Canopies

A canopy is a structure with a connected fabric or metal covering that can give shade or shelter from weather elements such as the sun, hail, snow, and rain. For example, a tent with no floor can be...

Please fill out the following form to submit a Request for Quote to any of the following companies listed on

This guide contains everything you need to know about contract sewing.

You will learn:

Contract sewing represents a specialized field that offers manufacturing services to companies, focusing on the production of an extensive array of products with the support of highly trained personnel and cutting-edge sewing machines. This industry's strength lies in its capability to deliver sewing solutions for soft goods across various sectors such as medical, military, clothing, aerospace, and custom clothing.

The contract sewing process is significantly more intricate and demanding compared to traditional sewing practices. Success in this field hinges crucially on the meticulous planning and preparation dedicated to each client's project, emphasizing quality and efficiency.

Another facet of contract sewing includes contract sewers—individuals who lend their expertise to contract sewing firms or manufacturers to execute small-scale projects, typically 100 pieces or fewer. These professionals excel in various sewing techniques and are instrumental in crafting garments and more sophisticated items.

An important advantage of contract sewing is its ability to work with a diverse range of materials and fabrics, including vinyl-coated nylon, neoprene, Hypalon, canvas, anti-static materials, cotton, polyester, felt, plastic, webbing, and leather. Products crafted by the industry are tailored based on designs and concepts provided by their clients.

Contract sewing is an essential part of the modern manufacturing supply chain, providing comprehensive, scalable sewing and textile production solutions to businesses that lack in-house sewing capabilities or technical textile expertise. This industry emerged to address manufacturers’ demands for sewn goods and custom fabric components that they designed but were unable to efficiently produce at scale using their existing operations.

To meet this demand, manufacturers outsource to contract sewing companies that function as a crucial extension of their production process. These specialized sewn product manufacturers combine deep technical knowledge, skilled labor, and advanced industrial sewing equipment to deliver consistently high-quality finished textile products. From small-batch prototyping to large-scale production runs, contract sewing enables companies to introduce new products quickly and reliably meet growing market needs.

The contract sewing industry serves an expansive range of businesses across sectors including automotive, aerospace, safety, medical, and industrial markets. Companies utilizing contract sewing services frequently operate in unrelated fields where sewing is only a minor aspect of their overall product offering—allowing them to focus on core competencies while relying on expert partners for fabric assembly, textile component fabrication, and precision sewing.

One of the primary reasons contract sewing has become so indispensable is its ability to turn innovative product concepts into manufactured reality. Through close collaboration and adherence to detailed specifications, contract sewing providers bring visions to life and deliver expertly finished sewn goods that meet stringent quality, durability, and safety standards.

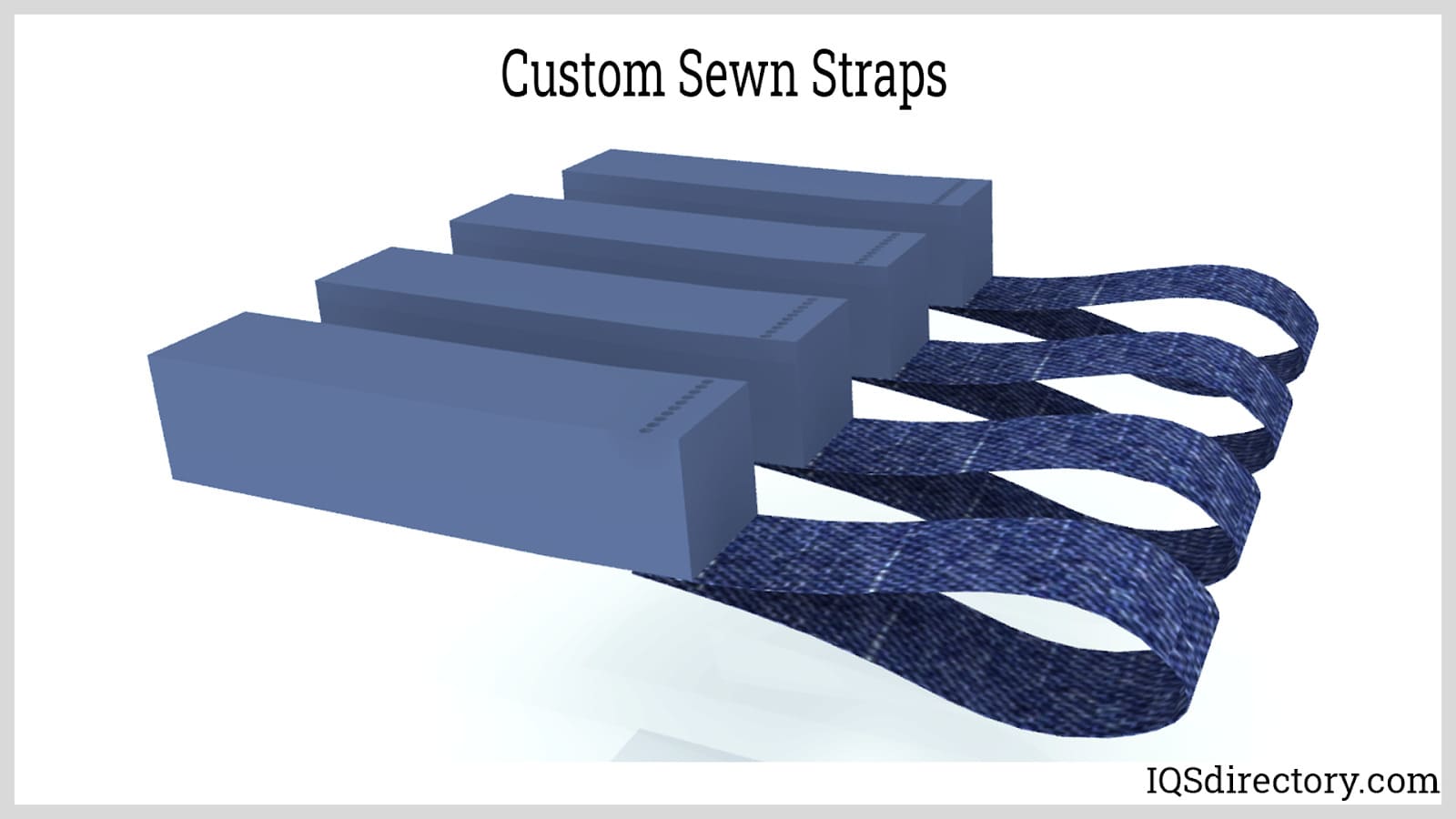

A key advantage of contract sewing services is the ability to produce high volumes of sewn textile products with rapid turnaround, regardless of item dimensions or complexity. While custom clothing production is a common association, the industry’s capabilities span much further, as demonstrated below. Industrial sewing solutions encompass a diverse product mix, leveraging specialized materials, automated stitching technologies, and rigorous quality control to create functional and durable sewn assemblies for various industries.

Fabrics for the automotive industry require superior durability, abrasion resistance, and UV/heat tolerance, as car interiors are regularly exposed to sunlight and heavy use. Specialty sewing machines and automated cutting systems are utilized in automotive contract sewing to meet strict OEM standards and demanding design requirements. Seam strength and precise stitching are critical to ensuring automotive seats, headliners, and trim maintain their integrity and integrate seamlessly with the vehicle’s overall design aesthetic.

The modern auto upholstery market sources a wide array of textiles, including high-performance leathers, engineered vinyls, woven cloth, and multi-layer technical fabrics. Each material’s properties—from flexibility to flame retardance—are carefully matched to its application, highlighting the precision and versatility of professional contract sewing services in automotive textile manufacturing.

Automotive airbag production is among the most technically demanding applications in contract sewing. Airbag fabrics are engineered to be extremely dense and robust, resisting rupture during rapid deployment and withstanding extreme forces. Specialized sewing techniques and automated stitching systems are used to create airbag seams that are both compact and highly secure, ensuring the finished product meets stringent automotive safety regulations. Quality assurance and thorough post-production testing are integral to this process, guaranteeing each airbag reliably protects vehicle occupants in critical situations.

Knee pads combine impact-resistant padding materials with advanced reinforcement stitching for enhanced protection and comfort. The production process involves sewing together performance textiles such as neoprene, nylon, and PVC to create gear that withstands demanding worksite conditions. Industrial-grade knee pads require ergonomic construction for worker comfort as well as durability against potential hazards like sharp objects, debris, or moisture, making contract sewing the preferred solution for labor-intensive and safety-focused industries.

Industrial aprons are fabricated using premium raw materials—leather, cotton, polyester, rubber, or specialty textiles—to provide effective protection against chemicals, oil, water, heat, and workplace hazards. Contract sewing enables mass customization of apron types (cobbler, no pocket, bib, etc.) and lengths tailored to various workplace requirements, including food processing, welding, and hazardous environments. Advanced seam sealing techniques and high-strength fasteners further differentiate products intended for industrial and commercial use.

Modern luggage design integrates durable textiles—such as ballistic nylon, reinforced polyester, and heavy-duty canvas—with engineered fasteners and ergonomic handles. The contract sewing process includes precise cutting, automated stitching, and custom finishing to produce secure, visually appealing products like duffel bags, sports bags, briefcases, travel cases, and messenger bags. Value-added services such as logo embroidery and RFID compartment integration are often available, reflecting the versatility and scalability of contract sewing companies serving luggage OEMs and private labels.

