Forklifts

Forklifts are industrial vehicles used in applications such as warehouse storing and distribution for the lifting, moving and loading of heavy products, materials and packaged pallets. Forklifts typically have a power-operated, moving forked platform attached to the front of the vehicle. This is designed to be inserted under loads and raised in order to move the load to a desired location.

Forklifts are sometimes referred to as forklift trucks or simply lift trucks. Practically speaking, these terms are all interchangeable. In a technical sense, a lift truck is more accurate since not every type of this machine possesses actual forks for lifting. Since the vast majority of lift trucks do possess forks, the term forklift is sufficient and will be used for the purposes of this article.

Quick Links to Forklifts Information

The History of Forklifts

The discovery of hydraulic power – the scientific foundation of forklifts – can be traced to the work of French scientist Blaise Pascal in the mid-seventeenth century (1647-1648). Pascal discovered that pressure exerted on an enclosed, incompressible liquid spreads equally to all areas of that liquid. A consequence of this is that, under the aforementioned circumstances, liquid will escape through any existing outlets with the same pressure being exerted on it in the container. This scientific observation has come to be known as Pascal’s Law and forms the basis of all hydraulic systems.

Despite Pascal’s discovery, forklifts as we know them today did not develop until well after the start of the Industrial Revolution. World War I triggered their invention due to sheer practical necessity. Facing manpower shortages, a couple of American companies invented mechanized lifting trucks to facilitate their operations around 1917. At first, these machines were little more than tractors with attachments; nevertheless, curious customers began taking notice of them. One company named Clark began selling these machines (known originally as "Tructractors") as other companies started placing orders for them. In 1923, a company called Yale & Towne added forks and a mast that could exceed the height of the truck to this invention. Thus, Yale is typically credited with inventing the first true forklift.

One factor that spurred the increasing production of forklifts was the creation of the standardized pallet in the 1930s. Another factor, ironically, was World War II. In the same way that the First World War triggered the creation of the forklift, the Second World War accelerated the development of the forklift as armies worldwide scrambled for ways to effectively transport staggering amounts of material.

In the decades following 1945, forklifts continued to gain new features and popularity. The 1950s saw significant developments in forklift design, including the use of battery power, designs for maneuverability in narrow spaces, increased vertical lifting capabilities, and safety cages to protect operators. Some significant developments of the latter decades (particularly the 1960s-1980s) included overall improvements in electronic controls and balancing capabilities. Average yearly sales of a million forklifts across the globe testify to the importance of this machine in manufacturing today.

Forklift Design

As indicated earlier, hydraulic systems are used for lifting power in most forklifts (although some companies today have developed electric actuator controlled lifts). These machines harness the pressure transfer described in Pascal’s Law to power virtually all aspects of their moving and lifting operations. Hydraulic power has been combined with forklifts since shortly after the First World War – or, in other words, almost from the beginning of their invention.

Since hydraulic principles only apply to incompressible fluids, forklifts run by necessity on incompressible substances such as oil. More specifically, forklifts run on the power caused by moving oil as it is forcefully transmitted from one "container" to another by some sort of tubing or connecting system. The initial "container" is usually a type of reservoir (known as a "sump") located in the frame or base of the vehicle. A pump, usually consisting of twin rotating gears, ejects oil from the reservoir (contrary to the direction of their rotation) before redirecting the oil to a control valve. This control valve then further redirects the oil to the appropriate set of sealed tubes, or cylinders, that are typically connected to pistons and actually responsible for motion. (A forklift typically has two separate sets of pumps and corresponding cylinders, for both steering and moving/lifting functions.) The pressure of oil flowing hydraulically into the cylinder causes the cylinder to move. Energy is lost in this system as heat (due to resistance from various connections), but whatever energy loss occurs obviously does not disrupt the overall function of the hydraulic system.

A major benefit of hydraulic systems is the ease of modifying their power. This ease is due to the mechanical engineering concept of "trading force for distance." When the size of one "container" in a hydraulic system is changed (which in this case means changing the size of the cylinder/piston combination), it also proportionally changes the force in the overall system. For example, if a "container" on the receiving end of a hydraulic system is three times bigger than the original "container", it will multiply the force transmitted to it from the original container by three. Thus, modifying the different hydraulic components inside a forklift can result in vastly different combinations of moving power.

