Wastewater Evaporators

The main goal of the wastewater evaporation industry is to develop a safe, reliable, and efficient method for reducing the volume of waste to be dumped into landfills and waste facilities.

Quick links to Wastewater Evaporators Information

History of Wastewater Evaporators

The waste management industry has been aware of moisture in waste material but has had difficulty developing sufficiently productive methods for removing it. The initial process was to have large pools exposed to the sun that allowed the water to evaporate and leave the contaminants behind. This process took time and large areas.

Though heating of waste to remove water content was a very viable method, there were concerns regarding the vapors created from the process and how to properly dispose of them. This led to the development of wastewater evaporators that provide a very safe, efficient, and cost-effective way for removing moisture from waste without polluting the environment.

Wastewater evaporators are rapidly gaining popularity due to their ability to reduce the volume of waste without damaging the environment. By using engineering expertise and well-designed processes, wastewater evaporator manufacturers help industry dispose of otherwise harmful materials.

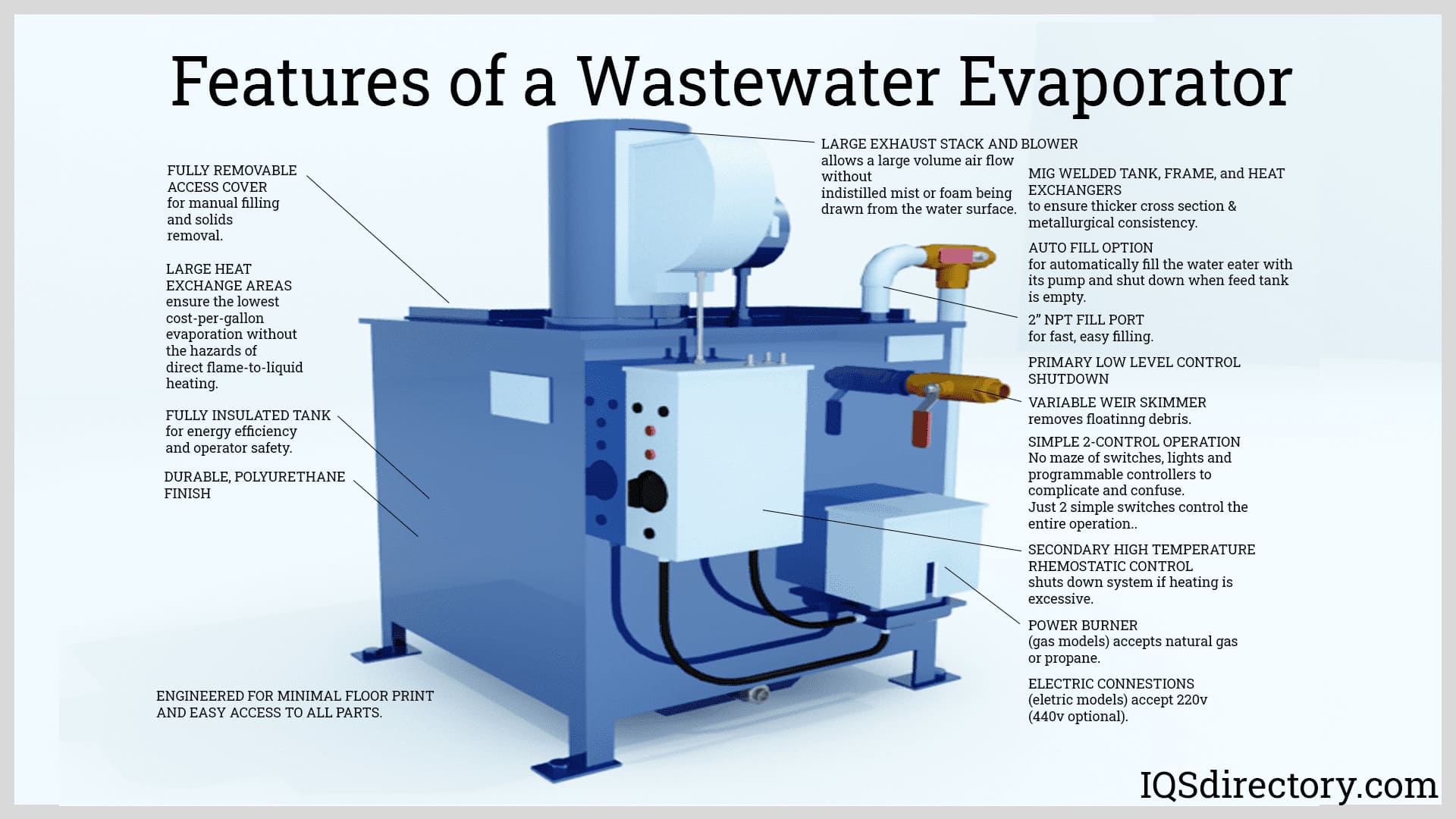

The purpose of a wastewater evaporator is to remove moisture from waste to reduce waste volume. The process involves the use of heat to change the water in waste to a vapor, which is removed by a blower system. Once water is removed, contaminants and other materials are left behind for proper disposal.

Process of Wastewater Evaporators

The process of wastewater evaporation is critical to several industries, with special emphasis on waste management. Much of the waste material that is collected from industry and private residences has a moisture content. By removing moisture, the volume of the material is significantly reduced. This, in turn, reduces the amount of waste that has to be dumped into a landfill.