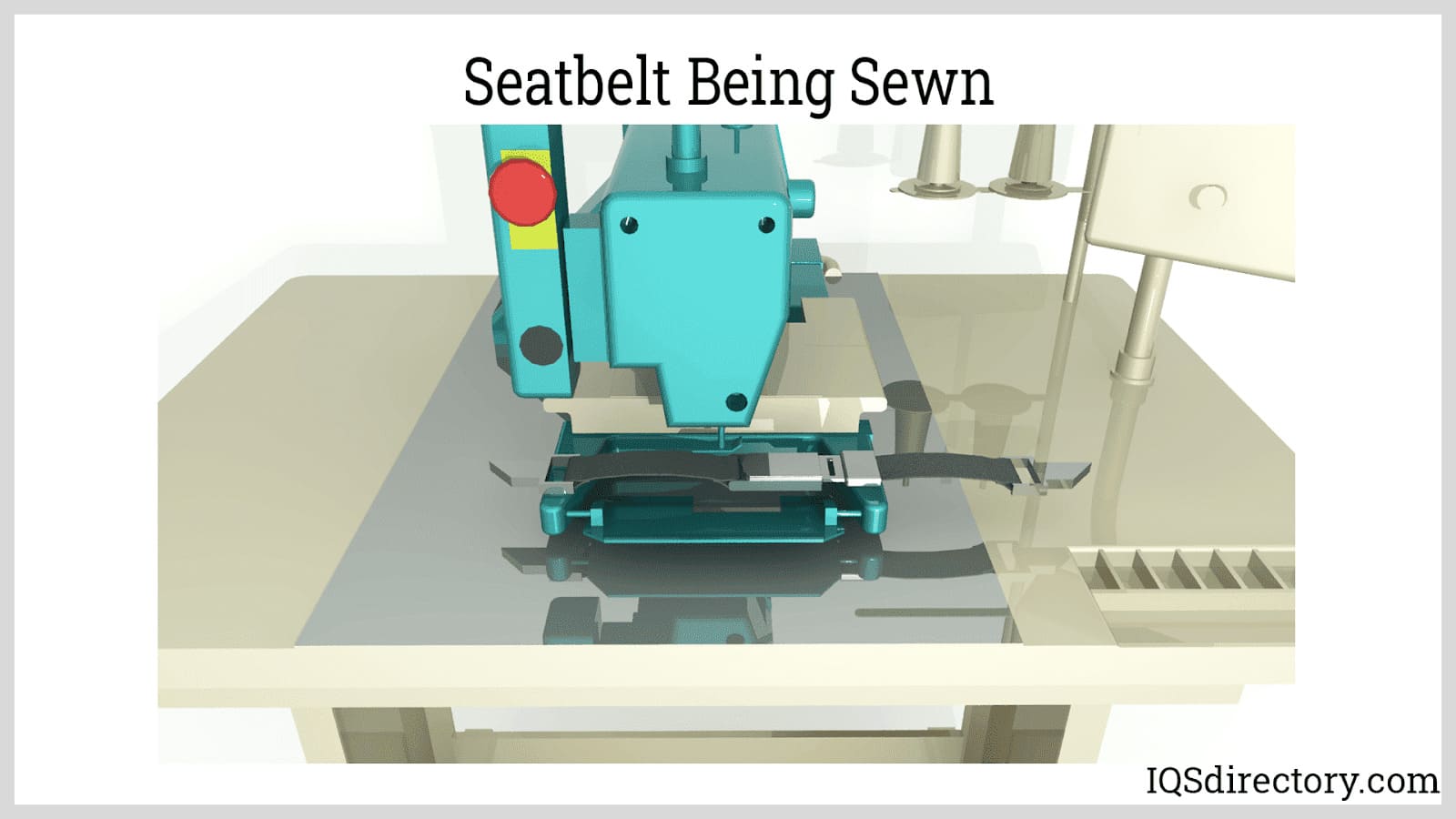

The manufacturing of airplane seatbelts centers around high-tensile webbing, robust buckles, and precision assembly—all essential for compliance with international aviation safety regulations. Webbing colors and specifications are customized to match airline branding while meeting FAA (Federal Aviation Administration) and EASA (European Union Aviation Safety Agency) standards for strength and reliability. Every seatbelt must undergo rigorous performance testing, with each unit engineered to safely absorb and withstand impact forces up to 16 times the force of gravity (16Gs). Expert contract sewing ensures consistency, traceability, and absolute safety.

High-Visibility Safety Apparel (HVSA) manufacturing is a highly specialized segment within contract sewing. Compliance with the American National Standards Institute (ANSI) and other industry safety standards is mandatory, demanding technical knowledge of retroreflective tape application, garment patterning, and performance fabric integration. HVSA includes garments for road workers, construction teams, warehouse employees, and emergency personnel—ensuring visibility in low-light and hazardous environments. The three safety apparel classes (O, R, and P) correspond to application environment and unique material requirements, demonstrating the contract sewing industry's ability to deliver technical, regulatory-compliant apparel at scale.

Contract sewing providers help employers and purchasing managers evaluate HVSA garment options by offering custom design, material selection, and certified manufacturing processes, ultimately supporting workplace safety and compliance objectives.

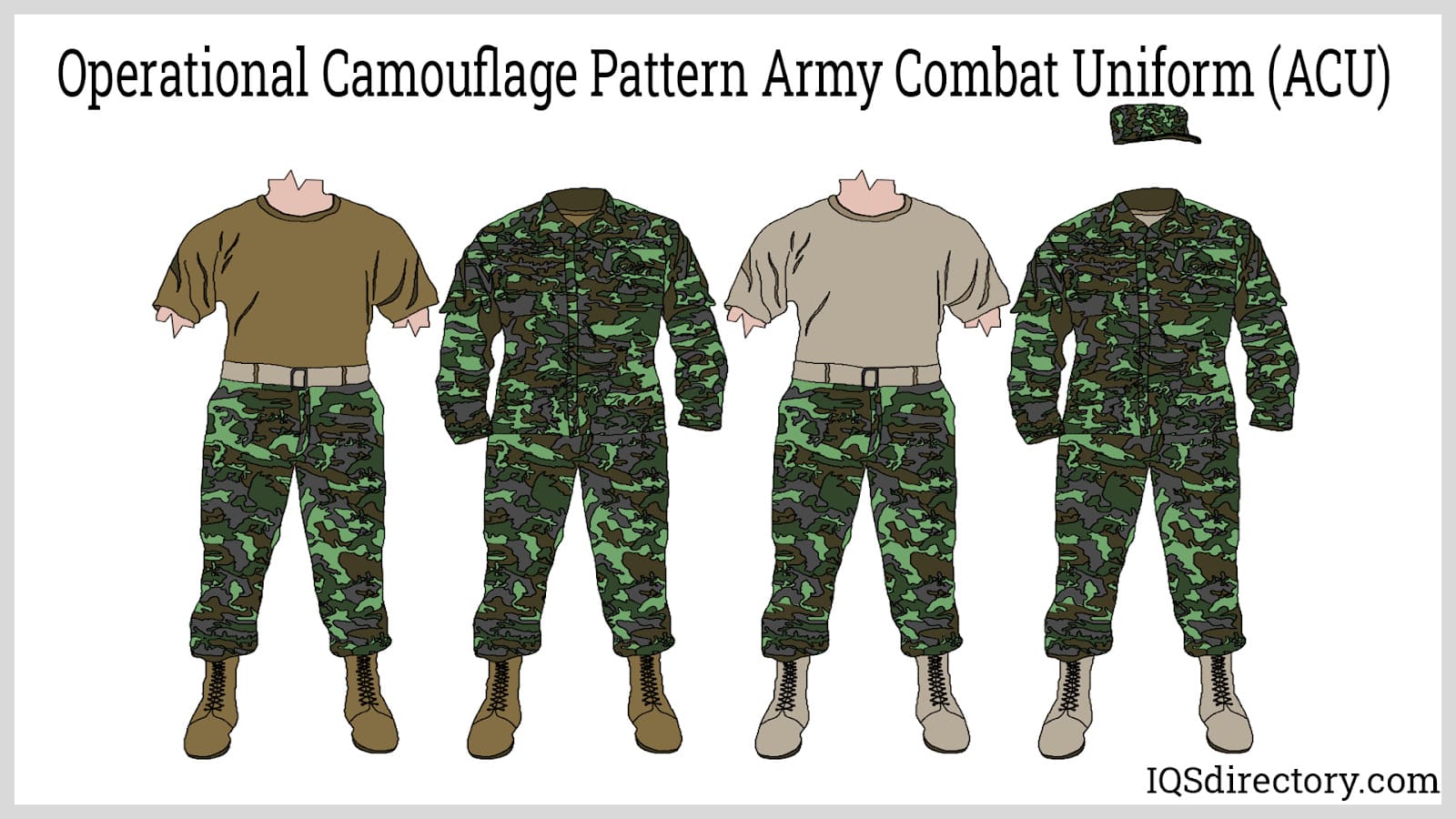

Uniform production involves the use of tactical fabrics and military-grade textile technology to meet robust demands for camouflage, durability, colorfastness, and functionality. Specialized contract sewists apply precise stitching, edge finishing, and quality control to produce work uniforms, military attire, and branded apparel capable of withstanding extreme conditions. Uniforms may be subject to unique requirements—including National Fire Protection Association (NFPA) or Occupational Safety and Health Administration (OSHA) standards—depending on their application in public safety, hospitality, healthcare, or defense.

Industrial and commercial seating solutions rely on contract sewing for ergonomic upholstery, resilient assembly, and material integration that balances longevity, comfort, and support. From executive office chairs to public safety dispatch seating, sewn components—including adjustable headrests and lumbar supports—are tailored to client specifications using high-durability textiles and foam padding. The contract sewing process ensures seamless panel fitting, attractive stitching patterns, and adherence to strict quality benchmarks for heavy-use environments.

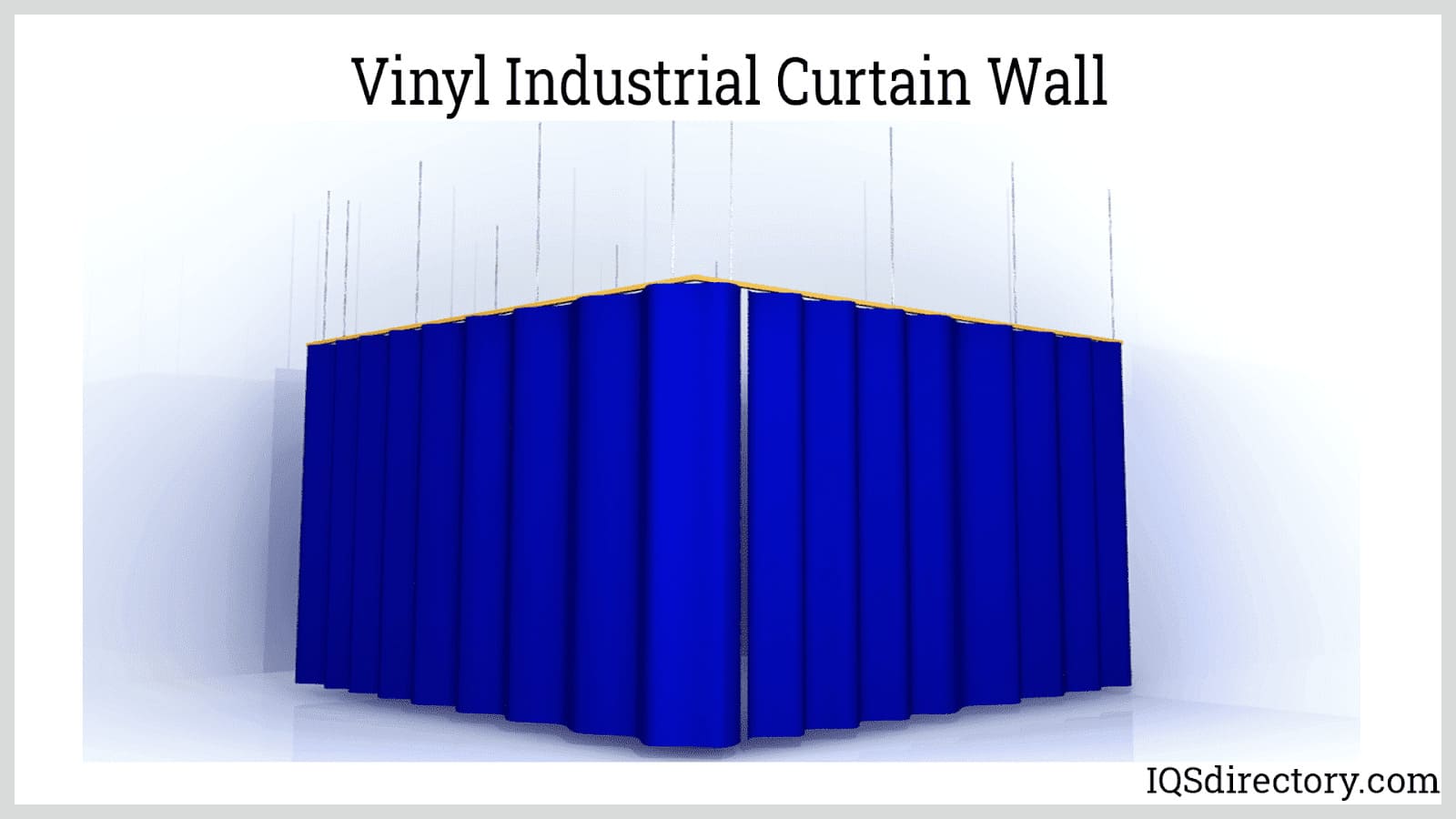

Industrial curtains are engineered from technical textiles such as PVC film, vinyl, and specialty reinforced fabrics to address the needs of factories, warehouses, and commercial facilities. Custom contract sewing integrates features such as grommeted headers, reinforced hems, and snap fasteners for reliable installation. These curtains provide solutions for noise reduction, dust and particulate control, workspace separation, and temperature management. Businesses turn to contract sewing partners to ensure their curtain systems meet unique operational requirements and regulatory standards for workplace safety.

