-sparking lead, ceramics, brass, bronze and flint. The basic parts of a grinding mill vibratory type sample pulverizing machine are: steel grinding bowl, ring and puck. The ring and puck rotates inside the cage at a speed around 400 RPM or fast enough to crush and pulverize rocks. Grinding mills are machines designed to crush solid material into small pieces. They can take on many different forms, including ball mills, hammermills, jaw crushers and roll crushers.

- Ball Mills

- Cylinders partially filled with a spherical grinding medium used to grind material. A ball mill is constructed from a rotating cylinder that is mounted horizontally. They use grinding media such as steel balls or rods, which, as the cylinder turns, are tossed around the cylinder, smashing into the material to be grinded as they do so.

- Hammermills

- High-speed rotor equipped machines with large hammers for crushing material into reduced sizes. Hammermills utilize numerous hammers encased in steel that rapidly revolve in a vertical plane.

- Jaw Crushers

- Macerate feed materials when they pass through two plates to turn out coarse particles.

- MPS Mill

- A type of mill known as an applied force mill, meaning that the force used in this type of mill has both magnitude and direction. MPS mills utilize large tires as their grinding media and are primarily used for the pulverizing of coal.

- Bowl Mill

- Very similar to MPS mills and come in two main designs: deep bowls and shallow bowls.

- Gyratory Crusher

- Another example of a more application-specific pulverizer is a gyratory crusher. This type of crusher is very similar to a jaw crusher, but it utilizes a different motion to crush materials in that it does not rotate. Instead, its motion is eccentric, or off-center. Gyratory crushers are most commonly used in mine or ore processing plants for either primary or secondary crushing.

- Cone Crusher

- A similar crusher to gyratory crushers is a cone crusher. A cone crusher is more commonly used for secondary crushing of ore and rocks than primary, and it functions by squeezing the materials between its mantle and bowl liner, where they fall lower and lower until they are small enough to fall through a narrow opening at the bottom of the crusher.

- Pulverizer

- Similar to a shredder in function, a pulverizer differs from a shredder in that it can reduce material to tiny particles and can be exact with reduction sizes.

- Laboratory Pulverizer

- Before sending any soil or test sample for an X-ray fluorescence (XRF) spectrometer (an x-ray instrument used for routine, relatively non-destructive chemical analyses of rocks, minerals, sediments and fluids), titration, ICP or other assay method, the use of a laboratory pulverizer is a must. It is necessary to pulverize or fine grind a dry representative portion of the rock sample. This is done by using a laboratory pulverizer. The pulverizing machine used to bring the particle size of the test sample down to low micron – the finer is better.

- Concrete Crushers

- Pulverization equipment used in the crushing or breaking of concrete into concrete aggregate.

- Grinders

- Size reduction tools that abrade away a material's surface until it has taken the appropriate shape.

- Jet Mills

- Use a combination of air and fluid pressure to pulverize material in a sanitary environment at a low energy cost.

- Rotary Feeders

- Devices that move material or objects along in a process by a main rotating plate that picks up the items and moves them.

- Size Reduction Equipment

- Equipment that crushes, shreds, compacts or in some way decreases the size of an object or material.

- Stone Crushers

- Pulverizers that are used to compress or break apart very hard materials. These materials can include any kind of hard, solid, nonmetallic mineral.

Applications for Pulverizers

Some of the industries in which crushers and impactors are used include:

- Pharmaceutical Application

- Pharmaceutical product development, for grinding of various medicines into powder form for encapsulation and other applications.

- Construction Use

- Construction in which stone crushers and concrete pulverizer or crushers are popular for use in the reduction of building materials. Loosening, pulverizing, and leveling packed or encrusted soils in preparation for seeding or laying of new sod, making them well suited for use by landscapers, rental yards, construction contractors, and professional turf managers.

- Industrial Manufacturing

- Industrial manufacturing for material processing applications.

- Agricultural Uses

- Agricultural as size reduction equipment for grain and other produce for use in food products.

- Printing Production

- Printing to create pulp and other pastes used in the creation of paper.

- Power Generation

- Power generation in which coal mills are used to process coal in advance of its use in power plants.

