Industrial Mixers

Industrial mixers are machines that blend, homogenize, emulsify, or mix components into a homogenous substance. Industrial mixers are used to thoroughly combine any type of liquid or solid during the manufacturing process. They are usually large tanks or vats with motorized blades or paddles that rotate on a stationary shaft or remain stationary themselves. The terms industrial mixer and industrial blender are often interchanged, but there are subtle differences between the two terms. Mixing is commonly referred to as a process that puts items together, while blending is used when referring to a product that is uniformly processed. A good example of a mixed product is trail mix, whereas yogurt is a blended product.

Quick links to Industrial Mixers Information

Applications of Industrial Mixers

Industrial mixers are widely used in many industries, including:

- Cosmetic

- Pharmaceutical

- Chemical

- Agricultural

- Pulp and Paper

- Automotive

- Water Treatment

- Adhesive

- Sealant Industries

These mixers are equipped to handle various substances, such as:

- Toothpaste

- Glue

- Petroleum Products

- Cement

- Biodiesel

- Dry and Wet Chemicals

- Medicines

- Food Coloring

- Syrups

- Beverages Such as Milk

- Medical Ointment

- Lotions

- Creams

- Vitamins

- Shampoos

- Detergents

- Hair Dye

- Silicone

- Adhesives

- Polyurethane

Scientists will often use industrial mixers to create new chemical combinations. Additionally, pharmaceutical manufacturers will also use these high powered industrial mixers to develop medicines.

Industrial Mixer Design and Customization

Depending on the application of an industrial mixer, some models may have sharp blades while others may have large flat paddles. The attachments or heads are generally removable to maximize the mixer’s effectiveness with different materials. Stainless steel is most commonly used, especially within the food and beverage industry because of the metal’s sanitary and hygienic properties. Other possible materials include aluminum, steel, or cast iron.

Industrial Mixer Images, Diagrams and Visual Concepts

Mixers combines and mixes of substances and chemicals for industrial usage.

Mixers combines and mixes of substances and chemicals for industrial usage.