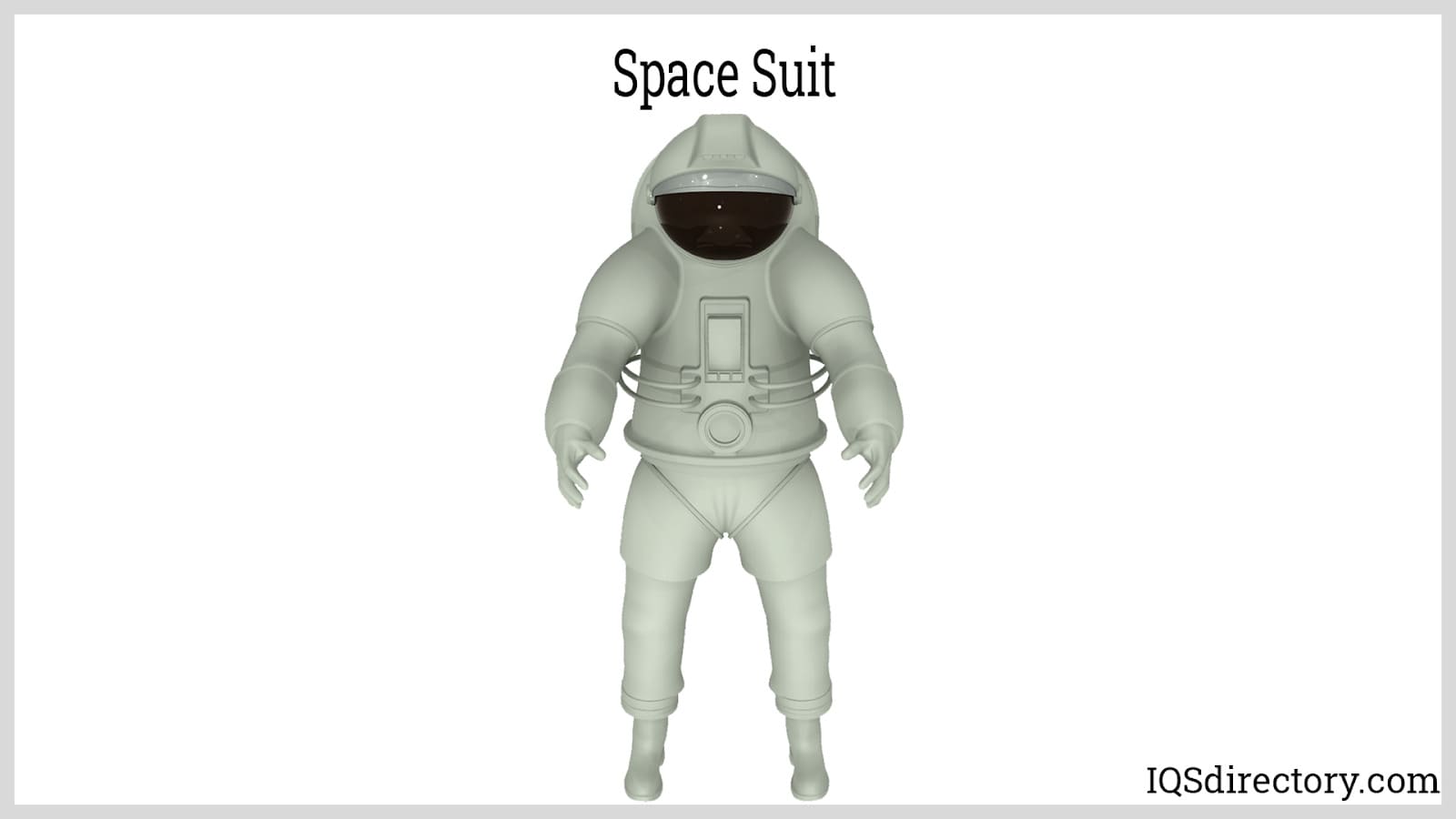

The aerospace sector often requires advanced, mission-critical textile products that meet extreme standards for safety, sterility, and performance. Contract sewing in aerospace encompasses the manufacturing of space suits, pressure garments, insulation blankets, environmental containment, and flexible fuel bladders. Aerospace sewing projects rely on engineered fabrics such as coated nylon, Dacron, neoprene, and advanced composites, assembled with high-precision equipment under strictly controlled processes. Every finished product undergoes rigorous inspection and testing to ensure it can perform under the harshest environmental and operational conditions.

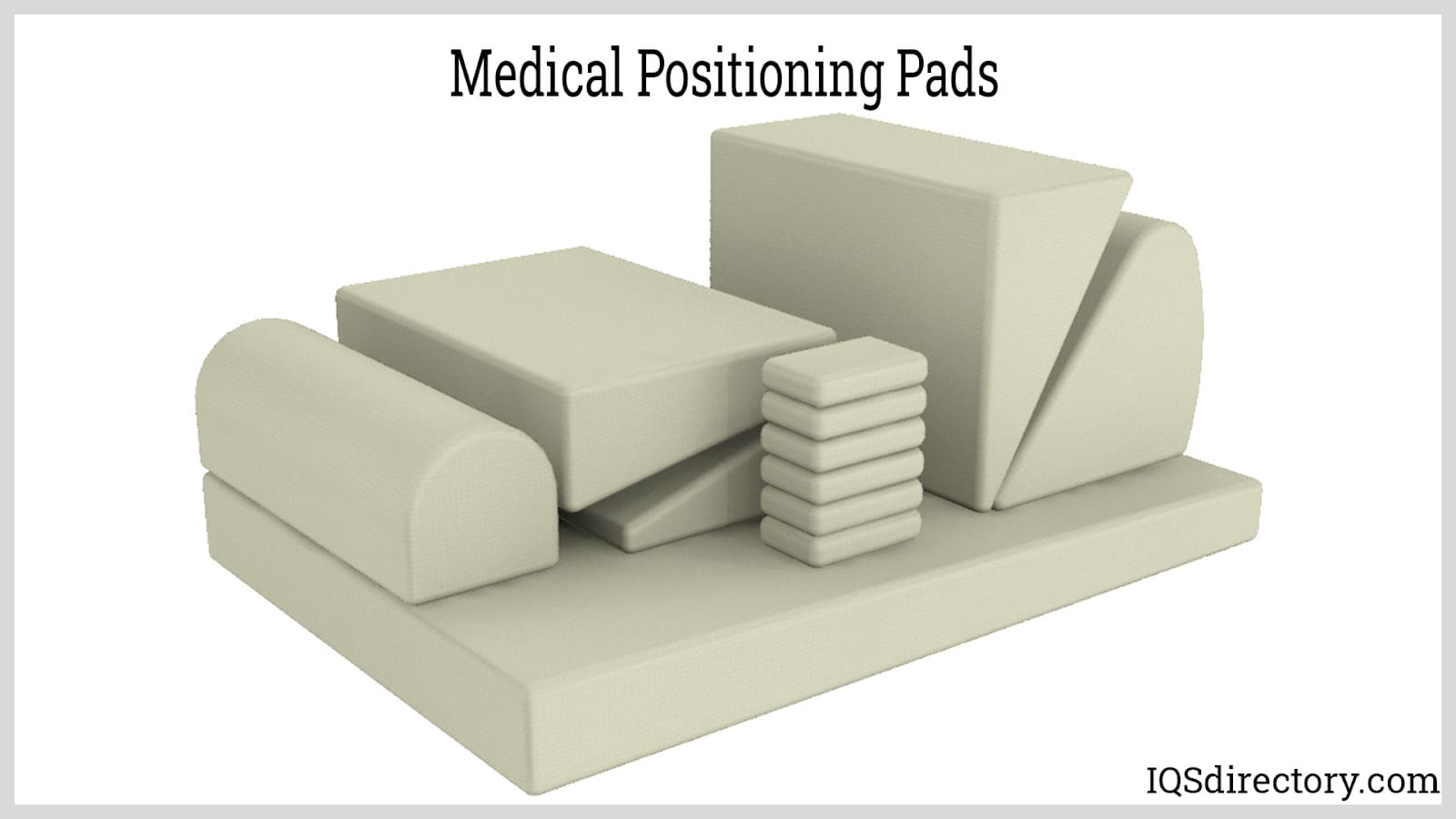

The healthcare sector depends heavily on contract sewing for the production of critical medical textiles, garments, and biocompatible components. Medical contract sewing involves the assembly of surgical drapes, gowns, patient slings, hospital bed linens, organ holsters, wound care mesh, and sterile fabric products that must meet regulatory requirements for safety, sterilization, and patient well-being. Manufacturers use specialized antibacterial, antimicrobial, and fluid-resistant fabrics to ensure each product is appropriate for its end use. Traceability, lot control, and validated cleaning processes are standard features, meeting the stringent expectations of hospitals, clinics, and OEM medical suppliers.

Contract sewing also facilitates rapid prototyping and scalable manufacturing of new medical devices or custom-fabricated medical products, supporting innovation and speed-to-market within the dynamic healthcare industry.

Choosing the Right Contract Sewing Partner: When sourcing contract sewing services, it’s crucial for procurement specialists, product developers, and manufacturers to assess potential partners based on quality certifications (such as ISO 9001 or AS9100 for aerospace), expertise with relevant textile applications, engineering support, capacity for prototyping, and flexibility to scale volume production. Well-chosen contract sewing providers add value by reducing lead times, improving supply chain resilience, and delivering consistent, regulatory-compliant textile products for virtually any industry.

