Hinges

A hinge is a type of mechanical bearing that is used to join two objects together. When it joins objects together, it allows them to move on a limited angle of rotation relative to each other. Plus, it allows them to do so without falling apart.

This hardware type is used in a variety of different industries, most notably including architecture, commercial and residential building construction, jewelry, furniture and cabinets, material handling, barriers and fencing, and electronics. Some places where they can be found are on doors, containers, cabinets, boxes, pianos, cosmetic containers, gates, tables, laptops, home appliances, lockers, lockets, animal cages and more.

Quick links to Hinges Information

The History of Hinges

Hinges are very old hardware. No one knows for sure when exactly they first made an appearance, but we do know for sure that they were at least in use in the Near and Middle East during the Bronze Age. For example, archeologists have found early versions of the modern hinge in Turkey, on the site of the ancient capital city of the Hittite Empire, Hattusa. These date back to around 1600 B.C. and were used only for sacred and important public buildings. In the Old Testament, hinges are only mentioned once, in reference to King Solomon’s temple. Likewise, while hinges have been found on the sites of ancient Babylonian and Assyrian temples, they were not part of the everyday home.

Towards the Middle Ages, metal became less expensive and blacksmiths became more prevalent. Because of this, hinges became more common among the common folk. As the years went on, hinges were used for more and more things, like the jewelry boxes, ships, wagons, gates and locking parts. Once the Industrial Revolution hit, hinge production really took off. This is because hinges were a required component of so many new machines. In 1899, Stanley’s Bolt Manufactory (now StanleyWorks) won a patent for hinges with ball bearings. Since the turn of the 20th and 21st centuries, hinges have evolved in a number of ways. For example, they now allow gates to move both ways. Also, they’re important parts of devices used on airplanes, military vehicles, computing devices and more.

Hinge Design

The hinge production process begins with the heating of metal material and its subsequent machining. Some of the machining processes that manufacturers use most often to create hinges include casting, extrusion, cutting, and deformation. The choice of which machining process to use depends on factors like required production speed, required production volume, design intricacy, an Die Casting Companies Servicesd budget.

After machining, manufacturers may choose to perfect the hinge with secondary processes such as smooth, rust-proofing, plating, galvanization, painting, polishing or coating. It’s important to consider these secondary processes. Hinges are susceptible to abrasion, wear, and corrosion simply because of their design and the fact that they are so constantly used. Also, those hinges that are exposed to the elements are particularly vulnerable. Processes like coating, rust-proofing and the others protect them from corrosion and other damages.

Hinges are made out of various materials. Most often, these are solid or hollow metal materials. These metal materials include copper, brass, nickel, bronze, stainless steel, chrome, and steel.

