Stainless Steel Tanks

Tanks are containers that hold liquids, compressed gases and some solids. While they’re sometimes called drums, the most common names for these containers are tank and vessel. In their most basic form, they consist of an outer shell and a lid. Stainless steel tanks, as one might surmise, are tanks made from stainless steel. Stainless steel is a steel alloy made up of 10% to 12% chromium, known for its high strength and superior corrosion resistance.

Quick links to Stainless Steel Tanks Information

The History of Stainless Steel Tanks

Today, stainless steel tanks are a staple of our working world. However, just over a hundred years ago, they did not exist. That is because stainless steel wasn’t discovered until the early 20th century. Before stainless steel carbon steel was the only option. In 1913, Harry Brearley of Sheffield, England invented what he first called "rustless steel." While others made attempts at it before, Brearley was the first to create true stainless steel, with the key ingredient of 12.8% chromium.

The first stainless steel tank was fabricated in 1925. Made from stainless steel plate, it was used to hold nitric acid and labeled as a chemical tank. This was important because it was the first metal tank that could hold acid without corroding. It was a great improvement from early steel tanks, which were riveted at the seams and prone to corrosion. In 1927, an American shipping truck company, Heil Truck of Milwaukee, produced the first welded stainless steel tank for the road. With it, they were able to ship dairy products safely. The next year, brewers began using the tanks as fermenting vessels to brew beer. After that, the food and beverage industry embraced stainless steel vessels as a commodity.

Today, stainless steel tanks are more popular and diversely used than ever. They’re made all over the world. For example, in 2010, China produced over 11 million washing machines that featured stainless steel drums. Modern stainless steel tanks aren’t just available in single shell configurations, but instead be made quite complexly. For instance, LNG ships like the new Methane Shirley Elisabeth now use stainless steel gas tanks called membranes. Membranes feature alternating layers of stainless steel and thick foam insulation, along with other materials. On the inside, they are lined with stainless steel corrugated in two dimensions to keep the frozen gas from sloshing around. As the years advance, we can expect the stainless steel tank industry to become even more sophisticated.

Advantages of Stainless Steel Tanks

Stainless steel tanks have so many advantages. For one, they’re corrosion resistant. Because of this, they can take on corrosive chemicals and acids that other tank types cannot. In addition, they are easy to keep clean and to sterilize. Third, they make excellent pressure vessels. This is because stainless steel has such good thermal conductivity and thermal expansion rate, which is key to tanks of any sort, particularly pressure vessels. Stainless steel also resists heat transfer.

Stainless Steel Tank Design

- Production Process

- Stainless steel tanks are thin-walled constructions manufactured either through a hot or cold-rolling process, or through welding. Rolling is preferable because rolled tanks don’t have seams. Under undue levels of pressure, tanks can leak or burst at the seams.

- Stainless steel tanks are quite simple to operate. You fill them through the manway and seal them up. When you need access to the material inside, you open up the manway and use any number of accessories to get it out, like pumps. In addition, you can track pressure levels with gauges and digital readouts.

