Die Castings

Die casting is a metal forming process in which molten metal is forced into mold cavities under high pressure and then cooled in order to form solid metal parts. Facilities where die castings are made are referred to as foundries. Die cast products are typically made from non-ferrous metal castings such as zinc, aluminum, copper, magnesium, lead, tin, bronze, and some alloys; alloy tool steels may be formed through die casting as well, although the preferred fabrication method for steel parts is forging.

For many years, die castings have presented a cost-effective and highly versatile alternative to other metal shaping methods such as forging and hand tooling. Die casting designs are capable of reaching much closer tolerances and far more complex shapes than forgings or stamped metals while requiring minimal secondary tooling and processing. Die casters can manufacture large quantities of aluminum die castings, zinc die castings, and other metal castings with exceptional detail, surface quality, and dimensional consistency at relatively low costs. Die castings are manufactured by hot chamber or cold chamber die casting under carefully controlled pressures. The demand for die castings, particularly automotive castings and other castings used in industrial products, is very high throughout the world.

Many manufacturing industries use die cast parts both in their products and equipment. Since the advent of cost-effective plastic formation processes like vacuum forming and injection molding, the prominence of die cast metal shapes has diminished somewhat. For example, store cash register housings used to be made almost exclusively of die cast metal. Today, almost all cash registers are made of molded plastic. Despite this shift, the number of industrial, commercial, and consumer utilities that are products of die casting is too large to be accurately counted. Parts that require the strength of metal still use whole die cast parts, such as gumball machine bases, sink faucets, gas pump handles, and a wide range of other metal parts. Computer and electronics industries use high tolerance magnesium die castings as housings and interior EMI enclosures as well as miniature die cast parts for various electronic equipment applications. In the automotive industry, almost every engine block is a die cast product. Die cast aluminum valve covers are also commonly applied in automobile engines. Cast zinc products are also widely used as door and cabinet handles.

Every die cast metal part is formed in a die. Dies are also sometimes called molds, and every mold is specially designed for shaping metal in a certain way. For closed die castings, which make up the majority of castings, the mold is cut into two separate metal blocks; in order to form a complete mold, the tooled blocks are placed together with cavities aligned. Once the die has been created, it is sprayed with a lubricant that helps control its temperature and assists in part removal once the cast is complete. The die is then closed, and molten metal is poured into the shot sleeve and injected into the die under high pressure by a plunger. Pressure is maintained within the die until the cast has solidified, then the die is opened and ejector pins push out the solidified "shot.” This metal piece is considered a shot until the excess material that has solidified around it during casting is removed. This excess material typically consists of sprue, gate, runners, and flash that have formed in channels leading to the die mold and possibly in leakage areas between the mold cavities. The cast part is tooled and deburred to remove this excess and is sometimes put through additional secondary processes such as surface finishing, plating, and CNC machining.

Die casting is a high volume, low cost means of forming relatively complex metal parts. Because this forming method does not create a uniform molecular structure or grainflow in the same way that forging and extruding processes do, die cast parts do not have high strength and often have microfractures and grainflow inconsistencies that can lead to part failure or breakage under strain, corrosion, or heat stress. For this reason, die cast parts are often heat-treated and carefully tested after manufacturing. There are some cases in which a die cast metal part is less appropriate for a task than a forging is. Consistently though, die castings can be applied and relied on for their strength and durability if installed and maintained correctly. It is also important to carefully pair the correct die casting with its application; choosing the wrong metal for a die casting application can be catastrophic, particularly when it comes to engines and heavy machinery. A combination of careful design, materials selection, installation, and maintenance will ensure the continued reliable operation of a die cast part for many years.

Quick links to Die Casting Information

Advantages of Die Casting

Die casting is a popular method of metal part manufacturing. In this process, liquefied metal is used for creating a perfectly molded cavity. The melted metal is poured into the die (mold) that has the exact shape and size that the manufacturer wants the casting to have. With this method, metal parts in bulk numbers can be created with great accuracy.