Forklift Images, Diagrams and Visual Concepts

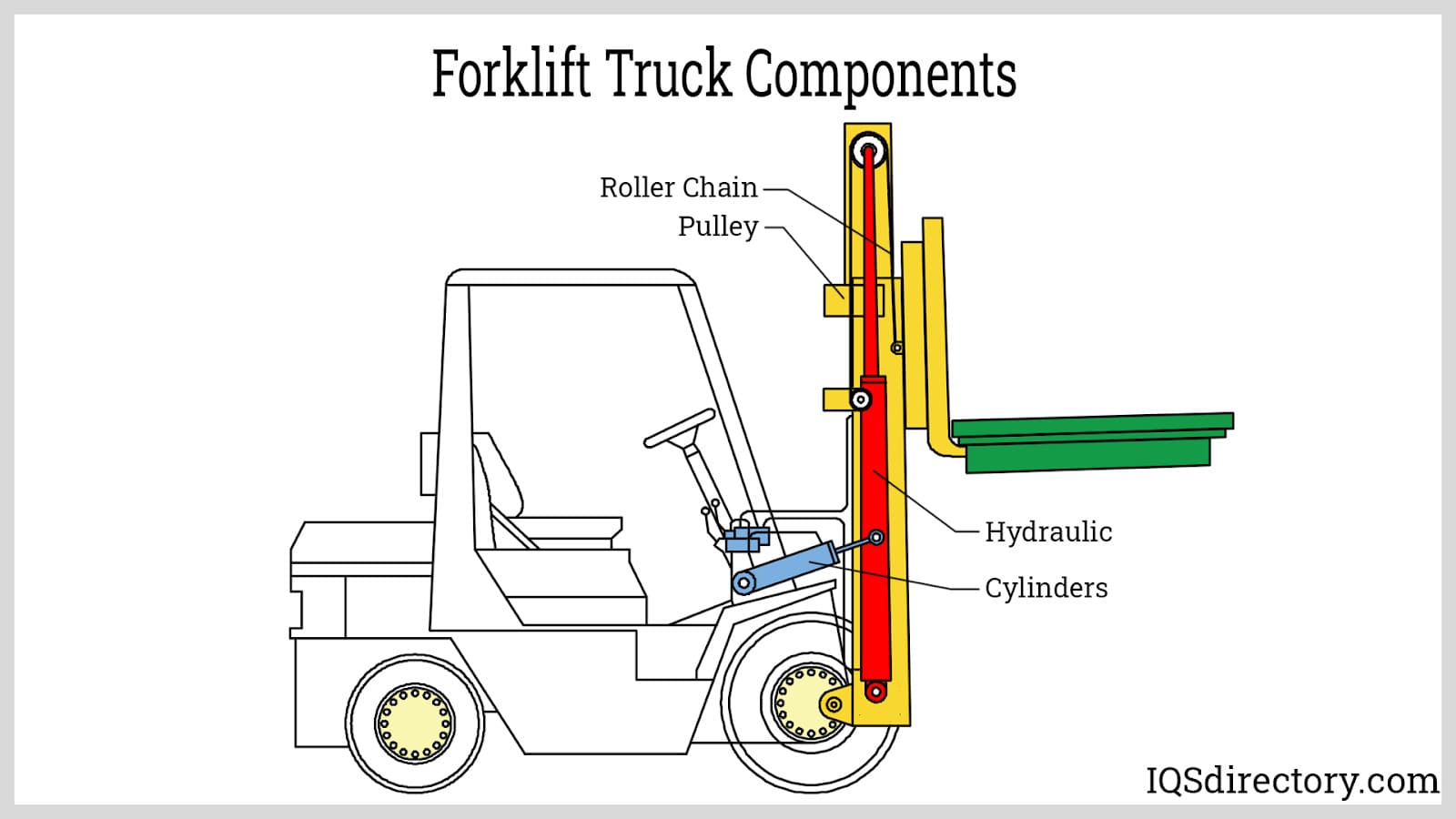

Forklift truck, an electrical or gas powered industrial equipment with a metal fork platform attached to its front to lift heavy loads.

Forklift truck, an electrical or gas powered industrial equipment with a metal fork platform attached to its front to lift heavy loads.

