Hard Cases

A hard case is a type of carrying case that is made from molded plastic, aluminum, veneered or laminated wood, or different types of metals. They are the most secure and durable forms of carrying cases and...

Please fill out the following form to submit a Request for Quote to any of the following companies listed on

This article contains concise information regarding carrying cases and their use.

You will learn:

Carrying cases offer a convenient solution for organizing and transporting various items, regardless of their similarities or differences. They are invaluable for protecting and storing anything from mobile phones to audio systems and technical gadgets, ensuring delicate materials remain secure during transportation.

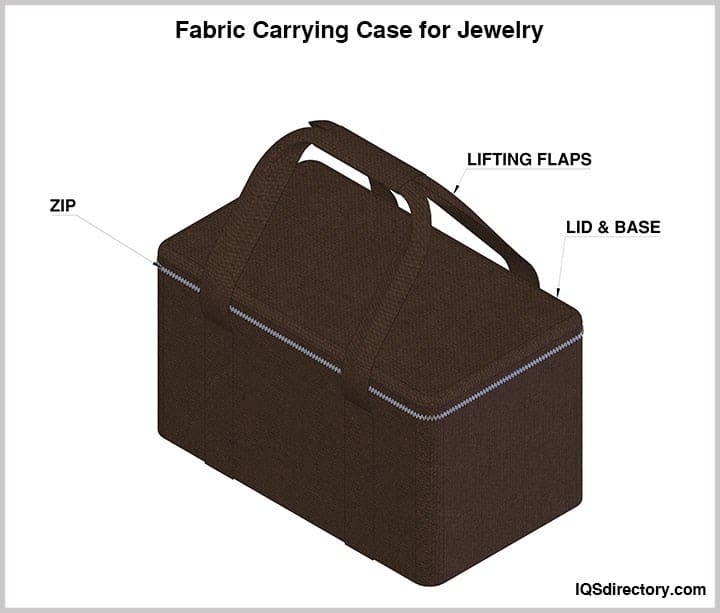

The design, configuration, and dimensions of carrying cases are specifically tailored to fit the items they are meant to hold. Depending on their intended use, carrying cases can be made from sturdy materials like reinforced fabric, plastic, aluminum, nylon, leather, wood, or a mix thereof.

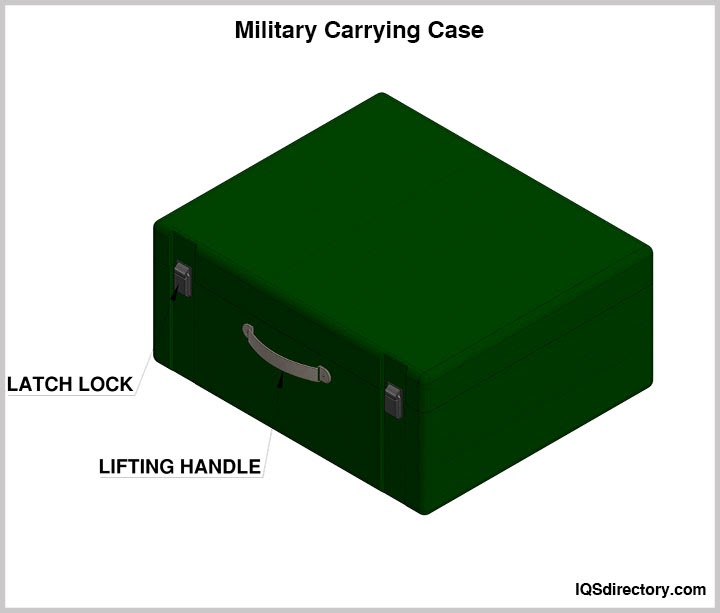

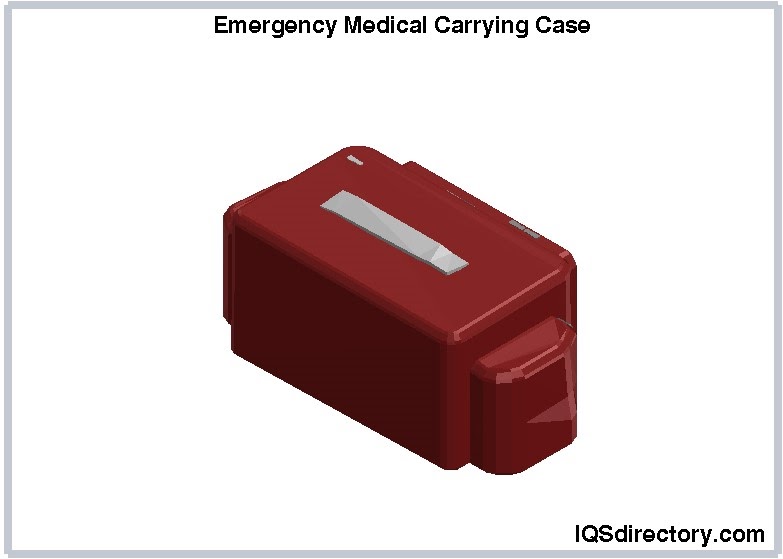

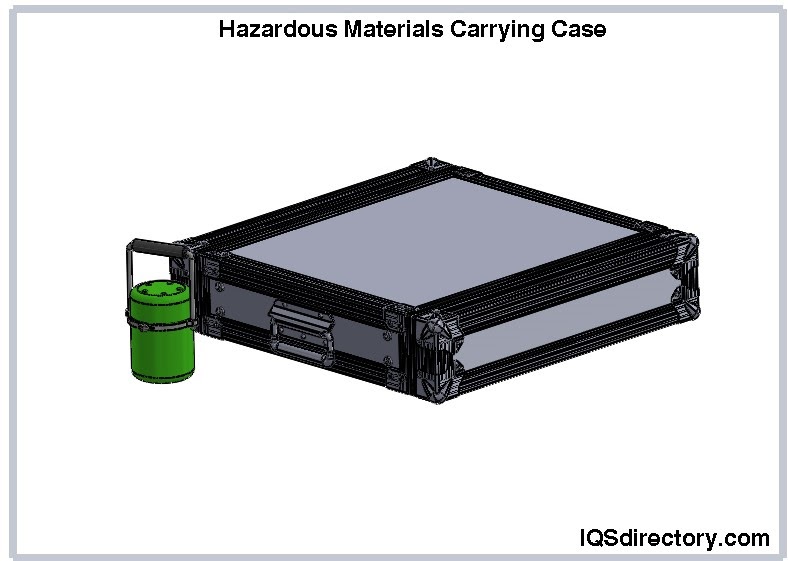

Some carrying cases are specifically designed for unique applications, illustrated in the accompanying image, and are produced to satisfy precise specifications.

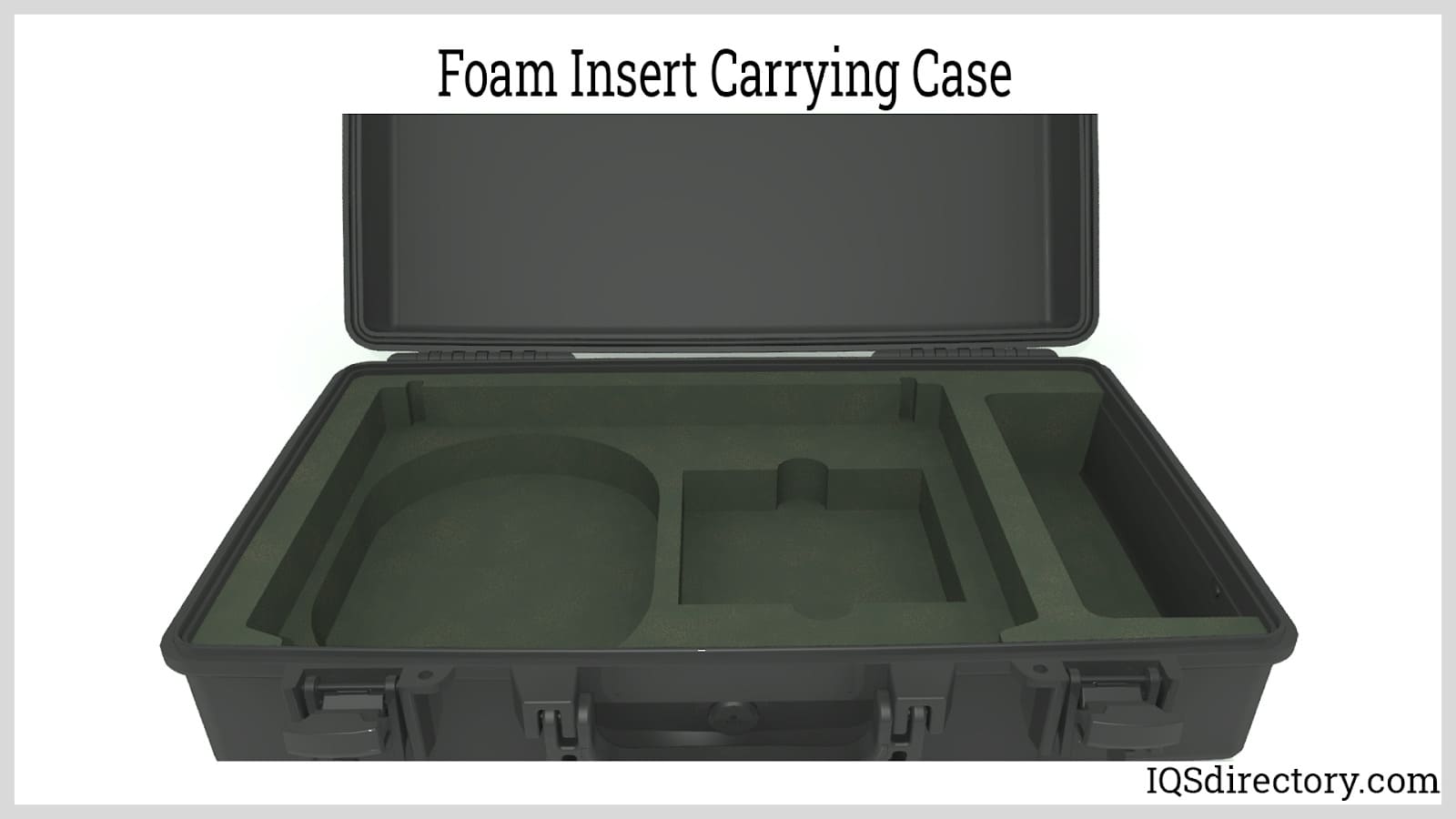

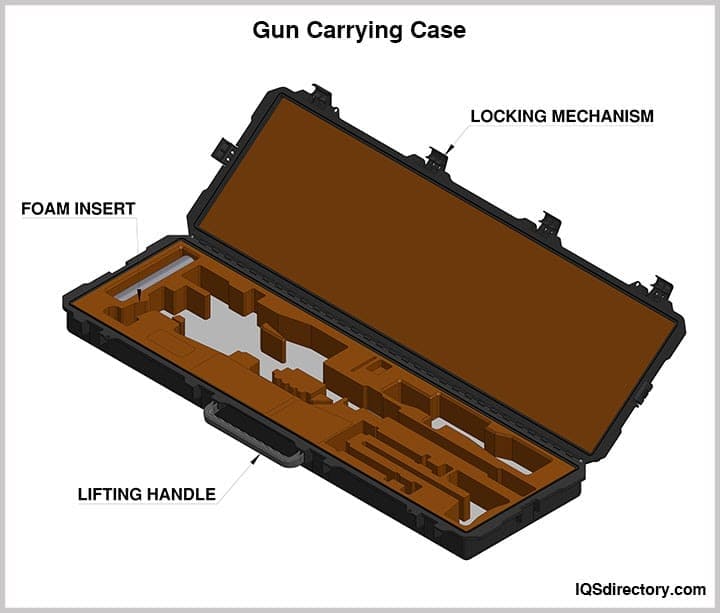

Numerous carrying cases include foam inserts that are expertly molded to snugly secure tools, devices, components, and intricate instruments, keeping them firmly in place.

