Copper

Copper is a metal material found abundantly in nature that is widely used in both commercial and industrial applications because of its many useful properties. Its name comes from the Latin phrase aes cyprium, meaning "metal of Cyprus."

Copper is a native metal, meaning that it is found in directly useful metallic form. It is also a chemical element on the periodic table; its chemical symbol is Cu and its atomic number is 29.

Quick Links to Copper Information

The History of Copper

- Historical Uses

- Copper is one of the oldest forming materials known to man; historians and archaeologists believe that the only metals used before copper were gold and meteoric iron ore.

- Copper metal has been in use since the aptly named Copper Age. Some of the oldest copper artifacts, such as a pendant from northern Iraq, date to around 9000 BC. Between 6000 and 3000 BC, Native Americans living right here in Michigan and Wisconsin cold-worked copper for weaponry, tools and decorative objects. In antiquity, the Greeks and Romans used copper and copper alloys like bronze to make all sorts of things, such as temple roofs, coins, jewelry, sculpture details and swords and spears. Copper was also important in ancient India, Israel, Turkey, Iran and Egypt. The Egyptians were particularly clever with their use of the metal material; they used it to make items such as cookware, dishes, hoes, sickels, saws, chisels, knives, mirrors and razors. They even used copper metal compounds to produce makeup.

- In early modern times, people began mining copper ore. One of the oldest copper mines in existence is the Great Copper Mountain, a mine that operated in Sweden from the 10th century until 1992. That very mine accounted for the production of two-thirds of Europe’s copper supply through the 17th century. During those years, copper was used largely to make weapons and to form sculptures. In the 18th century, ship makers used copper sheathing and copper plating to protect underwater ship hulls. In 1876, the first modern electroplating plant, the Norddeutsche Affinerie, opened its doors in Hamburg.

- In the late 1800s through the 1990s, copper was mined heavily around the world, especially in the USA. Today, many of those mines, which were causing pollution, have closed. Nevertheless, contemporary copper has countless applications, from jewelry to anti-biofouling.

- The uses for copper are ever expanding, especially recently within the computer manufacturing, electronics and telecommunications industries. Existing telephone lines are composed of twisted pairs of copper wires, and they are now being used to connect computers as a less expensive high-speed alternative to fiber optics for communications and networking. Also, aluminum computer chips are being replaced by copper chips because of copper’s superior conductivity. This enables the conductor channel lengths and widths to be greatly reduced, which means faster operating speeds. Finally, copper is a big player in the up-and-coming electric car market.

- Material Use Evolution

- Archaeologists believe the chronology of copper forming progresses as follows: first, cold working of native copper, then annealing, then smelting and finally, lost-wax casting

- Copper smelting was invented at different times around the world. For example, most likely, it was invented in China before 2800 BC, in Central America around 600 AD, and in West Africa between the 9th and 10th centuries AD.Investment casting came around between 4500 and 4000 BC in Southeast Asia. Also, the amount of arsenic found in the hair of the famous frozen male, Ötzi the Iceman, suggests that he was involved in copper smelting; he died between 3300 and 3200 BC. Carbon dating tells us that humans were mining copper metal in Cheshire, UK, at least by 2280 BC.

- Humans began alloying copper around 4000 years after they began smelting it. During the Bronze Age, people such as the Egyptians, Sumerians and Vincas mixed copper with tin, arsenic or other metals to create a harder, bronze-like metal. Later, the Greeks and the Romans discovered and made heavy use of brass, a copper alloy of zinc.

- In 1830, German scientist Gottfried Osann accidentally invented powder metallurgy while trying to determine copper’s atomic mass. Powder metallurgy is a way to take powdered metals, like copper, and use them to make new materials or products. This advancement, along with many others in the Industrial Revolution, increased the versatility of copper and copper alloys.

- In 1949, use of copper became more energy efficient, when Outokumpu, a group of companies in Finland, came up with flash smelting. Flash smelting is a metal extraction method that uses chemical reactions to copper matte, iron oxides and sulfur dioxide.

- Today, powder copper is often sintered for heat pipe construction. It has also been developed into countless alloys, so that it can be used to support just as many applications. Purity standards are higher than ever. For example, copper wires, which conduct electricity better than any metal other than silver, must be 99.98% pure in order to be used for electrical applications. It is likely that, in the coming years, engineers and manufacturers will find new ways to manipulate the metal.