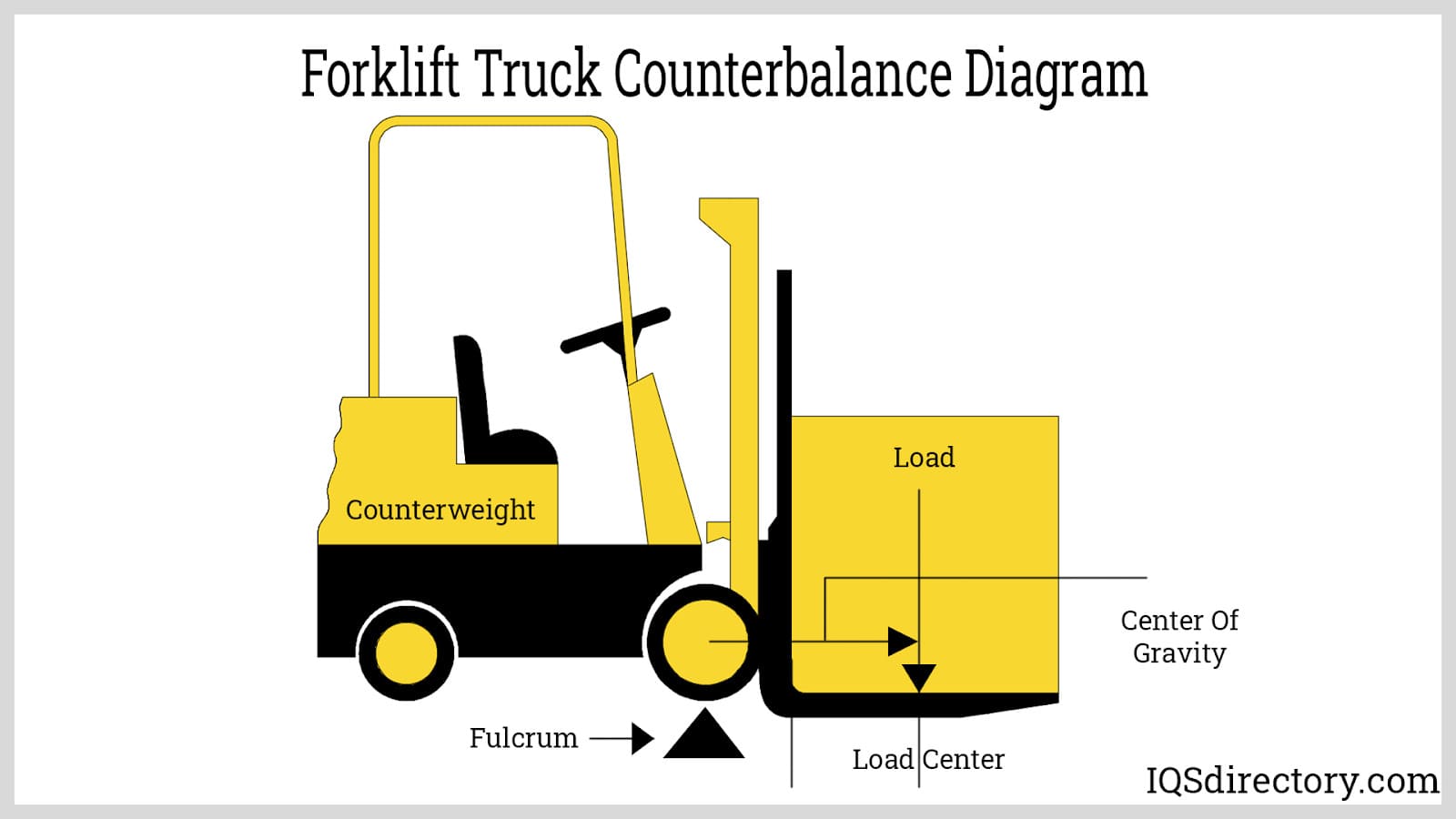

Counterweight is attached to the rear of the forklift to counterbalance the lifted load.

Counterweight is attached to the rear of the forklift to counterbalance the lifted load.

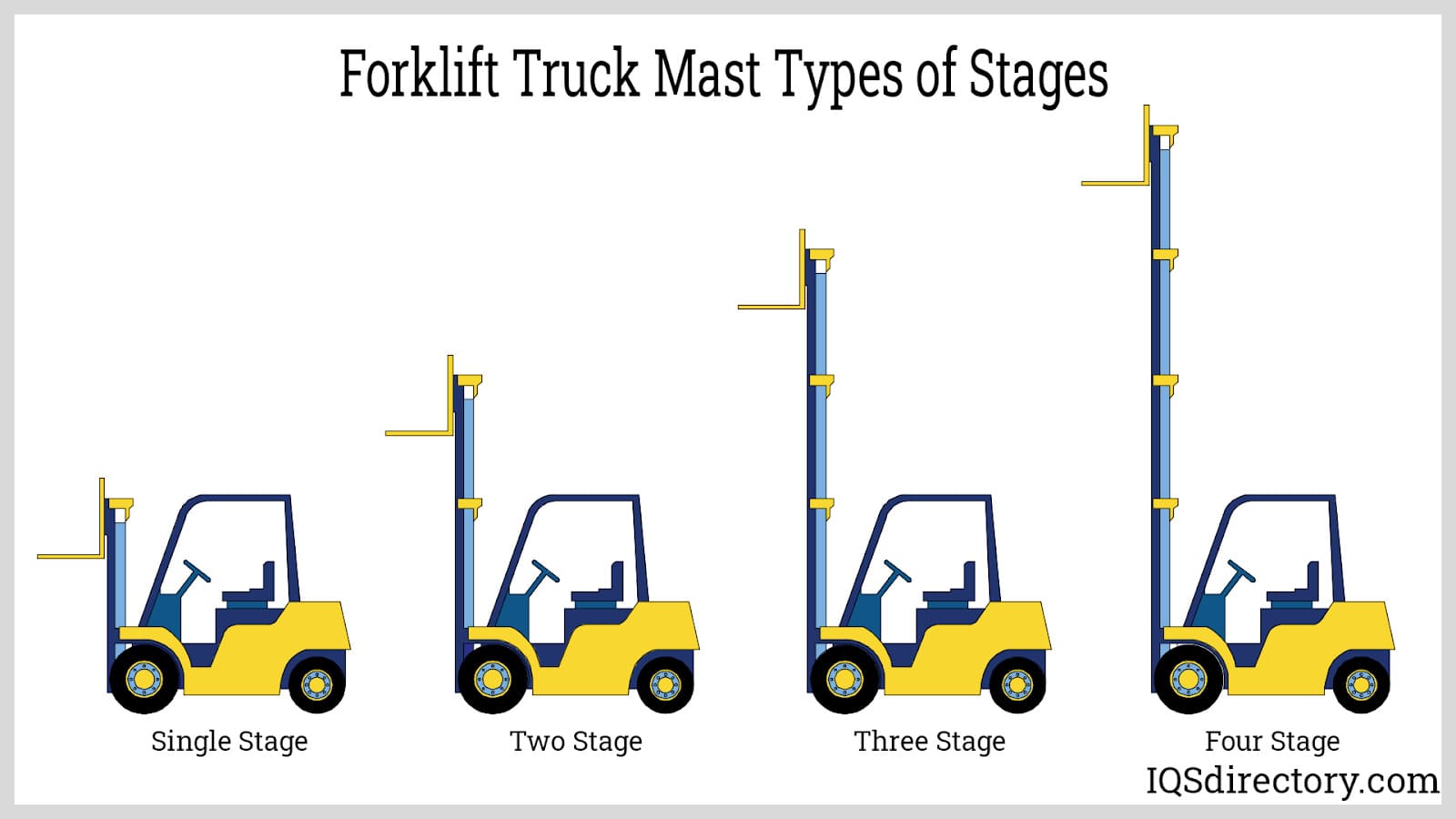

The mast of a forklift truck, is the vertical assembly that raises and lowers loads and includes interlocking rails for lateral stability with rollers or bushings as guides.

The mast of a forklift truck, is the vertical assembly that raises and lowers loads and includes interlocking rails for lateral stability with rollers or bushings as guides.