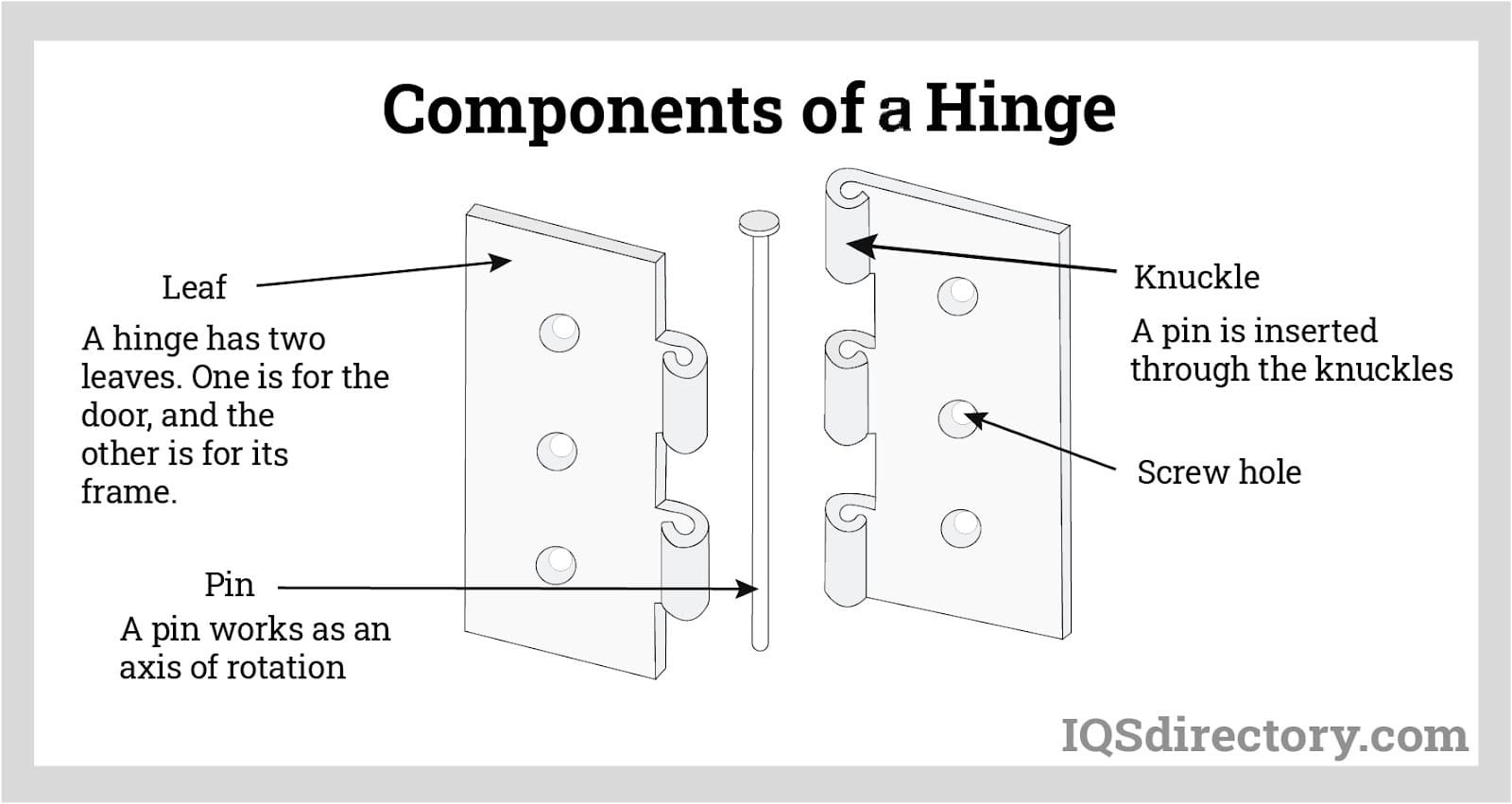

Most hinges are produced with three basic design elements: the leaves, the pin, and the knuckle. The leaves are plates that function as the portions of the hinge that extends outward. They are the parts that manufacturers and end users attach to the surfaces they want to be connected. The hinge pin goes inside the knuckle and holds the leaves together. The knuckle, which acts as a joint, is hollow and usually circular. These three elements are the most important pieces of a hinge. Aside from these, you can design a hinge nearly any way you want.

There are so many ways that you can customize your hinges. Hinges can be decorated with shiny finishes to add a pop of decoration to a piece, or they can be completely hidden and built into the objects it is connecting. Also, manufacturers can make a custom hinge in any color and give it a finish to match any setting. In addition, depending on the application and use, hinges can be long and continuous, or very short and small.

