Industrial Ovens

Industrial ovens are thermal processing machines. Ovens use heat to treat materials in many ways. The name for a given heat treatment process reflects the kind of property changes that occur in a product when it is heated; drying, baking, and dehydrating are processes of moisture removal, curing is the process of strengthening, and firing is the process of hardening ceramics. Industrial ovens are also used to activate adhesives, gel and fuse materials together, heatset, heat shrink, preheat, sinter, melt, laminate, and thermal bond materials.

Industrial ovens may be used for a broad variety of applications. These include powder coating, drying, baking, curing, and many others. These ovens are capable of reaching a wide range of temperatures. Higher temperature industrial ovens may be used for drying materials and are sometimes called kilns, though they do not reach temperatures quite as high as traditional ceramic kilns. Lower temperature industrial ovens may be used for baking or curing and are found in places such as factories or bakeries. Industrial ovens come in many shapes and sizes; some come designed similarly to a home oven, while others are large enough for people to walk into them. There are also some industrial ovens that have a conveyor running through them in order to heat mass quantities of items over a short span of time.

Industrial ovens vary greatly in size and shape. Some are very large and contain many shelves and could be used for baking many loaves of bread at once. Ovens may be installed in large trucks or on carts for portability. The one thing all of these ovens have in common is they are all temperature controlled according to their purpose. Industrial ovens specifically designed to remove the moisture from objects placed inside are called drying ovens. Industrial ovens designed for curing are made to cause chemical reactions between the coating and the product itself. Like ovens found in homes, some industrial ovens are designed specifically for food production. Although industrial ovens used for food production are typically much larger and reach temperatures much higher than the average domestic oven, the method of baking food is the same.

Heat is a major factor in all manufacturing industries. Virtually every product engaged in the production process requires heat introduction at some point. Among the major sources of this form of energy are industrial ovens. They are hot and insulated chambers utilized in industries for drying, baking, or treating various parts or components before, during, or even after their creation.

Quick links to Industrial Oven Information

Benefits of Using Industrial Ovens

Industries utilize ovens for a variety of reasons:

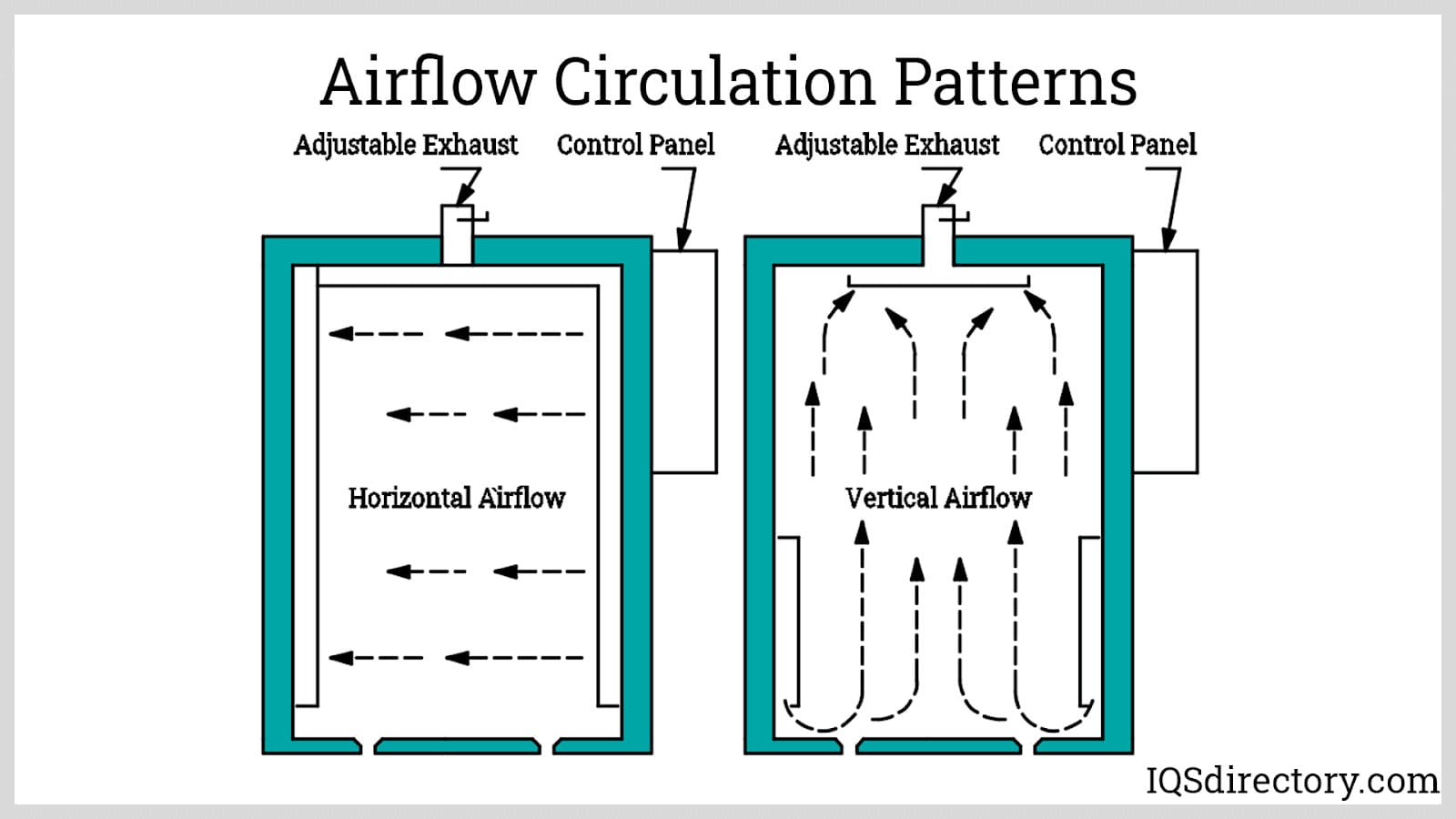

- They are air flow efficient. Ovens allow temperature uniformity in all areas of the device. Substantial airflow guarantees a smooth performance. This is important since airflow is a critical factor in the proper functioning of the machine.

- Using these devices in industrial capacities offers easy temperature management, which ensures that work is done well. There are fewer chances of uneven temperature distribution, which could affect the overall application.

- Manufacturing ovens are cost effective. Electric types are inexpensive and are ideal when less capital investment and minimal upkeep is desired.

- The ovens are perfect for fast heat waves in raw materials without the exhaustion of too much power. This allows for the accomplishment of several tasks within short periods.

- Most ovens are designed with stainless steel cabinets. As a result, they are durable, have a high performance, and are extremely reliable.

Industrial Oven Applications

The number of applications for industrial ovens is almost infinite. They are used in the electronic industry for degassing epoxy resins, reacting elements, and other purposes. Food and beverage companies also use ovens for sterilization of items before packaging and other purposes.

Other industries that use ovens include:

- Pharmaceutical and medical, for chemical reactions, sterilization, and incubation of samples.

- Research and Development for temperature grading and other functions.

- Plastic for melting, shaping, or aging of products.

- Aerospace and automotive for various stages that require thermal energy such as creation of components and parts.

- Steel for iron melting.

In applications that require temperatures above 2000 degrees F, an industrial furnace is ideal. Furnaces require large spaces, and the desired temperature is introduced directly into the chamber, unlike ovens that utilize a system of ductwork to distribute hot air onto the raw materials being processed.

History of Ovens

Technology has changed greatly since the first use of ovens. The first ever ovens date back to 2900 BC in Central Europe, where they were utilized in boiling and roasting pits in yurts for mammoth cooking. Later on, the pits used hot coal covered in ashes. By 3200 BC, almost all settlements had hearths used in food cooking and brick making. Ovens were later employed as kilns for pottery and bread baking; this was introduced by the Greek.

Many years later, instead of ceramic and earth ovens, fireplaces with cauldrons were used. Transitions occurred, and ovens were either using wood, coal, or iron gas, and later, electricity. The early 1700s saw the introduction of the Stewart Oberlin iron oven, which was smaller and had a chimney of its own. During the earlier years of the 19th Century, coal ovens were introduced, and years later, gas ovens came about. James Sharp patented the first ever gas stove in the year 1826. The AGA cooker invented in 1922 by Gustaf Dalen was an improvement of the gas stove.

Since then, further advancements have followed, and although the first electric ovens were invented late in the 19th Century, power was not yet as extensive as it is today. The introduction of high-tech ovens began with Percy Spencer’s microwave in 1946. After it was patented, more productions, adaptations, and the creation of large scale ovens emerged.

How Industrial Ovens Work

Ovens provide consistent burning environments, and with separate chambers for cooling and warming, they have various sources of thermal energy. Hot water, electricity, and gas are the most common sources, all of which are introduced into the oven through forced convection.