- Material Process

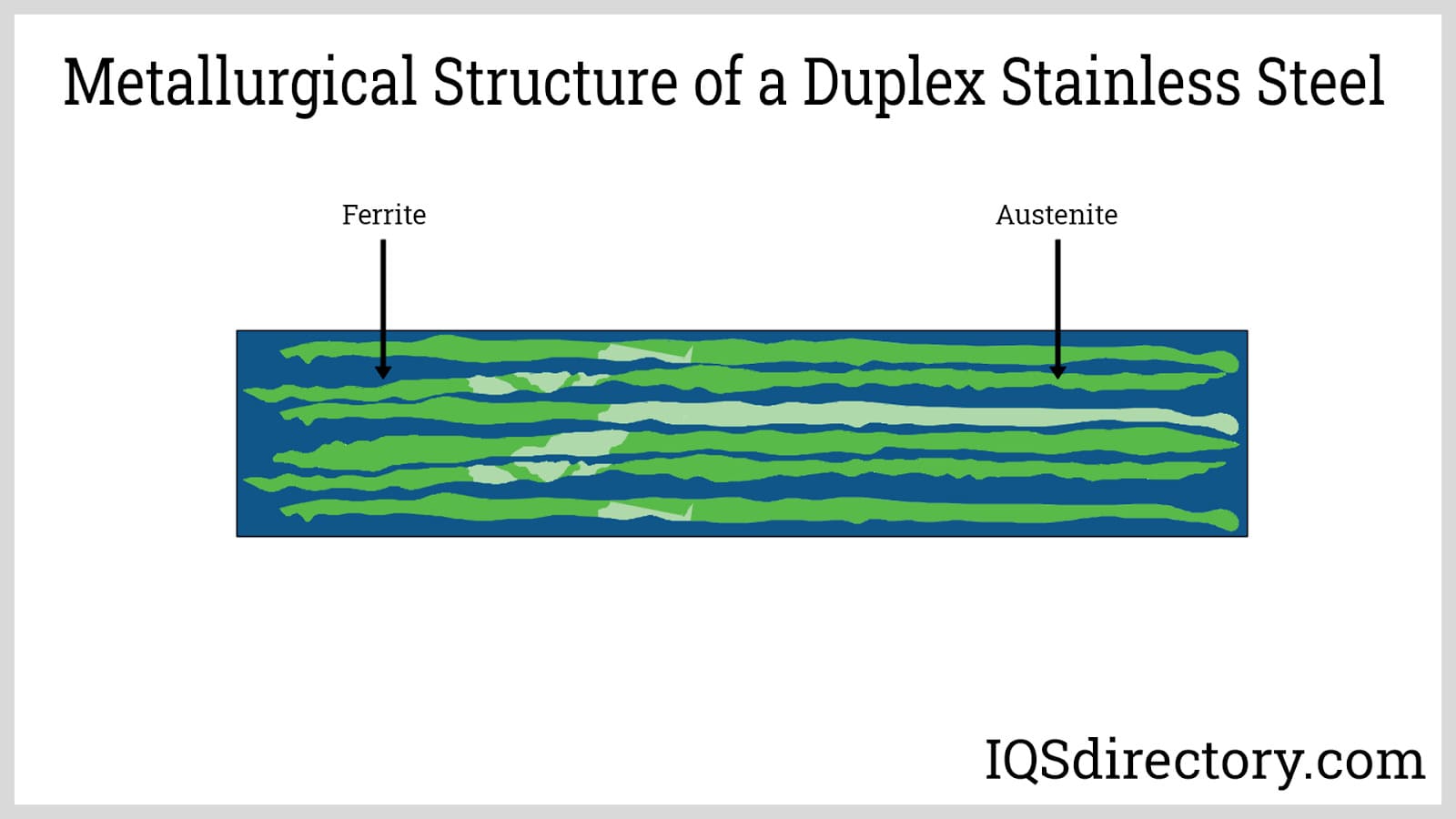

- Stainless steel tanks are made via stainless steel construction only. However, they can be from a few different types of stainless steel. The main one is duplex steel. Duplex steel is composed of austenitic and ferritic steel. Together, these metals are much stronger than either individually. This type of stainless steel is extremely crack and corrosion resistant. Manufacturers do not use other steels, like mild steel or carbon steel, because they simply aren’t strong and resistant enough, and if they were to fail, they could cause injury or death.

- Design Considerations and Customization

- Stainless steel tanks are available in a variety of different shapes, including: vertical and horizontal cylindrical; open top and closed top; flat bottom, cone bottom, slope bottom and dish bottom. Tank covers are rectangular, circular or oval, and come with levers, bolts, clamps or swivel arms for opening and closing.

- When deciding tank dimension and shape details during both standard and custom tank design, manufacturers think about things like: pressure levels, required capacity (they may hold anything from one gallon to millions of gallons), frequency of tank transportation, etc. For instance, in order to make it easier for them to withstand hydrostatic pressure, they tend to design large liquid storage tanks with either vertical and cylindrical sides, or cylindrical sides with rounded corners that transition from vertical wall to bottom profile.

- The manway (lid), which is an opening where contents are poured or accessed, can be customized as well. Manways vary based on factors such as tank pressure level, temperature needs and frequency of content inspection. Based on these, manufacturers will design a manway with different seal materials, thicknesses, diameters, closing/opening mechanisms, and more. Neoprene gaskets, for example, are perfect manway components for tank contents that do not exceed temperatures of 200?. For more information on standard and custom tank design, talk to your supplier.

