AGVs

Developments in automation have introduced many types of automatic guided vehicles and have greatly increased the range of applications for which they can be used.

Quick links to AGV Information

The Benefits of Going Automated

Typically, when a company needs to boost production to meet an increase in demand, they hire more people. There are issues that come along with mass hiring, especially in industrial settings. For one, training can take time and attention away from production. An AGV won't need a month, a week, or even a day to master the functions it has to perform. From the moment an AGV is employed in the day-to-day operations of a warehouse, it is ready to start paying for itself through the manpower it cuts, the time it saves, and the risks it won't take.

The closest a machine will get to needing acclamation is needing programming. The guidance system will have to be calibrated to the routes the machine will cover, and it will have to be programmed for handling the functions of the facility in which it is operating. Also, more bodies mean a greater risk of human error which can lead to injury and product damage.

Automated vehicles that perform loading, palletizing, towing, and lifting functions all on their own don't need to be trained. It is more cost efficient to keep a machine running than it is to cover living expenses of injured employees or recall compromised products that are a result of human error. Factory and warehouse management teams have lost valuable time, products, and people due to carelessness, but self guided vehicles only do what they are programmed to do.

Simply put, people are very limited in their physical capabilities, which is why technology has developed astronomically. Tasks that couldn't be done before, are completed with ease with the help of self-guided vehicles, making them increasingly popular in manufacturing applications.

AGVs are commonly used by airplane builders to tow engines weighing several tons across the facility. Some AGVs are fitted with robotic limbs to help perform functions that require more dexterity than strength, such as tooling change out. At every level, automation reduces the risks associated with human involvement, making these self-governing machines ideal for day-to-day operation. Food and beverage companies, farmers, car and airplane manufacturers, and even the builders of these automated machines utilize them.

The 3 Most Common Types of AGVs

- Towing AGVs

- Can be used to pull loads that weigh several tons across a warehouse floor. This greatly reduces the hazards associated with moving heavy equipment and finished products by manpower. Typically, these machines are capable of handling anywhere from 10,000 to 50,000 pounds from point A to point B. The distance that these machines can carry these loads depends on the tracking abilities of the machine.

- Fork AGVs

- Fitted with a forked lifting mechanism that elevates to retrieve or place materials as well as move and stack pallets. These machines are often utilized for bringing materials in and placing them, or retrieving them for shipment. These AGVs can replace the need for experienced lift truck operators, who may demand higher pay because of their qualifications.

- Heavy Load Carrying AGVs

- The hulk of the family due to its ability to carry upwards of 250,000 pounds. They are most commonly used in the metal and paper industries to carry coils, ingots, dies, and other materials that are heavy or typically come in very heavy loads.

Less Common AGV Types

The unit load type is not as common as the tow, fork, and heavy carrier automatic guided vehicles. It is self-contained and has a loading platform. These machines are normally used to transport totes, pallets, and racks at a rate of about two at a time. While they may not be as equipped for heavy duty, they still save on labor costs that arise from the need to complete transport tasks. The unit load AGV performs hauling applications that are not physically possible for a human, and they have a greater capacity to tow more in a load, which saves valuable time. Also, these vehicles are commonly programmed for load transferring.

There are smaller AGVs that are more for light duty work. These are called commercial or office AGVs. These machines can carry small loads of 500 pounds or less, and are used as automated mail carts in offices. They are also used in areas where cleanliness is paramount, and human presence is undesirable.

The Evolution of Driverless Vehicles

- The First AGV

- The first automatic guided vehicles were not called that by their creator, Arthur "Mac" Barrett, of Barrett Electronics Corporation. In 1954, when Mac unveiled his Guide-o-Matic, he accurately called it a driverless vehicle, and it is credited with being the first ever AGV. It was a towing machine that followed a signal given off by a wire placed in the ceiling of a facility. Later, the wire was moved underground.

- Developments in AGV Technology

- Over time, developers and manufacturers have made improvements on the original idea. Today, AGVs are laser guided or follow magnetic tape or bright colored paint on the ground, or follow wire embedded in the floor. Machines guided by magnetic tape, paint, or wires have a fixed route that they travel in the warehouse or factory. They are programmed with sensors that pick up the frequencies of the tape or wiring and guide the AGV accordingly. Laser navigation technology allows for greater range of operation and can follow a programmed route while using the laser guidance to detect obstructions and avoid collisions in the warehouse or manufacturing facility.