Electrically fired ovens are the most popular types because of their rapid sweltering process and their durability. They are inexpensive and are less polluting. On the other hand, ovens fired by gas are available in direct and indirect configurations and can either use propane or natural gas. They are more expensive than the electric types, but with considerably cheaper running costs. In hot water ovens, the water passes through radiator coils for the emission of energy. They are the preferred choice for applications that require lower temperatures and where quick heating time is not necessary.

The most common type of oven, the convection oven, functions by blowing jets of hot steam through coils or hot panels. When this happens, the material is quickly warmed up, improving the functionality and the operational efficacy of the machine. Once the raw materials have been placed in the oven, a temperature knob is adjusted to a particular degree. Each task has a different temperature specification.

In other models, the air is drawn by fans through the coils and propelled back to the compartments via plenums installed in the side walls; this results in temperatures that are uniform and consistent.

Components of the Industrial Oven

Ovens are made up of several components. They include:

- Motor

- Which powers the whole system.

- Exhaust and Recirculation Fans

- For air circulation within the oven.

- Duct Distribution Network

- Which is used for venting.

- Flame Controllers and Purge Timers

- Burners

- Direct fired types are supported by most electric motors. Other types incorporate radiant tube burners for thermal transfer from gas combustion.

Use and Installation of Industrial Ovens

Several factors influence the installation of ovens. Location is one of them. Industrial ovens should be located where they are protected from damage by high temperatures, vibrations, or even mechanical damage. Space should be adequate, and they should not be against a wall. Because most ovens are made of stainless steel cabinets, they tend to expand when they burn. This is why leveling them with shims is appropriate. Proper ventilation is a must in the installation area. This should prevent accumulation of vapor that could be potentially hazardous.

Another thing to pay attention to during installation is the method of heating. Whether by electricity, hot water, or gas, the installation should be done according to the specifications and codes provided.

The most important thing is to let professionals do the work for you. Do not attempt to install or operate the machine if you do not have the technical know-how. Familiarize yourself with all the necessary aspects that will ensure optimum performance.

Design and Customization of Industrial Ovens

Many aspects go into the design of an oven. As an alternative to buying a pre-designed device to fulfill a specific task, you can design your own or customize an existing machine to fit a particular job. While there are many standard models available, a custom designed oven can be made to fit your needs exactly.

The first thing to consider is the exact purpose of the custom machine. Will it be used for food processing or in the manufacture of equipment? Determination of the specific task, or a combination of functions, influences the optimizations you will consider. The next thing to consider is how the machine should function—for instance, by electricity or gas. Also worth noting is the temperature requirement.

Other Necessary Components for Industrial Ovens

Although ovens are standalone fixtures, there are other necessary components required during their installation. Apart from sources of power, gas and water, piping and venting options, other components like shims are required to keep them firmly in place. Incinerators and exhausts for waste disposal are also necessary. To foster safety, the installation of alarms and fire extinguishers is highly recommended.

Safety and Compliance Standards for Industrial Ovens

Due to many hours of operation, with doors closed and compartments spattered with raw material resins, ovens need regular cleaning and maintenance if you want to get the best out of them. There are various compliance and safety standards to be considered.

During operation, wearing protective gear is of great importance. It is imperative one avoid direct smelling of gases and keep away from hot parts. Should there be any wet spills or boil overs, use appropriate cleaning measures with industrial grade solutions. Ensuring compartments are sealed appropriately is the first thing to do before firing on the machine.

Other safety precautions include:

- Extensively Reading the Manual for Installation Operation Guidelines

- Installing Ducts in Places with Noncombustible Material

- Never Leaving the Oven Going Without Attendance

- Always Ensuring the Safety Equipment is in Place

- Conducting Regular Inspections for Flaws and Necessary Adjustments

- Keeping Moving Parts Well Lubricated After a Given Period of Time

Choosing an Industrial Oven Supplier

Many manufacturers offer many types of ovens used in the industrial production processes. However, not all of them will benefit you. The most important thing is to choose a manufacturer who not only provides the right machine for your needs, but a machine that fits the available space, has optimum performance, and will last for ages.

Some machines on the market are not up to required standards in terms of operation and maintenance. The right vendor will offer a device that has less operational costs and is easy to clean and maintain. Additionally, check whether the supplier meets the certifications required for the oven and ensure that chances of delay in support and troubleshooting after the product is in use are averted.

The right supplier offers factory acceptance testing. What this means is that the supplier will run the oven and confirm everything is in order before shipping it to you. Finally, check that the supplier provides installation services after the purchase. Do they have a team ready to offer maintenance whenever necessary?