The design and manufacturing process of a carrying case is highly dependent on its intended application and target industry. Standard off-the-shelf carrying cases, such as those found in department stores and online retail, are distinctly different from custom carrying cases manufactured for specialized and high-value uses—including transportation of scientific instruments, medical devices, electronics, military equipment, and fragile goods. Selecting the correct design is essential for users who require unique case features, superior protection, or precise fit for their sensitive equipment.

Carrying cases are engineered from a diverse range of materials, such as aluminum, injection-molded plastic, engineered wood, heavy-duty fabrics (like ballistic nylon), lightweight composite metals, and genuine or synthetic leather. The primary requirements for any high-performance carrying case are exceptional durability, built-in flexibility, impact resistance, and ease of portability. Certain case designs integrate multiple materials to optimize structural integrity, water resistance, and longevity—crucial for industries where ruggedness and reliability are non-negotiable.

The process for manufacturing carrying cases is customized to fulfill end-user requirements. Cases tailored for air travel, industrial shipping, or secure transportation must adhere to strict guidelines regarding weight, permitted materials, closure mechanisms, and the ability to be securely locked. Premium and industrial-grade carrying case manufacturers often exceed basic standards by offering additional features such as reinforced corners, pressure-release valves, tamper-resistant latches, and custom foam inserts for shock absorption and precise fitting.

Choosing between a stock or custom carrying case is a critical step for organizations looking to protect valuable or sensitive equipment. Custom case manufacturers offer advanced services including computer-aided design (CAD) prototyping, 3D printing for rapid prototyping, and CNC machining for precise part fabrication. This collaborative engineering approach ensures final case solutions are optimal for specific user applications.

Case manufacturers employ a broad spectrum of materials selected to balance cost, weight, and performance. Lightweight metals, industrial-grade polymers, and robust textiles such as ballistic nylon and neoprene rubber form the backbone of today’s protective cases. Plastic cases, often manufactured using advanced blow molding, injection molding, or rotary molding processes, may be finished with abrasion-resistant cloth, custom foam padding liners, or anti-static coatings for sensitive electronics.

Plastic remains the most dominant material choice for modern carrying cases. Among alternatives such as wood, aluminum, technical fabrics, and various metal alloys, plastic offers unmatched formability, UV-resistance, and cost-efficiency. Molded plastic cases are popular for their wide range of options: from small, hand-held custom tool cases to large, wheeled hard cases for shipping industrial equipment, medical supplies, or audiovisual gear.

The adaptability of engineered plastics allows designers to tailor case shapes, internal compartmentalization, and exterior aesthetics—making plastic the material of choice for custom carrying solutions in fields like aerospace, electronics, photography, and laboratory transport. Rugged outdoor cases are often engineered with enhanced sealing to provide IP-rated dust and waterproof protection suitable for extreme environments and military standards.

The mechanical strength and lifespan of a carrying case depends substantially on the selected plastic resin. Plastics, derived from refined petroleum, are extruded into resin pellets or powders, which are then melted and formed according to the chosen manufacturing process. Plastics commonly used by professional carrying case manufacturers include high-density polyethylene (HDPE), fiberglass-reinforced polyester (FRP), carbon fiber composites, rotationally molded polyethylene, ABS, polycarbonate, and linear low-density polyethylene (LLDPE). Each plastic type offers specific benefits in terms of impact resistance, weight, thermal stability, and chemical resistance for specialized packaging applications.

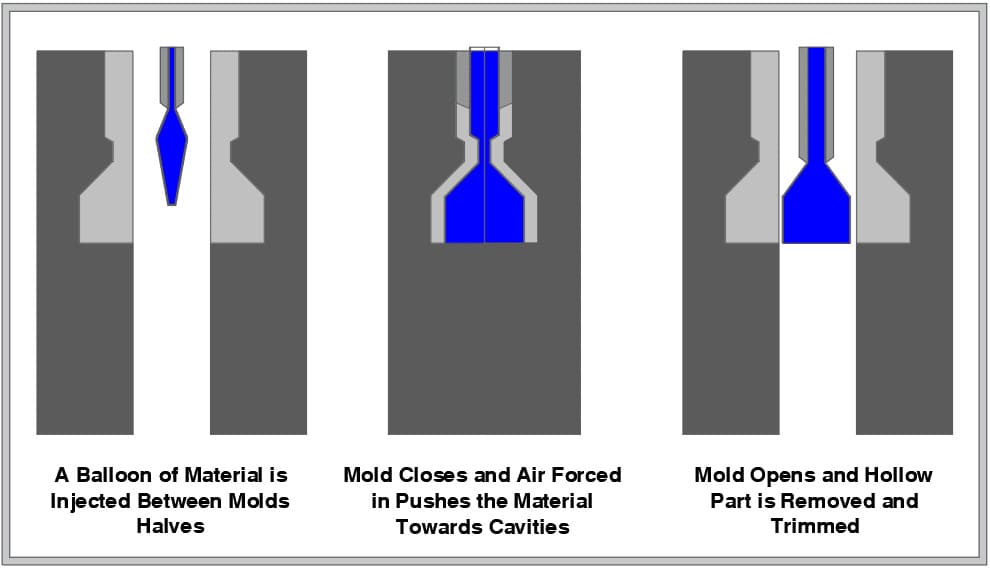

In the blow molding process used by many leading plastic case manufacturers, softened thermoplastic is forced into a custom metal mold via compressed air. The material fully conforms to the mold’s contours, ensuring even wall thickness and seamless construction for high strength and longevity. Industrial blow molding is widely employed for making tool cases, instrument enclosures, and lightweight retail display cases, chosen for their shock-absorbing properties, cost-effectiveness, and consistently high production output.

Thermoforming is a versatile process in carrying case manufacturing, employing heat to transform plastic sheets into three-dimensional products. Plastic sheets—typically of ABS, polycarbonate, or HDPE—are continuously fed from rolls and heated until sufficiently pliable. Advanced molding machines may use state-of-the-art automation for precise temperature and vacuum control, key for producing protective packaging, custom foam-filled cases, and medical device transport cases.

There are three primary thermoforming techniques: mechanical, vacuum, and pressure forming. Vacuum thermoforming relies on negative air pressure to contour the plastic to the mold, while pressure forming uses positive air to press fiber or plastic sheets into finer mold details. Mechanical thermoforming utilizes both male and female molds for intricate case features and engineered snap-fits, supporting the rapid manufacturing of bespoke packaging solutions and custom-fit cases.

Industrial-grade molds used in injection molding are usually engineered from hardened steel for repeatability and tight tolerance. During the injection molding process, plastic granules are heated and pushed by a reciprocating screw into complex, multi-cavity molds to produce cases with detailed hinge mechanisms, living hinges, handles, or integrated locks. The technique is particularly suited for high-volume runs of protective phone cases, compact electronics enclosures, and precision instrument cases. Multi-shot injection molding even allows manufacturers to combine soft-touch surfaces with hard shells, offering both grip and structural integrity in customizable carrying case designs. Overall, injection molding is preferred for precision and part consistency, though typically reserved for smaller to medium-sized products due to machine capacity constraints.

Rotational molding, or rotomolding, is the go-to process for manufacturing large, custom protective shipping cases and rugged outdoor transit cases. Often used for cases deployed in industrial, defense, or film production logistics, rotomolding starts with raw resin in a metal mold that is sealed and rotated bi-axially within an oven. This steady movement distributes the melting material evenly, forming a seamless product with heavy-duty corners, integrated handles, and optional hardware mounting points.

Rotomolded custom cases can feature double-walled constructions, gasketed lids for watertight performance, and recessed hardware to meet demanding ATA and military standards. Many leading protective case suppliers use this method for field equipment, camera transport, and high-value shipping cases where impact, vibration, and weather resistance are essential. The rotomolding process is ideal for low- to mid-volume production and for cases requiring detailed branding or custom color options.

This technique enables the creation of a broad range of case designs, such as double-entry, lift-off, hinged lid cases, and multi-compartment organizers. Most rotomolded cases are produced as custom orders, allowing for unique sizes and features to fit specific business or professional needs.

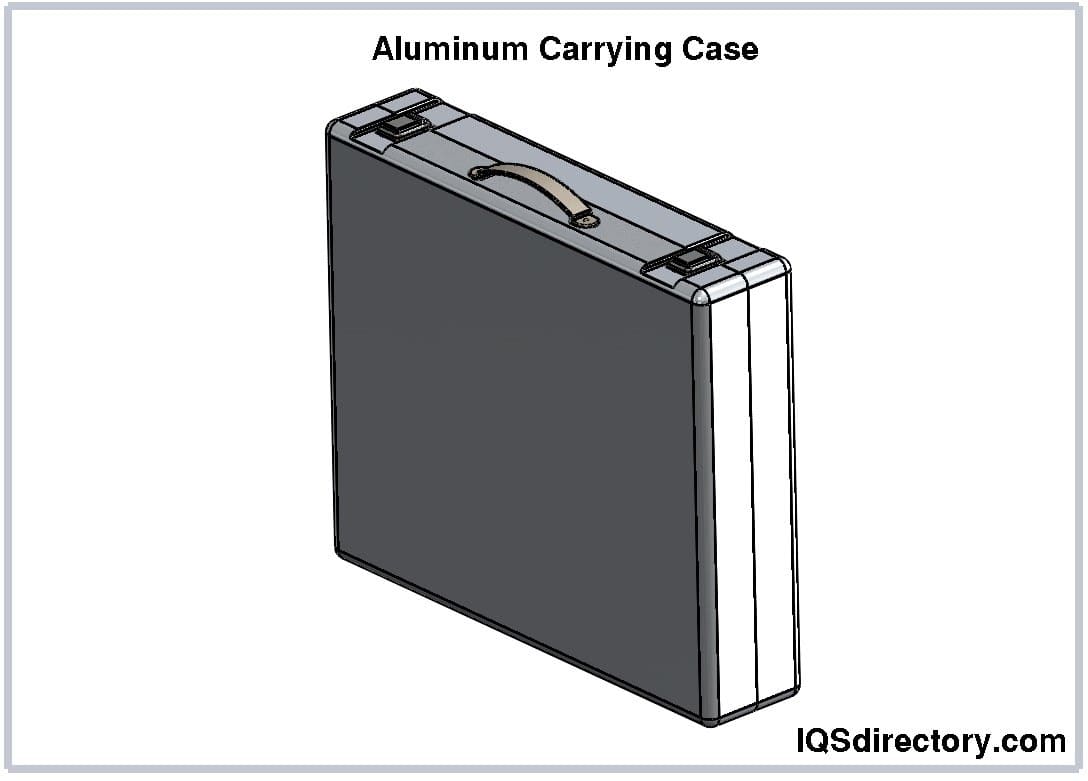

Aluminum carrying cases are recognized for their strength-to-weight ratio, corrosion resistance, and sleek professional appearance. The production process is comparable to thermoforming, commencing with flat-edged aluminum sheets—often pre-treated or anodized for scratch and weather resistance. These sheets are skillfully rolled, extruded, or pressed to form the main body panels, then bent and joined to create the top, bottom, and sidewalls of the case structure. Frame edges, heavy-duty hinges, and trim enhance the case’s structural integrity, while rubber gaskets and foam seals can be added to provide waterproof and dustproof performance.