Advantages of Copper

There are many reasons to love copper and copper alloys. First, it is highly sustainable. It is abundant in nature, and easily recycled. Also, because of its recyclability, copper scrap is valuable, and almost as much copper is recycled as is mined every year.

Another advantage of copper is its cost-effectiveness. Not only is it inexpensive and accessible, but it is also typically long lasting and requires little maintenance.

In addition, copper is a non-sparking metal, which makes it highly valuable for applications inside hazardous areas that have exposure to combustible or explosive vapors and gases, like oil rigs.

Finally, copper is very easy to alloy. So, even if pure copper is lacking in the properties you need, such as hardness, chances are that there is an alloy out there that can get the job done.

Production Process of Copper

The first step of copper manufacturing is preform fabrication. Preform fabrication makes use of copper powder and powder flake, which is sourced from powder plants.

Once they have preforms, copper manufacturers can use any number of processes to make products. Examples include: drawing and cold drawing, casting, hot and cold rolling,forging and extrusion.

Copper mills often cold draw wire and rod because doing so improves strength and electrical conductivity. Foundries cast parts from scrap copper and ingots. Brass mills use numerous processes, including hot and cold rolling, drawing, forging and extrusion, to create copper and copper alloy products. Because copper is soft in its pure state and not recommended for building applications, much of the manufacturing in brass mills is done with copper alloys.

After a brass or copper shape has been fabricated, they may also undergo a multitude of secondary operations, such as annealing (which alters the copper's temper), bending, stamping, welding, etching, engraving, polishing or applying clear protective coatings.

- Alloys

- Copper has upwards of 400 alloys, all with different amounts of copper and different properties. These alloys can be grouped loosely into seven main categories: copper, high copper alloy, brasses, bronzes, copper nickels, copper–nickel–zinc (nickel silver), leaded copper, and special alloys.

- The most well-known copper alloys are brass and bronze, made primarily from copper and zinc and copper and tin, respectively. They have large amounts of copper in them. Other very common copper alloys include: aluminum bronzes, silicon bronzes, phosphor bronze, cupronickel (also known as copper-nickel) and copper-silver.

- Still other alloys include: beryllium copper, copper-steel alloys and copper-stainless steel alloys.

Copper Images, Diagrams and Visual Concepts

Copper in it raw state before processing.

Copper in it raw state before processing.