Industrial Oven Images and Illustrations

An electrical industrial oven is powered by incoloy sheathed heating elements which allows for the oven to be less expensive and not produce pollutants or emissions.

An electrical industrial oven is powered by incoloy sheathed heating elements which allows for the oven to be less expensive and not produce pollutants or emissions.

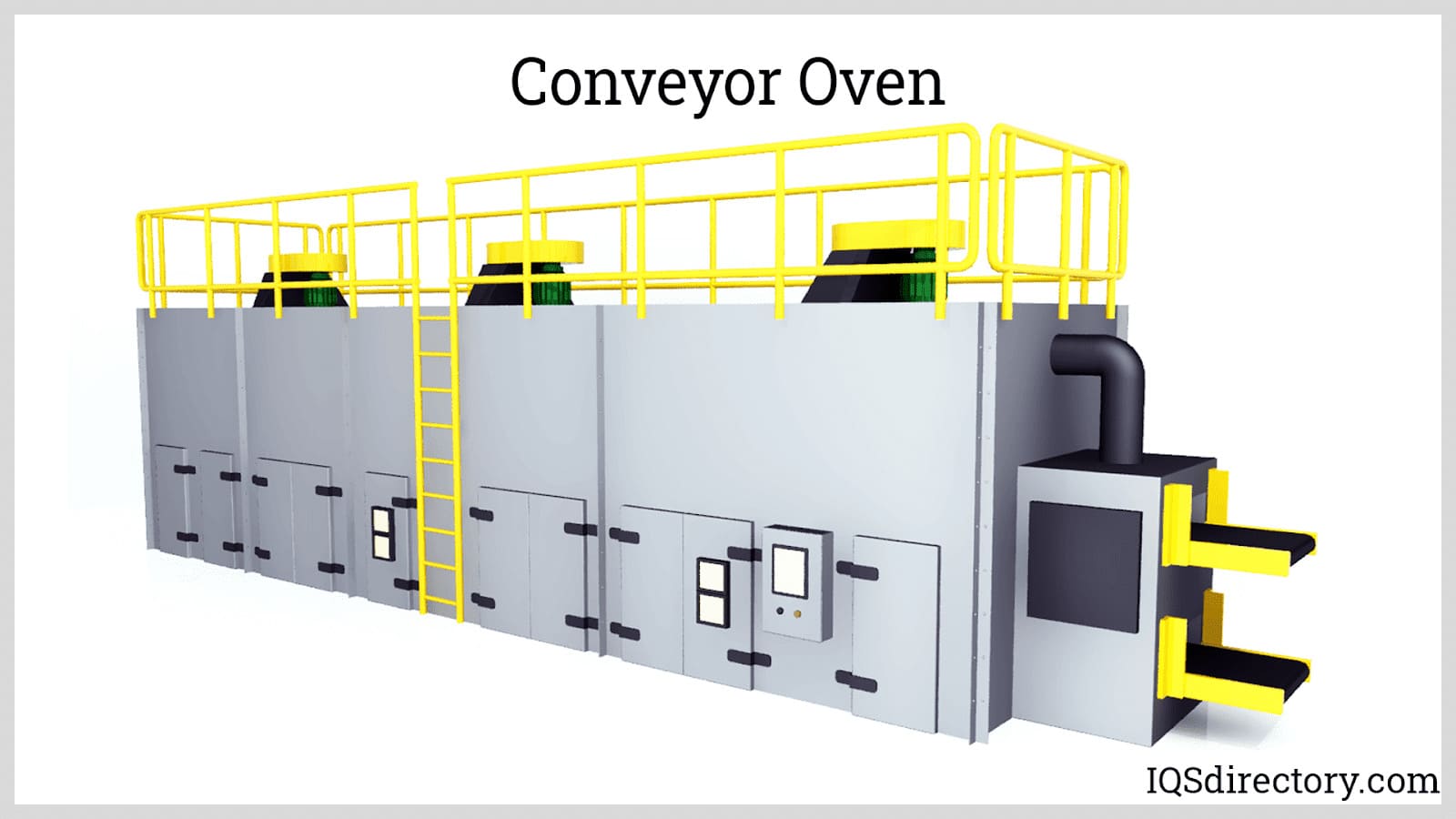

Continuous ovens are primarily used for mass production, while having the abilities to dry, cure, anneal, relieve stress, bonding, tempering, preheating, and forming.