Stainless Steel Tank Images, Diagrams and Visual Concepts

Stainless steel tanks are widely used in manufacturing processes where cleanliness and purity are important.

Stainless steel tanks are widely used in manufacturing processes where cleanliness and purity are important.

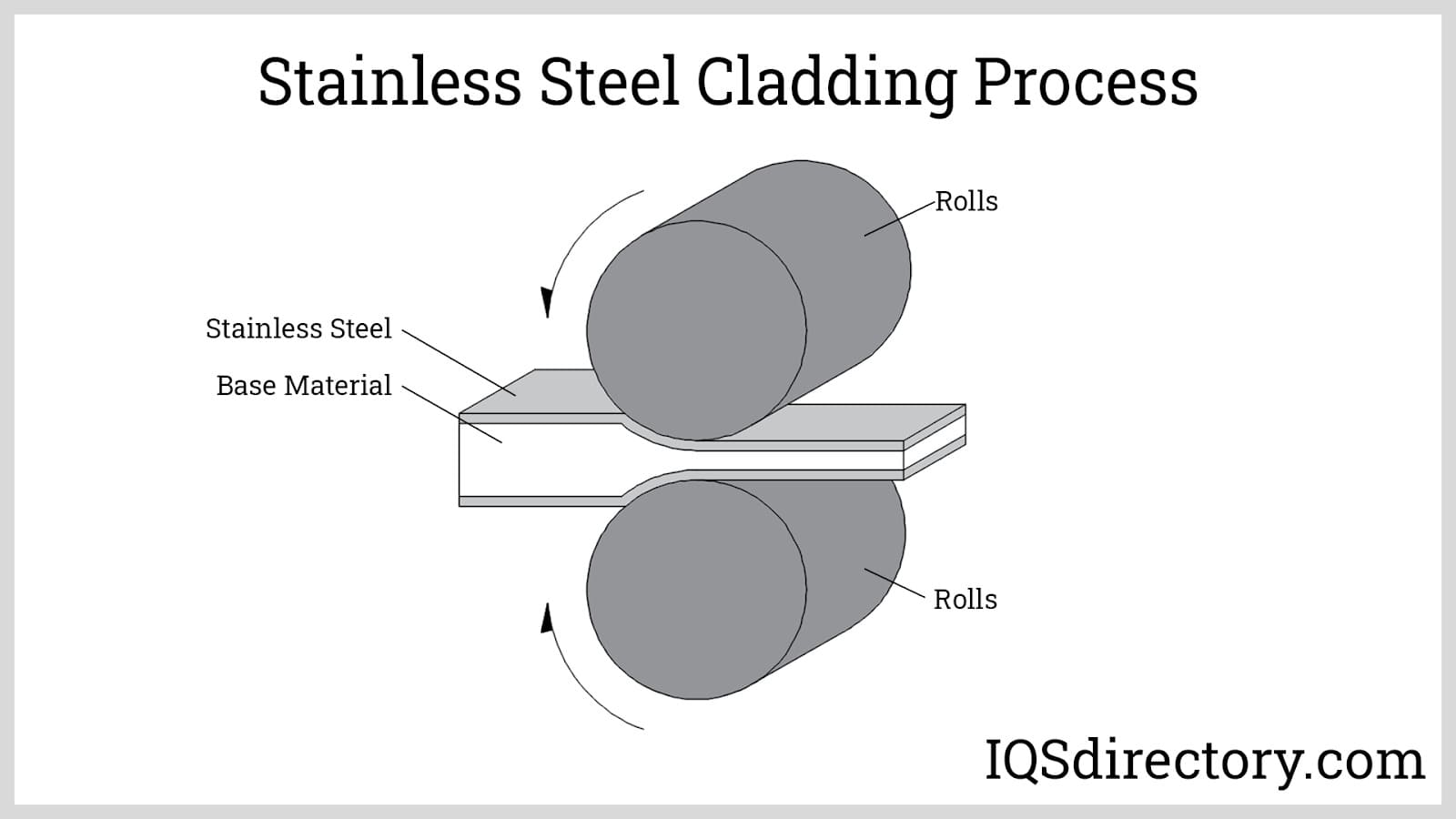

Stainless steel cladded carbon steel plates are formed by pressing and heating the two metals together.

Stainless steel cladded carbon steel plates are formed by pressing and heating the two metals together.