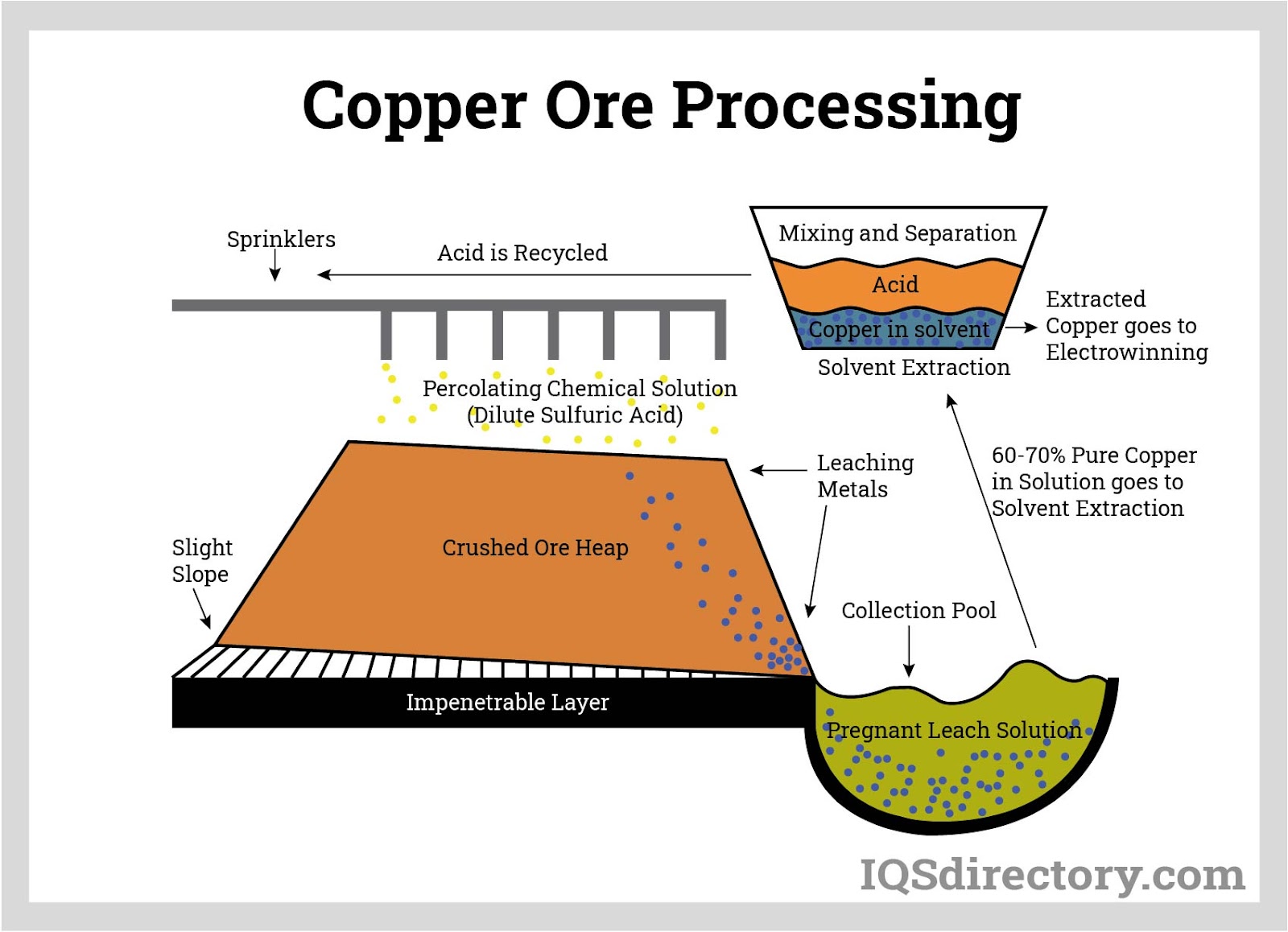

The process that turns raw copper ore into usable material by crushing into a fine sand, then sits in chemicals to particulate water-repellent, air is passed through the mixture which the copper floats to the surface, and the copper froth is thickened and smelted into refined copper.

The process that turns raw copper ore into usable material by crushing into a fine sand, then sits in chemicals to particulate water-repellent, air is passed through the mixture which the copper floats to the surface, and the copper froth is thickened and smelted into refined copper.

Copper after processing has been completed.

Copper after processing has been completed.

Beryllium copper, a combination of 0.5% to 3% beryllium and copper which creates a high strength, non-magnetic, and non-sparking alloy.

Beryllium copper, a combination of 0.5% to 3% beryllium and copper which creates a high strength, non-magnetic, and non-sparking alloy.