Robust aluminum cases are commonly produced for the aerospace, military, and broadcasting industries, valued for their ability to withstand harsh environments and for ease of integration with modular interior systems. Larger cases may include telescoping handles, reinforced wheels, and stackable designs, offering optimal portability and protection for mission-critical applications and high-value instrumentation.

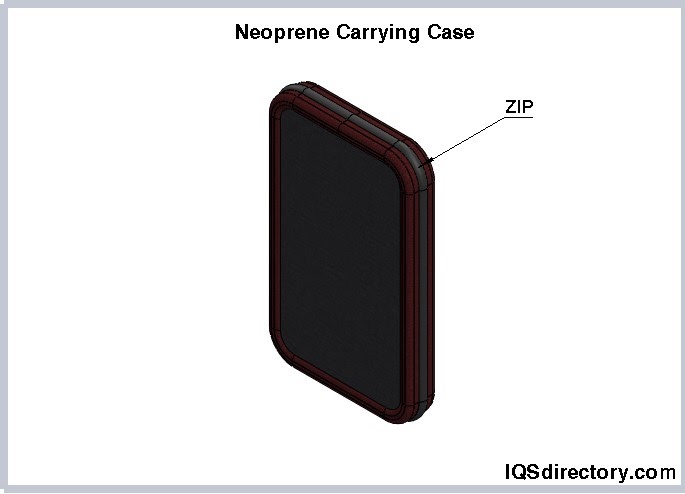

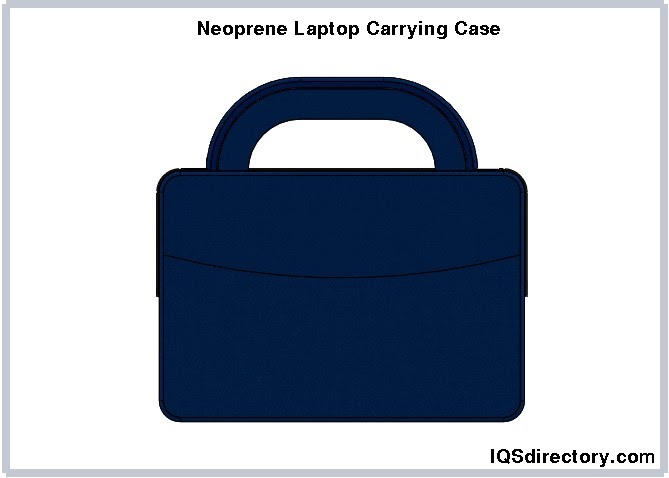

Neoprene, or polychloroprene rubber, is acclaimed for its remarkable flexibility, non-conductive nature, and superior weatherproof barrier. Frequently used in portable electronics sleeves, camera bags, and sports equipment cases, neoprene delivers effective shock absorption and thermal insulation. Its resistance to punctures and environmental exposure (water, oil, UV) renders it an excellent choice for mobile professionals and industries that require dependable protection in unpredictable field conditions.

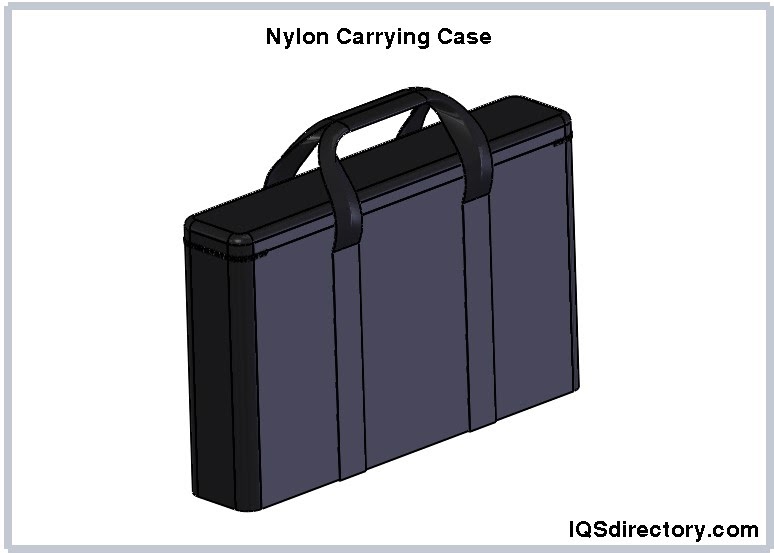

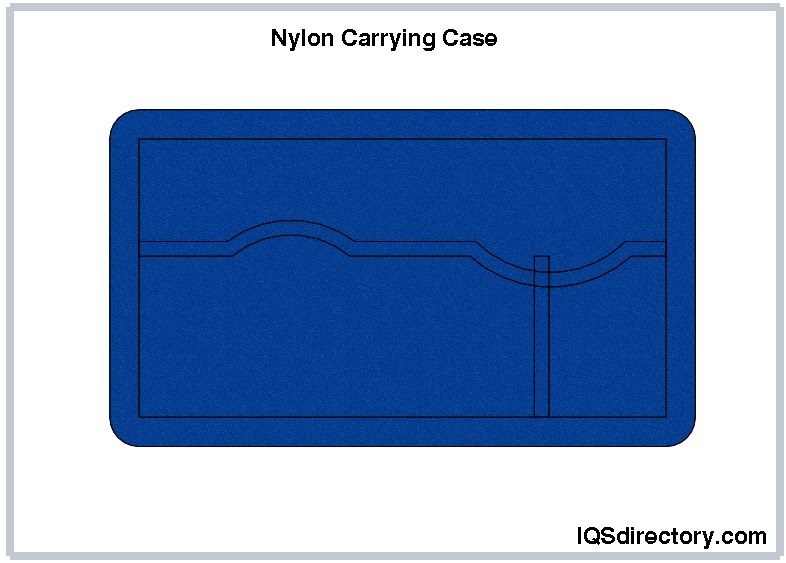

Nylon carrying cases are engineered for frequent transportation of audio, video, and IT equipment, benefiting from padded interiors and high-tensile outer shells. These cases are popular in the broadcast, music, and medical device sectors, providing reliable tear resistance and enduring shape retention—even after years of daily handling. Advanced nylon blends like Cordura or ballistic nylon further enhance abrasion resistance, making these cases ideal for rapid deployment and heavy-duty use. Additional water-resistant coatings and customized foam interiors are common for safeguarding sensitive devices and precision tools.

Leather carrying cases vary significantly by grade and finish, affecting both aesthetics and performance. Full-grain leather, considered the highest quality, is lauded for its natural resilience, tactile richness, and exceptional longevity—favored for executive briefcases, luxury laptop bags, and bespoke instrument cases. Top-grain and split leathers are more affordable alternatives, often used for stylish but less rugged applications. Premium leather cases typically include features such as stitched reinforcements, sturdy metal hardware, and custom lining options for added protection and visual appeal.

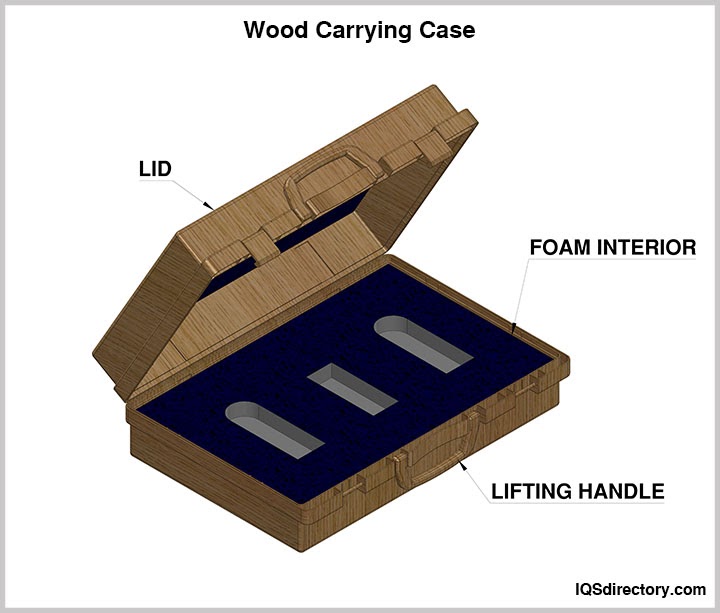

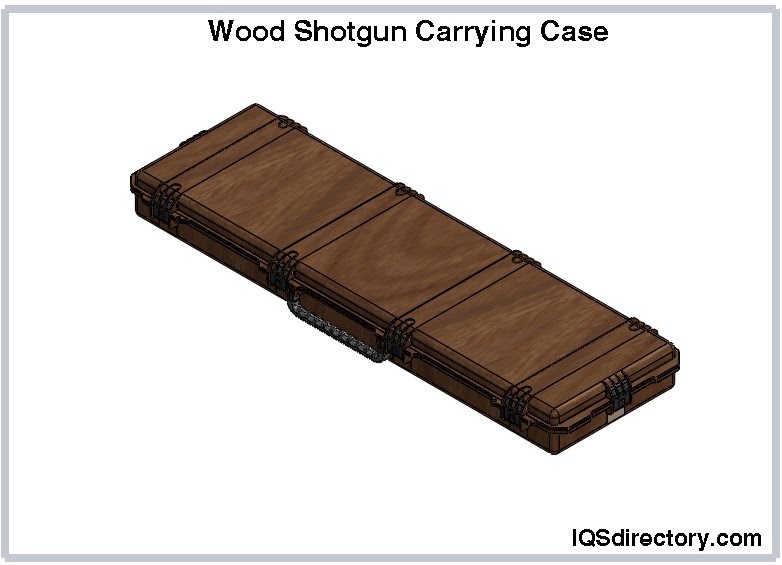

Wooden carrying cases offer a classic blend of sophistication and resilience. Crafted from durable hardwoods like pine, cherry, birch, and mahogany, these cases are valued in scientific, presentation, and collectible fields for their long lifespan and visual appeal. Interiors are commonly fitted with custom cut foam, felt, or plush lining to secure contents, while exteriors might be clad in leather, abrasion-resistant laminate, or fabric veneer for additional protection and style. Custom embossing, laser engraving, and decorative hardware options enable further brand differentiation and product personalization.

Expert carrying case design is a collaborative process, beginning with needs assessment and moving through prototyping and final product evaluation. Top-tier manufacturers employ advanced design software (such as CAD and 3D modeling) to ensure form and function align with client specifications—be it for heavy-duty shipping cases, watertight military transit cases, or lightweight presentation cases. Every detail matters: handle ergonomics, hinge geometry, latch security, interior fit, and material choice all impact the overall usability, protection, and service life of the end case.

Cases engineered to meet American Transportation Association (ATA) specs must pass rigorous vibration, drop, and impact tests, ensuring that ATA-certified cases can reliably safeguard cargo during commercial transit and air freight. These cases may utilize composite construction (wood core with HDPE, aluminum sheet, or fiberglass laminate exteriors) and incorporate reinforced, recessed hardware to minimize handling damage. By adhering to global standards for protective cases, manufacturers guarantee durability, shock absorption, and compliance with airline, military, and industrial logistics requirements.