The contract sewing process is an advanced industrial manufacturing method for mass-producing a wide range of textile products for both commercial and industrial applications. Contract sewing services support leading brands and original equipment manufacturers (OEMs) by providing high-volume, scalable production of sewn goods such as apparel, soft goods, upholstery, and technical textiles. The production of these sewn products involves precise selection of components, which are expertly assembled and joined through industrial sewing techniques to achieve consistent quality and durability.

As a backbone of the textile manufacturing industry, contract sewing enables companies to efficiently plan, develop, design, and refine sewn products and manufacturing procedures. “Contract sewing” succinctly describes the outsourced process used by companies to create specialized and high-volume sewn materials—often in partnership with expert sewing contractors. This collaborative approach streamlines the supply chain, reduces lead times, and ensures robust quality control for various industries, including automotive, medical, sports, hospitality, and military sectors.

The prototype and design phase is essential in the contract sewing workflow, ensuring proper evaluation of product design before full-scale manufacturing. This step allows manufacturers to identify potential design flaws and production challenges at an early stage and to design solutions tailored to material type, usage requirements, and cost targets. By uncovering issues that digital models cannot always predict, contract sewing experts can optimize product functionality, appearance, and structural integrity while minimizing waste and costs during mass production. In today’s market, rapid prototyping accelerates time to market for new sewn products, helping clients stay competitive and innovative.

Unlike traditional printed patterns, modern contract sewing utilizes state-of-the-art computer-aided design (CAD) software for digital pattern development. CAD-driven patterns allow for accurate 3D visualization of apparel, upholstery, or industrial sewn goods, enabling designers and engineers to inspect, edit, and perfect every construction detail. Through digital patternmaking, technical designers can quickly modify dimensions, seam allowances, and construction methods, ensuring each iteration fits the intended end use and production process.

Virtual 3D samples produced by CAD applications have replaced many physical prototypes, simplifying communication with clients, buyers, and procurement teams. Sewing patterns can now be efficiently stored and managed in digital libraries, streamlining inventory and documentation for future product runs or design changes. After digital pattern approval, files are transmitted to skilled pattern makers or sewing contractors for conversion to production-ready layouts.

Pattern instructions, or “sewing specs,” are custom developed for each product line—ranging from technical specifications for industrial sewn components to consumer product construction guides. The flexibility of the electronic pattern process ensures manufacturers can optimize for size grading, cut planning, and production yields. Especially in apparel manufacturing, CAD enables the visualization of every garment size, material cut plan, and seam placement. Determining fabric consumption at this stage is critical, as it directly affects material sourcing, cost estimation, and supply chain logistics.

Upon final pattern approval, wide-format or plotter printers produce physical templates used during the fabric cutting and sewing stages. Some manufacturers opt to print patterns on durable materials suited for reuse in high-volume or heavy-goods production.

Once product development is greenlit, the commercial sewing contractor proceeds with material selection, grading, and marking. This phase is pivotal for optimizing material yield and ensuring all required components—such as fabrics, textile reinforcements, threads, fasteners, interfacing, foam, webbing, ribbons, linings, buttons, snaps, hook-and-loop closures, and zippers—are sourced to exact specifications.

Upon receipt, raw materials undergo rigorous inspection for defects, colorfastness, and performance characteristics. Pre-treatment processes such as pre-shrinking or heat-setting may be performed, especially for fabrics that are prone to dimensional changes during industrial sewing. This quality assurance step, whether for natural fibers (cotton, leather), synthetics (polyester, nylon, vinyl), or high-performance technical textiles (Kevlar, Cordura, medical-grade nonwovens), guarantees that production runs meet end-use requirements and regulatory standards.

Once approved, a pre-production sample, often referred to as a “first article” or “pre-pro,” is produced for evaluation before committing to high-volume manufacturing. This sample is reviewed for fit, finish, durability, and compliance with client or industry standards, ensuring full satisfaction before ramping up production capacity.

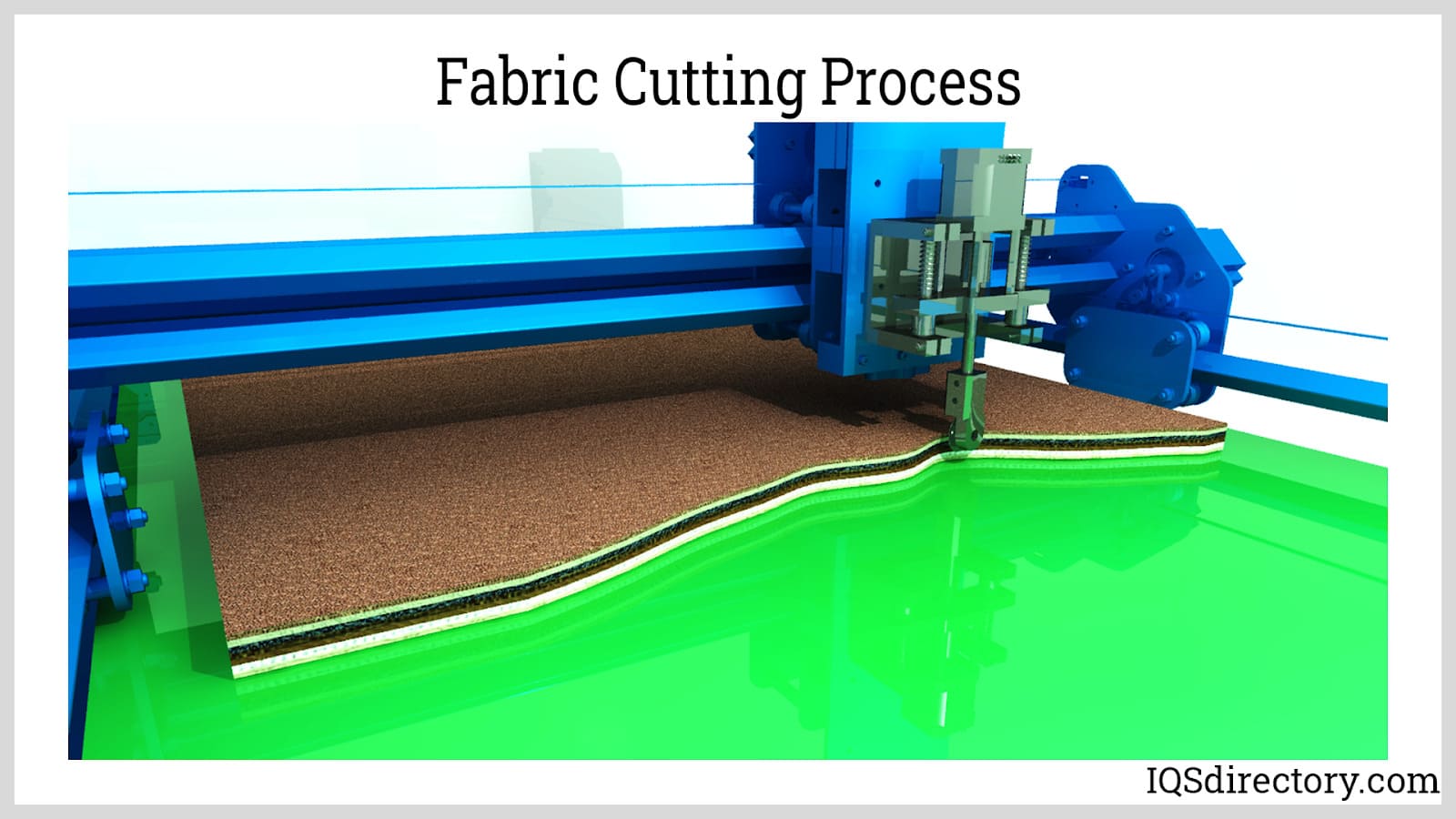

The cutting stage marks the transition from digital design to physical production. Skilled operators lay out printed patterns onto material spreads, aligning grain direction and optimizing fabric placement to minimize waste. Advanced cutting equipment—ranging from precision saws and straight knives to rotary cutters—slices cleanly through multiple plies of fabric to maintain consistency across large production runs. For specialized materials such as leather, vinyl, or composite textiles, unique cutting tools or die-cutters ensure accuracy and efficiency.

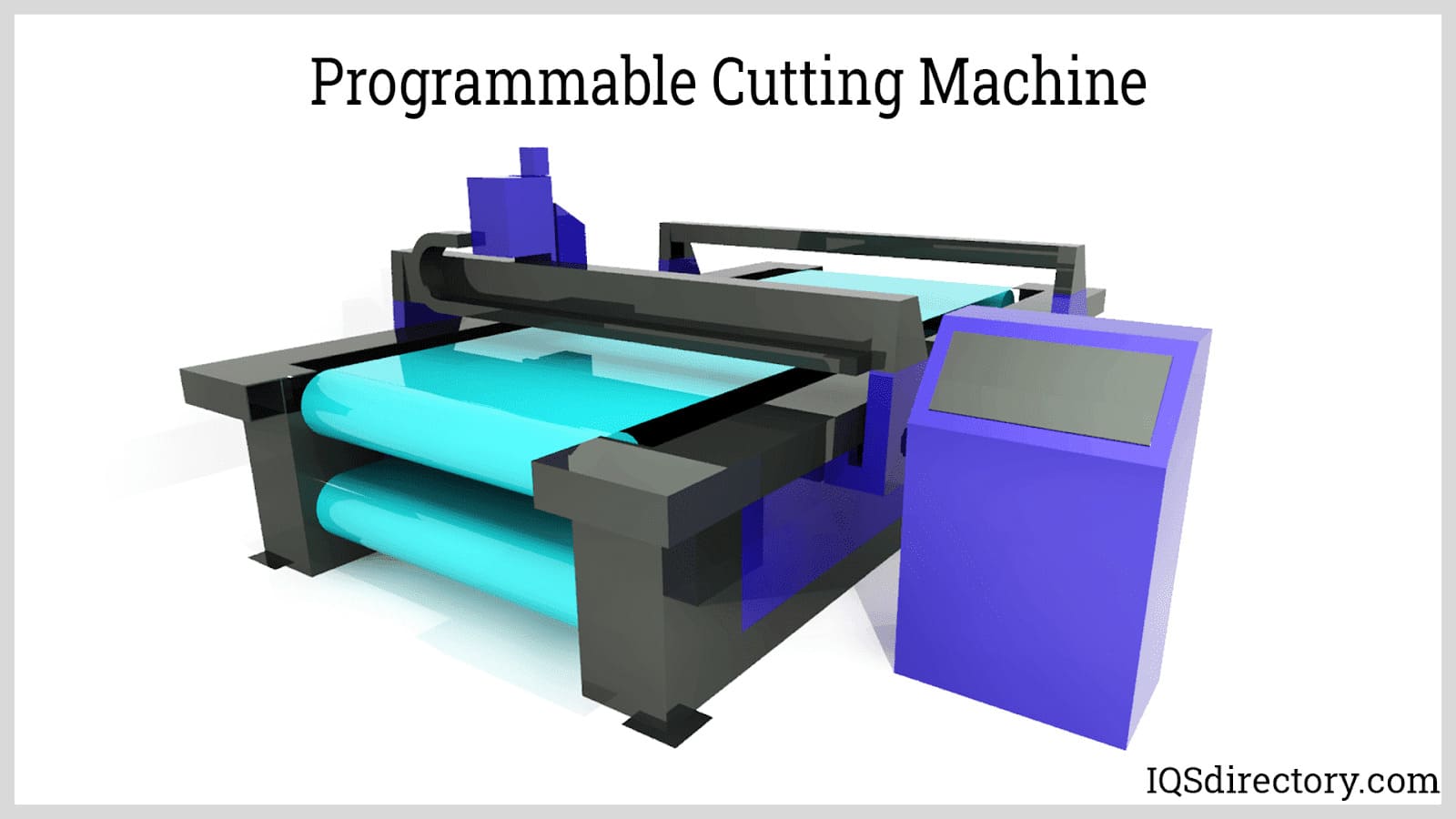

Modern contract sewing facilities increasingly rely on automated computerized cutting systems—such as CNC (computer numerical control) high-ply cutters—for scalable, repeatable production. These digital cutters process cutting instructions generated during the CAD patterning phase, determining the optimal nesting and orientation of each part to maximize material usage. Integrated sensors and precision blades enable high-volume, error-free cutting for apparel, upholstery, medical products, and technical textiles. This technology reduces material costs, labor, and turnaround time while ensuring every piece meets stringent tolerances for assembly.