There are many benefits to the die casting metal process:

- No Delays in Production

- The process does not take much time to complete. The molten metal is forced into the die. Then, it is allowed to cool down. As the metal solidifies, the two parts of the die are separated to take out the hardened casting. No matter how big the order from your client is or how sophisticated its design is, with the die casting method, you can efficiently meet production and delivery deadlines.

- Cost-Effective

- Most die casting manufacturers have a large number of reusable dies, which they use in their production repeatedly. Unlike the injection molding process, the dies are not discarded after use. This is the reason why products manufactured through the die casting process are more economical than the products made using other metal parts manufacturing methods. In addition to this, the die casting process does not require the deployment of machines. Sometimes, machines can be used, but only for injecting the molten metal and clamping the sections of the dies. Reusability of dies and fewer or no requirements of machines help manufacturers keep costs down.

- Versatility in Design

- You can form a die of a desired shape and size and use it to produce metal castings as demanded by your client. Most of the time, dies are created in two sections; however, sometimes, dies can be of three to four sections. An intelligent designer can create a variety of designs, and there is no limit to it.

- Complexity Becomes Convenient

- Die casting is a simple method, but it can be used to produce complex shapes easily and conveniently.

- Durable Parts

- Through the die casting manufacturing process, parts with higher strength can be created. While the metal is in the liquid state, some add-ons can be introduced (such as a stronger metal or alloy) to increase the strength and durability of the casting.

- Metal Parts with Visual Appeal

- Your designers can design a resourceful die to create parts of nice visual appeal. Other metal manufacturing processes may not be able to offer the precision in design that die casting does.

- Multiple Finishing Techniques

- As mentioned earlier, with the die casting method, parts can be produced with smooth or textured surfaces. You can apply desired finishing on the surface of the casting to suit the application requirement.

- Dimensional Accuracy

- Die castings are made from thoroughly-designed dies. This helps the manufacturers to achieve dimensional accuracy in the product. The parts have the exact measurement asked for by the client.

Die casting parts are durable and resistant to wear and tear. They also have great heat resistance in addition to better finishing and surface strength.

Products Produced by Die Casting

Because die casting can produce well defined metal parts with no need for further detailing after casting, the range of industrial, commercial, and consumer products produced by this process is very wide. Any non-ferrous metal product can be created with the computer numerical control or CNC machining process to ensure a highly detailed, durable end result, and the sheer amount of products produced in this way reflect that fact. From products as basic as a door handle to those as delicate as the counterweight in a top of the line speedometer, the precision allowed by die casting machines provides a fail-proof way to consistently produce quality metal goods whose solid build and quality detailing far outweigh any tooling cost sustained. Specific examples of products produced by die casting include air valves, engine cooling fans, camera housings, air conditioner components, and even the bezels of most designer watches.