Carrying cases play an essential role in the safe transport and organization of a vast range of items, making them indispensable in both personal and professional settings. As usage scenarios expand and technology advances, modern carrying case design has evolved to address specialized needs, from the secure transfer of delicate electronics to the efficient organization of business materials. Today, custom carrying cases, protective cases, and storage cases are developed for a growing variety of industries—including medical, electronics, sales, photography, and engineering—driven by shifting user requirements and the need for enhanced mobility, security, and efficiency.

The types of carrying cases are remarkably diverse, with manufacturers constantly innovating to deliver bespoke protection for emerging products and technologies. The increased demand for field services, mobile workforces, and on-site customer support has further accelerated innovation and prototype development within the carrying case manufacturing sector. As end-user expectations grow, so does the need for lightweight, ergonomic, and highly durable options tailored to specific applications.

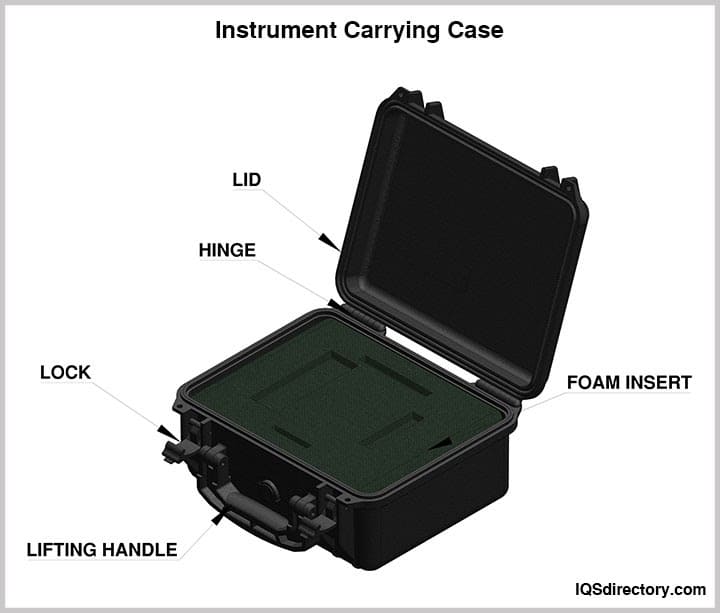

Instrument cases are precision-designed to protect sensitive and fragile instruments from mechanical shock, vibration, and environmental hazards during transit. Whether it’s sensitive medical devices, laboratory instruments, or diagnostic tools, these custom instrument carrying cases safeguard electronics that measure readings, collect critical data, or calibrate machinery, ensuring optimal performance upon arrival. Since exposure to impact, dust, or moisture can disrupt calibration or functionality, instrument cases are engineered with features like weather-resistant exteriors, airtight closures, and anti-static materials to meet advanced protection standards.

Musical instruments, as another example, are highly susceptible to temperature, humidity, and physical damage. Investing in a durable, padded musical instrument case ensures longevity and performance for professionals and students alike. Quality instrument cases aligning with ATA (Air Transport Association) or MIL-SPEC certifications offer peace of mind for traveling musicians, scientists, or engineers transporting delicate equipment.

Maintaining the structural integrity and organization of an instrument inside its case is vital; thus, both hard and soft exteriors are commonly paired with shock-absorbing foam or contoured inserts. Specialized cases for multi-component devices, such as oscilloscopes or field analyzers, include modular internal layouts for secure transport and quick access. Foam inserts—precision-cut through die cutting, contour cutting, or compression processes—are tailored to the instrument’s contours and may include flocked foam layers for extra cushioning and scratch resistance.

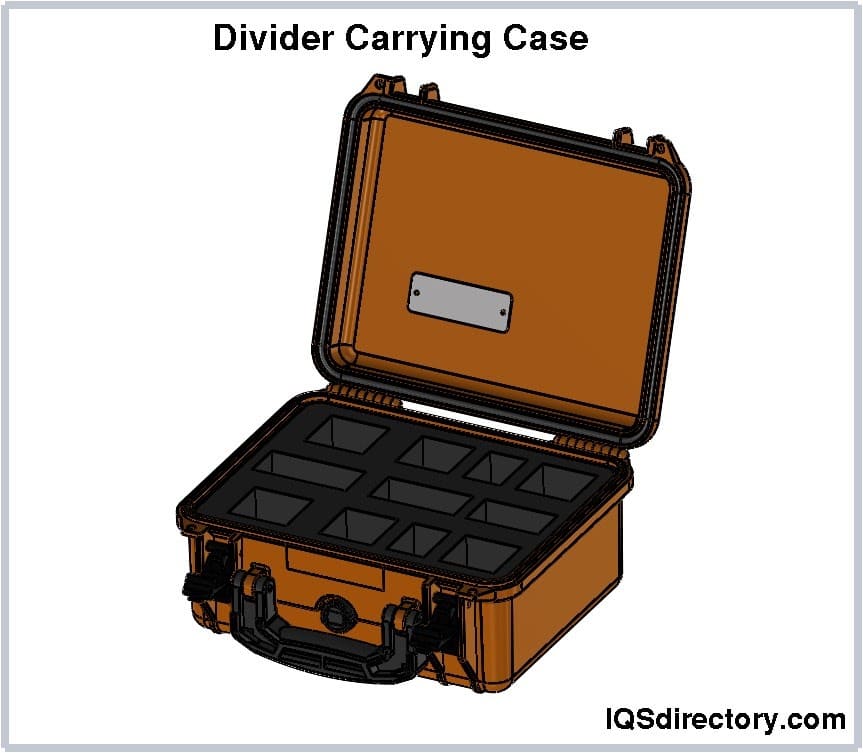

Divider carrying cases offer versatility and efficient organization by utilizing customizable sections to isolate and secure different components, tools, or delicate electronics. Designed for industries such as medical device manufacturing, electronics repair, and field service, divider cases use high-density rubber or closed-cell polyethylene foam dividers to protect contents from collision and abrasion during transit. These modular dividers enhance workflow and inventory management, enabling swift access to specific items and minimizing the risk of loss or damage.

The dividers are constructed from stiff plastic or foam cores and covered with tear-resistant, soft-touch materials for enhanced durability. Cases can be configured with as few as two or as many as twenty-plus sections to accommodate technician toolkits, sample kits, or service equipment. For professionals working in confined spaces or mobile environments, compact, lightweight divider cases built with ergonomic handles and reinforced corners ensure both reliability and portability.

The need for custom divider case designs is particularly pronounced in sectors such as avionics, telecommunications, and scientific research, where specialized equipment must be meticulously organized and securely stored. Features like watertight seals, antistatic linings, and reinforced latches are common options for divider cases intended for critical applications.

Equipment carrying cases are engineered to provide optimal protection and mobility for a wide variety of equipment commonly used in industries such as medical diagnostics, industrial engineering, field services, and audiovisual production. These cases safeguard mission-critical devices—from power tools to portable computers—against drops, impacts, and harsh environmental conditions during handling and transportation. Advanced features such as shock-absorbing exteriors, reinforced protective corners, and airtight gaskets are often included to prevent ingress of water, dust, and contaminants.

For high-value items like medical instruments, measuring devices, or electronics, equipment cases are custom-molded or foam-lined to fit precise dimensions, ensuring stability during movement and preventing internal collisions. Impact-resistant shells made from polycarbonate, polypropylene, or aluminum are popular material choices, offering both strength and lightweight portability. Industries with stringent security requirements may also opt for cases with integrated locking mechanisms, tamper-evident seals, and tracking features for additional theft protection. Equipment carrying cases with interior organization systems—including modular trays and cable management solutions—further enhance usability for frequent travelers and field technicians.

These professional-grade cases are often designed to meet regulatory transport standards (such as ATA or MIL-STD certifications) and can be tailored with branding, labels, or color-coded finishes to streamline identification and deployment in busy environments.

Transit cases are manufactured for exceptional protection and endurance, designed specifically for shipping and repeated transport of sensitive or valuable equipment. Renowned for their rugged construction, transit cases are frequently selected by the aerospace, defense, broadcast, and military sectors, where maintaining operational readiness during travel is critical. The robust exteriors—often made from ruggedized composites or impact-resistant polymers—defend against mechanical damage, while interiors are fitted with high-density foam or polymer padding molded to precisely fit each item.

When transporting highly sensitive electronics, laboratory equipment, or optical devices, transit cases may be required to be ATA-certified or MIL-SPEC compliant (passing rigorous tests for waterproofing, airtightness, corrosion resistance, and impact survivability per MIL-STD-810). As such, transit cases frequently include reinforced locks, sealed latches, heavy-duty handles, and extra-thick protective edging for security and ease of handling under harsh conditions. Configurations can be tailored to shipping requirements, and customization options for labeling, asset tracking, or integrated shock sensors are available for mission-critical shipments.

Some advanced transit cases are engineered to be stackable, modular, and reusable, promoting sustainability and cost efficiency for organizations with ongoing logistical demands. Their versatility, durability, and long lifespan make them an ideal investment for frequent shipping and repeated deployment.

Foam insert carrying cases offer unparalleled customization, providing tailored protection for unique, high-value, or fragile items. These cases use custom-cut soft foam inserts to cradle equipment, components, or instruments and minimize movement during transit, dramatically reducing the risk of damage. Applications span from transporting sensitive medical devices, calibration tools, and optics to firearms and collectibles.

By selecting the appropriate foam density and design—using methods such as die cutting, CNC routing, or waterjet cutting—manufacturers can create intricate cavities that support intricate shapes. This is particularly beneficial for industries where precision and repeatability are key, such as defense, medical, and aerospace sectors. Interior foam inserts can incorporate color coding for visual management, anti-static properties for electronics, and multiple layers or trays for increased storage efficiency. Investing in quality foam insert cases not only protects contents but also enhances presentation and professional image in client-facing scenarios.

Pouch carrying cases are compact and versatile, ideally suited for safely transporting small tools, measuring instruments, or specialty accessories that require quick access and flexible storage. Popular among technicians, field engineers, artists, and craftspeople, pouches can be attached to belts, equipment, or larger cases, thereby enhancing convenience and organization for daily tasks or field operations.

Pouches are constructed from resilient fabrics like neoprene, Hypalon, nylon, or reinforced polyester—each selected for features such as water resistance, abrasion resistance, and chemical durability to withstand challenging environments. Secure closures, such as Velcro, zippers, or snap buttons, keep contents safe during movement. For highly specialized jobs, pouches may incorporate anti-static linings or thermal insulation, ensuring items remain protected from temperature and static-related hazards. Modern pouch cases, sometimes referred to as utility pouches, function as versatile add-ons to larger cases or as standalone transport solutions for small electronics, medical supplies, or sensitive documents.

The material and construction of pouch carrying cases directly impact their durability and application suitability. Legacy leather pouches, while supplanted by newer synthetics due to weight and care requirements, remain prized for their aesthetics in certain crafts and collector markets. Meanwhile, innovative fabric blends continue to improve weatherproofing and longevity for industrial and consumer needs.

Catalog carrying cases are engineered for durability and efficient document management, serving professionals who need to transport paperwork, brochures, catalogs, and sales materials securely and efficiently. Built with firm, impact-resistant shells—commonly vinyl-coated for added water resistance and scratch protection—these cases excel under frequent use in business, legal, architectural, and educational settings.

Interior layouts can be customized with dividers, accordion files, and organizer pockets for seamless file categorization. Popular among sales representatives, consultants, and event organizers, catalog cases increasingly feature padded compartments for electronics such as laptops, tablets, or portable projectors. Sturdy piano hinges and secure locking mechanisms ensure both ease of use and document protection, while sleek exteriors communicate professionalism and attention to detail.