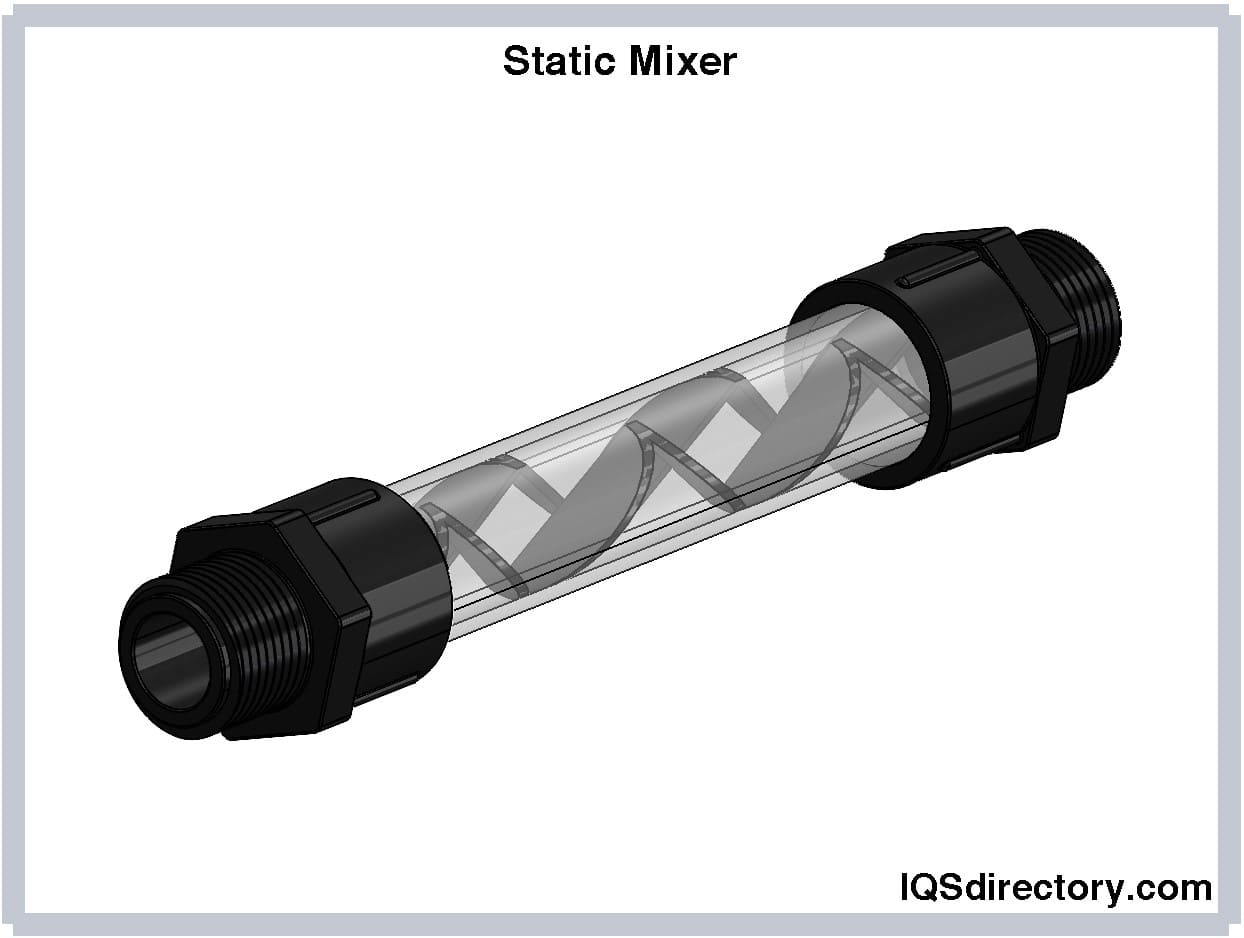

Static mixers continuously blend fluids and materials in flow streams using mixing elements placed in a pipeline with flanges at either end.

Static mixers continuously blend fluids and materials in flow streams using mixing elements placed in a pipeline with flanges at either end.

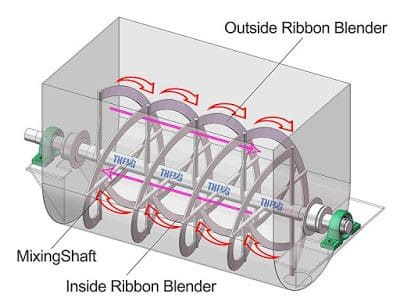

Ribbon blenders blend powder and bulk solid blending.

Ribbon blenders blend powder and bulk solid blending.

Paddle mixer are used for mixing solids and liquids or for wet dry mixing.

Paddle mixer are used for mixing solids and liquids or for wet dry mixing.

Agitator mixers mixes liquids together or gases and liquids.

Agitator mixers mixes liquids together or gases and liquids.