History of Die Casting

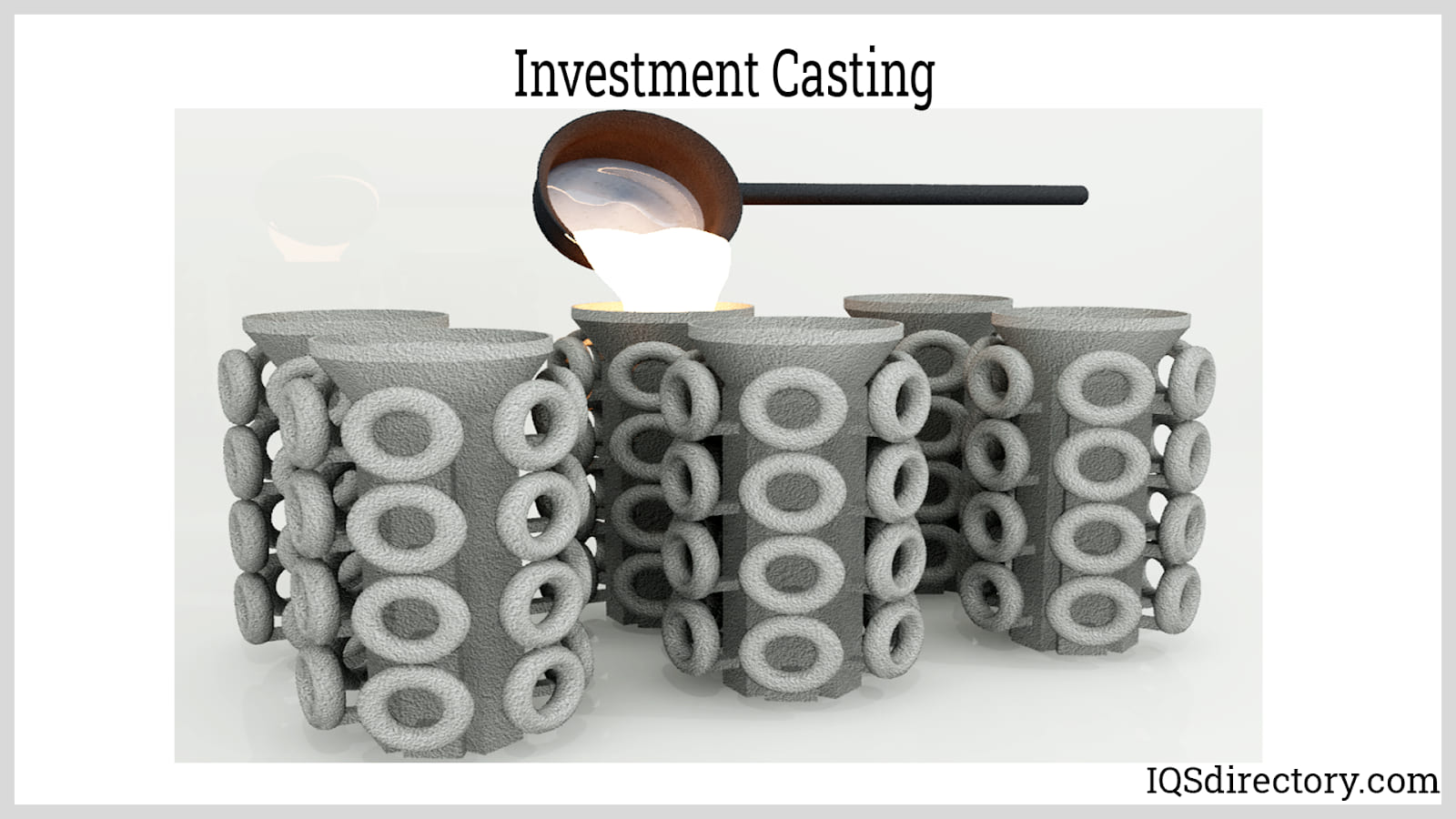

While a process known as investment casting (in which hot wax in a ceramic casing is melted, leaving a ceramic cast behind) has been around for thousands of years, the modern die casting process was first invented in 1838 for the purpose of providing movable type for printing presses, and a small, handheld device that mechanized the printing industry was patented in 1949. In 1885, Otto Mergenthaler invented the closest precursor to the modern die cast machine, called a linotype, but the machining and process of die casting still revolved very closely around the printing industry. It wasn't until the turn of the new century, in the 1890s, that the broader applications of die casting began to be clearly understood, and there was a sudden variety of shape in the dies created—mass-produced elements like cash registers, phonographs, and frames were now able to be quickly cast without sacrificing quality for quantity.

One of the biggest changes to the die casting process throughout history has been the shift in the metals used. Originally, lead and tin were the primary metals used in any form of die cast, and the malleability of these metals greatly affected their strength-to-weight ratio. Around 1914, zinc and aluminum die castings began to hit the market. This greatly improved the strength of die cast products, and by the 1930's, metals like copper and magnesium were in frequent use. Now, any non-ferrous metal can potentially be used in a die cast, with zinc, aluminum, magnesium, copper, lead, and tin still being the most prevalent metals in use.