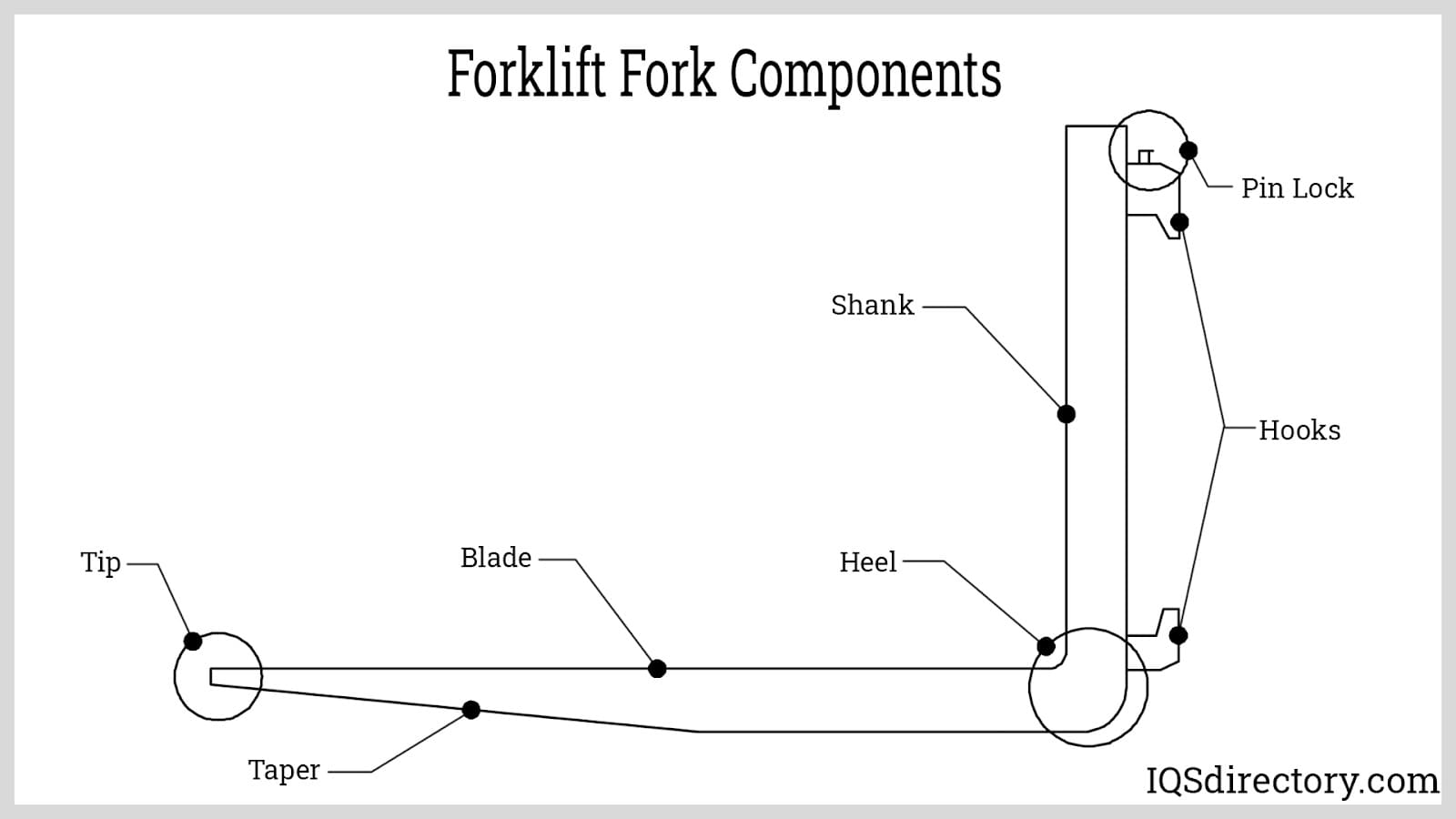

The forks make contact with the load, the dimensions and conditions of the forks guarantees the safe operation and prevents possible damage.

The forks make contact with the load, the dimensions and conditions of the forks guarantees the safe operation and prevents possible damage.