Unlike standard briefcases, catalog cases are typically more spacious and rugged, boasting features like metal hanging frames for bulk files, reinforced corner guards, and exterior quick-access pockets. Designed to withstand demanding travel schedules, they help users improve workflow and maintain organization on the move.

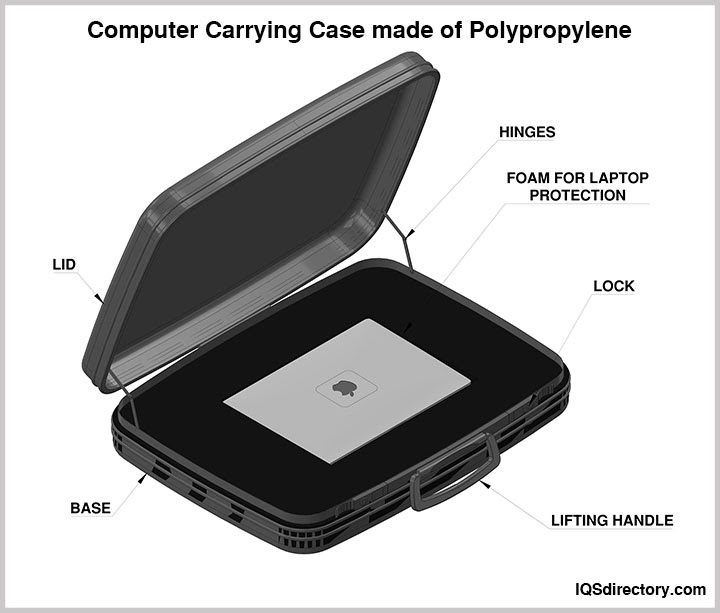

As laptops and portable computing devices become more integral to modern business and field operations, computer carrying cases have advanced in both protection and functionality. The market offers an extensive selection of notebook cases, laptop bags, and rugged laptop cases, each tailored to specific models and end-user requirements across education, government, technology, and business sectors. The primary function remains safeguarding devices and accessories from impact, vibration, water intrusion, and unauthorized access during daily commutes or travel.

Main categories include soft-side laptop briefcases—crafted from padded nylon or polyester for lightweight protection and multi-compartment organization—and hard-side laptop cases made from blow-molded plastic, aluminum, or composite materials for superior crush resistance. Additional options include rolling laptop cases, backpack designs, and wheeled cases for enhanced mobility.

Custom computer cases or specialized notebook cases may integrate foam inserts, shock-proof liners, lockable zippers, RFID-blocking compartments, and weather-sealed seams. Accessory storage is a key consideration, with dedicated sections for cables, software, portable drives, and presentation devices. Selecting the appropriate computer case supports device longevity and data security, while ergonomic designs and padded straps improve user comfort over long distances.

High-quality computer cases align with industry standards for impact resistance, corrosion protection, watertightness, and dustproofing. Many organizations rely on branded or custom-printed cases to facilitate asset management, identification, and theft prevention during business travel or trade shows.

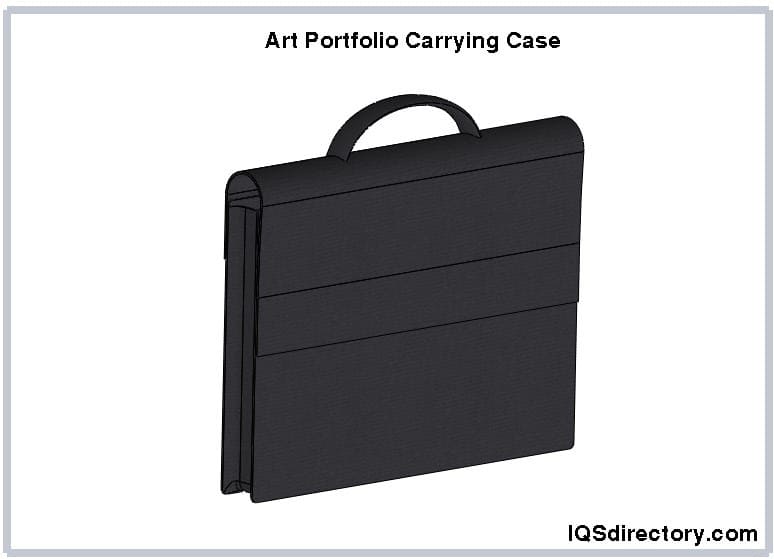

Portfolio carrying cases are purpose-built to safely transport artwork, blueprints, presentation boards, and other large-format materials, ideal for artists, architects, designers, and engineers. These cases are manufactured from varied materials including lightweight aluminum, leather, ballistic nylon, or rugged polypropylene, offering a combination of durability, weather resistance, and style.

Featuring reinforced handles, zippered closures, document sleeves, and sometimes telescoping tubes for rolled media, portfolio cases deliver flexible protection for irreplaceable creative work or technical schematics. Custom foam inserts or interior dividers provide added organization and ensure that artwork and presentation materials remain free from creases, smudges, or exposure to external elements. Whether for traveling to an exhibition, client meeting, or art fair, portfolio cases preserve the integrity and presentation quality of important visual materials.

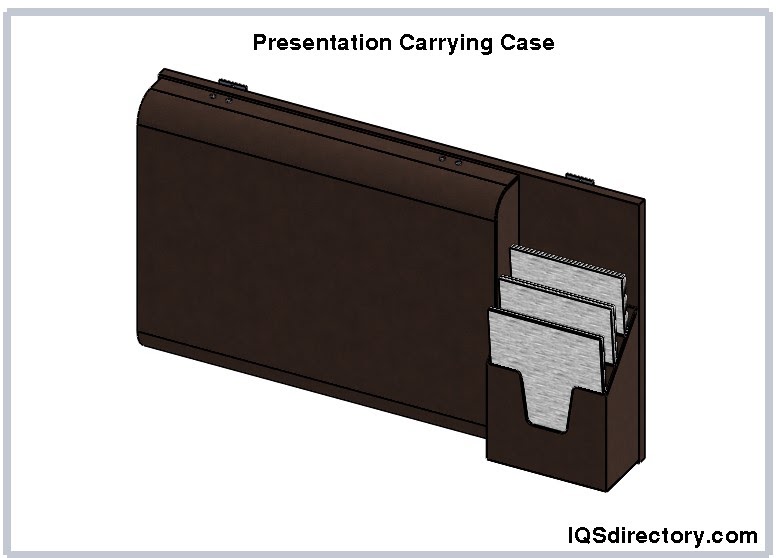

Presentation cases are expertly designed to deliver secure, professional transport of demonstration products, sales materials, or promotional collateral, ensuring that contents arrive in pristine condition. Featuring hard exteriors, reliable latching systems, and sometimes built-in wheels or telescoping handles, presentation cases balance durability and portability for frequent travelers, sales teams, and trade show exhibitors.

Internal customization is a key element, with padded linings, cut-foam inserts, or custom-molded trays to keep materials protected and organized. Presentation cases come in an array of formats—including ATA cases, pouch cases, and catalog-style designs—to accommodate everything from electronics to literature and product samples. Popular features include locking mechanisms, removable trays, multi-compartment layouts, and integrated branding for enhanced professionalism.

Security is paramount in presentation cases; as such, latches and locks are engineered for tamper resistance and secure closure. Designed to house high-value items or company representation materials, these cases project an image of quality and reliability in every use case, from corporate meetings to industry conventions.

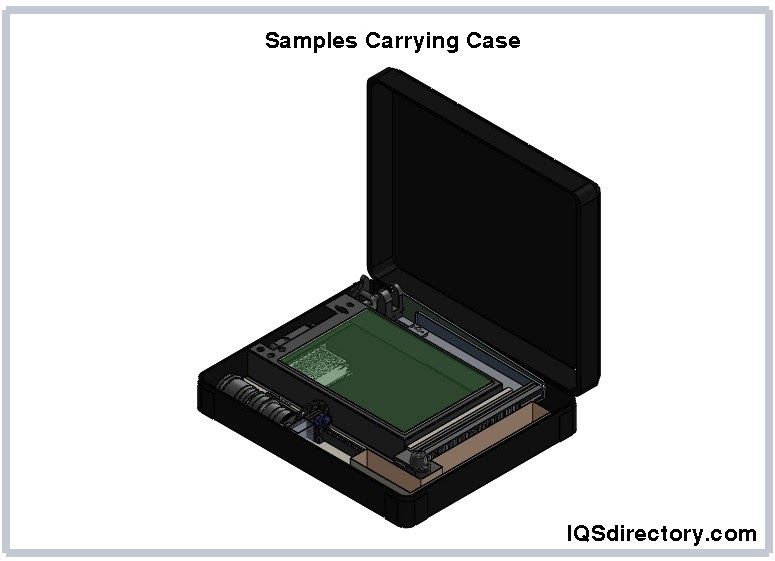

Sample cases function as high-impact marketing and sales tools, equipping representatives with organized, portable solutions for transporting product samples, literature, contracts, and demonstration kits. Whether presenting consumer goods, medical supplies, or technology products, these cases provide structured compartments, foam padding, and customizable layouts for client meetings, tradeshows, and field presentations.

Available with wheels, telescoping handles, and locking options, sample cases are designed to handle heavy loads and frequent travel, maintaining a professional appearance throughout. Durable exteriors and shock-absorbing padding prevent damage during handling, while modular inserts and customizable branding maximize flexibility and brand visibility. Sample cases help streamline the sales process, improve client engagement, and optimize product presentation in a competitive marketplace.

Shipping cases are industrial-grade transport cases, purpose-built to ensure safe delivery of merchandise, machinery, equipment, or trade show displays across long distances. These robust cases are typically constructed from high-strength materials such as aluminum, steel, reinforced woods, high-density polyethylene (HDPE), or fiberglass-reinforced polyester. Designed to guard against shock, vibration, water intrusion, and dust, shipping cases are the gold standard for protecting valuable cargo during logistics operations.

Careful selection of shipping case materials and features is based on shipping conditions, equipment fragility, and travel distances. Lightweight aluminum cases offer excellent mobility but may be more susceptible to denting, whereas rotationally-molded (roto-molded) polymer cases excel in ruggedness, chemical resistance, and lifespan. Many shipping cases are equipped with custom foam interiors for tailored support and are tested for impact resistance per ATA or MIL-STD standards. Additional features such as stackable lids, locking mechanisms, and reinforced wheels further improve usability and adaptability in warehousing or field deployments.

Reinforced wood cases made from composite plywood, often finished with protective coatings, remain a budget-friendly option for repeat shipping needs, maintaining their shape and performance over successive trips. Leading shipping cases provide regulatory compliance, organization, and exceptional value for businesses with frequent shipping requirements.

Tool carrying cases are engineered for optimal protection, organization, and accessibility of hand tools, power tools, and specialized repair equipment. They can be either standard or custom-manufactured, designed to accommodate any tool set, regardless of size or complexity. Constructed from robust materials such as aluminum, high-density polyethylene (HDPE), carbon fiber, or reinforced polyester, tool cases excel in environments where exposure to moisture, caustic chemicals, salt spray, and airborne dust is common. Optional features include waterproof seals, pressure relief valves, impact-resistant shells, and stackable profiles, ensuring reliable performance in industrial, automotive, and field service settings.

Customized tool cases offer modular layouts, removable trays, dedicated slots for calibration equipment, and foam or rubber padding to prevent movement and damage. For technicians who travel frequently, tool cases equipped with ergonomic handles, wheels, and exterior pockets enhance functionality and convenience. The increasing specialization of tool cases—spanning industries from aviation maintenance to network installation—reflects the growing trend toward tailored toolkits that maximize efficiency and extend tool lifespan.

