EMI Filters Industry Information

EMI Filters

EMI Filters

EMI (Electromagnetic Interference) filters, also known as RFI (Radio-Frequency Interference) filters or EMC (Electromagnetic Compatibility) filters, are electronic devices or components designed to mitigate or suppress electromagnetic interference in electrical and electronic circuits. Electromagnetic interference refers to unwanted electromagnetic emissions or radiation that can disrupt the proper operation of electronic equipment, cause signal degradation, and interfere with nearby devices.

How Do EMI Filters Work?

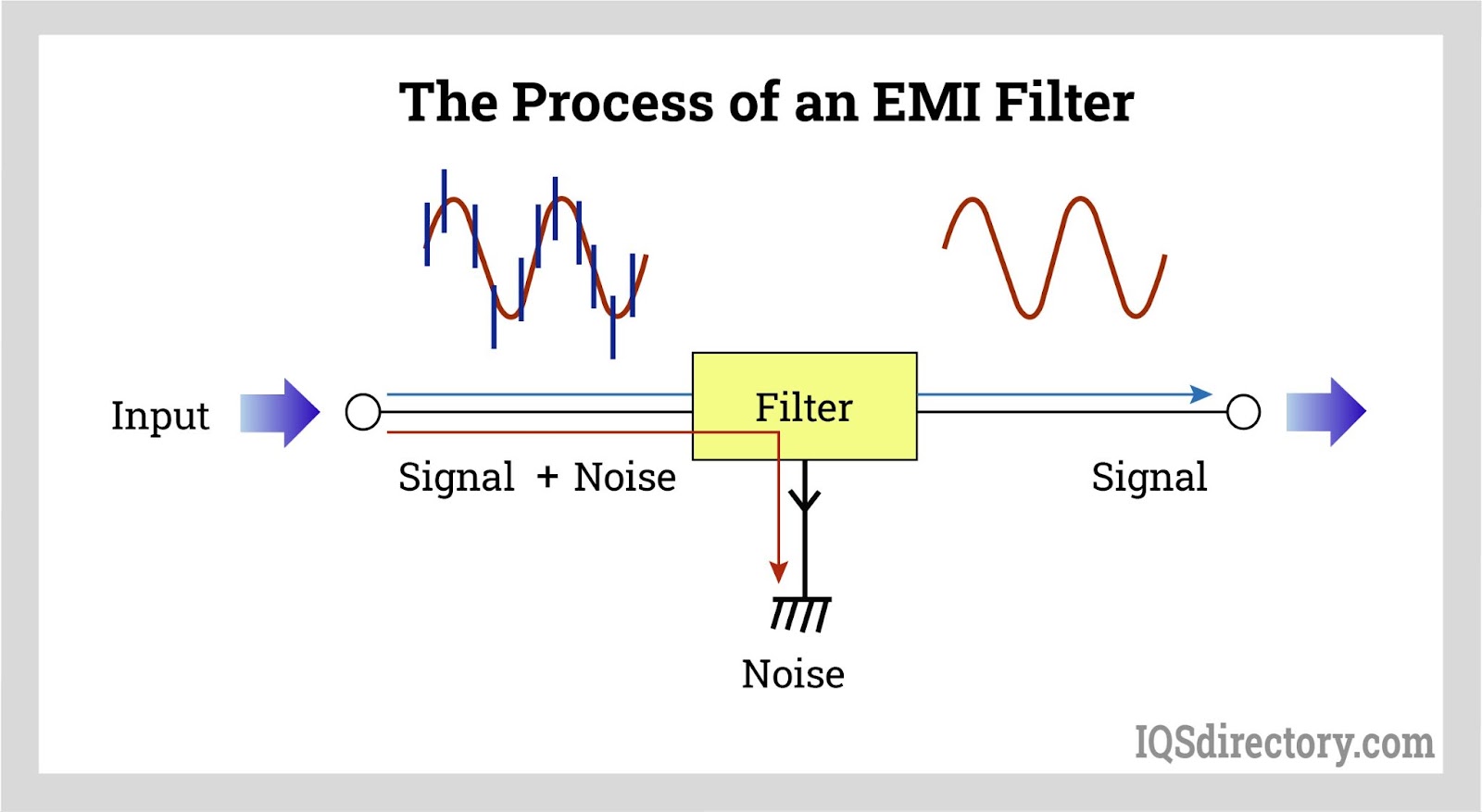

EMI filters work by blocking or dissipating electromagnetic interference (EMI) and radio frequency interference (RFI) currents from entering or leaving an electrical device or circuit.

Here are some key points about how they function:

-

Inductors and capacitors: EMI filters use a combination of inductors and capacitors to form passive low-pass and high-pass filters. This impedes the flow of interference currents at specific frequencies.

-

Shielding: Ferrite magnetic cores and shielding enclosures are often used to enclose inductors and capacitors. This further blocks interference waves from propagating.

-

Low-pass filtering: Low-pass filters using inductors and capacitors in series and/or parallel attenuate high-frequency interference currents attempting to enter or leave a device. This prevents emissions.

-

High-pass filtering: High-pass filters using the same components block lower frequency noise and signals from passing through. This improves immunity.

-

Common mode/differential mode: Filters are applied between signal wires and ground/earth to suppress both common mode and differential mode noise.

-

Frequency selectivity: The component values determine the filter's cutoff frequency characteristics, blocking electromagnetic energies above or below certain thresholds.

Types of EMI Filters

There are several common types of EMI filters, each designed to address specific aspects of EMI. The choice of filter depends on the application and the type of interference to be filtered. Here are some of the most common types:

-

Common Mode Choke Filters: These use chokes (coils) to block common mode interference produced by differential mode signals flowing in and out of a device. They work by creating opposing electromagnetic fields that cancel each other out.