Continuous ovens are primarily used for mass production, while having the abilities to dry, cure, anneal, relieve stress, bonding, tempering, preheating, and forming.

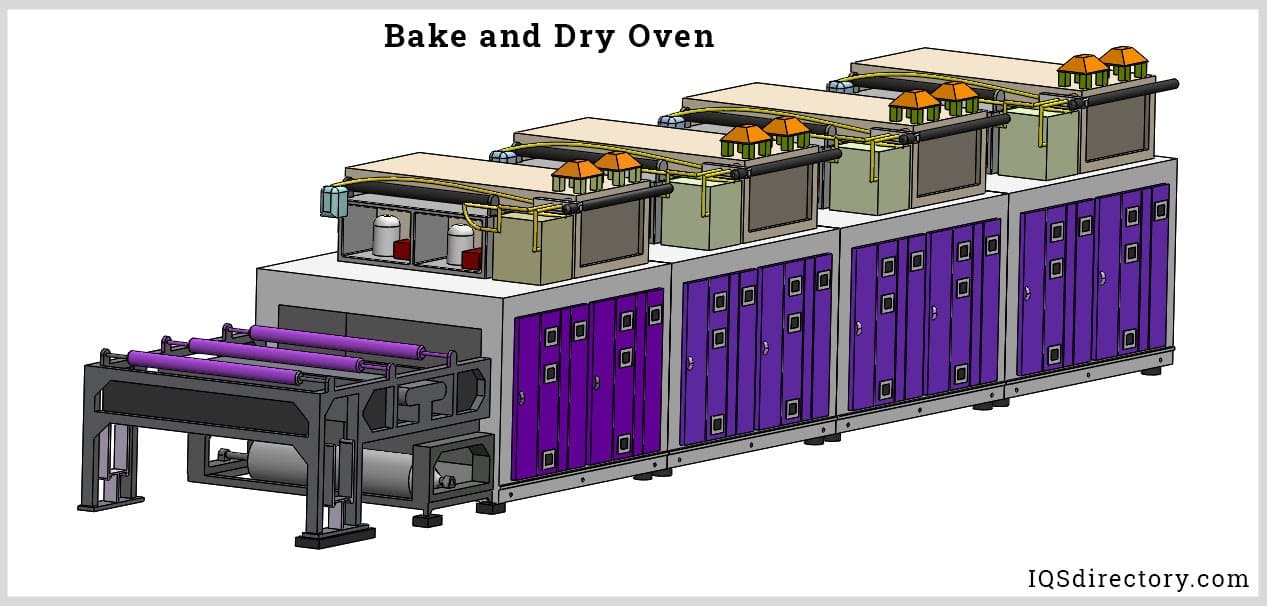

Releases moisture, volatile compounds, or trapped gases from coatings on the finished product.

Releases moisture, volatile compounds, or trapped gases from coatings on the finished product.