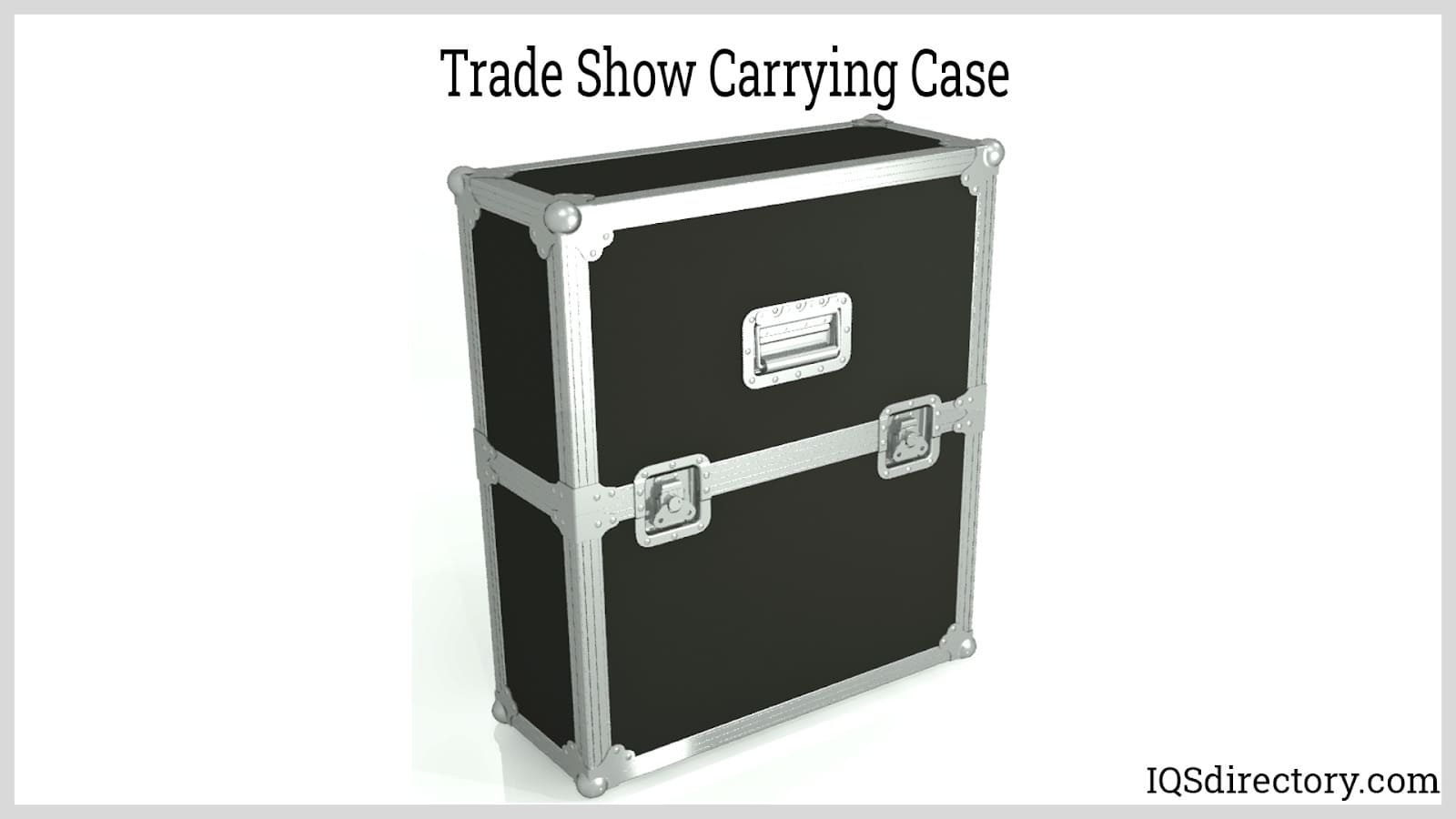

Trade show cases are specifically designed to streamline the transport, protection, and display of materials for exhibitions, conventions, and trade shows. These cases are crafted to protect sensitive promotional assets—such as banners, booth displays, samples, electronic devices, and signage—from damage during shipping and handling. Construction features typically include heavy-duty molded exteriors, reinforced corners and edges, built-in wheels, and telescoping handles for convenient maneuverability across convention centers.

Many trade show cases offer modular interiors with removable dividers, foam cushioning, or adjustable shelves to adapt storage space for varied booth components and marketing collateral. Their stackable design, lockable latches, and identifiable exteriors ensure efficient storage onsite and facilitate rapid booth setup or tear-down. With customization options for colors and branding, organizations can use trade show cases to create a cohesive professional presence at every event.

Continued development in trade show case design has focused on reducing shipping costs through lightweight materials and maximizing internal usable space for high return on investment—a key consideration for modern exhibitors.

A personal utility case offers rugged, portable protection for small valuables such as smartphones, credit cards, cameras, and sensitive electronics. Featuring impact-resistant exteriors, watertight and dustproof seals, and padded interiors, personal utility cases are a preferred choice for outdoor enthusiasts, travelers, emergency responders, and anyone needing reliable everyday carry solutions.

Most personal utility cases are compact and light, equipped with strong latches, carabiner attachments, and internal organization trays. Advanced models may feature RFID-blocking linings, anti-microbial materials, or reinforced lock loops for additional security. These cases provide a practical, cost-effective option for protecting valuables against environmental hazards, accidental drops, and theft, making them indispensable for safeguarding personal items in any scenario.

Carrying cases are essential for safely transporting, organizing, and protecting items across industries like medical, electronics, defense, sales, photography, and engineering, accommodating both delicate devices and bulky equipment.

Foam inserts are custom-cut to fit specific items, reducing movement during transit. They provide cushioning and shock absorption, especially for sensitive electronics, instruments, and high-value equipment, minimizing the risk of damage.

Highly durable carrying case materials include high-density polyethylene (HDPE), aluminum, polycarbonate, ballistic nylon, and reinforced composites. These materials provide superior impact resistance, weather protection, and longevity for demanding applications.

Custom carrying cases employ processes such as blow molding, injection molding, thermoforming, rotational molding, CNC machining, and 3D printing. The chosen method depends on case size, required features, and intended industry use.

Carrying cases designed for air travel or industrial shipping adhere to ATA or MIL-SPEC certification. They undergo rigorous testing for vibration, drop, waterproofing, and impact, ensuring compliance for commercial transit and military needs.

Cases made from polycarbonate, aluminum, or injection-molded plastic with custom foam inserts, waterproof seals, and anti-static linings are ideal for protecting electronics during mobile use or field missions.

Carrying cases come in a wide variety of types, each tailored to specific needs and uses. While some designs adhere to traditional, foundational styles that are universally valued, the differences among carrying cases are influenced by factors such as the materials used in their construction, industry standards and regulations, and their intended purpose.

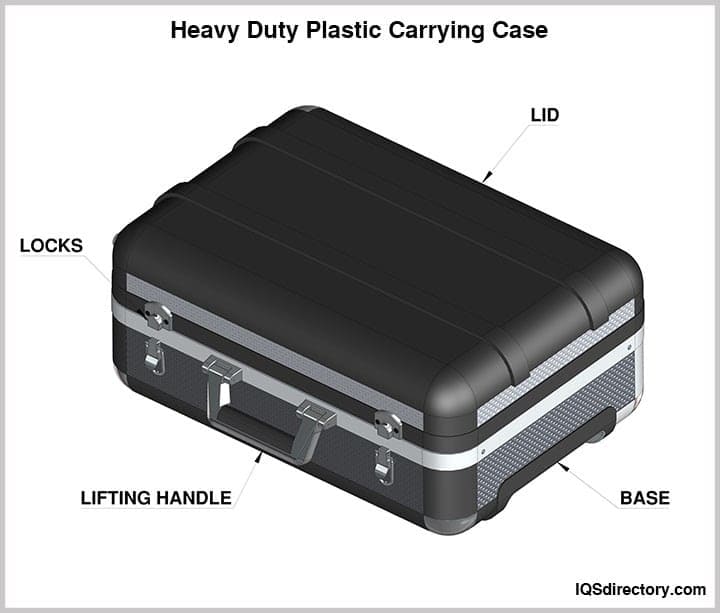

Heavy-duty carrying cases are constructed from the same robust materials used for shipping containers but are designed to be lightweight and user-friendly. They are built to meet or exceed American Transport Association (ATA) standards and are reinforced with ribs for added protection and durability. These cases are typically made from materials such as aluminum, high-grade plastics, stainless steel, and certain gauges of steel.

While heavy-duty carrying cases serve similar functions to shipping cases, they are manufactured from smaller molds, making them easier to load and transport. The primary advantage of heavy-duty carrying cases is the enhanced protection they offer for sensitive instrumentation and valuable components. These cases must also adhere to military standards for carrying cases to ensure reliability and durability.

Due to the weight of their contents, heavy-duty carrying cases are designed with ergonomic considerations in mind. Despite their exceptional protection and durability, they need to be convenient to carry, accommodating various modes of transportation such as airplanes, cars, trains, and trucks.

Most heavy-duty carrying cases feature vertical or horizontal ribbing, similar to briefcases, to enhance their strength and stability. This ribbing not only makes the cases easier to stack but also increases their overall durability.

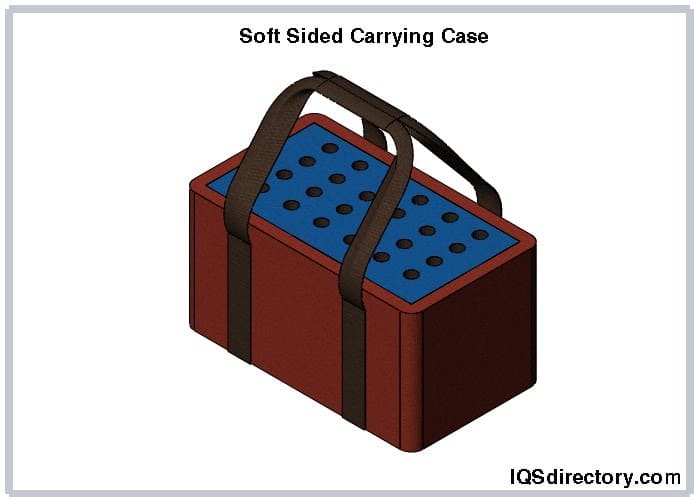

Soft-sided cases are made from materials such as neoprene, canvas, nylon, leather, or vinyl, available in a range of colors, sizes, and designs. They are both water and dust resistant, designed to withstand harsh conditions and inclement weather. The soft, pliable interior provides added protection for instruments, components, equipment, and technical devices. Soft-sided carrying cases are lightweight, ergonomically designed, and flexible, allowing them to adapt to various environments and conditions.

Key features of soft-sided carrying cases include their flexibility, convenience, and durability. They are capable of carrying sample trays, instruments, fold-away boxes, and small tools. The soft sides offer exceptional protection against environmental factors and harsh conditions. When not in use, a soft-sided case can be easily folded and stored, making it a practical choice for diverse applications.