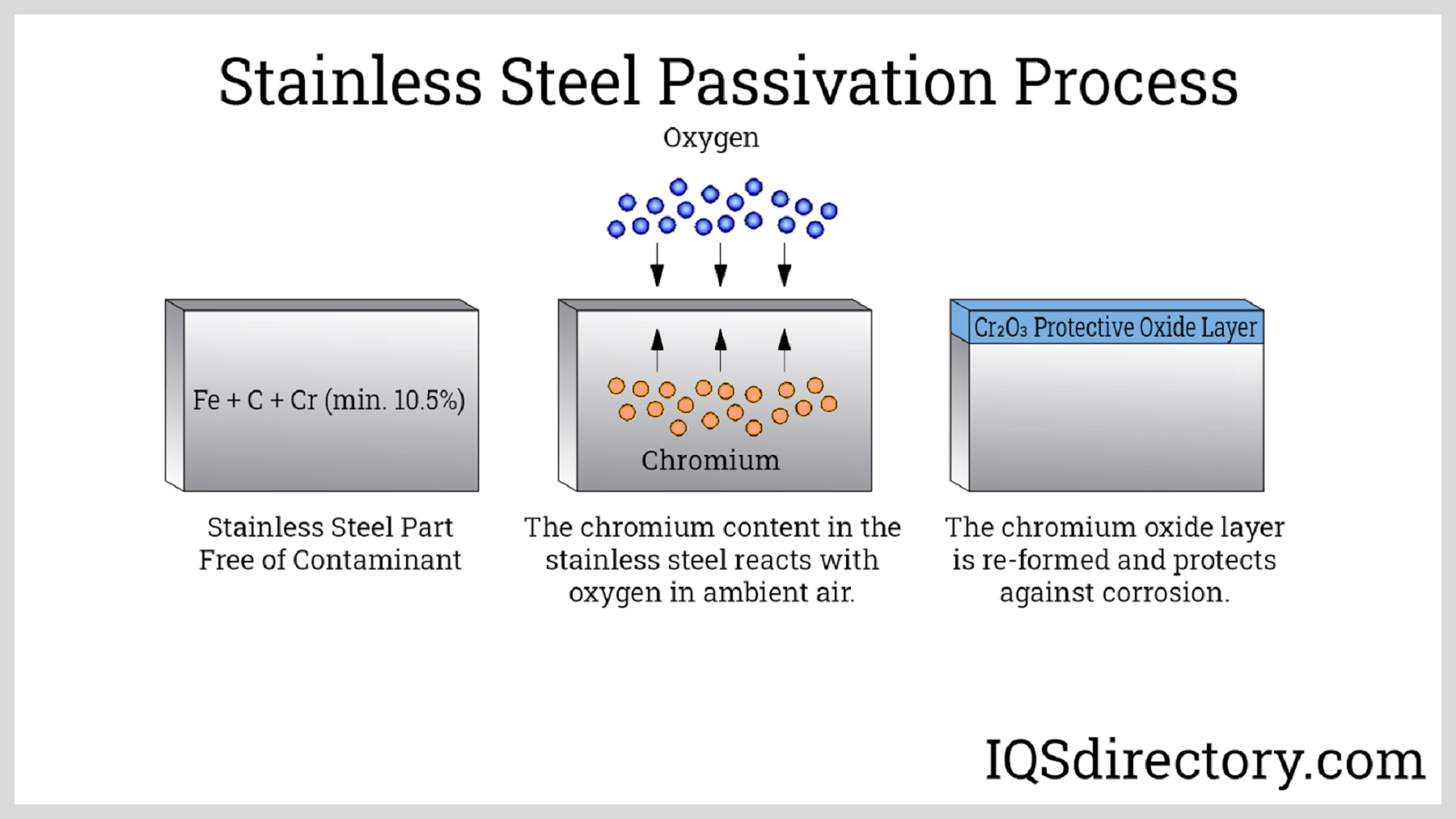

Stainless steel utilizes the principle of passivation wherein metals becomes unreactive to oxidation from corrosive compounds in the atmosphere and process fluids.

Stainless steel utilizes the principle of passivation wherein metals becomes unreactive to oxidation from corrosive compounds in the atmosphere and process fluids.