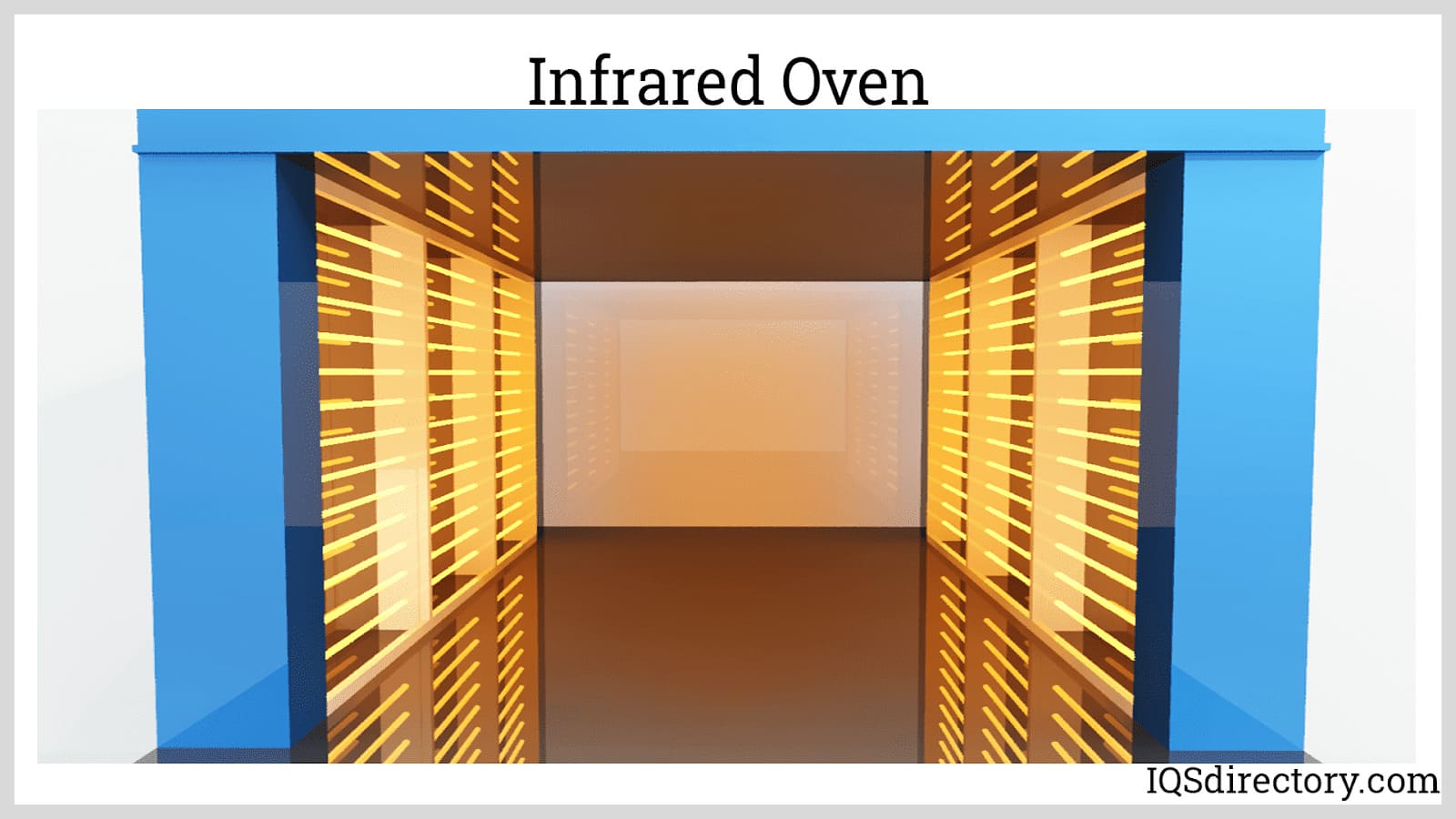

Uses high intensity lighting to maximize production while minimizing the energy usage.

Uses high intensity lighting to maximize production while minimizing the energy usage.