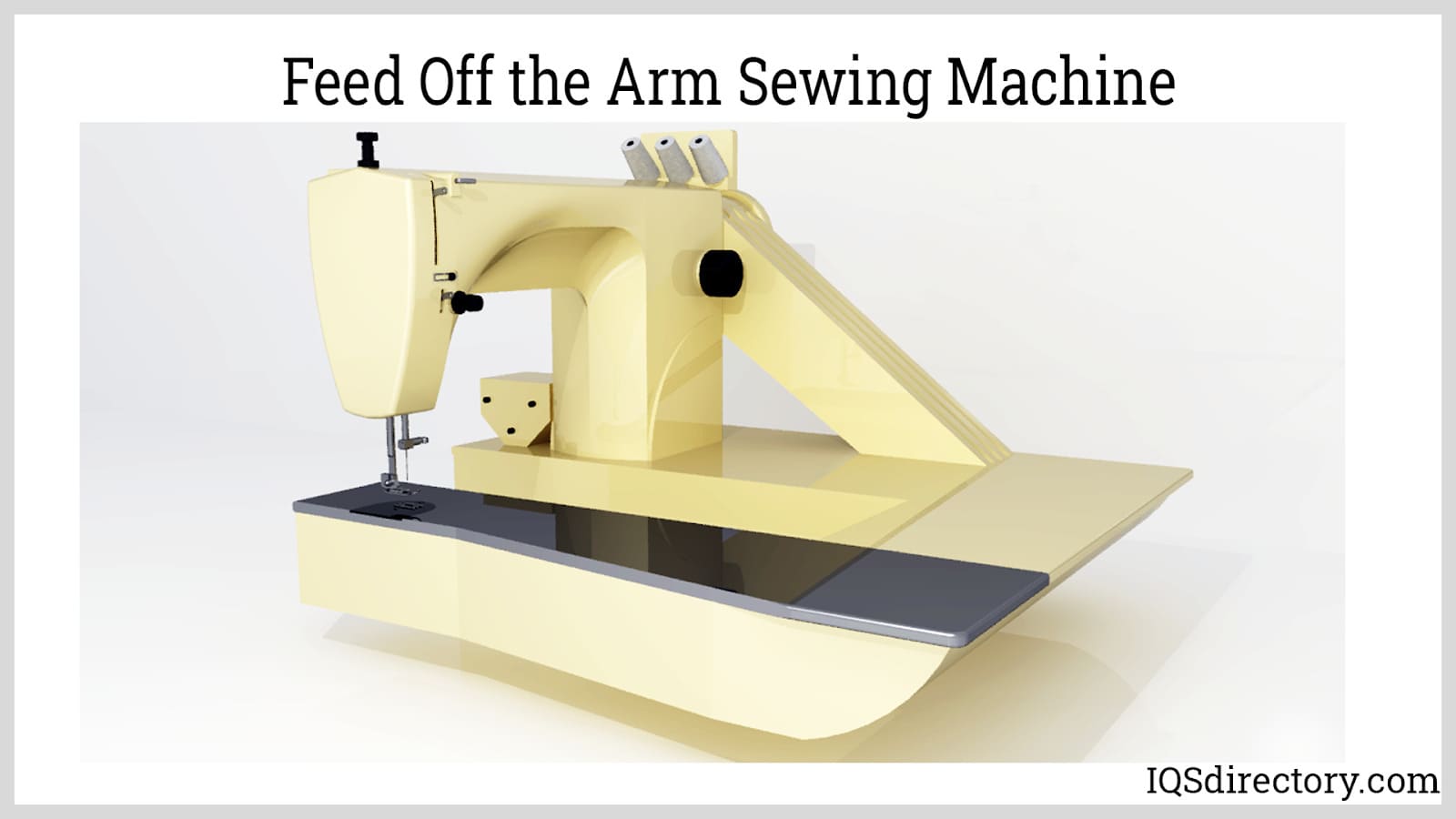

Several processes are used to produce soft-sided carrying cases, with the method selected depending on the type of raw material used.

In high-volume production, soft-sided carrying cases are typically sewn using automated machines. For specialty and custom cases, however, experienced craftspeople may sew them by hand to ensure precise assembly and quality.

Gun carrying cases come in various types and sizes, tailored to the specific weapon they are designed to protect. These cases can be either soft-sided or hard-sided, but typically feature a soft interior layer for added protection. Strict regulations govern the use of gun carrying cases, and informed gun owners are well aware of these rules. Enthusiasts of guns, handguns, shotguns, and rifles often take extra precautions when traveling with their weapons, and gun carrying cases play a crucial role in ensuring safety during transit.

ATA cases are a specific specialty case that is designed to withstand being frequently shipped and meets the standards of the ATA. To be categorized as an ATA case, a case has to be able to endure being shipped over 100 times and maintain its structure. They are well known for their durability, ease of use, ability to be easily loaded and unloaded, and reusability.

ATA cases are constructed using fiberboard for the exterior walls, which is typically coated for added durability. The interior features protective foam or a honeycomb design to safeguard the contents. The corners and edges are reinforced with extrusions made from plastic, aluminum, stainless steel, or steel, and are often equipped with metal or plastic corner brackets for additional protection.

The latches and handles of ATA cases are made from steel to ensure extra strength and stability. The edges of the lids are also reinforced with aluminum, steel, plastic, or stainless steel extrusions. For ease of movement, ATA cases are equipped with locking casters. Common latch types for ATA cases include spring-loaded twist latches and draw latches.

ATA cases must meet the standards outlined in ATA-300 Category I, which specifies the durability required for a case to be classified as an ATA case. ATA-300 approval signifies that a case can withstand rough handling for up to 100 trips without compromising its integrity. The primary characteristic of an ATA case is its ability to endure harsh conditions typically encountered during transport by train, air, or sea.

Road cases, also known as ATA cases, are designed to transport various types of instruments and sensitive equipment. While they share the same rugged design principles as ATA cases, they may not necessarily have ATA certification. The term "road case" implies that the case is built from durable materials capable of withstanding the demands of frequent travel.

Road cases are typically constructed with plywood panels covered in fiberglass. The panels are joined with metal or plastic connectors and reinforced with solid metal corner brackets. The interior configuration of a road case varies depending on its intended use. Basic road cases often feature a raw wood interior for general transport and storage, while more advanced versions include padded interiors with polymer foam, which can be custom cut and shaped to fit specific equipment.

Although road cases serve a similar purpose as shipping containers, they are distinguished by their specialized construction, including reinforced metal edges and corners. Due to their large and bulky nature, road cases often come equipped with casters for easy maneuverability, while smaller models may include convenient recessed handles.

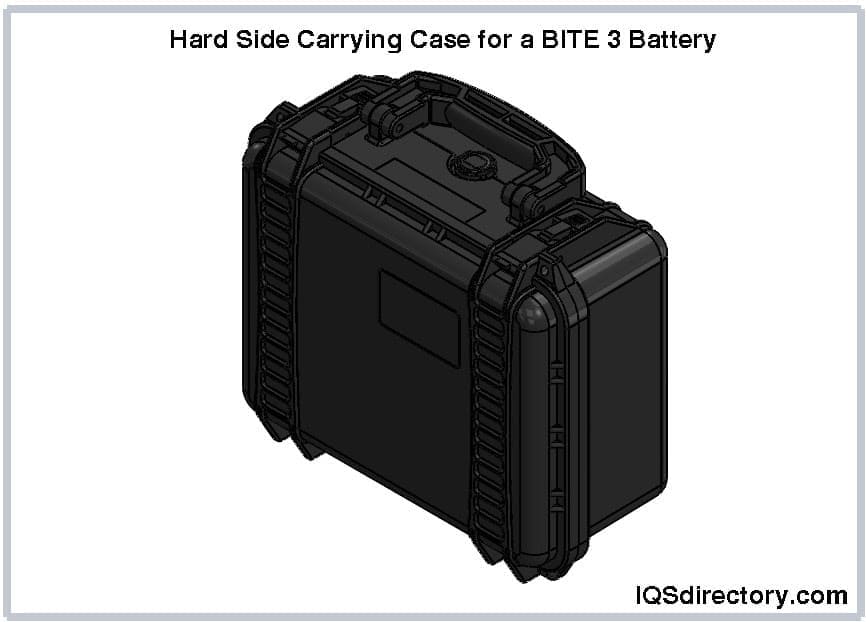

Hard cases are constructed from high-density molded plastics, aluminum, veneered or laminated wood, and other non-ferrous metals. They offer exceptional protection and are known for their durability and security. Hard cases are commonly used for shipping and storing military equipment, sensitive instruments, and emergency gear for police and first responders.

There are four primary plastic shaping methods used in the manufacture of hard cases: blow molding, injection molding, roto molding, and thermoforming. Blow molding involves blowing molten plastic into a two-sided mold to form the shape of the hard case. Similarly, injection molding injects molten plastic into a two-sided mold to create the case.

Roto molding, suitable for larger cases, involves placing plastic resin in a two-sided mold connected to a rotational machine. As the machine rotates and heats the mold, the molten plastic spreads evenly across the mold's surface. After the plastic has fully coated the mold, the machine enters a cooling phase where the plastic solidifies. The finished hard case is then removed from the mold.

Thermoforming, a vacuum molding process, involves heating a plastic sheet and drawing it into a two-sided mold to form the case's lid and base. After cooling and setting, the plastic is removed, and additional components such as latches, hinges, and handles are added.

Each molding technique produces hard cases with thick, impenetrable walls made from high-density plastic, designed to withstand the rigorous conditions they face. Manufacturers of hard cases focus on ensuring that their products deliver the durability, strength, and longevity needed to protect valuable equipment, instruments, and tools.