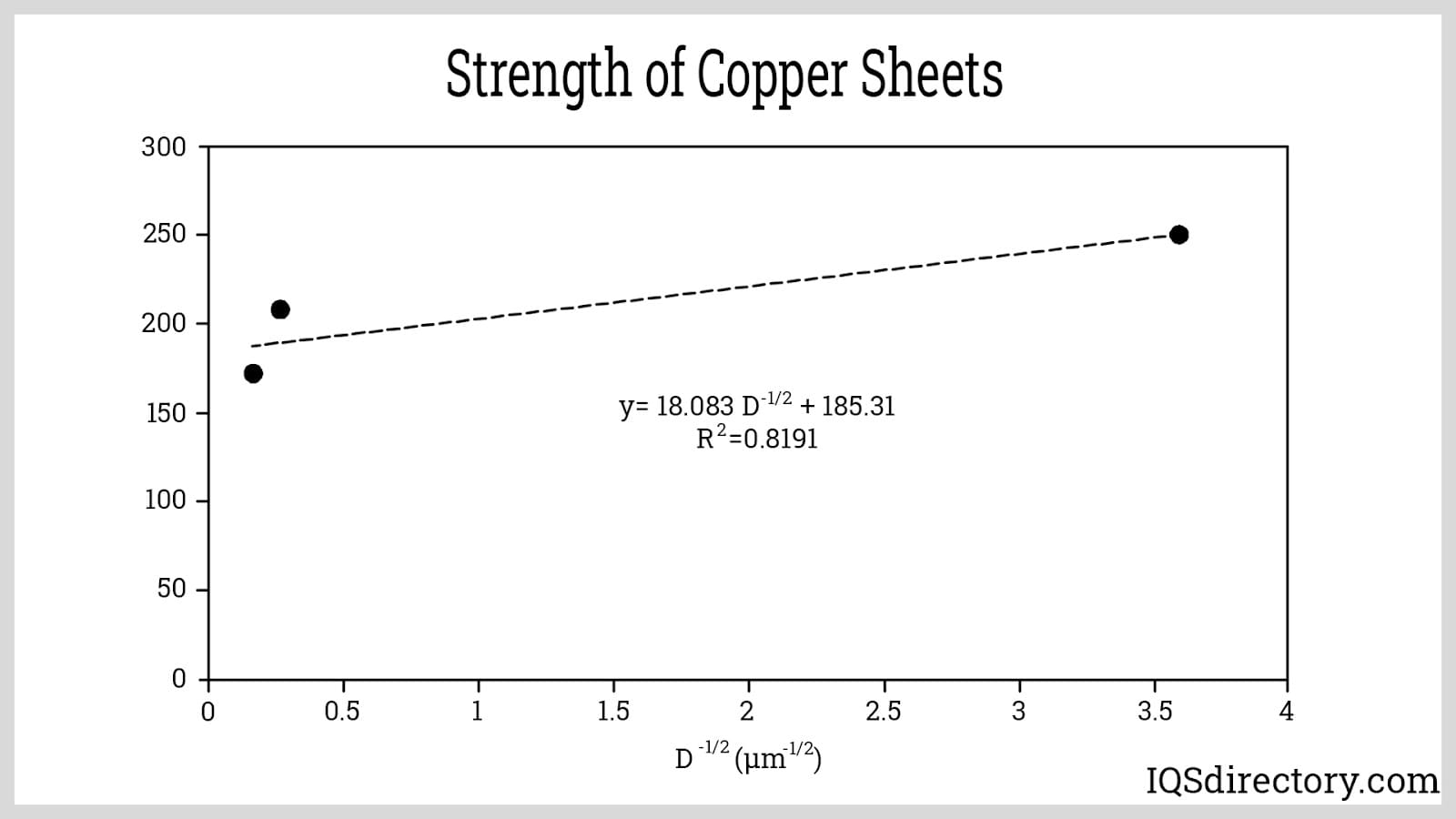

The copper sheet are a highly malleable and workable metal with electrical, thermal conductivity, and corrosion resistance.

The copper sheet are a highly malleable and workable metal with electrical, thermal conductivity, and corrosion resistance.

The strength of copper sheets can increase based on what other elements or alloys added to the material.

The strength of copper sheets can increase based on what other elements or alloys added to the material.

ETP copper has a minimum conductivity value of 100% IACS which makes it useful for electrical applications and those requiring low resistance levels.

ETP copper has a minimum conductivity value of 100% IACS which makes it useful for electrical applications and those requiring low resistance levels.

Copper Types

- Beryllium Copper

- The strongest, most durable copper alloy that contains anywhere from 0.5 to 3% beryllium, an alkaline earth metal that is mainly used as a hardening agent in alloys.

- Brass Bars

- Solid, straight uniform preforms, billets and blanks that are supplied in metalworking facilities.

- Brass Plates

- Solid, thin pieces of square or rectangular copper and zinc alloy.

- Brass Rods

- Solid, straight preforms that are used as billets and blanks.

- Brass

- Metal alloy containing copper and zinc.

- Bronze

- Metal alloy containing copper and tin.

- Copper Bars

- Solid, straight uniform products of copper that can be extruded. These products have cross-sections in a variety of shapes, from circular to triangular, square and more.

- Copper Billets

- Large pieces of pure copper that can be cut into smaller lengths in order to be extruded or forged as copper tubing, rod or bar.

- Copper Coil

- Thermally and electrically conductive component in many different systems and machinery. It is made of copper wire or tube that is bent and wound into a rounded spiral shape.

- Copper Pipe

- Has excellent electrical conductivity.

- Copper Sheet

- Formed from the rolling process and can be used as roofing.

- Copper Strip

- Long sheet of metal with a length many times its width.

- Copper Suppliers

- Manufacture and distribute preformed copper and copper alloy billets, blanks and parts.

- Copper Tubes

- Hollow aluminum products, useful in HVAC, plumbing and similar applications where corrosion-resistant tubing and a high level of heat transfer are required.

Properties of Copper

This reddish-orange metal is categorized as a transition metal, a nod to its ductility, malleability, and ability to conduct heat and electricity. In its pure state, copper is also very soft. It is nonmagnetic, machinable, formable and durable. Additional properties, such as hardness, can be reached by adding alloying elements.