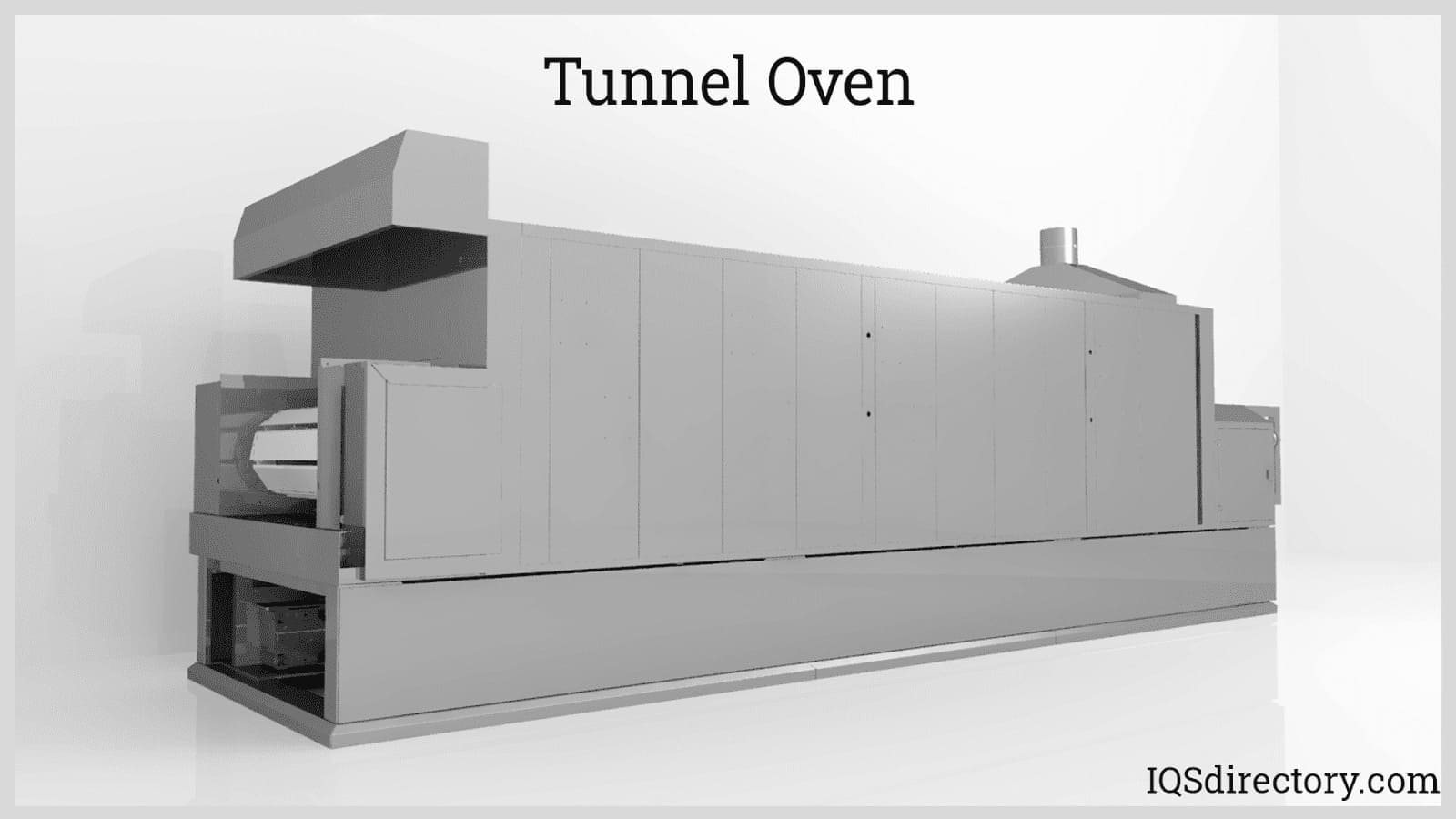

Tunnel ovens are open-ended chambers with a metal belt and a baking platform.

Tunnel ovens are open-ended chambers with a metal belt and a baking platform.

The air circulation patterns which can affect uniformity, pattern, and impingement.

The air circulation patterns which can affect uniformity, pattern, and impingement.

Industrial Oven Types

- Baking Ovens

- Used for baking materials or food, are made of inflammable materials, and have smooth interior surfaces to allow cleaning.

- Batch Ovens

- Also known as walk-in ovens or cabinet ovens. They are big enough to accommodate a variety of batch processes that incorporate aging, drying, annealing or curing. A batch oven is applicable where the same heat treatment procedure is required to be conducted at different times and where the substance being processed changes between batches. The cooking of raw materials with this particular oven involves loading them inside the oven itself, on trucks, carts, or even racks. The accommodation of manual and automatic loading is also considered.

- Bench Ovens

- Small, sometimes portable ovens usually placed on tables or stands. Bench ovens are used during low volume process heating applications.

- Commercial Ovens

- Used to dry, bake, heat, and cure various materials.

- Continuous Ovens

- Can perform a number of applications at the same time. They are applied in mass processes that require consistent thermal treatment. These machines are equipped with separate warming and cooling compartments, which hastens the thermal treatment process as you don’t have to wait for a particular chamber to cool down. As a result, the total time taken to complete a specific task is significantly reduced.

- Convection Ovens

- Provide consistent process heating through the fluid circulation of gases. The heated gas warms the internal air, which maintains the temperature inside the oven.

- Conveyor Ovens

- Contain a variety of accessories and are used in continuous high volume process heating applications.

- Curing Ovens

- Including composite curing ovens, paint curing ovens, and UV curing ovens, alter and prepare certain products, materials, and substances by chemical or physical processing such as in the hardening of rubber or paint, and they can be used in powder coating and food preservation as well.

- Drying Ovens

- Have a design that rids raw materials of any moisture. These ovens operate in a three-sequence process. The first step is the heat-up, where the substance gains the optimum temperature required to withdraw the moisture at a given moment. The second phase involves the soak process. The material is left to soak, again for a particular period before the final process, which is a cool-down stage. The hot air is exhausted from the oven, and cold air is fed in. These types of ovens are applied in sterilization, temperature testing, and the incubation of temperature sensitive experiments.

- Electric Ovens

- Heat treatment machines that use electricity for heat generation

- Heat Treating Ovens

- A type of industrial oven. Heat treating ovens are used to alter the chemical and physical properties of metal or glass, including their hardness, tensile strength, and toughness through a three-step process of heating, cooling, and reheating.