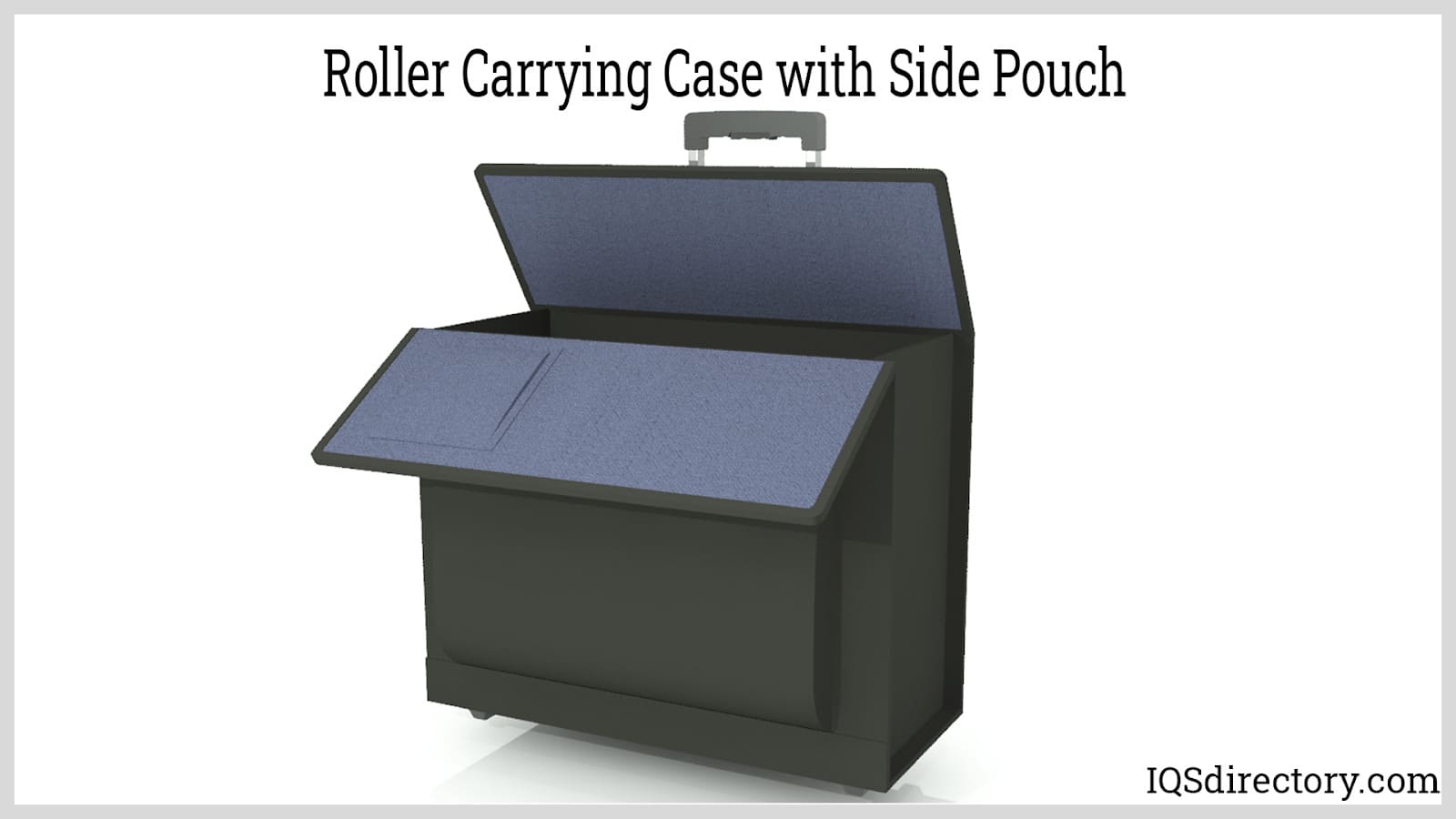

Rolling carrying cases feature small wheels on the bottom, allowing for easy transportation without the need to carry them. They are particularly suited for large or bulky instruments and devices. These cases are equipped with telescoping handles for effortless maneuverability and are available in various sizes with multiple interior padding options to suit different needs.

Storm carrying cases are built to withstand severe conditions, featuring an exceptionally tough exterior crafted from highly durable materials. These cases are designed to safeguard fragile or sensitive instruments and equipment from damage. When not in use, storm carrying cases also serve as excellent storage containers, protecting contents from contaminants and harsh environments. The interior is lined with soft fabric or foam for added protection.

Protector cases are built from exceptionally robust materials, designed to endure hostile environments and challenging conditions. These cases are essential for safeguarding delicate and complex technical instruments, whether they are used for data recording, team communication, or memory storage. When not in use, protector cases offer enhanced protection and secure storage for these vital tools.

Protector cases are watertight, crushproof, dustproof, and resistant to vibrations and impacts. They feature solid, thick walls made from lightweight materials. Designed with double latches to prevent accidental openings due to impact, protector cases are ideal for protecting handheld electronics.

Air cases are a type of protective case crafted from sturdy yet lightweight materials, designed to withstand impacts and shocks. These cases feature an airtight design to keep out air and dust, making them suitable for a variety of applications. Air cases come in various configurations to meet different needs.

Available for traveling, hiking, or simply keeping electronics safe, air cases share common features regardless of their size. They can include dividers for additional protection and security.

Backpacks have been used for centuries to conveniently carry a wide range of items, including clothing, books, tools, weapons, and hiking gear. They have long been a staple in military gear and are now common in schools. Backpacks are made from various materials, with canvas, cotton, and nylon being particularly prevalent. Depending on their intended use, backpacks can be crafted from soft, pliable materials for comfort or from tougher materials for enhanced durability and strength.

Backpacks are typically sewn from pre-cut fabric pieces. The pattern is laid out on the fabric, pressed, and cut electronically. The pieces are then assembled using heavy-duty commercial sewing machines with strong nylon thread and a 301-type stitch, although other thread types are weaker.

After the main components are sewn together, additional features such as zippers, snaps, and buckles are added. These components are also sewn on with nylon thread. The design and features of a backpack depend on its intended use. For military backpacks, quick and easy access is crucial, with secure snaps and zippers that can be opened with minimal effort.

Purses come in countless styles, sizes, and types, each serving specific functions. They can be practical for carrying daily necessities or serve as a decorative fashion statement. Regardless of the variety, all purses function as pouches for carrying items, whether they are elaborate and adorned or simple leather bags with flaps. Purses have been a convenience and necessity for all genders for centuries.

Manufacturing methods for purses vary, producing distinctive personal items. Purses can be woven from yarn, cut from fabric, pieced together like a backpack, or adorned with glued and sewn jewels. The method chosen depends on the material, purpose, and design of the purse.

Leather is often the material of choice due to its durability and longevity, although synthetic fabrics are increasingly used for their ease of sewing and cost-effectiveness. Mass-produced purses are sewn using industrial machines, while designer purses are hand-sewn with fine thread to ensure high quality.

The production of custom-designed carrying cases is continually evolving as new and unique equipment emerges. These specially crafted cases are engineered to serve specific functions and are created through advanced planning and sophisticated engineering techniques.

The rigorous demands of military operations necessitate equipment and materials that can endure extreme conditions. Military carrying cases must not only be durable but also watertight, shockproof, corrosion-resistant, and dustproof. They are designed for ease of handling, including loading and stacking.

Medical equipment is both delicate and costly, requiring robust cases to prevent damage and ensure it remains effective in life-saving situations. The primary requirement for medical carrying cases is exceptional protection and reliability during emergencies. These cases come in various forms, designed to hold equipment, medications, and supplies needed for wound care and other medical treatments.

Similar to medical carrying cases, fire and rescue operations demand equipment that remains reliable under extreme conditions. Fire and rescue carrying cases must be both portable and lightweight while offering the durability needed to endure hazardous environments. These cases come in various designs and often feature organizational inserts, ensuring quick and efficient access to essential life-saving equipment.

Just like in human care, veterinary carrying cases come with specific requirements. They must facilitate the hygienic transport of diagnostic supplies, medications, and other essentials. These cases should feature document pouches and be constructed from highly durable materials such as aluminum or synthetic leather. Given the diverse environments in which veterinarians operate, the cases need to offer ample storage space for collecting samples and other necessary items.

Shipping and moving hazardous materials necessitate cases that comply with stringent government regulations for handling such materials. Hazmat carrying cases are custom-designed to meet specific application needs while adhering to legal requirements and safety standards.

Drones, which serve various purposes beyond personal use—such as exploring terrain, inspecting oil fields, or surveying battlefields—are valuable and require meticulous care. Given their expense and delicate nature, they must be handled with the utmost caution.

Bel-Air Cases is a prominent plastic case manufacturer that provides solutions for a variety of applications and situations. Their rugged and durable cases are engineered to endure the challenges of transportation and frequent use. Bel-Air offers medium-duty cases for less frequent use and heavy-duty cases for regular shipping. The company takes pride in crafting cases that are appropriately sized, competitively priced, and aesthetically pleasing, all while being built to last. For specific needs, they also offer custom-designed cases to meet their customers' exact requirements.

Tetrafab is a leading custom case manufacturer with facilities in Asia, South America, and the United States. They collaborate closely with clients to create the ideal case tailored to the specific conditions and applications required. Tetrafab's success is rooted in the meticulous effort they invest in ensuring their products are of the highest quality. Their designers work with clients to produce computer-generated renderings of cases that align perfectly with customer specifications.

Pelican's success is built on its dedication to producing cases that endure even the harshest and most demanding environments. Whether used for personal travel or industrial applications, Pelican cases are designed to withstand rigorous conditions. The company's mission is to ensure that the contents of their cases remain protected under extreme stress and strain. Pelican offers a comprehensive range of cases to suit various needs, from family vacations to industrial operations.

Royal Case Company provides an extensive range of cases, including injection and blow-molded plastic cases as well as soft-sided carrying cases. Their team of designers and engineers transforms customer concepts and designs into professionally crafted and durable cases. As a national leader in case manufacturing, Royal Case Company excels in producing both hard and soft cases for well-known brands, focusing on safeguarding critical and life-saving equipment.

Shell-Case specializes in producing both soft and hard cases for diverse applications such as medical devices, electronic equipment, measuring instruments, and optics. They bring customer visions to life through innovative and original design techniques. Each case is meticulously planned and constructed with the highest quality materials, ensuring a precise fit from the inner structure to the outer shell.

Carrying cases are constructed from materials chosen for their durability and ability to withstand harsh conditions. Plastic is a popular choice due to its resistance to various environmental factors. Other materials include aluminum, valued for its corrosion resistance; leather, known for its durability; sturdy fabrics, which offer flexibility; rubber, which maintains its shape; and wood, appreciated for its protective qualities and reliability.

Plastic is the most commonly used material for manufacturing carrying cases due to its versatile properties. It is airtight, water-resistant, and resistant to crushing and dust, often exceeding ATA specifications. Plastic carrying cases can be blow-molded into various shapes and feature smooth, seamless surfaces.

Aluminum cases are valued for their lightweight, durability, and resistance to corrosion and dust. The inherent strength and endurance of aluminum make it an ideal material for carrying cases. These cases come in various sizes, ranging from compact briefcases to large shipping containers.

Certain types of wood are well-suited for crafting carrying cases, often serving as the core frame and structure. These wooden frames are typically covered with additional materials such as vinyl, plastic, or heavy fabric to enhance durability and functionality.

Nylon is a highly versatile and durable material, known for its expandability and self-healing properties. Available in various colors and thread sizes, it is ideal for both the interior and exterior of carrying cases. Nylon cases are well-suited for heavy use due to their tear resistance and long-lasting color that does not fade over time.

Leather is known for its durability and comes in a variety of grains. The strongest type is natural leather, which is tanned directly from animal hides. Over 24 different animal skins can be used in the production of leather cases, each offering unique qualities and strengths.

Neoprene is a highly durable and resilient synthetic rubber, available in both solid and soft, flexible latex forms. It retains its strength and durability even under harsh conditions, making it an excellent choice for manufacturing carrying cases. A notable characteristic of neoprene is its resistance to oils, which enhances its suitability for various applications.

A hard case is a type of carrying case that is made from molded plastic, aluminum, veneered or laminated wood, or different types of metals. They are the most secure and durable forms of carrying cases and...

A road case is a ruggedly built, highly functional protective container with varying wall thicknesses that is capable of withstanding the riggers and handling of shipping. They are designed to meet...

A tool case is a portable case designed to organize and protect tools and allow easy access and convenient availability. Standard tool cases can be used when working on a project. In addition, specialty and custom-designed tool cases are...

Cases designed to carry special valuables have been part of society throughout history back to the time of the Egyptians and before. Carrying cases are commonly found in any house stored in a garage, tucked away in a basement, or setting on a shelf...

Blow molding is a type of plastic forming process for creating hollow plastic products made from thermoplastic materials. The process involves heating and inflating a plastic tube known as a parison or preform. The parison is placed between two dies that contain the desired shape of the product...

A canopy is a structure with a connected fabric or metal covering that can give shade or shelter from weather elements such as the sun, hail, snow, and rain. For example, a tent with no floor can be...

Contract sewing is a specialized industry that provides services to manufacturers for production of a wide range of products using highly skilled workers and technologically advanced sewing machines. The strength of the contract sewing industry is its ability to perform any type of sewing services...

Cut and sew is a process for the manufacture of clothing where the design and pattern are printed on the raw cloth from which the garment is cut, ensuring full color, edge to edge print of the design and color...

A protective cover is a sewn fabric that is specifically designed and used for protecting equipment, people, surfaces, and enclosures. Protective covers provide protection from the elements, UV rays, dirt, dust, moisture, and...