- Many automation enabled vehicles have robotic arms attached to them as well. These robotic arms allow the machine to do more than just grunt work. They enable it to handle more intricate tasks like assembly and part changes on other machines. These machines are ideal for assembly lines and even order pulling in a distribution center or warehouse.

- AGVs have found a home in the e-commerce industry as well. There are automatic guided machines that can receive and pull orders for shipment. Manufacturers of AGVs have expanded the mobility of these unmanned vehicle systems to be able to move from side to side and spin. These seemingly simple upgrades in mobility greatly increase a company's capacity for production.

Common AGV Components

Included in all AGV types are several components. They are equipped with traction motors to provide movement and traction batteries to power the motor. There are many batteries with different capacities, but lithium ion phosphate batteries are very popular for powering AGVs. A computer onboard allows AGVs to communicate with a central control processor and receive instructions. AGVs are also equipped with a payload interface. This is usually either a fork, a loading deck, a conveyor, or a similar component tasked with handling whatever is to be acted upon.

Automation requires smart technology. Unmanned machines have to communicate with central command to carry out orders, but they also communicate with other AGVs. The main control system, which is the brains of the operation, sends prompts to the machines on its system, but all the AGVs must still interact with each other for safety and production efficiency purposes. These machines are on a common network; this allows them to recognize and aid or avoid each other using their laser guidance system and the central control system.

There are a lot of hazards to navigate in a factory, warehouse, or distribution center. AGVs are decked with safety features for this reason. They often have lasers to detect and avoid obstructions such as people or other equipment, and they are usually fitted with contact bumpers. Additional features include navigation, traffic, and job control systems. These additional features strengthen the safety and efficiency of these vehicle systems. They also allow the machine to perform material handle functions and load transfers.

Questions that Arise While Considering the Purchase of Automated Guided Vehicles

Deciding which machine would best suit your warehouse, distribution center, or factory is essential. You should start by determining what you require of an AGV. Once you know what you need from the equipment, the next step is to find a machine at a price within your budget from a manufacturer with a good reputation and an understanding of your needs.

Businesses, big or small, are confronted with difficult choices when making investments in assets or adopting new technology. When it comes to adopting automatic guided vehicles (AGVs), the decision becomes even more difficult, as the cost of each unit is substantial, and you need to make changes to infrastructure to accommodate drones.

To make that decision easier, we have compiled some questions that arise and answers from experts.

- What are the primary challenges or problems owners face with the adoption of automation equipment?

- The prices of components used in guided vehicles are significantly high. The costs may come down with increased adoption of the technology, however, given the high-cost of design and development of sensors and processors, it seems it will take time for the industry to produce an abundance of economical equipment. That said, some economical designs and models that have multiple applications and can work in dynamic environments and offer good return on investment are available.

- What newer technologies are game changers?

- Major investments in passive machine vision are paying off. The technology will eliminate or reduce reliance on expensive laser guided vehicles.

- What are the most exciting new developments in self-guided vehicle transit?

- Driverless automobiles by Tesla and Google and driverless supply trucks.

- Where will autonomous vehicle technology be in 5-10 years?

- A report titled "Automated Guided Vehicle Market by Type (Unit Load Carrier, Tow Vehicle, Pallet Truck, Assembly Line Vehicle), Industry Vertical (Automotive, & Others), Application (Transportation, Distribution, & Others), & Geography - Global Forecast to 2020," published by ReportsnReports.com, has predicted that automated guided vehicles will grow at a great pace in most regions of the world due to growing investment all across major industries. The benefits of AGV systems and their adoption by major industries have encouraged investments; soon guided vehicles will be a norm.