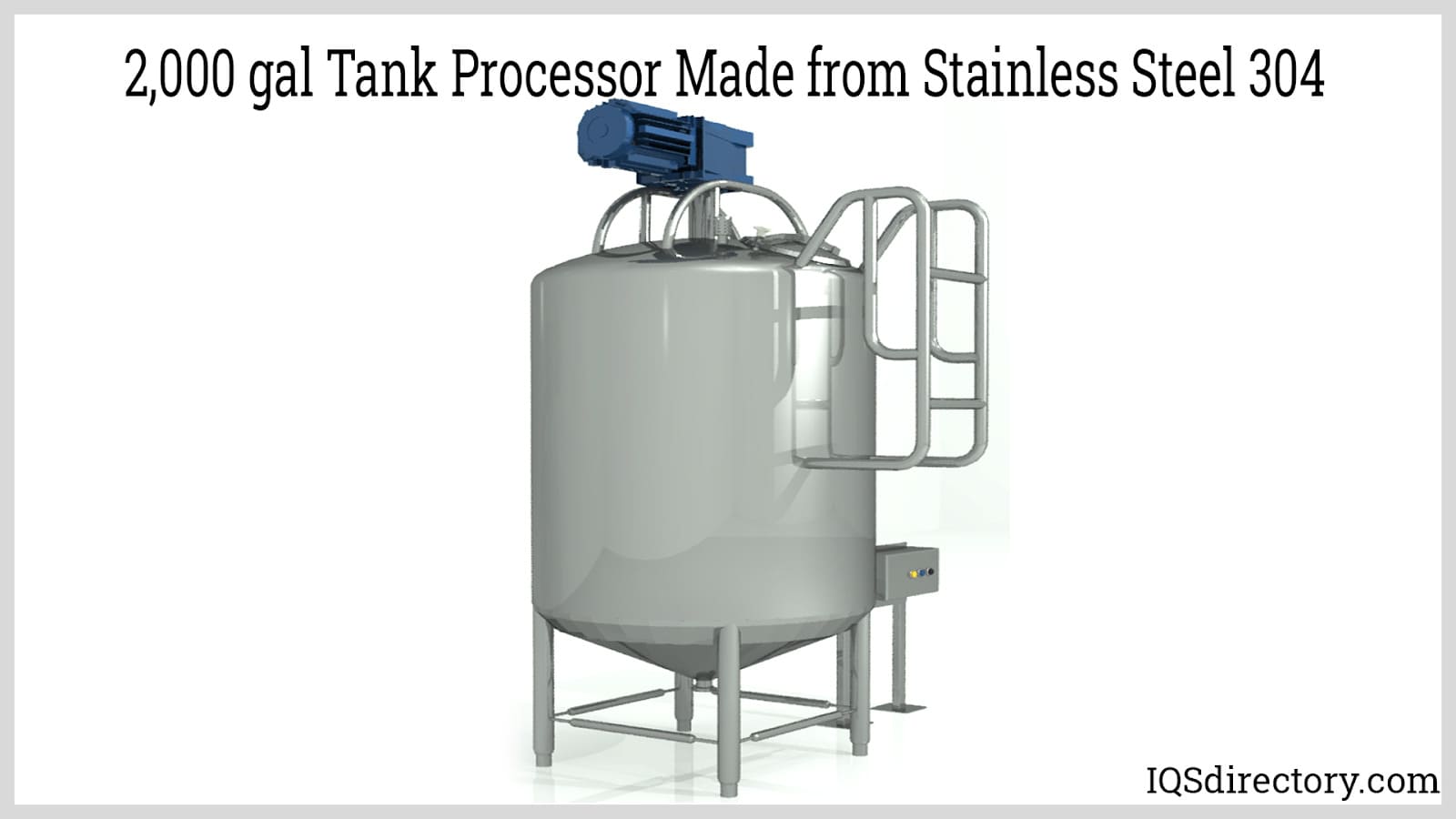

Stainless steel 304, is composed of 18-20% chromium, 8-11% nickel, and 2% manganese making it corrosion resistance and less expensive.

Stainless steel 304, is composed of 18-20% chromium, 8-11% nickel, and 2% manganese making it corrosion resistance and less expensive.