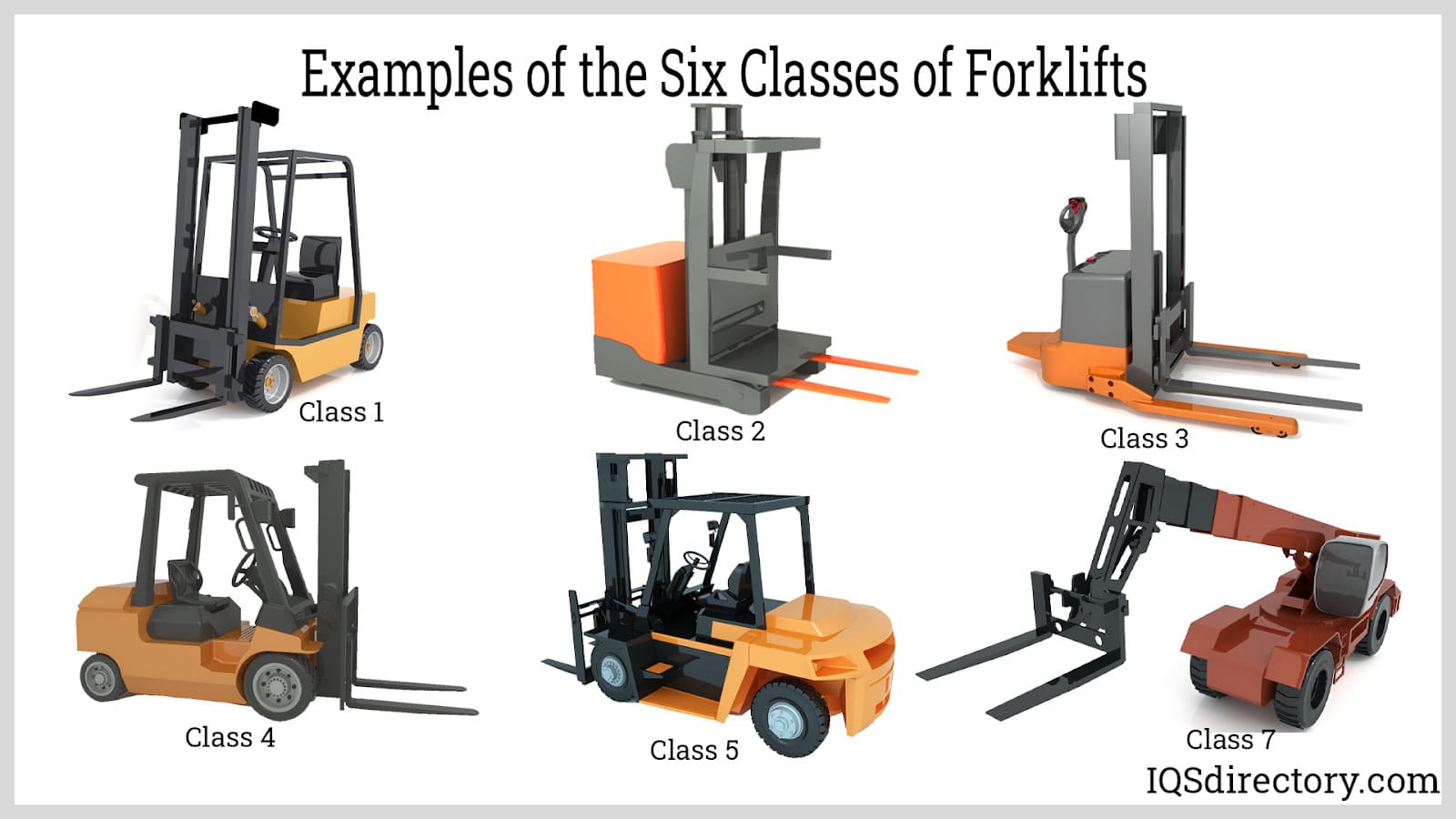

Forklift trucks are grouped according to their size, weight limit, operational terrain, and power supply, which each classification requires operators to be certified.

Forklift trucks are grouped according to their size, weight limit, operational terrain, and power supply, which each classification requires operators to be certified.

A stand up forklift truck where the operator frequently leaves to load and unload items.

A stand up forklift truck where the operator frequently leaves to load and unload items.

Forklift trucks are designed to safely and efficiently lift heavy loads.

Forklift trucks are designed to safely and efficiently lift heavy loads.

Types of Forklifts

Manufacturers divide their products into specific classes of design and capacity. These classes primarily depend on the type of engine and tires that are used. Some other factors in the classification of forklifts include the nature of counterbalance in the vehicle. Counterbalancing uses specifically placed weights to prevent the lift from toppling over under the weight of a load. This method is far more convenient than the other alternative of placing supports under the loads.

Major Classes of Forklifts

Altogether, forklifts appear in a total of seven classes:

- Electric motor riders (Class 1)

- They are rider trucks, either stand-up operator or seated three-wheel units, with an electric motor. They usually are counterbalanced with cushion or pneumatic wheels.

- Electric Motor Narrow Aisle (Class 2)

- They are electric motor vehicles used in narrow aisle or inventory stock picking functions and may include extra reach or swing mast options.

- Electric Hand Riders (Class 3)

- They are vehicles with a walk-behind or standing rider controller and have electric motors. They are commonly automated pallet lift trucks and high lift models, and are usually offset.

- Internal Combustion Forklifts with Cushion Tires (Class 4)

- They are vehicles with cabs and seated controls for a rider, and they have internal combustion engines.

- Internal Combustion Forklifts with Pneumatic Tires (Class 5)

- They forklifts are rider fork vehicles that feature cabs and seated controls and have internal combustion engines. They are usually equipped with pneumatic tires. They are often counterbalanced.

- Electric and Internal Combustion Engine Tractors (Class 6)

- Rough Terrain Forklifts (Class 7)

Different classes of forklifts are better suited for different applications. Rough terrain forklifts, for example, possess large tires and enhanced reaching capabilities to operate in environments such as construction sites.

Parts of a Forklift

A common theme in the subject of forklifts is variety. There are many different types of forklifts that can be used for a wide range of different applications. Despite this, there is a common set of features that most forklifts share. These forklift parts include the frame, power source, mast, carriage (containing the forks and load back-rest), counterweight, and a place for the operator to control the vehicle from.

The frame is the actual base of the forklift. Frames often have tilting and rotating capabilities to increase the vehicles' overall maneuverability and efficiency. Frames do not simply form the structural backbone of the vehicle; it also acts as a cooling system and absorbs heat generated by energy lost within the vehicle’s hydraulic system.

- Power Source

- Forklifts are constructed with either internal combustion engines or electric motors. Gasoline, compressed natural gas, diesel, liquid propane, and batteries are commonly used to power forklifts. Internal combustion engines are typically located in a compartment underneath the operator’s seat; the major exception consists of propane engines, which are usually mounted externally. Forklifts running on a hybrid power source (specifically diesel and a lithium ion battery) is a recent development.

- Cab Enclosure

- Most forklifts possess an enclosed cab area where a seated operator can control the vehicle with a set of controls. The steering wheel in this area usually controls the rear wheels of the forklift (for better control precision), and sometimes possesses a type of knob that enables faster turns. This cab area almost always has an overhead guard to protect an operator from falling objects. Some forklifts are stand up types, where the driver must remain standing while operating the truck.

- Mast

- The upright piece of a forklift (usually at the front) that is responsible for vertical motion. It is the hydraulically-controlled component which actually raises and lowers the carriage and forks. It is composed of connected rails with channels between them known as "stages." Masts come in varieties possessing one to four stages, with each additional stage providing a greater amount of lifting power. The mast is an important forklift component since a common forklift task is reaching high warehouse shelves to load or unload various types of material. Three stage masts are the most common type of mast found on forklifts.