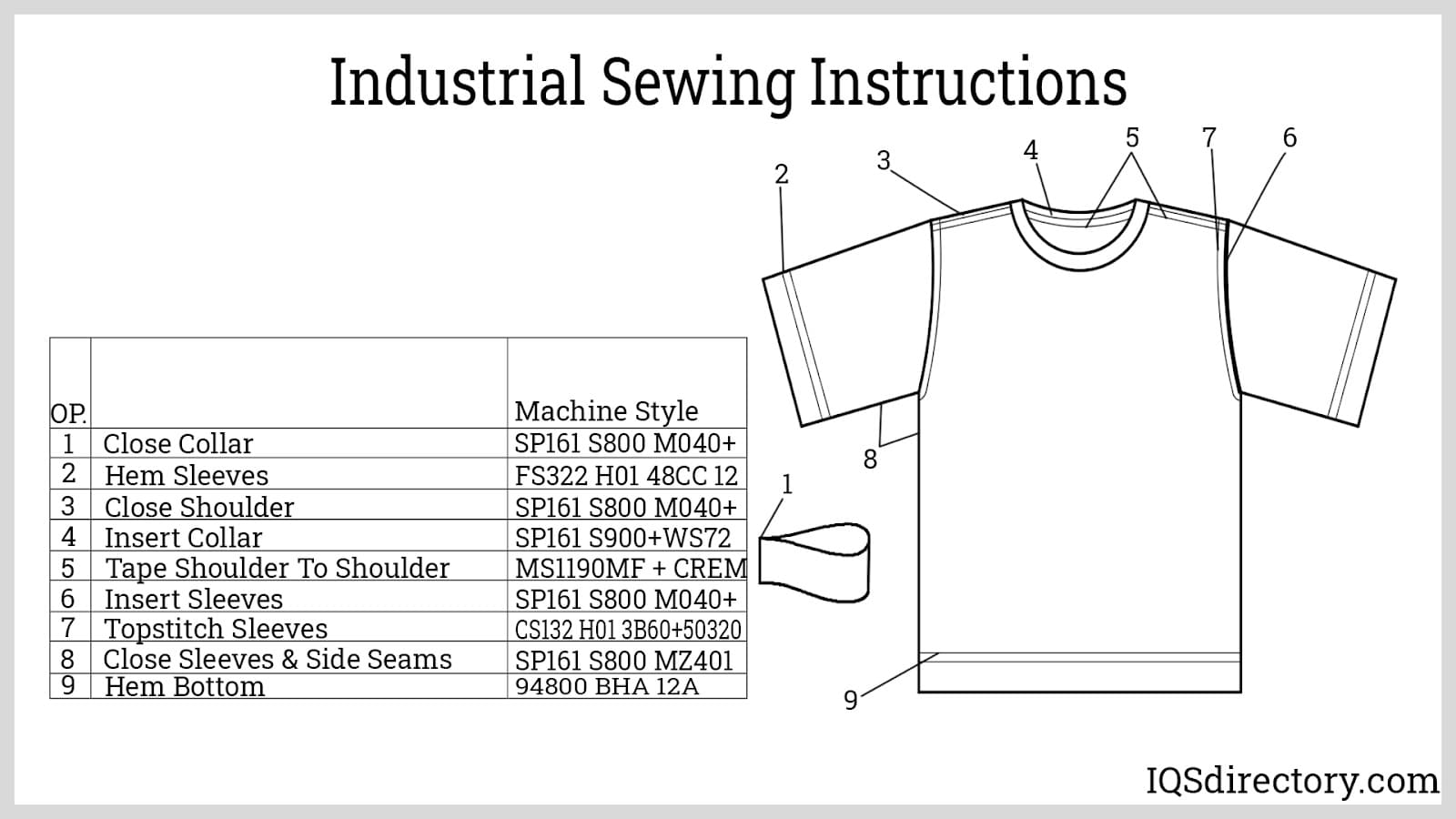

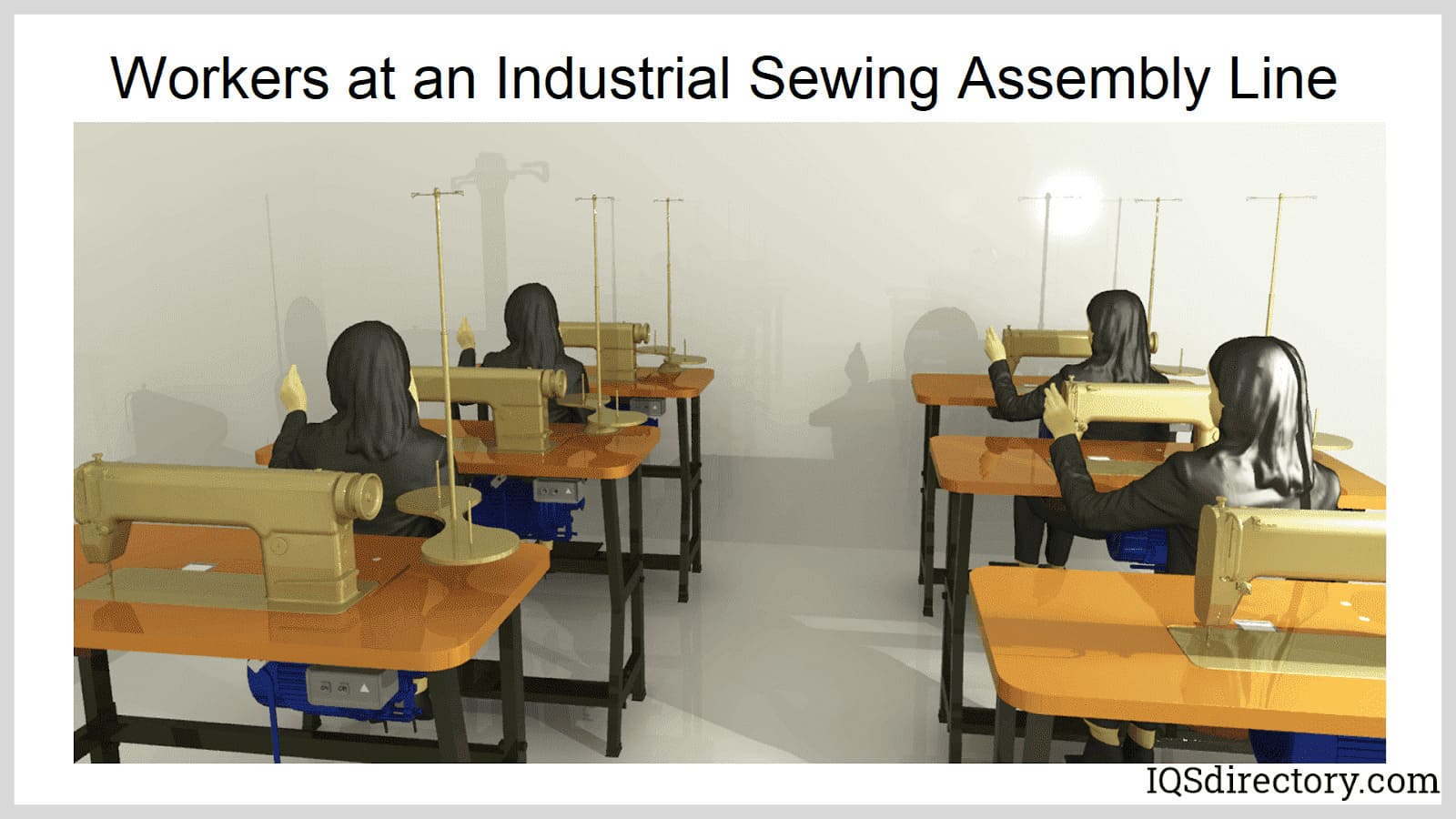

At the heart of the contract sewing process lies industrial sewing assembly. Unlike individual home sewing operations, commercial sewing lines are organized for efficiency and throughput. Production typically follows a progressive assembly system, with each operator performing a specialized function—such as automated seam joining, attaching trims, bar tacking reinforcements, or overlocking open edges—before passing the item to the next workstation. High-speed industrial sewing machines, ranging from single-needle lockstitch to automated programmable machines, are selected based on product type, fabric weight, and required seam characteristics.

Stitch selection is integral to the performance and durability of sewn products, directly impacting seam strength, elasticity, and appearance. Industrial sewing companies have deep expertise in matching stitch type to fabric properties, end-use environment, and regulatory requirements.

The single needle lockstitch—common in mass garment manufacturing—produces a flat, robust seam suitable for woven fabrics and general assembly. It employs one needle and two interlocking threads for a neat, puckering-resistant result.

Double needle lockstitches, offering parallel rows of stitching, are frequently used for heavy-duty upholstery, jeans, and decorative finishes. While they add seam strength, some materials may experience puckering from the additional needle.

The zigzag stitch provides elasticity and is ideal for sewing stretch fabrics, sportswear, and edge finishing. Its side-to-side motion accommodates fabric movement and prevents fraying.

A cover stitch, typically double or triple-needle, is favored for hemming knitwear, sports apparel, and stretch seams. Its characteristic parallel top lines and underlying zigzag offer flexible strength for high-mobility garments.

Bar tack stitching reinforces stress points, such as pocket corners, belt loops, and equipment straps, with tightly compact stitches for enhanced tear resistance in high-abrasion areas.

The box X stitch—crucial in industrial and commercial sewing—securely attaches webbing, straps, and handles to heavy-duty bags, safety harnesses, or tactical gear, offering superior load-bearing capacity.