Hinge Images, Diagrams and Visual Concepts

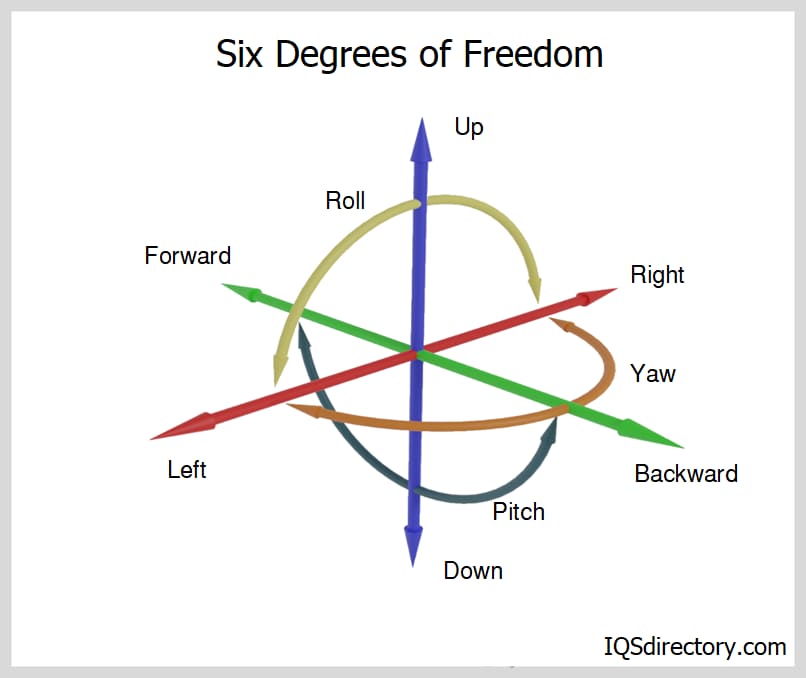

Hinges connects two bodies allowing angular movement about a fixed axis of rotation, all the while preventing translations and rotations on the remaining two axes.

Hinges connects two bodies allowing angular movement about a fixed axis of rotation, all the while preventing translations and rotations on the remaining two axes.

Hinges have limited movement, allowing the joint to move only at one angle and restrict the other movements of swinging parts.

Hinges have limited movement, allowing the joint to move only at one angle and restrict the other movements of swinging parts.

THe different components of a hinge to allow motion.

THe different components of a hinge to allow motion.

Weld-on hinges uses metal enclosures or gates where the hinge is needed to be fixed permanently through welding.

Weld-on hinges uses metal enclosures or gates where the hinge is needed to be fixed permanently through welding.

Friction hinges are designed which allows for them to maintains the desired position for extended periods of time.

Friction hinges are designed which allows for them to maintains the desired position for extended periods of time.