- Infrared Ovens

- Utilize electromagnetic radiation to transmit heat to the product. Infrared radiation is transferred directly to the product without heating the air inside of the enclosure.

- Laboratory Ovens

- Thermal treatment machines used for testing and experimentation.

- Ovens

- Thermal processing machines that are used to change the properties of a substance.

- Portable Ovens

- Small thermal processing machines designed for easy transportation.

- Powder Coating Ovens

- Either infrared or convection ovens in which the powder coating on a product is melted and allowed to flow for 2-10 minutes. Within the oven, the product is exposed to ultraviolet light for just a few seconds to cure and harden the finish.

- Rotary Ovens

- A type of industrial oven. Industrial ovens are typically large, producing enough heat to bake numerous items at once for commercial use. Industrial ovens are usually either used for baking food products for commercial resale or curing industrial materials.

- Storage Ovens

- Heat parts to make them easier to assemble and are utilized where pressure-sensitive adhesives perform more efficiently at higher temperatures and where pliability aids fit.

- Tunnel Ovens

- Shaped like tubes and material passes through the hollows. The raw materials can be loaded either continuously or by conveyor belts with stops. The tunnels utilize the speed of the belts to make the elements hot using different types of fuel. They are common in the food industry, especially the meat and baking industry.

- Vacuum Ovens

- Air tight enclosures in which the pressure level remains lower than that of atmospheric pressure. Vacuum ovens guard against undesirable effects of heat processes such as oxidation and contamination.

- Walk-in or Truck-in Ovens

- Large enclosures used for the process heating of large objects such as trucks or cars or for large product quantities. Walk-in ovens often contain large doorways, cabinets, shelves, and racks for convenience.

Industrial Oven Terms

- Aging

- The process of changing the properties of a metal or an alloy through temperature changes through the utilization of an industrial oven.

- Annealing

- The process of softening an object or changing other properties of the object through cycles of heating and cooling using an industrial oven.

- Atmospheric Pressure

- The amount of force the atmosphere exerts upon the earth's surface, measuring 14.7 psi at sea level.

- Baking

- Removing entrained gases by heating the object up to a low temperature in an industrial oven.

- BTU (British Thermal Unit)

- The amount of heat necessary to change the temperature of one pound of water by one degree Fahrenheit.

- Conduction

- A form of heat transfer through the application of heat to a solid object followed by the subsequent spread of the heat through the object in an industrial oven.

- Convection

- Heat transfer between two objects, one of which is either a liquid or a gas. During convection, the pull of gravity initiates fluid circulation, causing heated molecules to rise and cool molecules to fall.

- Curing

- The process involving the solidification of a material through heating and drying in industrial ovens. The temperature of the cured object is maintained during the process.

- Drying

- The process of removing a solvent such as moisture from an object through utilization of industrial ovens.

- Emittance

- The capability of the surface to emanate radiant energy.

- Heat Transfer

- The exchange between matter, or parts of the same matter, of heat; this always occurs from warm to cool.

- Heat Treatment

- The process of changing properties in solid metals or alloys through heating and cooling applications.

- Heatsetting

- The process of setting the shape of yarn or carpet fibers through the application of heat in industrial ovens and/or steam. For example, heatsetting creates a permanent twist in yarn.

- Postheating

- Applying heat to an object after a manufacturing process such as brazing, welding, or soldering.

- Powder Coating

- A dry finishing process that utilizes finely ground, electrostatically charged particles by spraying them onto a part to be coated. When placed in an industrial oven, the charged parts melt and fuse into a durable, even coating.

- Preheating

- The application of heat in industrial ovens before the manufacturing process.

- Process Heating

- The supplication of heat from industrial ovens to an object or material.

- Quenching

- The rapid cooling of an object heated in an industrial oven.

- Radiation

- The movement of energy in the form of particles, rays, or waves.

- Radio Frequency

- The creation of heat by the transfer of energy.

- Sintering

- The formation of large particles from a heap of small, fine particles through the application of heat. In the sintering process, the temperature remains below the melting point.

- Stress Relieving

- Reducing stress in a metal object by raising the temperature of the object and maintaining the object's temperature for a specified amount of time by utilizing industrial ovens.

- Tempering

- Heating steel to a given temperature in industrial ovens, then cooling it in order to reduce the brittleness in the hardened steel.

- Thermal Bonding

- The application of heat from industrial ovens to produce interlocking among fibers and fabrics.