The Mauser stitch is a flatlock construction performed on advanced sewing machinery, producing seamless, low-profile joins valued in performance apparel and technical garments for ergonomic comfort and strength.

Post bed lockstitch machines enable the assembly of three-dimensional or bulky products—such as car seats, orthopedic supports, and leather accessories—by offering lifted work areas, maneuverability, and stitch power for thick substrates.

The invisible blind stitch is used for unobtrusive hems or joining panels in formalwear, drapery, and high-end upholstery. Hidden within folds, the stitch remains discreet until the fabric is parted or stretched.

The nine stitches above represent just a sample of the many types that contract sewing companies utilize to achieve specialized results across various product lines. Selecting the correct stitch is a nuanced decision based on fabric dynamics, end-use requirements, and customer specifications. Expert sewing contractors continuously adapt stitch technology and processes to suit evolving trends, compliance standards, and advanced material innovations, providing clients with reliable, high-quality sewn products.

Contract sewing is a specialized manufacturing service for producing soft goods and sewn products across sectors such as medical, military, automotive, aerospace, clothing, and industrial markets using advanced equipment and skilled personnel.

Key benefits include rapid high-volume production, ability to handle diverse materials, strict quality control, scalability, and transforming innovative designs into finished products for a wide variety of industries.

The process includes product design and prototyping, digital pattern making with CAD, material selection, cutting, automated or manual sewing, and rigorous quality inspection to ensure durability and precision.

Products include car upholstery, airbags, knee pads, industrial aprons, luggage, airplane seatbelts, high-visibility apparel, uniforms, chairs, industrial curtains, aerospace textiles, and medical garments.

They utilize specialized manufacturing processes, source certified materials, follow regulations such as FAA, EASA, ANSI, OSHA, and NFPA, and conduct thorough inspections and testing for each production batch.

Key factors include quality certifications (like ISO 9001 or AS9100), experience with target applications, strong engineering support, prototyping capacity, proven ability to scale, and consistent regulatory compliance.

The contract sewing industry can transform any type of material into a component for another product or a final finished piece. The range of materials is vast and includes various forms of rubber, plastics, polyesters, and fabrics. An essential aspect of the sewing industry is selecting the right material for a project, as this choice greatly influences the finished product.

Several factors contribute to the choice of materials for a project, including strength, texture, product design, and the purpose of the product. The materials selected for manufacturing operations can differ significantly from those chosen for a fashion show.

Materials are divided into two categories: natural and man-made. Natural materials are derived from nature, while man-made materials are produced through chemical processes and manufacturing.

Cotton is a common material derived from a plant. It has been used for thousands of years to produce a variety of items. Cotton is soft, breathable, lightweight, and durable.

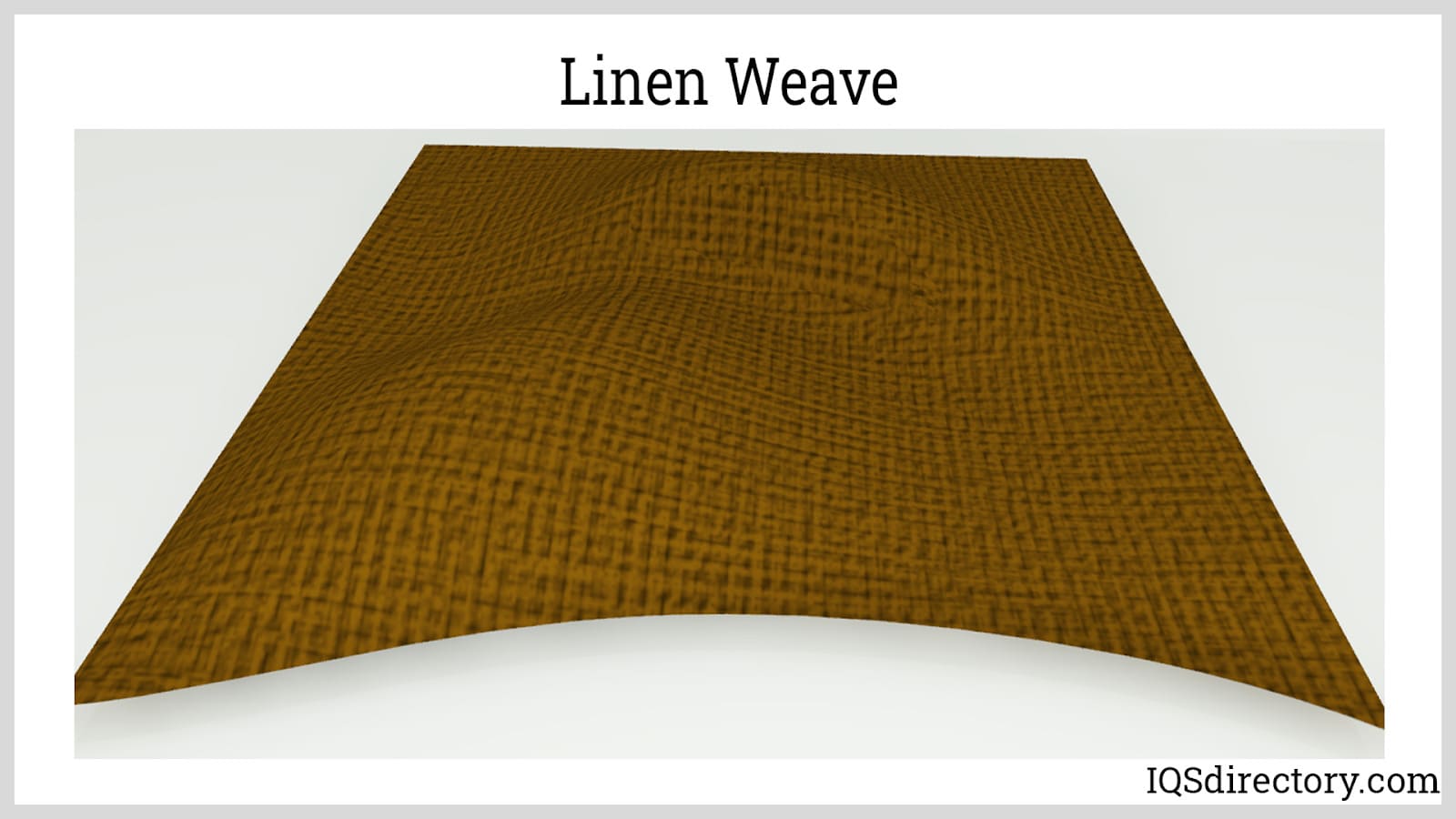

Like cotton, linen is derived from a plant and is a breathable material. It is easy to handle and work with, as well as durable. Linen is suitable for upholstery, curtains, and projects that require a strong yet lightweight material.

Jute is another material derived from a plant, specifically the bamboo plant. It is very stiff, sturdy, and durable, making it ideal for floor decorations and certain types of upholstery.

Wool, a material with a long history, comes from the hair of sheep. It is a heavy, durable fabric that is excellent for projects involving winter or cold weather.

Silk is a natural protein fiber obtained from the cocoons and webs of spiders and moths. While the process of making silk can use various forms of web or cocoon material, it is typically derived from those produced by moths or caterpillars. Silk is highly regarded for its softness, lightweight nature, and exceptional durability.

Polyester is a synthetic resin created by mixing polymers with cellulose acetate ester. It is economical, offers bright colors, and can be easily shaped. Polyester is manufactured using a combination of natural chemicals and synthetics. It is a strong fiber that is highly resistant to stains.

Rayon is made from purified cellulose found in wood pulp. Although rayon is based on natural cellulose, it is enhanced with chemicals, making it semi-synthetic. A common form of rayon is viscose rayon, which resembles cotton. Rayon is a versatile material that can be formatted, configured, and shaped into a wide variety of forms.

Fiberglass is made from woven glass fibers. It is lightweight, highly durable and strong, weather-resistant, and available in a variety of textures. Fiberglass is a type of reinforced plastic blended with thin glass filaments.

Vinyl is made from a synthetic resin containing polyvinyl chloride (PVC). It is tough, durable, and has exceptional flame-retardant properties. Known for its versatility, vinyl can be easily shaped, configured, sewn, and fabricated. It is used to make a wide variety of products, including protective gear, shower curtains, and raincoats.

Acrylic fiber fabrics are made from the synthetic polymer acrylonitrile, derived from petroleum-based chemicals mixed with various monomers. Acrylics are known for their heat retention and lack of breathability. They are commonly used in the production of sports equipment such as tracksuits, hoodies, and athletic pants.

Canvas is a highly durable woven fabric with multiple uses in the production of various products. It is made from the weaving of materials such as hemp, flax, cotton, or yarn. Canvas is commonly associated with producing tents, sails, bags, and sturdy cases.

Contract sewing plays a vital role in various industries by supporting the production of commercial and industrial products. Often, contract sewing companies collaborate with a range of producers to help bring designs and concepts to life.

The basic function of the contract sewing industry is to assist producers who do not specialize in sewing by creating items and components that aid in their production process. With many years of experience, sewing companies have the expertise to produce prototypes, suggest design improvements, and help develop a production plan.

Many fabric components for aircraft are produced by the contract sewing industry. This includes seat belts, upholstery for seats, carpeting, and the special pouches on the backs of seats. Products and components for the aircraft industry are closely regulated by the Federal Aviation Administration (FAA), which sets standards for safety and the protection of passengers and crew members.

Industries that handle large amounts of cash require money bags that are sturdy and capable of withstanding constant use. Money handling bags come in various sizes to accommodate different cash handling situations. They are designed with heavy-duty, tightly fitting zippers equipped with locking mechanisms. To help organize cash, numbered security seals can be added to track the location and pickup time. The primary function of money handling bags is to ensure security and safety.

The purpose of shipping bags is for direct delivery services. Similar to bank bags, delivery bags must be secure, safe, and have a minimal risk factor. They are made from extremely strong materials to ensure that items remain safe and are delivered properly. The main use of delivery bags is by courier services.

Sewing services for the military follow a distinct business model due to the military's established standards for every item they procure, known as MIL-STD regulations. Unlike products produced for private and public companies, military items are manufactured according to specific directions and instructions to ensure high quality and adherence to strict standards.

Military sewing projects encompass a variety of items, such as bags, parachutes, webbed safety harnesses, and medical aid kit bags. Each of these must be manufactured to strict and precise standards.

The primary role of the contract sewing industry is to produce clothing. Designers develop and plan their apparel items, then transfer the production to contract sewing specialists. These experts not only create prototypes but also provide recommendations for design adjustments to improve and streamline the manufacturing process.