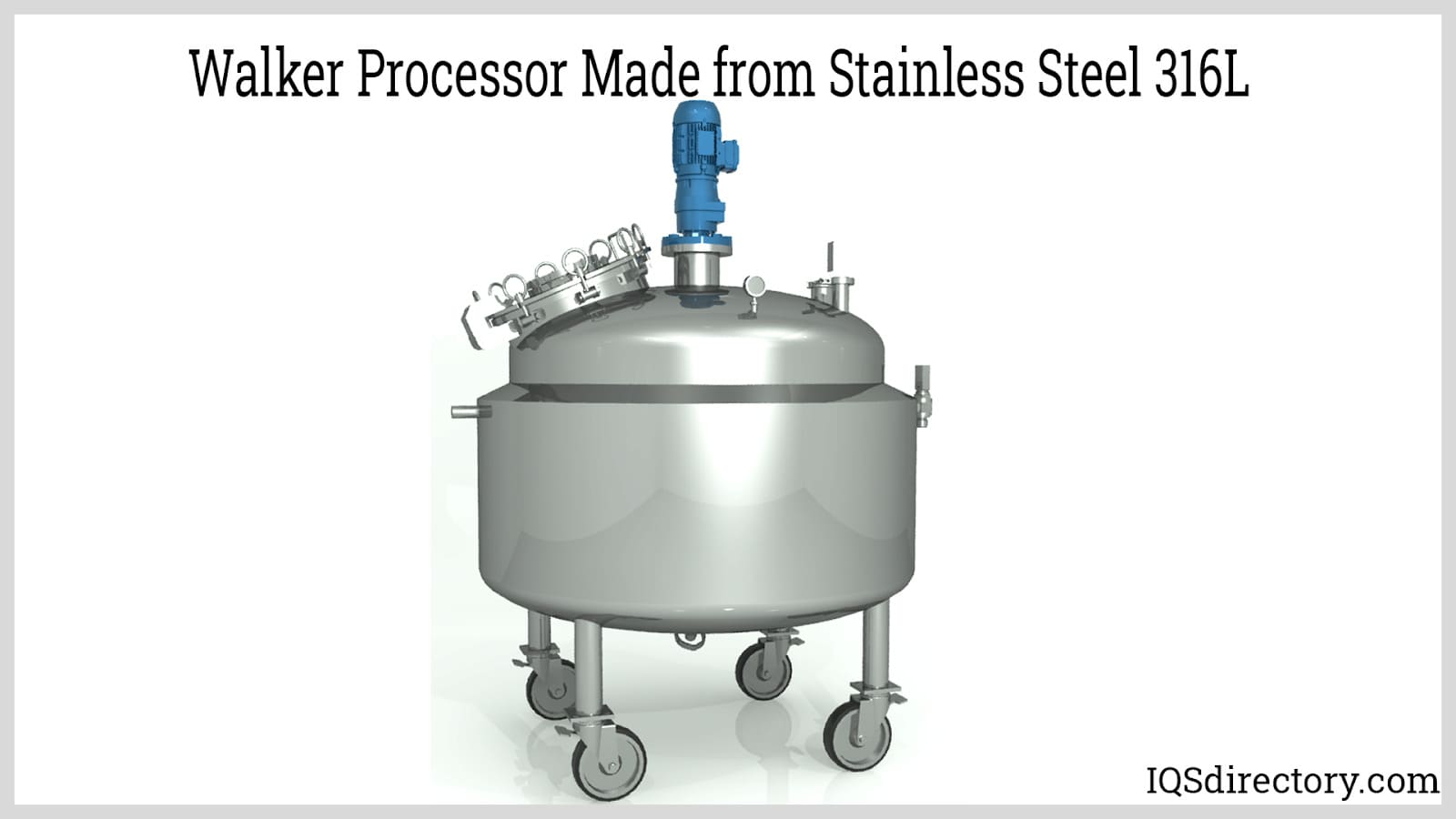

Stainless steel 316 contains 16-18% chromium, 10-14% nickel, 2-3% molybdenum, and 2% manganese making it more corrosion resistant.

Stainless steel 316 contains 16-18% chromium, 10-14% nickel, 2-3% molybdenum, and 2% manganese making it more corrosion resistant.

Duplex stainless steel contains 20-28% chromium, 2-5% molybdenum, and 5-8% nickel this makes have higher corrosion resistance and mechanical strength then either stainless steel 316 or 304.