AGV Images, Diagrams and Visual Concepts

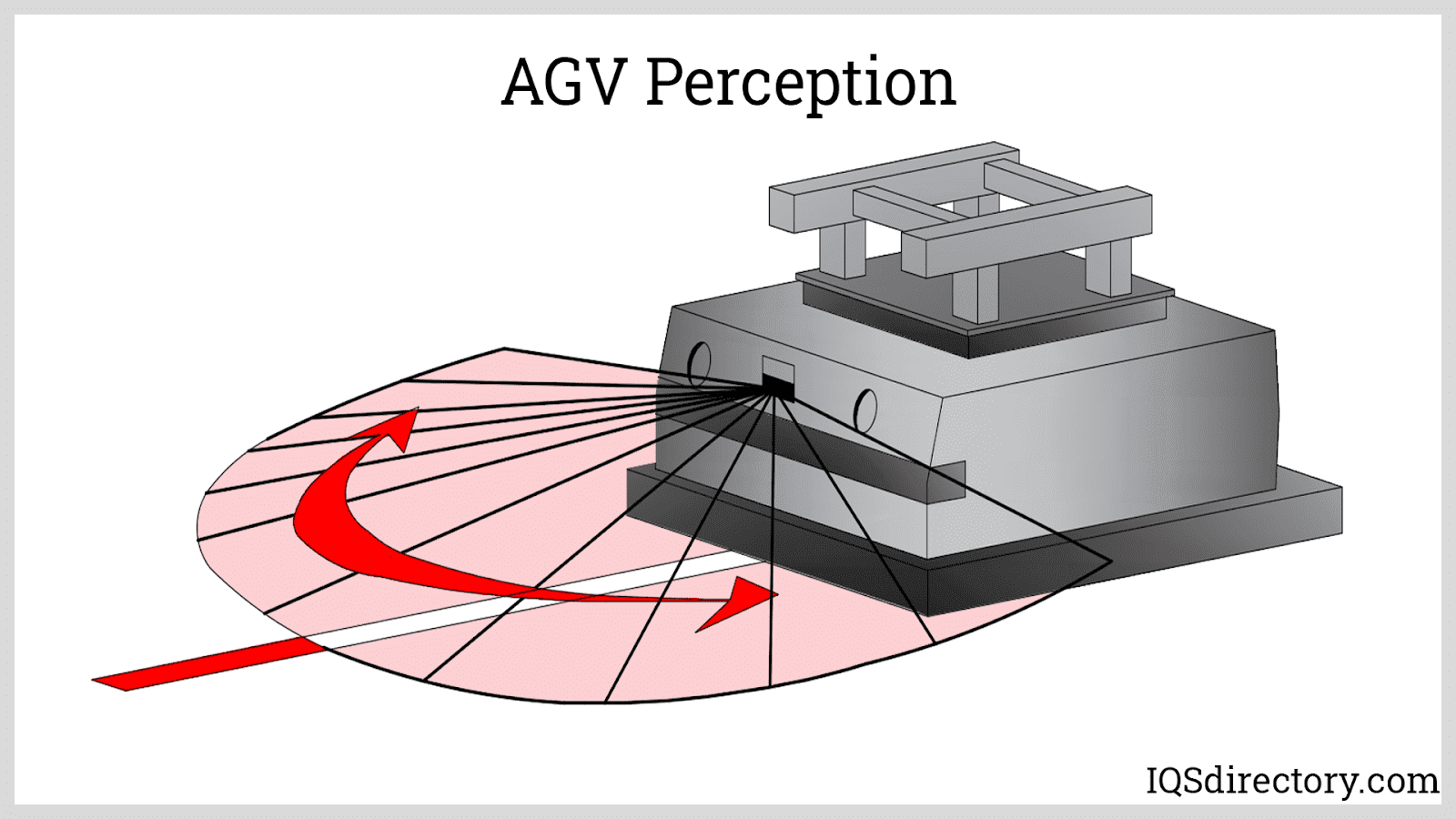

The perception of mobile robots, similar to robotic arms, is achieved using sensors.

The perception of mobile robots, similar to robotic arms, is achieved using sensors.