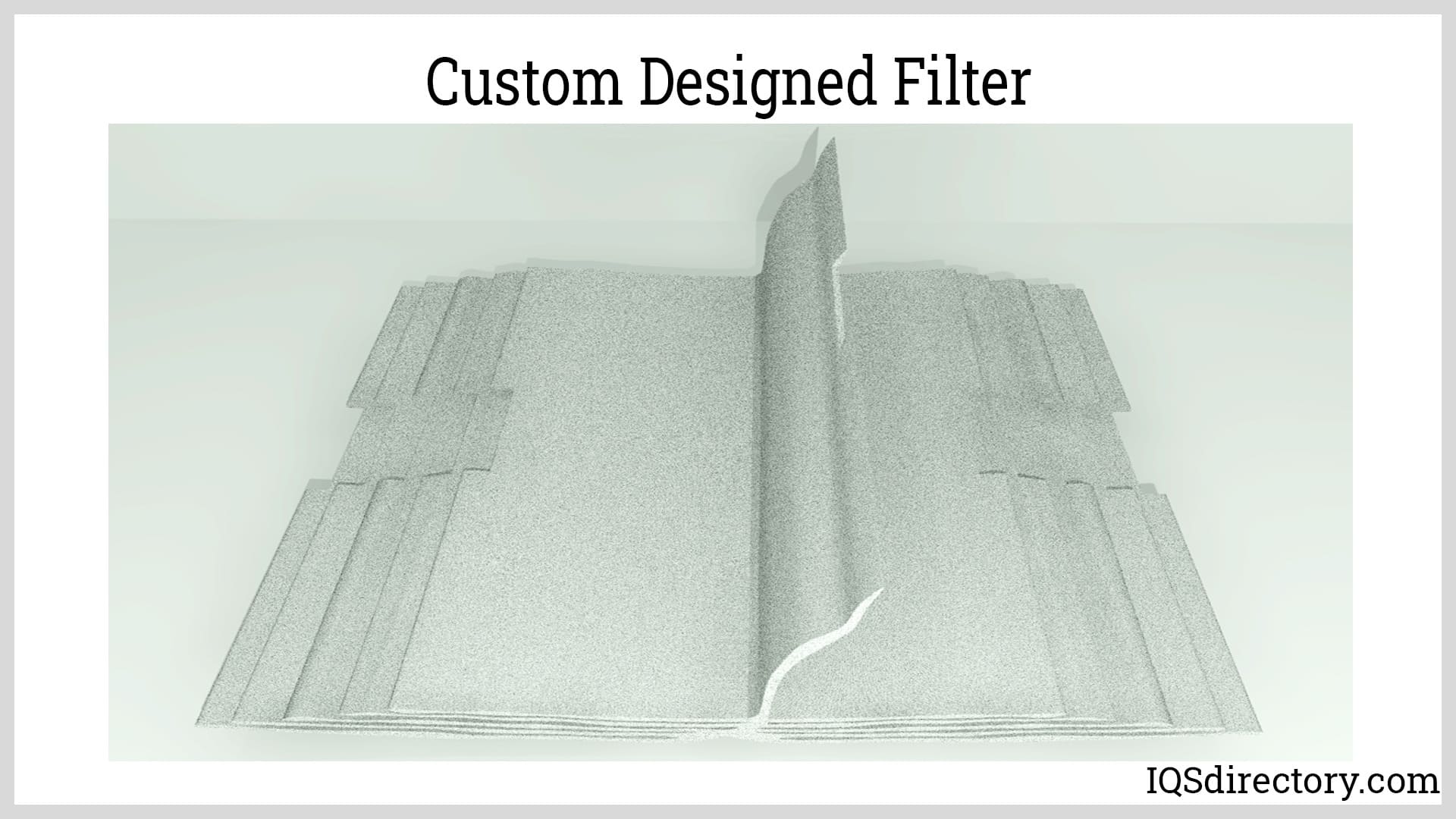

In air filtration systems, filters are essential for capturing particulates and allowing clean air to flow through. The contract sewing industry produces these fabric filter bags in various sizes and materials, including polyester, polypropylene, mesh, nylon, and flannel. These bags are designed to trap airborne pollutants and waste, ensuring that both the air and machinery remain clean and clear.

In the marine industry, the contract sewing sector designs and manufactures protective coverings for boats and marine equipment. These covers, made from durable marine-grade fabrics, are intended to safeguard equipment while moored or in storage. Given that boats vary in size and shape, marine covers are available in a range of styles and can be customized with various accessories.

The sports and athletic industries depend on contract sewing to create a diverse array of products, including golf bags, club covers, uniforms, protective gear, training outfits, and more. A distinctive feature of these products is the requirement to sew team logos onto the final items, an integral part of the original design process.

In the automotive industry, contract sewing focuses primarily on vehicle interiors. Similar to the aircraft industry, the United States Department of Transportation (USDOT) has stringent standards for producing components for automobile and truck interiors. A key concern is ensuring that materials used are non-toxic and safe for occupants.

The distinct aspect of vehicle interior products is that many of the enhancements, such as airbags, are not visible but must meet strict safety standards. Additionally, the contract sewing industry produces various components such as pouches, seat arms, and upholstery, all of which contribute to the overall functionality and comfort of the vehicle's interior.

Industrial sewing differs significantly from home sewing. While both use robust and durable machinery, industrial sewing equipment is distinguished by its emphasis on precision, accuracy, and efficiency. Unlike domestic sewing machines, industrial models are designed to meet the high demands of contract sewing, which often requires more advanced technology and higher performance levels. Additionally, industrial sewing equipment is typically more expensive due to its specialized features and capabilities.

Industrial sewing produces items with a professional finish, characterized by tight seams, clean cuts, and exceptionally secure connections. Beyond these fundamental qualities, industrial sewing is notably faster and more reliable compared to domestic sewing machines, making it ideal for high-volume and precision-focused production.

Flat bed sewing is employed to join flat pieces of fabric, resulting in a professional seam. While it resembles the sewing done on domestic machines, industrial flat bed sewing distinguishes itself by its speed, precision, and attention to detail, allowing for faster and more accurate production.

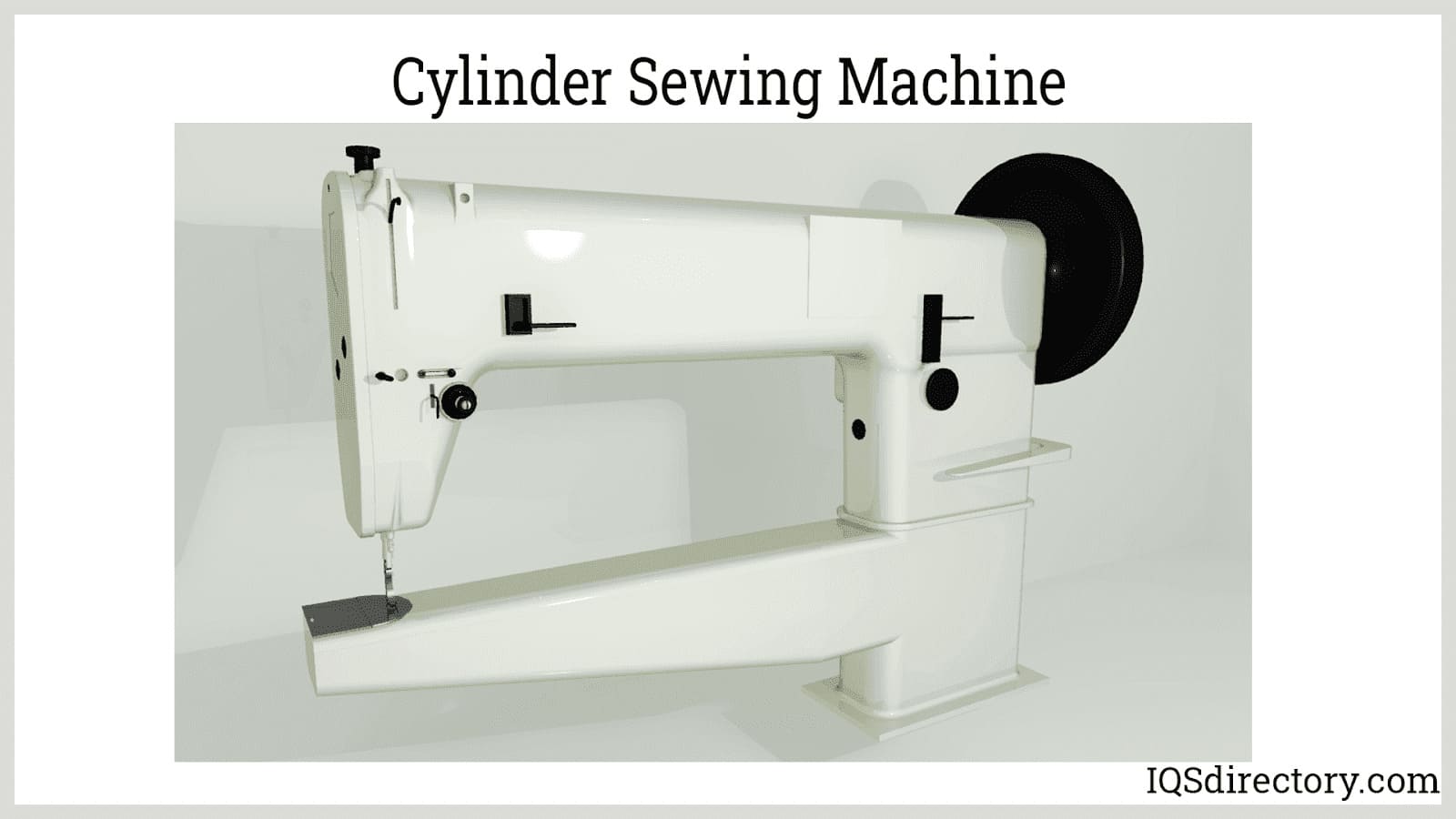

Cylinder bed sewing features a cylindrical sewing surface designed for stitching materials that require circular sewing. The fabric passes over and under this column, facilitating more efficient and precise stitching. Cylinder beds typically have diameters ranging from 5 cm to 20 cm, accommodating various sizes of circular or tubular components.

Post bed sewing is ideal for three-dimensional sewing and provides additional space for creating specialty items. With the bed elevated and projecting, it allows the material to be moved in multiple directions. This design minimizes the need for constant adjustments, making it easier to keep the material in place during stitching.

A free arm sewing machine is a variation of a cylinder sewing machine that features a removable base. This allows for easier access to cylindrical or tubular materials, enhancing the ability to sew items like sleeves and cuffs. While similar to other industrial machines in that many have removable bases, the free arm design specifically improves maneuverability and precision for certain sewing tasks.

In a cylindrical machine, the bed extends from the back of the machine, accommodating tubular or pipe-shaped items. This design is specifically intended for working with materials that require circular or cylindrical stitching, making it easier to maneuver and stitch these shapes effectively.