Duplex stainless steel contains 20-28% chromium, 2-5% molybdenum, and 5-8% nickel this makes have higher corrosion resistance and mechanical strength then either stainless steel 316 or 304.

Types of Stainless Steel Tanks

There are many different types of stainless tanks that differ in properties, depending on their applications.

- Stainless Steel Storage Tank

- Used to hold liquid or gas, usually in larger quantities. Storage tanks vary significantly in their sizes, shapes and applications. They are mostly built in a cylinder shape to endure stress from hydraulic pressure. They range from very small waste bins to huge multi-million-gallon stainless steel silos.

- Stainless Steel Mixer

- Used to blend different substances together. Mixers are often used in food processing to stir and combine large amounts of ingredients. They do so using a motor-powered propeller.

- Food Grade Tank

- Made specifically to hold perishable items that need a clean, sterile and temperature controlled storing environment, like dairy tanks.

- Storage in Silos

- Often the largest storage tank type, is typically found on farms. This type of stainless steel vessel is cylindrical and stands vertically. Silos are able to hold either liquids or solids in the dairy, food and beverage industries. Most often, they store animal feed and crops.

- Stainless Steel Vat

- Mostly found in wineries, breweries and liquor distilleries. They hold alcohol during the refinement process and can dramatically range in size and shape.

- Stainless Steel Bin

- Used for a number of different applications, including waste receptacles and kitchen storage.

- Stainless Steel Water Tank

- Used to hold drinking water, irrigation water, water for fire hydrants, for farming, or for water used in food preparation. They are located above and below the ground, and monitored regularly to ensure the water remains potable.

- Small Stainless Steel Tank

- Constructed in a thin-walled, cylindrical or drum-like shape using some grade of stainless steel. There is not just one type of stainless steel. Rather, the term "stainless steel" refers to a whole group of chromium-based steel alloys, all of which are at least 10.5% chromium. Other than that, and the fact that they are also mostly iron ore, stainless steel types may be partially made up of various different materials, such as aluminum, carbon, nickel, molybdenum and/or silicon.

- Fuel Tank

- Or gasoline tanks, are located in automobiles and hold the vehicle's fuel. They are airtight so as to prevent gasoline diffusion into the air. Gasoline diffusion wastes gas and harms the environment, so gasoline tanks are coated with aluminum or zinc to guard against this problem. They are built to last a long time against corrosion, cracking and flaking.

Stainless Steel Tank Applications

Stainless steel tanks are usually made for storage purposes. They’re used to hold and store a wide range of substances including food, beverages, chemicals, gas and water. Customers love them because stainless steel is durable and corrosion resistant, and easily temperature controlled, cleaned and sterilized. IQS Directory maintains a list of food grade steel tank producers.

These customers come to stainless steel tank manufacturers from numerous industries, including many from agricultural sectors like the dairy industry, food and beverage processing, medical, chemical and waste water and sewage management. They are commonly used where hygiene and corrosion are concerns.

Standards and Specifications for Stainless Steel Tanks

Any stainless tanks that carry food, beverages or anything else for human consumption must adhere to strict FDA, USDA and 3-A standards for health reasons.

Also, in general, we advise you to purchase an ASME tank. ASME certified tanks adhere to the ASME code, or ASME Boiler & Pressure Vessel Code (BPVC) code. This was designed by ASME (the American Society of Mechanical Engineers) to regulate tank construction and design. It is endorsed by the US government.

Things to Consider When Purchasing Stainless Steel Tanks

IQS Directory provides a detailed list of stainless steel tank manufacturers and suppliers to help you find stainless steel tank companies that can design, engineer, and manufacture stainless steel tank products to your specifications. Peruse our website to review and discover top stainless steel tank manufacturers with roll over ads and complete product descriptions. Connect with the stainless steel tank companies through our hassle-free and efficient request for quote form. You are provided company profiles, website links, locations, phone numbers, product videos, and product information. Read reviews and stay informed with product news articles.

Decide which supplier or manufacturer is right for you by reaching out to three or four of those we’ve listed. Discuss your specifications with them, such as how much space you have (measured by cubic foot), how much you’re looking to hold, the type of material(s), etc. Also, you should include those specifications related to budget, lead times, certifications, delivery and secondary services. You want a supplier with more than bare competence; you want a supplier who is interested in and committed to delivering you high quality products, no matter your price point. As you search, remember that customer service is key.