- Carriage

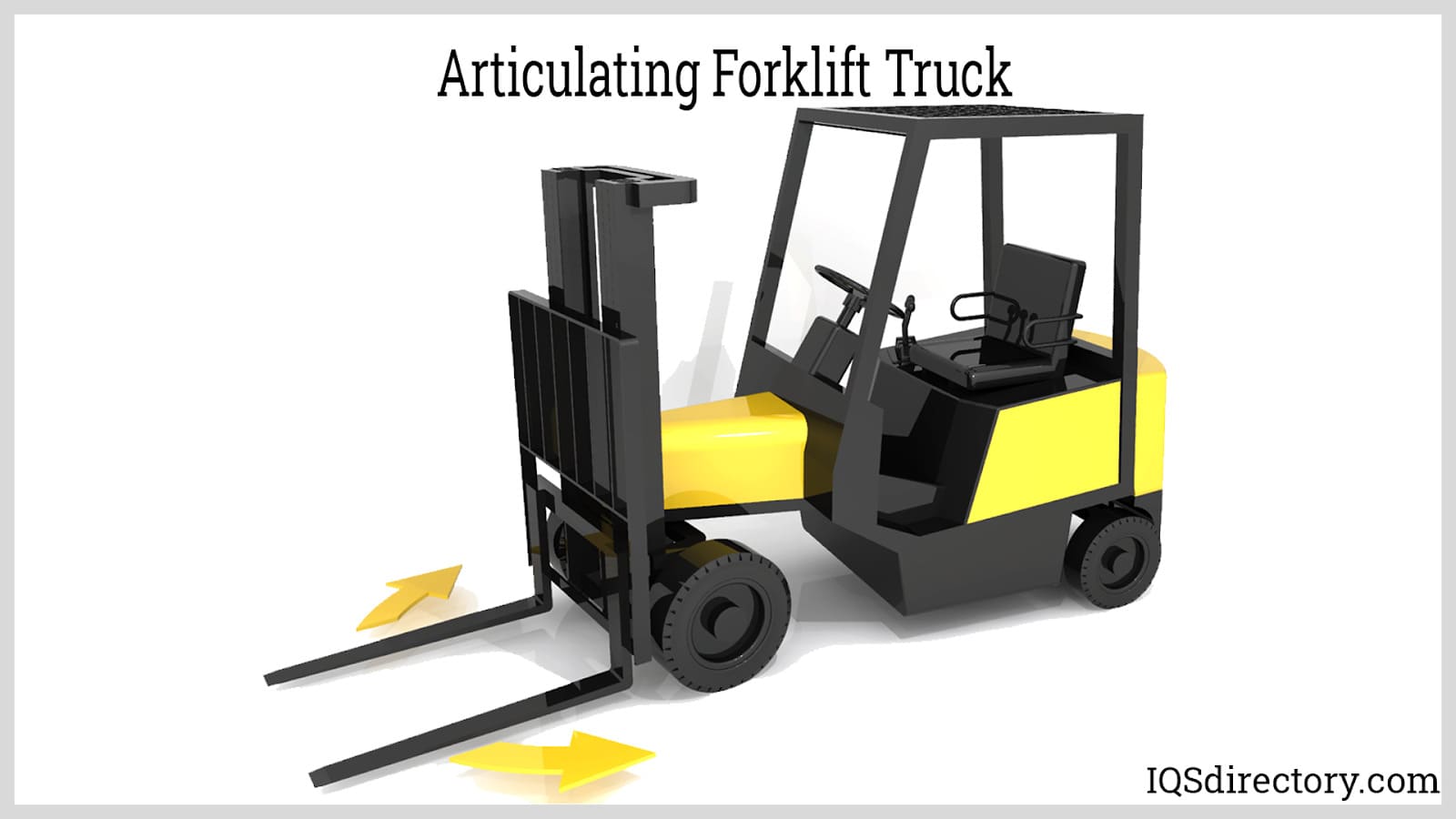

- Denotes the piece that is mounted into the mast and connects it to the actual lifting attachments (e.g. forks). (Sometimes the term carriage is used to signify any frontal part of the forklift that directly contacts loads.) Like the mast, the carriage is usually located at the front of the forklift; the main exception is found in the case of side-loaders in which the lifting mechanism extends from the side rather than the front or back. From this position, the carriage can be controlled by the mast and raised or lowered to handle loads. Various controls inside the cab (the side shift lever, the tilt lever) are able to move the carriage horizontally or change its angle. The carriage is critical for use in heavy duty applications and scenarios in which there is not much space to maneuver. For extremely heavy loads, reinforced stabilizing bars can be used to provide extra support for the safe raising and lowering of loads.

- Forks (Tynes)

- Some of the most identifiable and fundamental features of a forklift – are the elongated parts of the carriage intended to carry loads from the bottom. They are highly variable in relation to their intended use. The most common types of forks are standard ITA versions. Some examples of forks designed for specific uses are pallet truck forks, which have specific dimensions to fit a wide variety of standard pallet designs; and double extended forks, which can be attached to reach trucks for deep reaching applications. A forklift’s tilt cylinder (controlled by the tilt lever) is able to further modify forks for different uses by changing their angle. Some forklifts have safety rails installed around the lifting fork to minimize the risk of a load sliding or falling off.

- Load Back Rest

- The rear portion of the lifting platform that is attached to the carriage and used to stabilize loads during transport.

- Counterweight

- A solid piece used for offsetting a forklift’s load and maintaining balance and stability. It is often located at the rear of the forklift. In electric forklift trucks, the battery typically functions as the counterweight.