As the variety of metals in use has increased, so too has the strength of the machines used to process said metals. In the early days of die casting, the machines used could only function under low pressure in order to consistently produce high-quality products, but such is not the case anymore. High pressure die casts are able to create an extremely high volume of highly-finished products, and the growth of different alloys allows for high quality in markets other than printing or manufacturing—some of the more common include aluminum alloys, copper alloys, and zinc alloys.

Materials Used in Die Casting

As mentioned above, there are several metals that are commonly used in die casting today, with the most common being zinc, aluminum, magnesium, copper, lead, and tin. Each metal has its own advantages and disadvantages, and each is held to strict industry requirements.

- Zinc

- High density and high ductility, with good impact strength and very good surface smoothness, zinc can form very thin or fine parts, and its low melting point means that the cast die will be in use for far longer than dies used for some other metals. Unfortunately, because of zinc's susceptibility to corrosion, it often requires additional coating or plating before use, but it remains the easiest metal to cast, and, therefore, one of the most prevalent.

- Aluminum

- Unlike zinc, aluminum and aluminum alloys are very low density and highly resistant to corrosion. Aluminum is also highly stable and highly conductive, which allows for its prevalence in electrical industries. It is also relatively easy to cast. One of the only disadvantages to the use of aluminum as a metal is that it requires the use of a cold chamber, as opposed to most of the other metals on this list, which can be cast in a hot chamber machine.

- Magnesium

- Magnesium, like aluminum, is extremely low density and has a very high strength-to-weight ratio. Relatively easy to cut, magnesium displays excellent machinability even after it has been cast and processed, and it can be processed in either a hot or cold chamber machine. Unfortunately, magnesium is susceptible to creep or cold flow, making it generally unsuitable for use in very high temperature or high-stress environments, a weakness that is currently being combated with various magnesium alloys as magnesium becomes ever more popular in the worldwide industry.

- Copper

- Copper and copper alloys are extremely tough, extremely strong, and very resistant to corrosion and wear. Highly stable and conductive, one of copper's greatest strengths is also one of its greatest weaknesses, as the very high melting point found in copper and most copper alloys mean that dies and casting chambers used to treat this particular metal tend to have a significantly shorter lifespan than those used to treat various other metals.

- Lead and Tin

- Both high density. Both displaying extremely close dimensional accuracy, lead and tin were some of the first metals used in the die casting process, and are still in use today, albeit not with nearly the same prevalence as before. For public health reasons, lead and tin are not allowed for use in any food service applications, but they are typically used in combination with some of the metals listed above to prevent corrosion.

Process of Die Casting

Most die casting processes are broken down into five basic steps: clamping or preparation, injection, cooling, ejection, and trimming. The whole cycle is extremely fast, often taking less than a minute to complete.

- Clamping (Preparation)

- In the clamping or preparation stage, the mold cavity of the precision die cast is cleaned from the previous injection. Both halves of the permanent mold are treated with a lubricant to ease the ejection process. After preparation, the halves of the mold are firmly clamped together, tightly enough to keep them in place when the hot metal is injected, and the process moves on to the next step: injection.

- Injection

- In the injection stage, molten metal of any of the types listed above is transferred into a chamber from which it will be injected at a very high pressure into the prepared mold. If using a cold chamber machine, the metal will not be pumped into the mold, but rather ladled into the cast from a separately located melting pot. Depending on the thermodynamic properties of the metal used, the time taken in this stage varies, but it is usually extremely short to prevent one part of the filled mold from solidifying before another. Once the molten metal has filled every part of the mold, the next stage in the process begins.

- Cooling

- As soon as it enters the mold cavity, the metal will begin to cool and solidify, and the die cannot be opened until it has done so. Again, the amount of time in this stage will vary based on the properties of the metal as well as on the wall thickness of the mold, but it is still usually a very short amount of time. Once the solidification process is completed, the product is ready to be removed from the mold in the next step: ejection.