- Other Applications

- Tire Shredding and Recycling

- Industrial Rubber Shredding

- Automobile Crushers

- Electronic Scrap Shredding

- Hazardous Waste Shredding

- Ferrous Scrap Metal Shredding and Recycling

- Non-Ferrous Scrap Metal Shredding and Recycling

- Waste-to-Energy Recycling

- Industrial Paper Shredding and Recycling

- Industrial Plastics Shredding

- Solid Waste Shredding

- White Goods Recycling

Things to Consider When Purchasing a Pulverizer

The following criteria are important to consider when selecting a suitable pulverizer:

- Material Properties of the Sample (e.g. Breaking Behavior)

- Feed Size of the Sample

- Required Final Fineness

- Feed Quantity

If the initial particle size of the sample is coarse, it might be necessary to use two different pulverizer machines, one for preliminary size reduction and one for fine grinding, to achieve analytical fineness.

Choosing suitable grinding tools is also part of the selection process for finding the right pulverizer for your material. Here the important criteria are hardness, abrasion resistance, possible contamination and, for ball mills, the energy input.

IQS Directory provides a detailed list of pulverizer manufacturers and suppliers. Find pulverizer companies that can design, engineer, and manufacture pulverizers to your specifications. Peruse our website to review and discover top pulverizer manufacturers with roll over ads and complete product descriptions.

Connect with the pulverizer companies through our hassle-free and efficient request for quote form. You are provided company profiles, website links, locations, phone numbers, product videos, and product information. Read reviews and stay informed with product new articles. Whether you are looking for manufacturers of coal pulverizing mills, juicer pulverizer, and concrete pulverizer of every type, IQS is the premier source for you.

Pulverizer Accessories

Pulverizing mills have many possibilities. By adding an air heater to the system, pulverizers can also dry product while grinding and classifying. Direct Fired Roller Mills are also a great asset for pulverizing coal and petroleum coke fuel for direct firing into boilers and kilns.

Tractor Pulverizers mount to the three-point hitch of your tractor and are used to scarify, break up, smooth, and prepare dirt areas such as arenas for use, or to prepare rough dirt areas for primary seeding (seed bed) prep.

Pulverizers Terms

- Aggregate

- A coarse material, such as gravel, broken stone or sand, with which cement and water are mixed to form concrete.

- Centrifuges

- Devices that separate materials or components through centrifugal force or rapid rotation.

- Crush

- To break into very fine particles; this is the main job of a pulverizer.

- Feedstock

- Stock from which material is taken to be fed into a processing unit.

- Ferrous

- Iron-based metals like steel.

- Friable

- Term used to describe a substance that is easily crumbled or powdered.

- Hydraulic

- Involving, moved by or operated by a fluid under pressure.

- Industrial Balers

- Compress and bind materials.

- Industrial Mixers

- Used to combine materials.

- Industrial Shredders

- Equipment for the processing and size reduction of a wide range of materials.

- Mechanical Pulp

- Lignin-containing pulp produced from mechanically grinding logs or wood chips in refineries and pulverizers. It is used mainly for the production of newsprint and other paper.

- Mesh

- The class of particle size based on its passing through a sieve. Often used with powders and fine grains.

- Particle

- A small piece of matter having negligible dimensions or volume.

- Polytetrafluoroethylene (PTFE)

- Resin is a class of polymer that has some or all of the hydrogen replaced by fluoride.

- Powder

- A solid substance in the form of many tiny particles; a solid that has been pulverized.

- Pulp

- The raw material used for the production of paper made mechanically via a pulverizer or chemically by separating cellulose fibers from the other structures in wood or other materials such as used/recycled rags, recycled paper, bagasse and straw.

- Rotor

- The rotating or moving component of a motor or drive, can include the shaft or fan.

- Sheave

- Often used in drive systems, it is a wheel with a groove around it that guides or supports a rope, cable or belt.

- Sieve

- Acts as a strainer for separating chunks from material or for establishing the grade of particles.

- Slurry

- A liquid based mixture or suspension of solids.

- Teeth

- Jagged protrusions that are part of the plates that grind and crush in a pulverizer unit.

- Waste Capacity

- Measured in gallons, it is the volume of paper that the waste bag or other waste bin can hold.