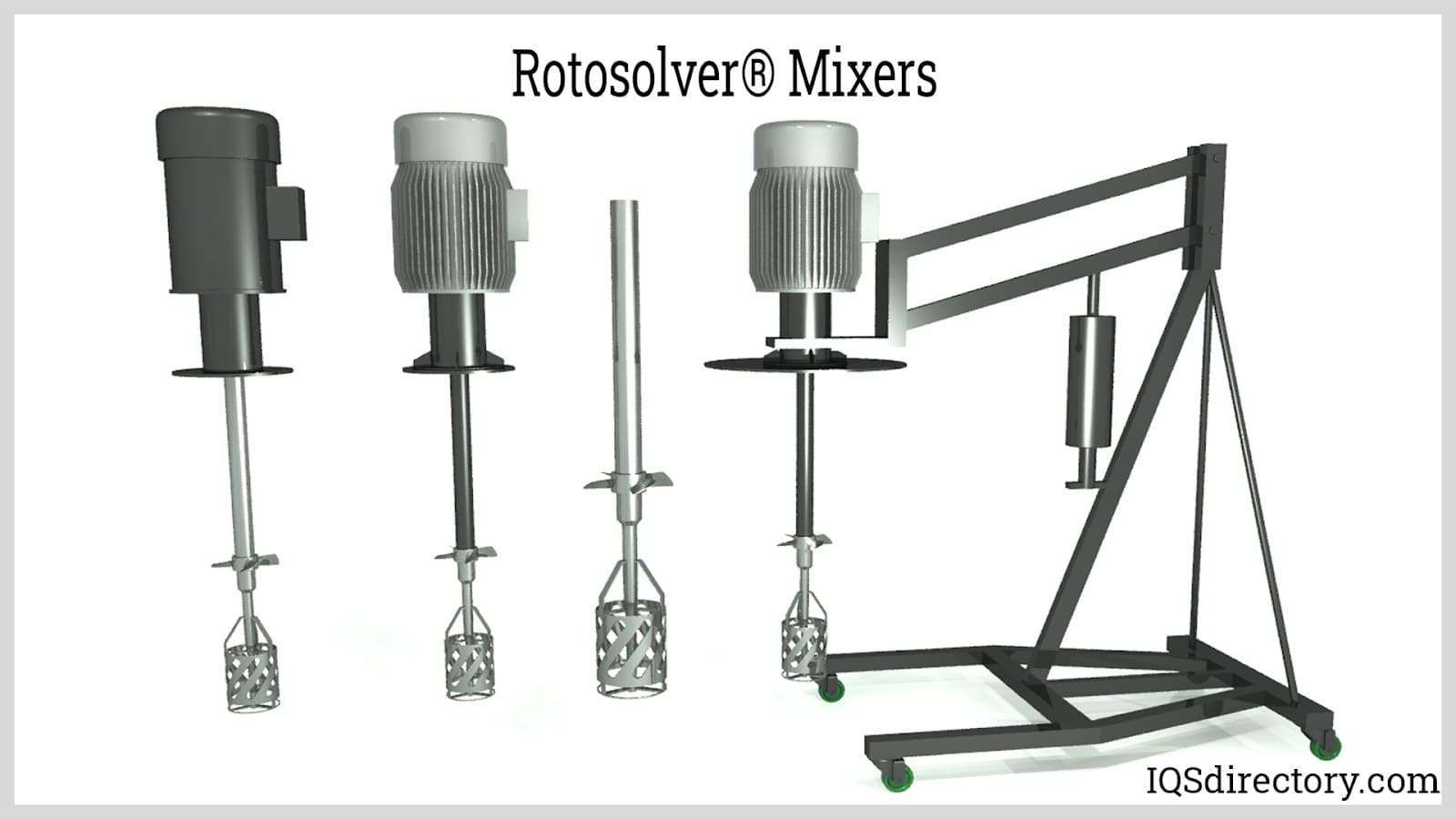

High shear mixers dissolve immiscible mixtures with components of the same or different phases.

High shear mixers dissolve immiscible mixtures with components of the same or different phases.

Notable Types of Industrial Mixers

Industrial mixers come in many configurations, such as:

- Ribbon

- V Blender

- Continuous Processor

- Cone Screw Blender

- Double Planetary

- High Viscosity

- Counter-Rotating

- Vacuum Mixer

- High Shear Rotor Stator

- Dispersion

- Paddle

- Jet

- Drum

- Banbury

Within the single category of industrial mixers, there are many kinds and varieties of these machines that have been specialized. Blenders are very similar if not identical to mixers; some prefer to differentiate between the two because blenders sometimes have sharper blades that move at faster speeds. In terms of processing speed and style, there are two modes. Batch mixers are the more common of the two kinds. Mixing begins after a substance is poured into the industrial mixer. Once mixing is complete, the substance is poured out of the mixer for further processing and the mixer is then cleaned before being refilled. Continuous-feed mixers can handle a steady flow of material. Static mixers are inline and continuous-feed mixers because they do not move. The materials are mixed as they flow around the strategically-placed blades and paddles. Another kind of industrial mixer is a drum mixer, which consists of a rotating drum on the frame. There are multiple mixers used to accomplish a solution or substance that is the same throughout. High shear mixers offer shorter mixing times than standard mixers. The speed of the product at the tip of the rotor is higher than the speed at the center, which emulsifies immiscible materials. Similarly, homogenizers and emulsifiers achieve the same results by forcing substances to pass through a screen. Agitators are industrial mixers that typically mix substances with low viscosities in low-shear applications.

Factors to Consider When Purchasing Industrial Mixers

With so many different options to pick from, customers may often feel overwhelmed when attempting to select a mixer. Fortunately, manufacturers will work with clients to determine the best product for the particular application, workload, and budget. The type of mixer is typically designed for a particular process. For example, in the food industry, there are mixers that are ideal for adding preservatives into the products. These newer innovations have been a catalyst in the changes of our food products and medicines on a molecular level. Manufacturers have implemented these technologies into production lines, which result in higher levels of uniformity in products. The precision and durability of these products are improved with each new advancement in technology.