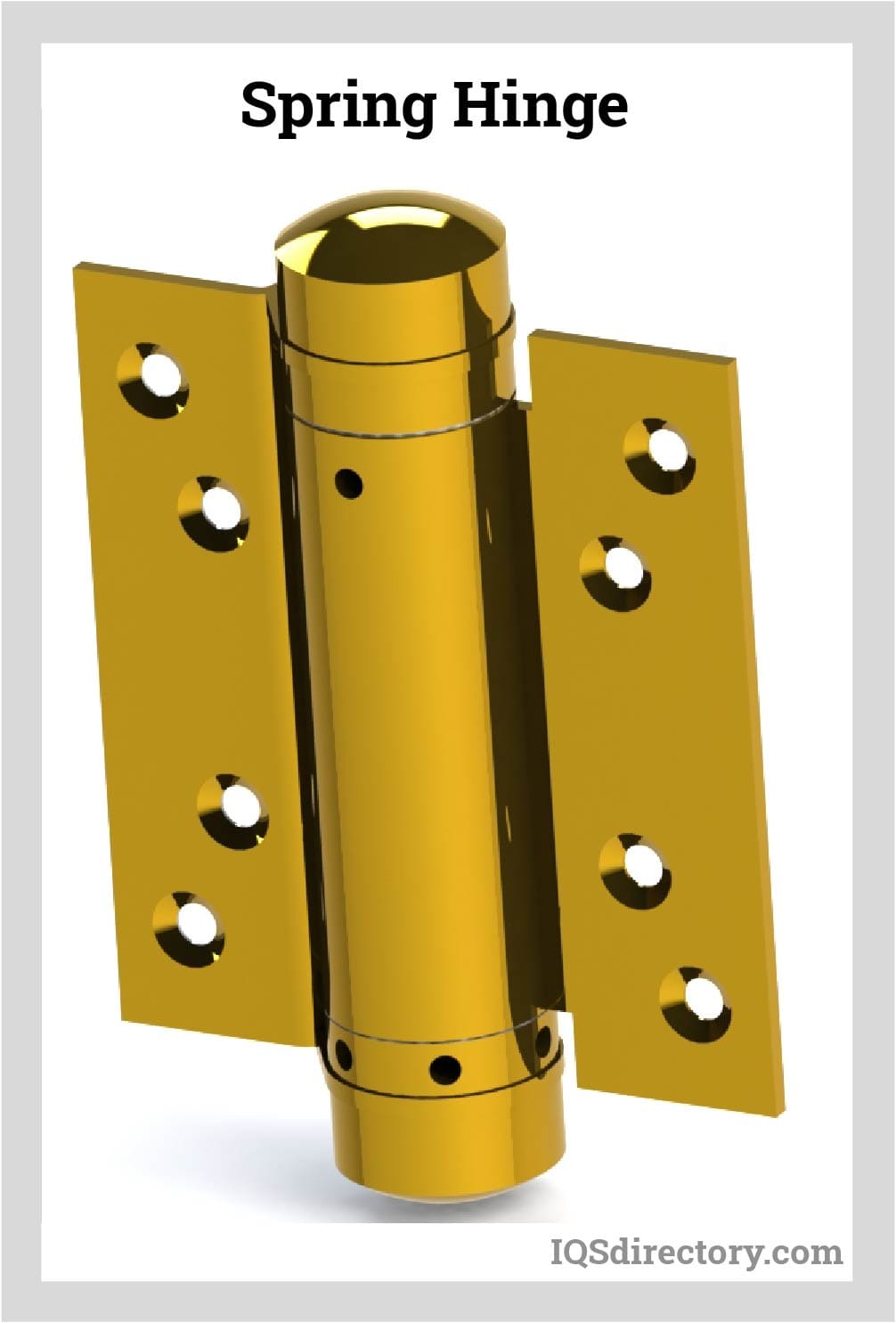

Spring hinge, a self-closing hinge that automatically closes two connected workpieces using the action of a spring that is loaded in the hinge's barrel.

Spring hinge, a self-closing hinge that automatically closes two connected workpieces using the action of a spring that is loaded in the hinge's barrel.

Hinge Types

- Ball Bearing Hinges

- Used for high frequency and indoor applications and on doors with closers.

- Bronze Bearing Hinges

- Suitable for outdoor or other harsh environments.

- Butt Hinges

- Secured to the door and the door frame. Swinging doors are one common application for which butt hinges are used.

- Cabinet Hinges

- Must be made from a strong, heavy material to prevent unevenness of cabinet doors.

- Continuous or Piano Hinges

- Longer than standard hinges, usually measuring five inches in length or more. Continuous hinges provide consistency in strength along the entire length of the hinge, supporting the objects to which they are attached and reducing the gap between objects and hinges.

- Door Hinges

- Used on a variety of doors in personal, office and industrial settings.

- Friction Hinges

- Hinges that simultaneously allow fluidity of motion and rigidity of position for the objects they join.

- Gate Hinges

- Used on gates and entryways. In addition to standard manual hinges, gate hinges are commonly automatic for convenience and protection.

- Heavy Duty Hinges

- Characterized by their high performance and load bearing capacity.

- Hidden Hinges

- Designed to function while being hidden from view. These hinges are capable of being installed so that no part of the hinge is visible from the outside when the objects to which they are attached are in use.

- Multiple Pin Hinges

- Have more than one pin and are used for double action.

- Panel Hinges

- Designed for use with doors that are set flush into a frame.

- Plain Bearing Hinges

- Used in a wide variety of applications that require low to moderate usage.

- Plastic Hinges

- Beneficial because they do not require lubrication, do not rust and remain silent and are more cost-effective than hinges made of metals, including stainless steel hinges. Most plastic hinges are also ultraviolet (UV), chemical and heat resistant.

- Pull Handles

- Hardware handles, such as drawer handles, that you pull on to move something. Other common names for pull handles include: industrial handles, grip handles, grab handles, pulls, door handles, cabinet handles, tubular handles, tubular grips and handle tubes. The most common are horizontal pull handles, like drawer pulls and car door handles.

- Slip Hinges

- Often used in applications where removable doors and lids are present. This means that slip hinges can be found across a wide range of applications and industries, and their ability to be manufactured from a number of different materials contributes to their versatility across industries.

- Spring Hinges

- Used on entryways requiring automatic closure. Spring loaded hinges can also be configured to open automatically.

- Small Hinges

- Join two pieces and allow movement, some serve as decorative pieces on tool kits and cabinets.

- Stainless Steel Hinges

- Useful in situations in which they are exposed to oxidation and corrosive substances because of the high corrosion resistance of stainless steel. Common applications in which stainless steel hinges are found include marine, oil/gas, petrochemical, chemical and pharmaceutical applications.