Proper Care for Stainless Steel Tanks

Although stainless steel is strong, it is vulnerable to buckling when the material is thin. Stainless steel tanks are most susceptible to damage during fabrication, transportation and installation. The contents of full stainless steel tanks actually aid its stability. So, our first tip is to treat your stainless steel tanks carefully, especially before you fill them. In addition, you should regularly test your tanks, either by pressure testing, subsurface testing or full tank removal.

If your tanks are used to house and/or manufacture food, you must clean them every time you empty them. In addition, if those foods are perishable, you need to also make sure to maintain temperatures that keep them from spoiling.

Always keep an eye out for leaks, especially if you have a stainless steel pressure vessel or underground tank. If you have underground tanks, you need to put systems in place that allow you to check this remotely. This is very important because leaking can cause toxins to seep into surrounding vegetation and underground water supplies.

Stainless Steel Tank Accessories

Accessories of stainless steel tanks include manway assemblies (kits containing: cover, O-ring, gasket, gasket, yoke(s), bolt(s) and nut(s)), hinged closures, fittings, emergency bilge pumps, gauge devices and submersible pumps. Emergency bilge pumps are designed to deal with leakages. They can pump out the rest of the fluids in a leaking tank or soil content that is contaminated. Submersible pumps are designed to be installed completely immersed within a tank. Oil-filled cavities of submersible pump motors protect them from contact with the transfer media. Submersible pumps can treat groundwater, extract pollutants or even remove the fluids completely.

Stainless Steel Tanks Terms

- Atmospheric Pressure

- The amount of force the atmosphere exerts upon the surface of the earth, measuring 14.7 psi at sea level. A tank that holds substances at pressure levels greater than 14.7 psi is considered a pressure vessel, while a tank that holds substances at pressure levels lower than 14.7 psi is considered a vacuum.

- Brittle Fracture

- Fracture of certain steels associated with exposure to very low temperatures, often in circumstances in which stress levels have not exceeded yield strength.

- CIP (Clean-In-Place) Fixtures

- Fixtures that provide an efficient and effective way of cleaning a tank without taking it apart. CIP fixtures include sprayballs, dishes and T-balls.

- Canadian Registration Number (CRN)

- A number given to pressure vessels shipped to Canada.

- Cladding

- A stainless steel coating applied to a lower-alloy steel to increase corrosion resistance. Cladding costs less than using stainless steel exclusively and can be applied by pouring, welding or coating.

- Corrosion Allowance

- An increase in vessel shell thickness designed to compensate for the corrosion and abrasion of certain pressure vessels. Protective coatings and linings are also added to pressure vessels to prevent corrosion.

- Creep

- Permanent deformation of steel caused by strength reduction resulting from exposure to high temperatures.

- Duplex Steel

- A type of stainless steel composed of austenitic and ferritic steel, the combination of which is stronger than either of the individual metals. Duplex steels are extremely corrosion and crack resistant.

- Electropolishing

- The removal of imperfections on the surface of stainless steel by dissolving the steel in a solution of electrolytes through which a current of electricity travels.

- FDA (Food and Drug Administration)

- Federal organization responsible for the regulation of food, drugs, medical equipment, cosmetics, etc. The FDA also regulates the storage of such products and maintains standards for stainless steel tanks used in applications involving these products.

- Fouling

- The build-up of deposits of marine organisms that occurs on submerged metal surfaces.

- Gauge

- A measurement of the thickness of steel.

- Manway

- Access port to the internal region of the tank or pressure vessel.

- National Board Inspection Code

- Worldwide standard for pressure vessel inspection, alteration and repair.

- Psi (Pounds per Square Inch)

- Unit that measures the amount of pressure applied to an object. Psi reflects the amount of pressure under which a pressure vessel substance remains.

- Sanitary Piping

- The piping systems between pipes that are interconnected and able to be cleaned.

- Stainless Steel

- Type of steel containing 10 to 12 percent of chromium. Stainless steel is a common choice for tanks because of its corrosion and temperature resistance.

- USDA (United States Department of Agriculture)

- Federal organization regulating many aspects of the agricultural industry. The USDA regulates food supply and promotes the safe processing and storage of meat, dairy products, etc., and maintains strict standards for stainless steel sanitary and dairy tanks.