- Wheels

- Divided into two basic classes: pneumatic tires and cushion tires. Pneumatic tires are rubber tires which resemble, to an extent, normal automobile tires. They give load vibration padding and allow for increased traction and a more comfortable ride for the operator. Pneumatic tires are commonly used in outdoor settings. Cushion tires, on the other hand, are solid rubber tires that do not need air inflation; as a result, they puncture less easily and require significantly less monitoring and maintenance than pneumatic tires. Cushion tires can be used in some outdoor applications (especially where the terrain is smooth, like asphalt); however, they are more generally intended for indoor environments, which tend to have hard, flat surfaces. Both types of wheels can be fitted with stabilizing outriggers.

- Safety Features

- Such as flashing lights or audible sirens, are common features which help keep co-workers aware of the vehicles' movement and presence in order to avoid injury and product loss. Some typical safety features are invisible; one example is the relief valve, which detects and defuses excessive cylinder pressure by opening and draining oil back into the reservoir (or sump).

Where Forklifts are Used

Almost every industry which handles heavy items and large quantities of materials or goods utilizes industrial trucks or pallet trucks. Using a forklift in most industrial or commercial situations improves storage potential, reduces risk of injury and cuts stocking time. Forklifts are used in both indoor and outdoor applications and can be designed to meet a number of specific requirements. They are particularly useful in storerooms, construction sites and loading docks where efficiency is improved by the addition of mechanical power. Forklifts also enable a facility owner to maximize vertical storage space by enabling loads to be stacked as high as the lift trucks can reach.

Other Forklift Types

A wide range of other forklift types exist among the various classes:

- Side-loaders

- Used for heavy duty applications.

- Reach trucks or Order Picker Trucks

- Warehouse forklifts used to access high shelves containing products and equipment.

- Pallet Trucks

- A type of lift truck designed specifically for the lifting of loaded pallets.

- Indoor Walkie Forklifts

- Electric forklifts which are designed for inside use on smooth concrete.

- Straddle Trucks

- A type of forklift which have wider bases in order to lift a heavy load higher than normal forklifts can.

- Turret Forklift Trucks

- Can rotate a high load up to a 90-degree angle.

- Platform Trucks

- A material handling vehicle composed of a simple wheeled flat bed with either a bar handle for manual transportation or a motor, steering wheel and seat. Although not technically lift trucks, platform trucks are used in applications similar to forklift trucks to handle material transportation.

- Automated Forklifts

- A relatively recent innovation that appear primarily in a striking range of industries (e.g. aerospace, automotive, manufacturing, etc.) They function independently of human operators with sophisticated guidance systems.

- Manual Drive Forklifts

- Manually move the load and are controlled by a person walking behind the lift.

- Motorized Drive Forklifts

- Include a cab or seat for the driver to operate the vehicle while riding in it. This is useful for larger travel distances.

Forklifts can generally be enhanced with various accessories to accomplish different functions. For example, forklifts can be customized with attachments able to move barrels instead of pallets.

How to Use a Forklift

While forklifts are immensely useful in a wide range of commercial applications, they pose many inherent safety risks. Negligence could result in serious accidents or equipment damage from collisions or the tipping over of lifting machines. Thus, safety around forklifts (and similar load handling equipment) is an imperative element of a work environment such as a manufacturing or construction facility. The following sections only sketch a high-level overview of proper practices for using a forklift. Operators must receive proper training and certification before they can regularly use a forklift in a work environment.

- Forklift Safety

- Begins with proper preparation. Before the engine is even turned on, critical components of the forklift such as fluid levels, hydraulic tubing (hoses, connectors, etc.), tires, and forks should be inspected for wear or other signs of damage. Once the engine is turned on, other components such as various controls (e.g. tilt lever, lift lever), warning lights, and alarm systems should be tested. When getting into a forklift, you should grab the appropriate holds and pull or slide your body into the vehicle (as opposed to jumping or simply stepping). You should never operate a forklift from an area of the vehicle other than the one approved by the official operating manual.

- Inexperienced forklift operators often mistakenly assume that driving a forklift is practically identical to driving a car. While obvious similarities exist, less obvious but crucial differences also exist (e.g. the fact that forklifts are primarily powered by their rear wheels). To ensure safe travel, forklift operators should take full advantage of machine aids such as rearview or concave mirrors and headlights. Some other actions facilities can take to make forklift travel safer include the use of spotters, physical barriers, and color-coded zones for machine and pedestrian travel.

- Visibility and Caution in Forklift Operation

- Paramount when traveling in a forklift. Changing direction or momentum can be particularly tricky. Best practices include:

- Making slow, sweeping turns.

- Cutting inside when turning (to offset the rear’s tendency to swing out in the opposite direction).

- Looking behind you when reversing.

- Making smooth braking motions (as opposed to sudden or choppy).

- Not turning with raised forks.

- Not turning on grades or inclines (no matter how small).

- Forklift Load Capacity

- One fundamental rule of forklift safety is not carrying a load over maximum carrying capacity. Never carry a load over the maximum carrying capacity. It is critical to note that this capacity is calculated assuming that all loads on the machine are centered. Thus, always make sure that loads are properly aligned and secured on the forks before and during transportation. When handling or transporting loads with a forklift, practice these rules of thumb:

- Approach a load with caution. Preferably, you should stop at least a foot in front of the load before advancing slowly to it.

- Do not move the forks unless the forklift is completely stopped.

- Make sure that forks are level, spread as widely as possible, and inserted underneath a load as far as possible (at least two-thirds of the way) when picking up any material.

- Do not remove the load back rest for any reason. If a load does become destabilized, tilt the carriage back to take advantage of the back rest’s stabilizing function.

- Carry loads at a low height.

- Do not tilt a loaded carriage forward.

- If a load blocks your vision, travel in reverse to preserve visibility.

- When raising loads, check to make sure you have sufficient overhead clearance.