- Standard Cut Off Hinges

- Have an even number of full knuckles. When the knuckle is facing up, a knuckle will be on the left end and a notch will be on the right end of the lower leaf.

- Stop Hinges

- Designed to limit the movement of the leaves to a certain angle

- Strap Hinges

- A type of hinge with long straps that attach to the face of exterior and interior doors and cabinets while allowing for up to 180 degrees of swinging movement.

- Weld On Hinges

- Smaller hinges that connect two separate metal parts, typically doors and door frames, without the use of knuckles.

Features of Hinges

These pieces of hardware work quite simply. Once they are installed, you simply have to push or pull the moving component to which they’re attached. An example of such a component is a door. In this case, the moving component is the door and the stationary component is the door frame.

Though diverse, hinges can be defined by their characteristics. These include end play (axial movement between the leaves and along the axis of the pin), gauge (thickness of the leaves), hinge width (from the outer edge of one leaf to the other), hinge length (parallel to the pin), knuckle length (an individual knuckle parallel to the pin), leaf width (from the center of the pin to the outer edge of the leaf), pitch (distance from an edge of a knuckle to the same edge of another knuckle on the same leaf) and slop (loose angular movement of leaves relative to the pin).

Hinges are unique and work better than simpler devices like slides because they do not allow adjacent components to separate from one another. In addition, they allow motion in two directions, not just one.

Hinge Standards and Specifications

For the best results, manufacturers should follow ANSI (American National Standards Institute)/BHMA (Builder’s Hardware Manufacturing Association) standards when making any and all hinges. They focus on aspects like materials, durability, safety and security, sustainability and appearance. These standards are nationally recognized. By abiding by them, manufacturers make hinge exchange easier and more universal.

Any other standards that manufacturers choose to follow are based on industry, application and area regulations. For example, in order to be legal, some hinges, including some gate hinges, must be ADA compliant. In other words, they must be wheelchair accessible or accommodate the needs of those that are less able to walk/climb.

Things to Consider When Purchasing a Hinge

Get the most out of your hinge by considering things like your application settings, the frequency with which your hinges will be used, industry requirements and regulations and the way you want your hardware to look. Also, consider the location, look, application, size, weight, and shape of the objects to which you will be adhering your hinges.

Then, take these specifications to the right hinge manufacturer. There are a lot of good manufacturers out there, but who is the right manufacturer for you? Simple: the right manufacturer is the manufacturer that will take a customer specific approach and suit your needs. They will listen to your requests seriously, consider your budget and do everything they can to accommodate you. Find the perfect standard or specialty hinge for you by browsing the list of companies we’ve provided above.

For more about any company: hover the mouse over their name and click the picture that pops up on the right-hand side. You can also return to the top of this page to find a conveniently organized list of hinge making companies.

Installation of a Hinge

Though the method varies from one hinge type and one surface type to another, the process of installing a hinge is fairly simple. The most basic procedure is as follows: First, line up your hinges and determine where the screws will go. Then, mark or drill those spots. Drill in one leaf, line it up with the pin and the knuckle, drop in the pin and drill in the other leaf.

Some hinges are not this easy to install, requiring more prep and forethought. Make sure you know the right procedure for installing your hinges by talking it over with your manufacturer or supplier.

Proper Care for Hinges

Guarantee that your systems last and continue to work well during that time by caring for them. Fortunately, hinge maintenance is fairly easy.

To care for industrial hinges, hinges in high use environments or hinges in harsh environments, we recommend you regularly lubricate them. The best way to do this is by removing the pin, applying lubricant generously and directly to it and then replacing it.

To remove any dirt or dust from your hinge, simply wipe it with a damp cloth. Dampen this cloth only with water. Also, if you find yourself with sagging or damaged screw holes, try reattaching it with carpenter glue.

To make your hinges work more efficiently, you’ll want to make sure that they resist rust, abrasion, corrosion and the like. The best way to ensure this is by making the right choices before you install them. These include selecting a corrosion resistant metal like stainless steel and opting for the application of a protective coating, painting or plating.

Hinge Accessories

You can order hinge sets with all kinds of accessories. Some are functional, while others are decorative. Examples of both include angle restriction clips, stainless steel eye bolts, compact adaptors, door cushions, doorstops, tip-on touch latches and more.