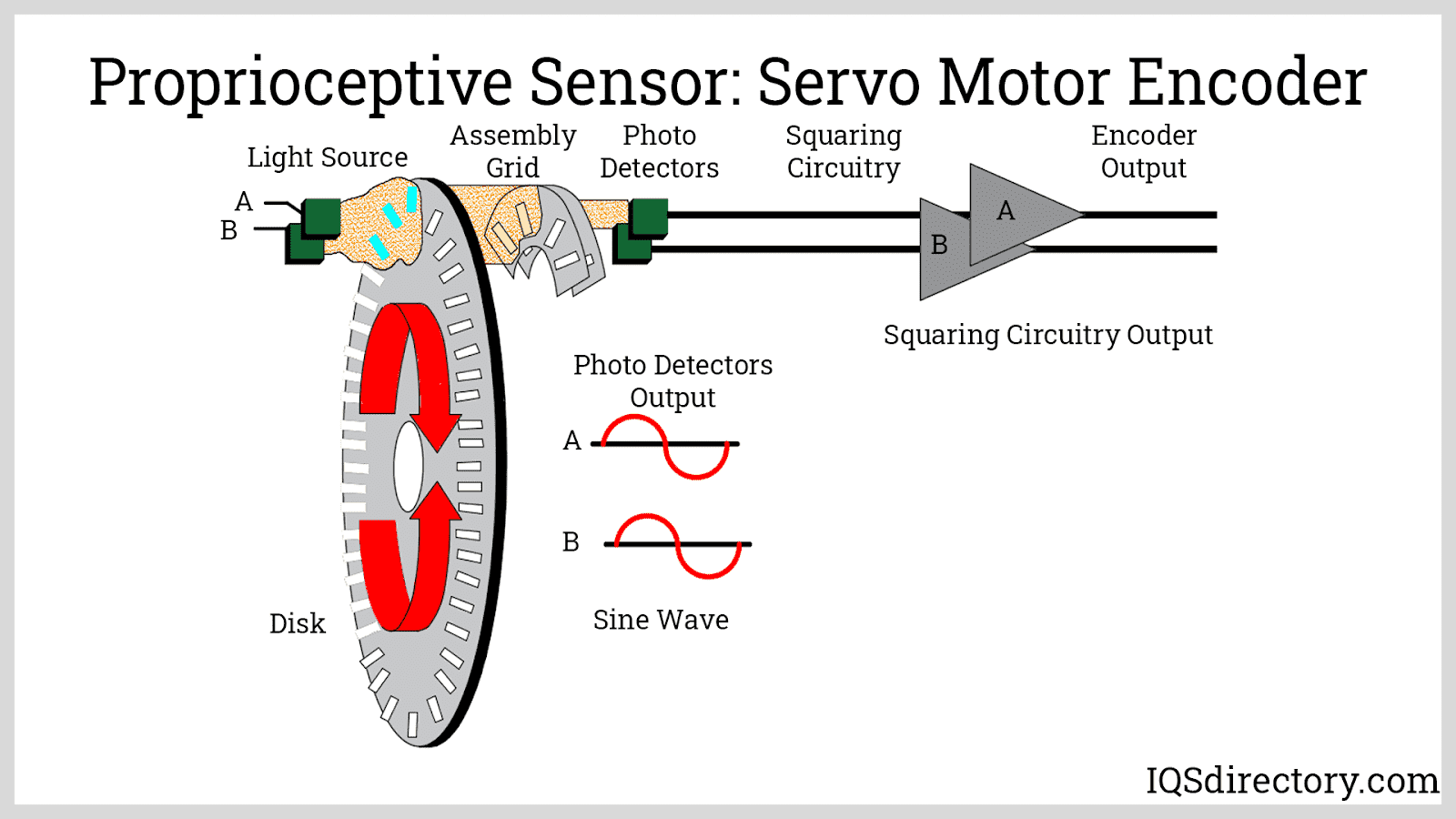

Proprioceptive sensors measure internal parameters such as motor speed, load, temperature, system voltage, and current

Proprioceptive sensors measure internal parameters such as motor speed, load, temperature, system voltage, and current

A combination of acceleration and heading sensors are commonly referred to as the Inertial Measurement Unit (IMU)

A combination of acceleration and heading sensors are commonly referred to as the Inertial Measurement Unit (IMU)

AGV Types

- Camera Guided AGVs

- Used when precise guidance accuracy is needed, such as in crowded environments and smaller sized facilities. An on-board camera focuses and guides the AGV.

- Forked AGVs

- Used to pick up and deliver various loads, such as pallets, carts, and rolls. These can be manually driven as well as automatic, and they have the ability to lift loads to many levels.

- Inertial Guided AGVs

- Use a magnet sensing device, a gyroscope that measures the unit’s heading, and a wheel odometer that calculates the distance traveled. Magnets mounted beneath the floor are detected by the onboard magnetic sensing device to determine location and plan routes.

- Large Chassis/Unit Load AGVs

- Used to transport heavier loads with various transfer devices such as rollerbeds, lift/lower mechanisms, and custom mechanisms.

- Laser Guided AGVs

- Use mounted laser scanners that emit a laser and reflect back from targets. The vehicle’s location can be determined based on distance to the target and time of reflection information.