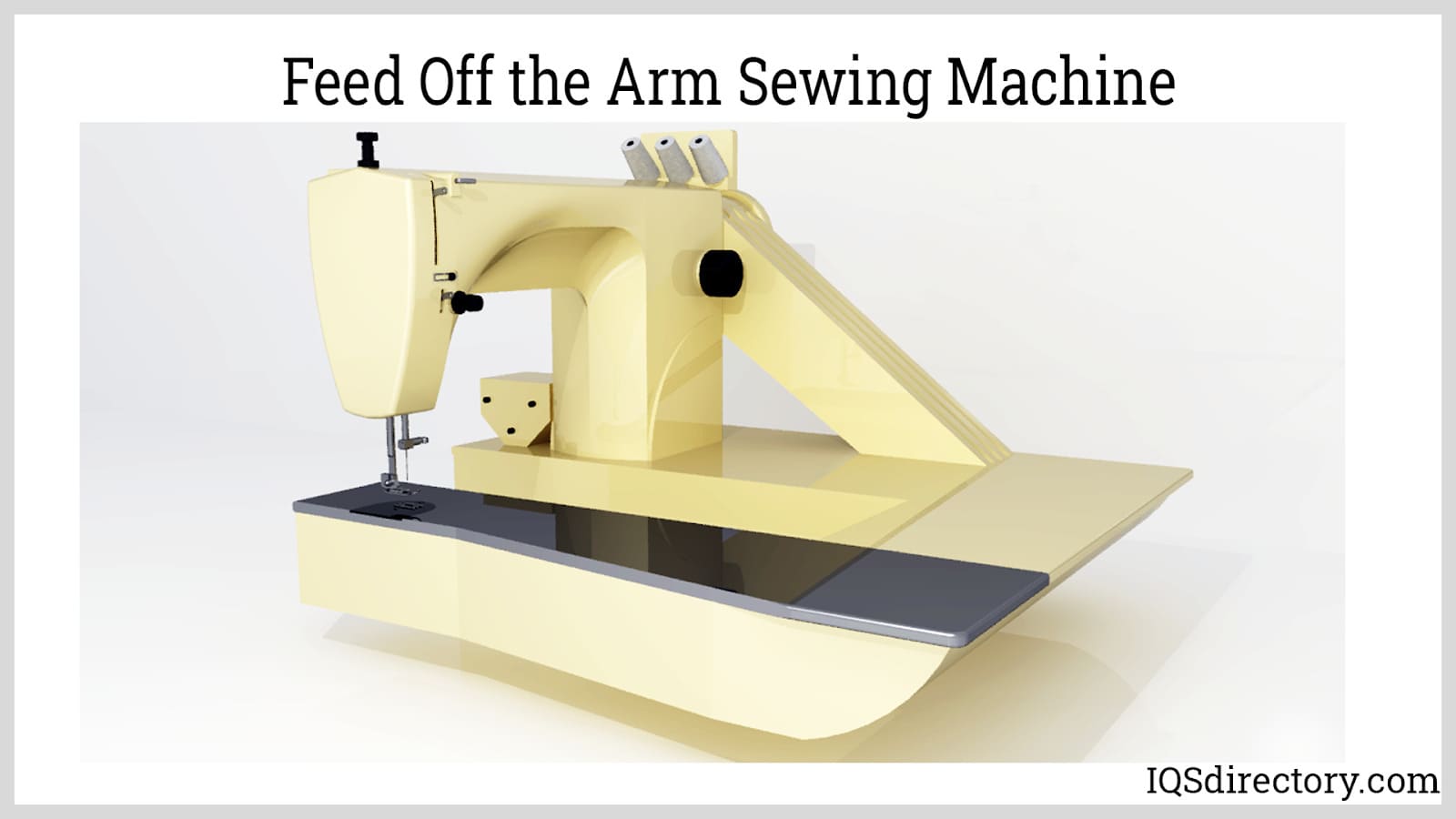

Feed-off-the-arm machines are versatile and equipped with two or three needles, enabling sewing with up to four threads. They produce two or three rows of chain lock stitches and use a looper instead of a bobbin. The primary advantage of these machines is their capacity to handle heavy or folded fabrics with ease.

Industrial and contract sewing machines offer various feed mechanisms, each suited to specific sewing operations and machine types. Selecting the appropriate feed mechanism is crucial for ensuring optimal performance and compatibility with the intended sewing tasks.

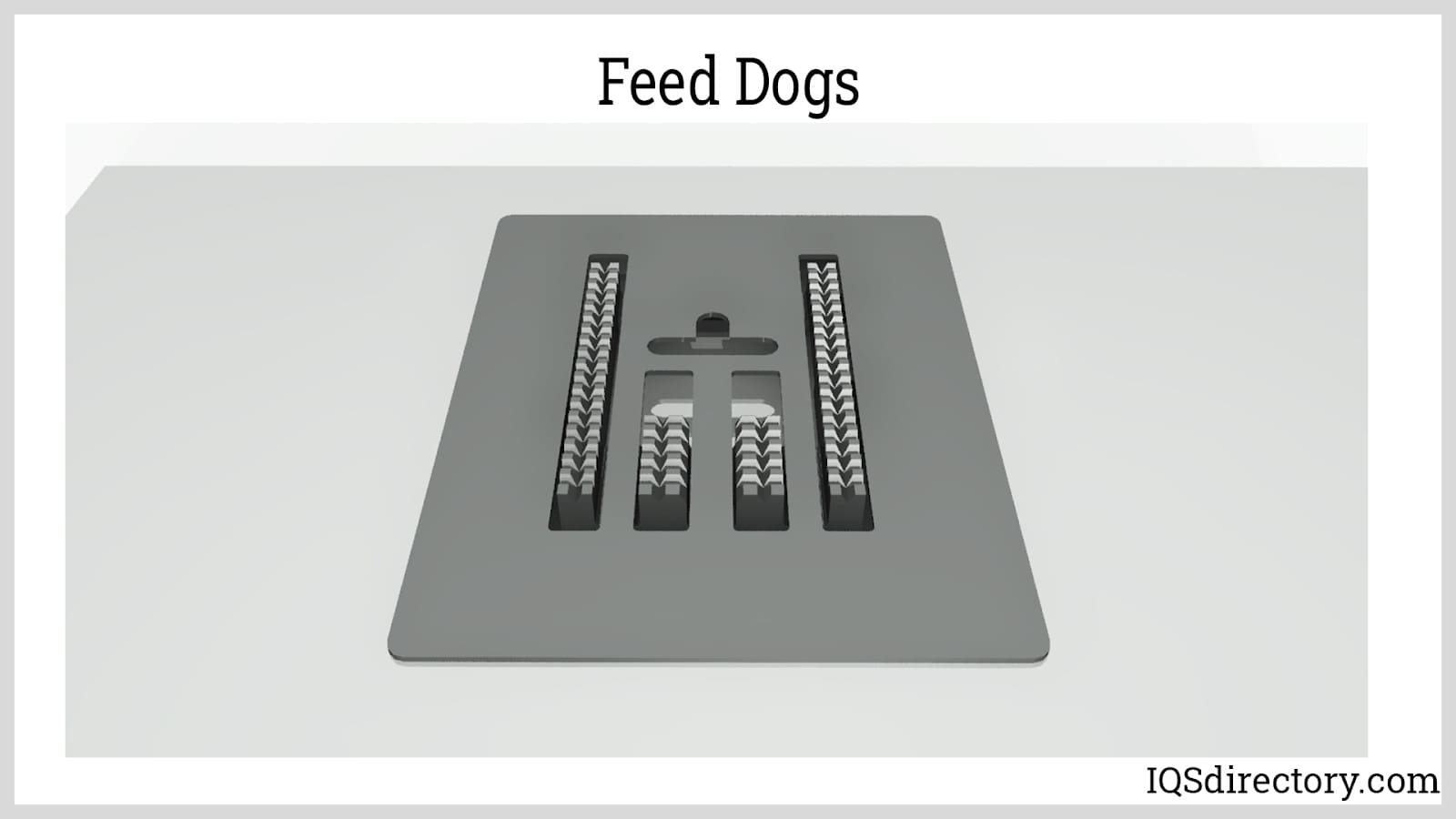

Walking Foot: the fabric is moved by feed dogs, teeth like ridges in the throat of the machine. They grip the fabric and gently move it through the machine. Feed dogs prevent slippage of slippery or padded fabrics.

In the contract sewing industry, several standards govern production, including those from the International Organization for Standardization (ISO), American Society for Testing and Materials (ASTM), United States Military (MIL-STD), and Occupational Safety and Health Administration (OSHA). ASTM and ISO standards focus on product quality and performance, while OSHA regulations address worker safety. MIL-STD standards specify acceptable threads and textiles used in military applications.

For the contract sewing industry, ISO 9001:2008 is a key standard, focusing on certifying the quality of product management systems. Additionally, ISO 8239:1987 specifies standards for sewing machine needles and needle holders, including tolerances and combinations. The primary concern is ensuring that needles fit securely and function correctly in the machinery.

OSHA's focus is on minimizing risk factors related to employee workstations, specifically addressing the strain on the body caused by the posture required for sewing operations. OSHA provides detailed guidelines on the appropriate types of chairs, worktables, and pedals or mechanisms to ensure ergonomic safety and comfort for sewing machine operators.

OSHA does not cite specific pieces of legislation but emphasizes overall worker safety. It requires management to ensure a hazard-free work environment, addressing general safety standards and practices to protect employees from workplace risks.

ASTM provides detailed standards for the sewing industry, including specific guidelines for threads, stitches, and seams. Additionally, ASTM standards include an extensive list of criteria for suitable textiles used in the industry, ensuring quality and performance in sewing applications.

MIL-STD standards encompass all aspects of the sewing process, detailing acceptable materials and thread quality. They include specific guidelines for seam design, positioning, and overall construction to ensure compliance with military requirements.

A canopy is a structure with a connected fabric or metal covering that can give shade or shelter from weather elements such as the sun, hail, snow, and rain. For example, a tent with no floor can be...

Cut and sew is a process for the manufacture of clothing where the design and pattern are printed on the raw cloth from which the garment is cut, ensuring full color, edge to edge print of the design and color...

A protective cover is a sewn fabric that is specifically designed and used for protecting equipment, people, surfaces, and enclosures. Protective covers provide protection from the elements, UV rays, dirt, dust, moisture, and...

A carrying case is a way of conveniently organizing and transporting a collection of similar or dissimilar items for future use. There is a type and kind of carrying case to fit every possible application from protecting and storing cell phones to cases for speaking systems and technical equipment...

Contract manufacturing is a business model in which a company hires a contract manufacturer to produce its products or components of its products. It is a strategic action widely adopted by companies to save extensive resources and...

A hard case is a type of carrying case that is made from molded plastic, aluminum, veneered or laminated wood, or different types of metals. They are the most secure and durable forms of carrying cases and...

A road case is a ruggedly built, highly functional protective container with varying wall thicknesses that is capable of withstanding the riggers and handling of shipping. They are designed to meet...

A tool case is a portable case designed to organize and protect tools and allow easy access and convenient availability. Standard tool cases can be used when working on a project. In addition, specialty and custom-designed tool cases are...

Cases designed to carry special valuables have been part of society throughout history back to the time of the Egyptians and before. Carrying cases are commonly found in any house stored in a garage, tucked away in a basement, or setting on a shelf...