- Ejection

- During the ejection stage, the finished casting is removed from the mold, usually by means of an ejecting mechanism, and the mold can be cleaned and re-clamped for another use.

- Trimming

- In the final stage of the die cast process, any irregularities in the casting are removed, often by use of a saw or trimming press, and discarded. The finished product is now complete, and the cycle can begin again.

Design aspects to be considered during the casting process include the complexity of the cast design, which may affect solidification time, and thickness or intricacy of various elements, which may also impact the amount of time the mold will spend in each successive stage.

The casting process can be customized to fit these needs by adjusting the time spent. There are many ways to adjust a specific die to reflect the needs or wishes of the client, as outlined further in the next section.

Die casting is a widely used metal manufacturing process. The method makes it possible for a metal fabrication business to create parts of different size, shape, measurement, strength, and surface finish with great precision. To create metal castings, the first step is to create dies with precise size and shape. This article lists a few tips on designing dies for creating die castings:

- Identify all the parts that can be created easily. If needed, you can use ribs to allow the part to have the maximum possible strength.

- Note all the requirements specified by your client. Ask your designers to be careful with the thin sections; these areas may need strengthening to prevent breakage.

- Usually, dies have two sections. Try to maintain uniformity in sections as much as possible. Any variation in design can directly influence the final casting. Additionally, having uniformity in the sections would help you circumvent unwanted surface tension in the product.

- Unless required, there is no point in making complex designs and shapes. Try to keep the shapes simple. Remember, you have to exclude additions and designs that are unnecessary.

- Make sure the dies have adequate holes or recesses. They will help you save raw materials. The cost of tooling can also be saved this way.

- For convenience, you can include a slight crown above the moveable die section. It will help when removing the clamping from the sections after the molten metal has solidified.

- Ensure that the sections have strategically designed cores. The cores allow easy withdrawal of toughened metal from dies. They also help in avoiding complexities in design and construction. The size of the cores should be adequate to avoid wastage of material.

- The length of the cores should not be too small. Small cores can easily turn or can be damaged while you try to remove sections after the toughening of the metal.

- Some die casting manufacturers prefer creating small holes in die casting. Most of them use drilling machines to make punctures in the casting. It is more convenient and cost-effective than designing cores.

- Ensure sufficient space between the sidewalls and the cores. Ample space allows effortless and safe removal of castings from the die. It also reduces the chances of damage.

- Check for sharp corners inside and outside. However, keep in mind edges and corners are sometimes part of the design.

- Do not forget to add ejector pins in the castings. Ejector pins enable you to remove the casting from the sections. They should be placed strategically and should be a part of the designer. This needs to be done at the design phase because they leave marks on the metal casting. Such marks can make the casting unappealing.

- Last but not least, all the inserts, including ejector pins, edges, and cores should be held firmly in the die casting.

Machinery Used in Die Casting

The main distinction in machinery used during the die casting process is the difference between a hot chamber machine and a cold chamber machine. A hot chamber machine is usually used for high pressure die-casting, as the molten metal will be injected into the chamber at an extremely high pressure and never separated from the machine. A cold chamber machine uses metal that is melted in a separate part of the foundry, and then ladled into the machine once it is ready for the second step in the die cast process.

This machinery can be customized to suit the needs of the customer, as each cast can be specially designed to reflect the customer's needs or design input, and the machines themselves will often reflect specific design alterations. Different manufacturers may wish to adjust the amount of time spent on various stages or the methods of removing or trimming the finished casting.

Variations in Die Casting Process

There are several variations of the casting process, including low-pressure casting, vacuum casting, squeeze die casting, and semi-solid die casting.

- Low-Pressure

- Usually used for aluminum components, low-pressure casting places the metal in a chamber below the mold, then pressurizes it, allowing the molten metal to rise through a tube and into the chamber, creating precise, usually symmetric designs (car wheel casings, for example).