- Optical Guided AGVs

- Use a latex-based photosensitive tape on a facility’s floor for guidance. Distance is measured by use of wheel odometers, which establish stop locations for the AGV along the course.

- Outrigger AGVs

- Have two horizontal stabilizing legs (outriggers) to provide lateral support, and they are used to handle pallets, rolls, and racks.

- Small Chassis AGVs

- Able to maneuver through crowded workplaces through laser sensing, while transporting smaller loads.

- Smart Vehicle AGVs

- Capable of determining their own traffic control and routing without a central controller.

- Towing AGVs

- Used to pull trailers and are usually manned by an operator who attaches and removes the trailers at designated stops. These can follow a basic loop or a more complicated path.

- Wire guided AGVs

- Use a charged wire that is buried beneath the floor for proper guidance and have small antennae composed of metal coils mounted on their bottoms. The stronger the field between the buried wire and antennae, the higher the voltage induced in the coils.

AGV Terms and Definitions

- Acoustical Operating Indicator

- A control on the sound and volume of the AGV that alerts the surrounding area when it is in motion.

- Accumulative Blocking

- A type of traffic control performed by the AGV using detection sensors that allow for one vehicle to slow or stop, then resume motion once there is a safe gap between machines. The sensor housing on the AGV detects stopped vehicles and slower vehicles in front of and behind it.

- Antenna

- Used for wireless communication that gives the AGV instructions and information about traffic control.

- Automated Guided Vehicle Systems

- Consist of the computer, software and technology that are the “brains” behind the AGV. Without computer software systems and communications networks, only the simplest AGV functions can be performed.

- Automatic Charge

- An AGV’s battery recharges without the removal of the battery itself. A copper plate in the floor makes contact with the conductor of an AGV overhead, activating a charge, and the AGV departs once charging is complete.

- Automatic Guided Vehicle Display

- Displays information necessary for operating the AGV system and keeps it operating efficiently.

- Automatic Guided Vehicle Operator’s Pendant

- A device with a joystick designed to manually operate the AGV as needed.

- Automated Material Handling

- The process of relocating or stocking materials using an automated device such as an AGV.

- Clamp

- A device on some AGVs that allows them to grab circular or cylindrical objects such as barrels and place them wherever needed.

- Communication

- Unit commands within the AGV system such as where to go, when to start, slow down, and stop. Within most AGV systems, the basic communication methods are infrared, radio, guide wire data, and inductive loop.

- ID Tag

- Marks on the floor indicating where the AGV is supposed to stop or change direction.

- Local Dispatching

- AGV dispatch that occurs from a nearby source, used for simpler systems. Onboard sensors, keys, and data couplers are all examples of local dispatching controls.

- Multi-Directional Wheels

- Wheels that, in addition to allowing the vehicle to move forward and backward, allow it to move sideways and spin.

- Navigation

- The means by which an AGV determines its calculated position and stop points. Laser, optical, wire, camera and inertial systems are types of navigation.

- Odometer

- A device that records the distance traveled. Wheel odometers are often implemented on AGVs to determine position and speed.

- Obstacle Sensor

- An ultrasonic sensor on an AGV that allows the vehicle to slow down or stop when faced with an obstruction.

- Open Path

- A navigation system that allows an AGV to select from a large number of pathways. Open path systems are useful in crowded warehouses and smaller facilities.

- Power Transfer

- When the battery of the AGV supplies power to pickup and delivery stations to make additional wiring unnecessary.

- Remote Dispatching

- A means of communication that involves a central controller dispatching information to the AGVs. Remote dispatching can be done through an RF network (broadband or wired) or infrared communication.

- Safety Bumper

- Usually a detection sensor designed to detect obstructions in front of and behind the AGV.

- System Monitoring

- Analysis of the entire AGV system, including hours of runtime, transaction queue(s), and parts and service records.

- Tug and Tow

- A function of certain AGVs that serves to pull or tow multiple items. Tug/tow AGVs are useful for moving wheeled products such as shopping carts.

- Vehicle Monitoring

- Analysis of AGVs and their individual components. Common vehicle monitoring examples are vehicle runtime, battery status, and error logs.

- Visual Operating Indicators

- Lights on an AGV that flash in the direction of travel during an operation.

- Zone Blocking

- A preventative method controlled by an AGV system controller. Sections of a guide path that have zone blocking allow only one AGV to be in a particular zone at one time.