Whether or not you should use an accessory depends entirely on your application. Touch latches, for example, are a great accessory of cabinet hinges, also known as cabinet door hinges. Choose them if you have a set of cabinet doors that you would like to be clean looking, free of knobs or handles. With these, you simply have to gently push your door, and it will pop open.

Hinge Terms

- Back Angle

- The angle of the hinges leaves, usually a minimum of 270, when the hinges are completely open.

- Bent Pin

- The pin found in hinges that contains a bent end to allow for easy removal of the pin.

- Both Leaves Half Swaged

- When both of the leaves are swaged one half the pin diameter with a small space between the leaves when closed.

- Closed

- Refers to the position of the leaves of the hinges when they are parallel and together at the 0 position.

- Coined Pin

- A deformed end of a pin that causes the pin to be wedged into place when driven into hinges.

- Crimped Ends

- Hinges pins that can not be removed due to depression of the hinge knuckle.

- Detent

- A device that locks hinges in the open position.

- End Play

- The extent to which hinges leaves move axially.

- Flat

- Refers to the position of the leaves when they are at the 180 position.

- Gauge

- Hinges measurement reflecting the hinge leaf thickness.

- Hinge Length

- The measurement of hinges running parallel to the hinge pin from one end of the leaves to the other end of the leaves.

- Hinge Width

- Also known as "open width", it is the measurement of the width of hinges, including both leaves and the pin. Hinge width is a measurement perpendicular to the hinge pin.

- Knuckle

- Also referred to as joint, node, curl and loop it is the individual, hollow joint of a hinge through which the hinge pin is inserted.

- Knuckle Length

- The length of an individual knuckle, equivalent to one-half of the pitch.

- Leaf

- Component of hinges that extends laterally from the knuckle and revolves around the pin.

- Leaf Width

- The measurement from the pin to the end of the leaf.

- Lock Punch

- Preventing leaf rotation by moving the material from adjacent knuckles to remove end play. It is located at the bottom of the knuckle in a uniform consistent pattern.

- Offset

- The process of decreasing leaf width through the formation of hinges leaves away from the hinge pin center.

- One Leaf Full Swaged

- When one leaf is swaged equal to the pin diameter. Both are parallel while closed.

- One Leaf Half Swaged

- When one leaf is swaged one half the pin diameter.

- Opposite Standardd Cutoff

- When the lower leaf has a notch at the left end and 3 knuckles.

- Paint Clearance

- The amount of space between the knuckle and the edge of the leaf in every position of the hinge during operation.

- Pin

- The rod inserted through the hinge knuckles to hold the hinge in place.

- Pitch

- The measurement reflecting the distance between the opposite ends of two adjacent knuckles.

- Plain Assembly

- When the leaves aren't swaged and lay flat in the same plane in an open position.

- Reverse Assembly

- When the leaves aren't swaged and the opposing leaves extend laterally from opposite sides of the pin. The leaves don't close to a parallel position.

- Reverse Swaged

- When one leaf is swaged, as in reverse assembly, but the leaves will not close in a parallel position.

- Side Play

- The amount of leaf movement perpendicular to the pin.

- Spun Pin

- Cold forming the end pins to a diameter larger than the inside portion to prevent axial movement. Mostly used for tamper-proofing.

- Spun Ends

- Hinge pin ends that have been peened, or flattened, in order to prevent pin removal. Although a pin with both spun ends is not removable, a pin containing only one spun end is still removable.

- Staked Pin

- A hinge pin that is not removable due to the staking of the hinge backside.

- Standard Cutoff

- A hinge that has an even number of full length knuckles (plain assembly only).

- Stop Hinge

- A type of hinge intended to provide a limitation on the angle of the hinge leaves to a particular degree.

- Stop Hinge, Inside

- When the leaves open to a stop angle.

- Stop Hinge, Outside

- When leaves move open positions and stop at a specific angle.

- Swaging

- A process of increasing hinge leaf width through the formation of the hinge leaf or leaves either toward or away from the hinge pin center.

- Welded Pin

- A type of pin in which the splined portion is slightly larger than the inside diameter on the curl of the pin. Welded pins are used in some slip joint hinges.