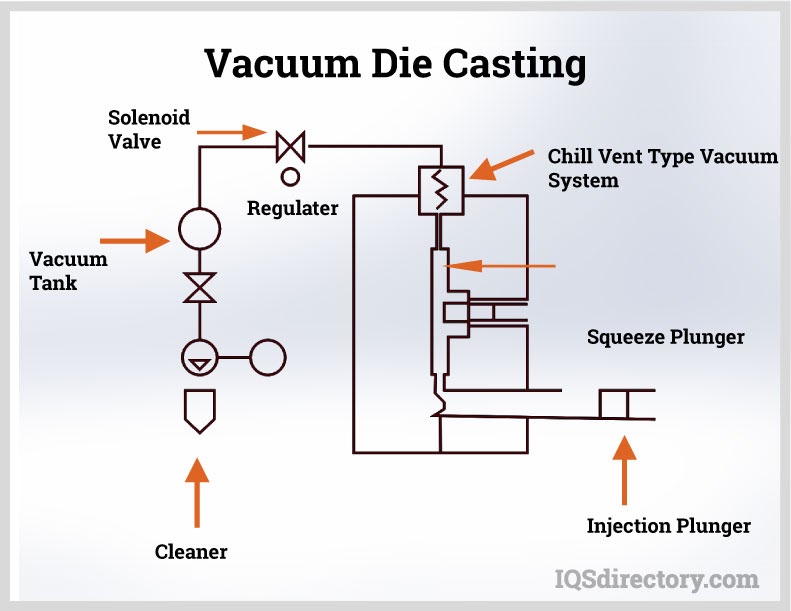

- Vacuum

- Vacuum pressure casting is very similar to the above process, except that it reverses the positions of the chamber of molten metal and the mold or cast to be filled—the metal is forced into the mold cavity via applied vacuum pressure, which reduces any turbulence created by the metal's sudden movement and limits the amounts of gas inclusions.

- Squeeze

- Squeeze casting is usually used for metals with low fluidity, as the metal is poured into an open die. The die is is then squeezed shut, forcing the semi-solid metal into every corner of the closed die and creating an extremely dense product often associated with molten aluminum and aluminum alloys that have a higher level of viscosity.

- Semi-Solid

- Semi-solid die casting cuts a workpiece into several smaller slugs, which are then melted to a somewhat slushy texture before being forced into a mold cavity where they harden. Also called Thixoforming, this process allows for greatly increased precision in the final casting and is often used for magnesium alloys or aluminum and aluminum alloys.

Things to Consider When It Comes to Die Casting

There are several good manufacturers in the industry of die casting. However, it is important to note that there is a distinction between a good manufacturer and the right manufacturer for each client. The right manufacturer will enable the client to get exactly what they need out of the process without adhering too rigidly to their own design or production choices, and thus, will succeed where a perfectly good competitor may fail. The right manufacturer is one who will work directly with the client to ensure they are satisfied with every step of the die casting process used, as well as with the finished product.

Die Casting Images and Illustrations

The die casting process.

The die casting process.

Investment casting a labor intensive process involving shaping of the mold from a wax prototype dipped in liquid ceramic.

Investment casting a labor intensive process involving shaping of the mold from a wax prototype dipped in liquid ceramic.

Pressure is created in the die cavity drawing in the molten metal where it solidifies and is ejected.

Pressure is created in the die cavity drawing in the molten metal where it solidifies and is ejected.

Only high fluidity can be used which influences the types of parts to be produced.

Only high fluidity can be used which influences the types of parts to be produced.

Die Casting Types

- Alloy Castings

- Metal shapes made by a metal formation machine called a caster. Alloys are combinations of at least two metals and sometimes non-metals like carbon and silicon.

- Aluminum Casting

- Die casting made from aluminum.

- Aluminum Die Castings

- Commonly used in the production of hardware and tools because of the great resistance of aluminum castings to corrosion and high temperatures as well as their conductivity. In addition, aluminum castings are used in applications requiring the production of intricate part features and components.