The process of wastewater management can be found in several industries that include metal finishing to remove chelating substances, food industry to dispose of biochemical materials, handling of waste from the pharmaceutical industry, and the production of paint, to name a few.

Wastewater Evaporator Images, Diagrams and Visual Concepts

Wastewater evaporator removes water from water-based waste by converting the water to vapor and leaving contaminants.

Wastewater evaporator removes water from water-based waste by converting the water to vapor and leaving contaminants.

Mist pads removes contaminants from a oil layer in the wastewater.

Mist pads removes contaminants from a oil layer in the wastewater.

Vacuum wastewater evaporators lower the pressure to reduce the boiling point of the wastewater.

Vacuum wastewater evaporators lower the pressure to reduce the boiling point of the wastewater.

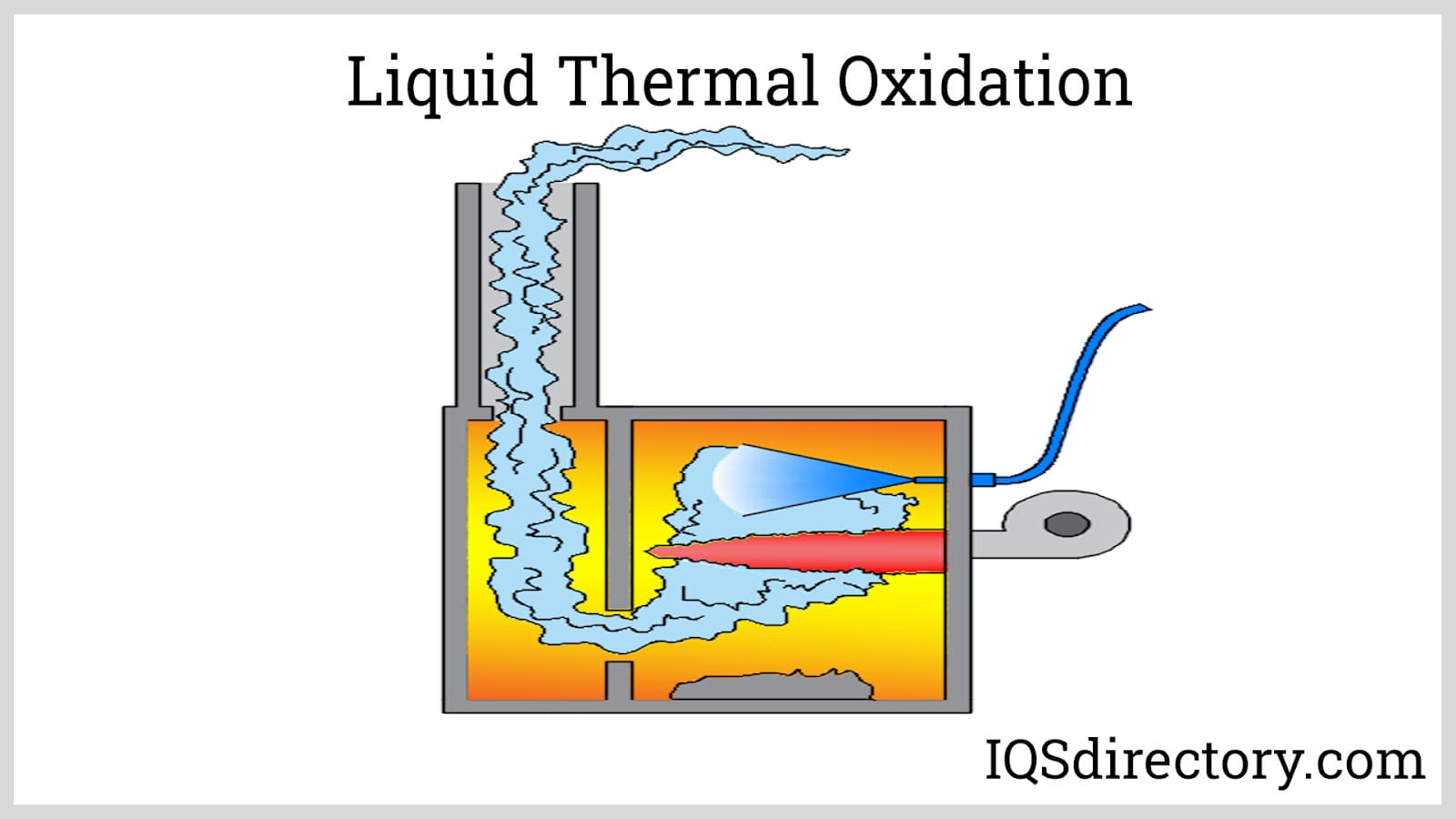

Liquid thermal oxidation involves spraying liquid waste, under pressure, and near a flame which oxidizes and dissolves contaminants.

Liquid thermal oxidation involves spraying liquid waste, under pressure, and near a flame which oxidizes and dissolves contaminants.

Types of Wastewater Evaporators

The two types of wastewater evaporators are thermodynamic and mass transfer phenomena.

- Thermodynamic

- This method uses heat, which is created by gas, electricity, or steam, to raise the temperature of the waste material to create the vapors.

- Mass Transfer Phenomena

- Form of boiling of waste material, where the droplets from the process are blown through a filter to capture any waste materials.