Applications of Copper

Copper is used for many different reasons. Manufacturers use it to make commercial and household products, to conduct electricity, to transmit power, to convey fluids, to conduct heat, repel microbes and for aspects of architecture.

Copper and its alloys are supplied to many different industries, including the automotive, architectural, building construction, electronics, food processing, marine, aerospace, wiring, power generation, lighting and telecommunications industries.

Products Produced With Copper

Copper suppliers specialize in manufacturing preforms, which include billets, blanks, copper strip and sheet copper, to be further fabricated into other products and parts. Copper strip and copper sheet metal are flat, flexible and come in rolls, as do copper coil. Copper tubes are often fabricated into copper pipe systems. Brass rod, brass plate and brass bar are all thicker, solid uniform pieces of brass that are often drawn or extruded into different shapes.

The preforms are fabricated into piping systems, propellers, hardware, kitchen products, small springs, wires, adapters, electrical connectors, lighting, valves, coins, offshore drilling equipment, microchips and roofing.

How to Choose the Right Copper Manufacturer

So, you’re ready to purchase a copper product, but there’s copper all over the world, so where do you start? How do you choose a supplier?

We know the market can be tricky to navigate; that’s why we’ve compiled a list of high quality copper manufacturers for you. Find it by scrolling up towards the top of this page. Set aside some time to browse the websites of each and every one of them. While you’re browsing, take note of three or four you believe could work well for you–they should offer the forming services and/or carry the products you need, offer customization services, and be close enough that they can ship products to you in a timely manner.

Once you’ve selected your core group, reach out to them individually and ask them questions about their lead times, prices and services. Make sure to detail your specifications, and get their assurance that they can meet them. Also look for good customer service; you want a manufacturer that cares about your application more than their bottom line. Compare and contrast between them, pick your supplier and get started.

Overseas Copper Market

Copper is a very affordable and abundant material. Despite its wide availability domestically, many American companies import their copper products. The United States is the third largest importer of copper and copper products in the world. The top exporter of copper ore is Chile. The main copper product that the United States does not import, but rather sources domestically, is copper powder.

Because of the expansion of the overseas market, large countries like the United States and the United Kingdom have had to develop strict standards and trade policies. These are in place to ensure quality, purity, etc.

Despite the frequency of copper imports, getting copper from American companies still has advantages. First, they are highly competitive, so you can get quite good prices. Plus, they ship quicker, and if you have any issues with your product, you can return it or discuss your issues more easily than if the product comes from overseas.

Copper Terms

- Aging

- Various surface treatments that can be done to copper to produce an "aged" or "antique" look.

- Bending

- A mechanical process, by which rollers, bending shoes or mandrels are used to bend a curved section on metal tubes, rods or other shapes.

- Brake Forming

- A type of bending that can be used on a sheet, strip or plate.

- Brass

- A copper alloy, primarily containing zinc.

- Brazing

- A method of joining metal pipe or tube by using a non ferrous filler material.

- Bronze

- A copper alloy, primarily containing tin.

- Castings

- Metal shapes produced from pouring molten metal into a mold and waiting for it to cool and solidify into the desired shape.

- Cleat

- A small copper strip that is used as a fastener for sheet copper components.

- Cold Forging

- The process of hammering a metal into shape at room temperature.

- Deoxidized Copper

- Copper that has had a deoxidizer, such as phosphorus, added to it in order to reduce oxygen.

- Extrusion

- A method of creating a metal shape with a uniform cross-section, by forcing heated metal through a die.

- Flashing

- Copper sheet that is used in construction in order to prevent or divert water penetration.

- High Conductivity Copper

- Standard copper that is used in electrical applications, capable of 100% electrical conductivity.

- Hydroforming

- A method of forming that involves using hydraulic pressure on sheet metal placed between a male die and a rubber piece.

- Laminating

- Bonding, usually with adhesives, of metal sheet or strip alloys to various substrates, including aluminum, plywood and steel. The resulting product is often very strong.

- Mechanical Treatments

- Treatments done to finish metal surfaces, including grinding, polishing and buffing.

- Patina

- The natural copper coating that results from atmospheric corrosion.

- Roll Forming

- The process of pressing metal sheet or strip between rollers.

- Scrap

- Metal that is leftover after cutting. Generally, this can be recycled.

- Soldering

- A method of joining that is used for watertight applications, such as for roofing and gutters.

- Spinning

- A method of forming a product by using a hand tool to shape a revolving metal piece.

- Stamping

- Using a die in a press or a hammer to shape metal sheet or strip.