- Automotive Castings

- Include engine blocks and cylinder heads as well as brake and suspension components, are increasingly being manufactured out of lightweight material, such as aluminum, to economize fuel consumption by decreasing the overall weight of the vehicle.

- Brass Castings

- Used in the architecture and construction industries and in decorative applications, such as doorknobs.

- Bronze Castings

- Used in applications requiring high strength, making them ideal for use in the architecture and construction industries.

- Cold Chamber Die Castings

- Cast metals that are formed in a cold chamber as opposed to a hot chamber.

- Copper Die Castings

- Used in applications requiring exceptional strength and resistance to corrosion. Copper castings consist of brass and bronze castings.

- Die Casters

- Shape metal by putting pressure on molten metal in a die.

- Die Casting Design

- The process of planning and deciding the configuration of a die cast product.

- Gravity Die Castings

- Produced by pouring molten aluminum into a metallic tool at a casting temperature of 750º. Gravity die castings have good tolerances and surface finishing.

- High Pressure Die Castings

- Have very thin walls. The metal enters the die cavity at high speeds and under great pressure; this increases the chance of porosity.

- Hot Chamber Die Castings

- Cast metals that are formed in a hot chamber as opposed to a cold chamber.

- Lead Die Castings

- Offer great corrosion resistance and are used in the production of parts in the plumbing industry. Lead castings and tin castings also provide close production tolerances but are generally not as strong as other die cast metals.

- Low Pressure Die Castings

- Formed when metal from an airtight furnace is transferred into a metallic tool through a rising tube. Low pressure die casting is suitable for relatively small lot sizes and for applications in which heat treatment is needed to improve the mechanical properties.

- Magnesium Die Castings

- Particularly useful in applications where weight is a factor. Magnesium die castings are very lightweight and cost-effective.

- Metal Castings

- Metal impressions made with molds.

- Pressure Die Castings

- Metal castings that have been formed under carefully controlled pressure conditions; all die castings can be considered pressure die castings.

- Sand Casting

- Or sand metal casting, is a process using sand as the molding material to produce metal castings. The term is also used to refer to the products produced by this process. Metals cast using the process include tin, cast iron, aluminum and steel, and copper and bronze.

- Zinc Die Castings

- Often used in the production of small parts for the electronics and automotive industries. Zinc castings lend themselves well to secondary operations such as painting and plating.

Die Casting Terms

- Automation

- Industry term commonly used to describe the mechanization of various aspects of the die casting process.

- Biscuit

- An excess of molten metal that is leftover in the shot sleeve of a cold chamber die casting machine. Biscuits are considered part of the cast shot and are removed from the die with the casting.

- Blister

- Die casting deformation consisting of a gaseous bubble on the surface of the casting and a hole in the casting underneath the bubble.

- Blow Holes

- Voids or pores that may occur due to entrapped gas or shrinkage during solidification, usually evident in heavy sections (see porosity).

- Cavity

- The recess or impressions in a die in which the casting is formed.

- Cold Chamber Machine

- A type of die casting machine in which the metal injection mechanism is not submerged in molten metal.

- Checking

- Fine cracks on the surface of a die that produce corresponding raised veins on die casting. Caused by repeated heating of the die surface by injected molten alloys. Also called heat checking.

- Die Lubricants

- Liquid formulations applied to the die to facilitate casting release and prevent soldering.

- Dimensional Stability

- Ability of a component to retain its shape and size over a long period of service.

- Draft

- The taper given to walls, cores, and other parts of the die cavity to permit easy ejection of the casting.

- Ejector Marks

- Marks left on castings by ejector pins.

- Ejector Pins

- A rod that forces the casting out of the die cavity and off of cores.

- Ejector Plate

- A plate that actuates the ejector pins attached to it.

- Fillet

- Curved junction of two surfaces. For example: walls that would meet a sharp angle.

- Flash

- Excess metal on a die cast part extending past the parting line of the die set, which blocks metal from flowing past the die lines and filling the die impressions.