- Pedestrian Safety

- Avoiding pedestrian collisions is a major facet of forklift safety, especially since forklifts commonly operate in fast-paced manufacturing environments. The following guidelines can help to reduce these type of incidents:

- Use physical and human aids described above (spotters, color-coded zones) to warn pedestrians of forklift traffic and preempt collisions.

- Keep in mind that not everyone in a forklift environment is equally familiar with the way a forklift works.

- Consider the noise level in your work environment and act accordingly. Even with experienced forklift operators, excessive noise can be an obstacle to hearing appropriate forklift alarms.

Things to Consider When Purchasing a Forklift

Forklifts are some of the most fundamental pieces of equipment in the manufacturing world. At the same time, high-quality forklifts tend to be very expensive (especially when bought new) while also being highly variable. This variableness can cause difficulty for companies who own multiple production facilities geared for different purposes – and thus require multiple forklifts for multiple purposes.

- Communication With the Manufacturer

- Clear communication with your forklift manufacturer or forklift supplier is essential for using forklifts to their full potential. Customers must be detailed about the specific applications they require forklifts for, and good suppliers must possess the knowledge and patience to find the forklifts that will best meet your specific needs. Your forklift’s performance is directly affected by a variety of factors which will determine the added value of a forklift truck to a specific application.

- Some factors to consider and discuss when exploring forklifts options are:

- Vertical lift travel (the height to which a forklift or reach truck can extend).

- Lift capacity (the largest weight capable of being handled by the lift).

- The type of mast required (directly related to vertical lift capacity).

- The nature of the material the forklift will handle.

- The type of forks required (e.g. standard ITA or custom).

- The environment the forklift will operate in (e.g. indoors vs outdoor environments, surface types).

- The estimated time of regular forklift usage (e.g. hours per day, hours per week).

- Forklift Options

- The following examples simply underscore the necessity of choosing the right forklift for the right application:

- In compact warehouses, it is best to use narrow aisle forklifts which are designed to maneuver in small spaces.

- In scenarios where refueling needs to be quick, forklifts powered by fossil fuels (especially propane) work best.

- Electrically powered forklifts are preferable for a number of different applications, such as the preservation of air quality. With new stricter emission standards in facilities and tendencies to outlast internal combustion forklifts, electric forklifts are frequently chosen over fuel or gas powered vehicles.

- Customization for Forklifts

- Keep in mind that forklifts are often adaptable to specific purposes. Customizable forklift equipment – such as sweeping, plowing, or even boom crane attachments -- can increase a forklift’s value by enabling it to perform functions other than straightforward material transport.

- Proper Maintenance Schedule

- To maximize forklift usage, it is imperative to maintain a proper maintenance schedule. Some forklift manufacturers and other forklift centers may enable you to save not only up front by offering used forklifts for sale, but also over the long term through routine forklift services that extend the lifespan of the vehicle.

Forklift Terms

- ANSI B56.1

- American Society of Mechanical Engineers (ASME) standard of safety for low-lift and high-lift trucks, approved by the American National Standards Institute (ANSI).

- Axle Weight

- The distribution of the load to the wheel axles in a weighed down or unloaded condition.

- Baseleg Opening

- Measurement between the inside of the baselegs, from the narrowest point.

- Batching

- A compilation of several orders zoned for optimum pick rate, which are sorted at a centralized location.

- Bi-Directional

- The term given to a vehicle, which is equipped for forward and reverse travel.

- Carriage

- A support structure for forks or attachments, generally roller mounted, which travels vertically within the mast of a fork truck.

- Carts

- Used to hold or transport items selected to fill an order condition, often customized to meet particular needs.

- Carton Clamp

- Hydraulic operated blade attachment that is fitted to forklift trucks and allows handling of cartons without the use of pallets.

- Deck

- One or more boards comprising the top or bottom exterior of a pallet.

- Drivers Cabin

- Protects the driver of a forklift truck from weather conditions when outdoors or in a cooler or freezer or falling elements indoors.

- Dwell Time

- Total stop time spent at pick front.

- Forks

- Horizontal projections suspended from the carriage to support loads.

- Load Center Horizontal

- The distance, horizontally, from the fork face and fork heel intersection, to the center of gravity of the load.

- Load Center Vertical

- The distance, vertically, from the carrying surface of the fork to the center of gravity of the load.

- Load Wheel

- Referring to reach and straddle trucks, those wheels that are located in the baselegs.

- Lowering Speed

- The velocity in FPM of the lowering load carriage in its operating range, for loaded and empty conditions.

- Module

- The device or container objects are deposited in or on by the one who picks.

- Outside Turning Radius

- Half the diameter of a circle made by the outermost projection of the truck.

- Pallet

- A carrying structure to support loads with stringers and decks with openings to allow pick up by a fork truck.

- Pick

- The process of locating, counting and retrieving an item for transportation to another area or for customer retrieval.

- Rail

- Part of a larger side guidance system used for forklift trucks. It also absorbs vehicle weights.

- Reverse Steer

- A steering option resulting in the vehicle turning to the right when the steering wheel is turned counterclockwise and the operator is facing opposite the direction of the forks.

- Sideshift

- A very common lift truck attachment. The sideshift device allows the fork carriage to slide left and right to allow more precise placement of a cargo.

- Skid

- A pallet having no bottom deck.

- Stringer

- Continuous, longitudinal, solid or notched beam section of the pallet used to support deck components, often recognized by location as the outside or center stringer.

- Underwriters Laboratory Listing (UL)

- A list of truck models that is used by insurance companies to determine the rates for coverage. The Underwriter's Laboratories is an independent testing agency.

- Wheel Loading

- The measurement of the effect the truck axle loading has on the floor it operates on. The two types of it are: Force (concentrated reaction per tire, in pounds, exerted by wheel on the floor) and P.S.I. (the wheel loading, in pounds, divided by the wheel contact area in square inches).