- Foundries

- To cast aluminum and aluminum products, engineers work in aluminum foundries. Foundries are factories that produce metal castings, so, in short, aluminum foundries are aluminum casting factories. Foundries also commonly process cast iron, bronze, brass, steel, magnesium, and other metals. Aluminum is cast by melting it into a liquid form, pouring it into a mold, then, after the aluminum cast solidifies and cools, removing it from the mold or cast. It may be cast into various shapes and sizes.

- Gate

- Passage for molten metal that connects runner with die cavity. Also, the entire ejected content of a die, including castings, gates, runners sprue (or biscuit), and flash.

- Growth

- Expansion of a casting as a result of aging or of intergranular corrosion, or both.

- Heat Checking

- (See checking)

- Hot Chamber Machine

- Die casting machine in which the pressure chamber is subjected to the molten metal through immersion. Hot chamber machines are used in the die casting of metals with low melting points, such as zinc die casting, copper die casting, and magnesium die casting.

- Impact Strength

- Ability to resist shock as measured by a suitable testing machine.

- Ingot

- Metal or alloy cast in a convenient shape for storage, shipping, or remelting.

- Injection

- The processes of forcing molten metal into a die.

- Insert

- A piece of material, usually metal, which is placed in a die before each shot. Molten metal is cast around it to produce certain features on and within the die cast part.

- Loose Piece, Knockout

- A type of core (which forms undercuts) that is positioned in, but not fastened to, a die. It is arranged to be ejected with the casting from which it is removed.

- Metal Saver

- Core utilized to prevent sections of excessive thickness from occurring and to reduce the amount of metal used in a metal casting.

- Multiple Cavity Die

- A die having more than one duplicate impression.

- Overflow

- An opening or cavity on the parting line of the die outside of the main die cavity into which unacceptable metal flows during the shot process. Reasons for metal unacceptability include improperly heated metal and metal that contains impurities.

- Parting Line

- A line along the surface of a die casting reflecting the small space between the die halves; also the mating surface of the cover and ejector portions of the die.

- Plunger

- Ram or piston that forces molten metal into a die.

- Porosity

- Very small voids or pores in cast metal parts resulting from trapped gas or shrinkage during solidification.

- Process Control

- Where parameters of a process are studied and correctly applied in the manufacturing process to produce high quality parts.

- Runners

- Horizontal mechanisms connected to the sprue that transfer the molten metal from the sprue to the mold.

- Shot

- The process in which the metal is poured into the die. The shot may also refer to the die cast part as it exists as a cast before secondary operations are performed to remove flash and to fix imperfections in the casting.

- Shrinkage, Solidification

- Dimensional reduction that accompanies the freezing (solidification) of metal, passing from the molten to the solid state.

- Shrink Mark

- A surface depression that sometimes occurs next to a heavy section that cools more slowly than adjacent areas.

- Slide

- The portion of a die arranged to move parallel to die parting. The inner and end forms a part of the die cavity wall that involves one or more undercuts and sometimes includes a core or cores.

- Soldering

- Adherence of molten metal to a portion of the die.

- Sprue

- Mechanism with which the molten metal first makes contact during the shot process. The sprue transfers the molten metal to the runners.

- Trim Die

- A die for shearing or shaving flash from a die casting.

- Trim

- The process in which overflow, flash, and other parts are removed from the die cast part or shot.

- Unit Die

- A die interchangeable with others in a common holder.

- Undercut

- Recess in the side wall or cored hole of a casting disposed so that a slide or special form of core (such as a knockout) is required to permit ejection of the casting from the die.

- Vent

- An orifice in the casting die that facilitates the release of air from the die cavity into the atmosphere to prevent casting imperfections, such as porosity.

- Void

- A large pore or hole within the wall of a casting usually caused by trapped gas. A blow hole.

- Waterline

- The channel in the casting die into which water flows to precipitate the cooling of the die casting.