-

Differential Mode Filters: Also known as line filters or line impedance stabilization networks (LISNs), they suppress differential mode noise using resistive, inductive, and capacitive elements in series and/or parallel combinations. Often used at power connections.

-

Radio Frequency Filters: Used to attenuate signals above a certain frequency threshold, usually in the RF range. Can be simple LC (inductor-capacitor) filters or more complex pi-filter or L-section filter designs.

-

Power Line Filters: Block noise conducted along power cables. Usually make use of common mode chokes, Y-capacitors, and sometimes X-capacitors for improved high-frequency suppression. Used near power supplies or where devices share a power line.

-

Buck-boost Filters: Specialized filters that provide adjustable voltage levels for circuits while also filtering noise. Often used in switched-mode power supplies and battery chargers.

-

Multistage Filters: Combine various filter types (LC, pi, L-section, etc) in cascaded stages to achieve very high attenuation over broad frequency ranges. More effective but also more complex and costly.

Advantages of Using EMI Filters

EMI (Electromagnetic Interference) filters are electronic components designed to mitigate and reduce electromagnetic interference in electrical and electronic systems. They offer several advantages when incorporated into electronic circuits and systems:

-

Reduce electromagnetic interference (EMI) emitted from electronic devices: EMI filters help control interference from devices that can disrupt other nearby electronics if left unchecked. This improves electromagnetic compatibility.

-

Meet regulatory compliance standards: Filters allow devices to meet FCC and other regulatory standards for maximum allowed EMI emissions, which is important for selling electronic products legally.

-

Improve signal integrity: Filters block interference from getting into a device's sensitive internal circuitry, keeping signal quality high and preventing noise from corrupting operation.

-

Protect downstream equipment: Installing filters at the source of EMI helps protect any connected devices or cables from potential interference issues. This increases reliability.

-

Lower fix costs: Adding filters upfront during design is cheaper than going back later and reworking a device's hardware to reduce EMI if issues emerge after production.

-

Improve electromagnetic robustness: The device itself has enhanced protection against external EMI sources that could otherwise cause malfunctions or errors.

-

Common mode rejection: EMI filters are particularly effective at rejecting interference that appears as a common-mode signal.

Choosing the Right EMI Filter Manufacturer

When choosing an EMI filter from an EMI filter manufacturer, it is important to compare at least 4 or 5 manufacturers using our list of EMI filter manufacturers. Each EMI filter manufacturer has a business profile page that highlights their areas of experience and capabilities, and has a contact form to directly communicate with the company for more information or request a quote. Review each EMI filter company website using our patented website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple EMI filter companies with the same quote.

When choosing an EMI (Electromagnetic Interference) filter manufacturer, several important factors must be considered to ensure that you select the right partner for your specific needs. Here are some key factors to keep in mind:

-

Technical Expertise: Look for a manufacturer with a strong technical background and expertise in EMI filtering. They should have a deep understanding of electromagnetic interference, noise suppression, and the design of effective EMI filters.

-

Customization: Consider whether the manufacturer can provide custom solutions tailored to your specific requirements. EMI filter needs can vary significantly depending on the application, so the ability to create bespoke filters is essential.

-

Quality and Certification: Ensure that the manufacturer adheres to high-quality standards and has relevant certifications, such as ISO 9001 and ISO 14001. EMI filters may also need to meet specific industry standards (e.g., CE, UL, or military standards).

-

Product Range: Look for a manufacturer with a comprehensive product range that covers different types of EMI filters, including common mode, differential mode, feedthrough, and power line filters. Having a wide selection ensures you can find the right filter for your application.

-

Lead Times: Check the manufacturer's lead times for product delivery. Quick turnaround times can be crucial, especially for industries with tight production schedules.

-

Supply Chain and Availability: Evaluate the manufacturer's supply chain and stock availability. It's important that they can consistently provide the required filters without significant delays.

-

Cost and Pricing: Compare the pricing of filters from different manufacturers. However, don't make cost the sole determining factor, as the quality and performance of the filters are more critical.

-

Support and Customer Service: Consider the level of technical support and customer service provided by the manufacturer. They should be responsive to your inquiries and provide assistance with selecting the right filters and troubleshooting issues.

-

Reputation and References: Look for reviews, testimonials, and references from other customers who have used the manufacturer's EMI filters. A good reputation and positive feedback can be indicative of a reliable manufacturer.

-

Longevity of the Company: The manufacturer's longevity and financial stability are important factors. You want to partner with a company that will be around for the long term and can support your ongoing EMI filter needs.

By considering these factors, you can make a more informed decision when choosing an EMI filter manufacturer that best suits your specific requirements.

Coded Version

<style>/*<![CDATA[*/

#clearstyles h1, #clearstyles h2, #clearstyles h3, #clearstyles h4, #clearstyles h5, #clearstyles h6 {

all: revert !important;

color: #a04c00 !important;

margin: 0.5em !important;

}

#clearstyles {

Font-size: 120% !important;

}

#clearstyles a {

all: revert !important;

color: #a04c00 !important;

Font-weight: 600 !important;

}

#clearstyles li {

list-style-type: disc !important;

}

#clearstyles p {

margin-top: 0.15em !important;

}

#clearstyles dt {

font-weight: 500 !important;

}

#clearstyles dd {

margin-bottom: 0.5em !important;

}

@media screen and (min-width: 1200px) {

#clearstyles {

margin-left: 20% !important;

margin-right: 20% !important;

}

#clearstyles h2 {

margin-left: -5% !important;

}

#clearstyles h3 {

margin-left: -3% !important;

margin-top: 2em !important;

background-color: #2e5c6917 !important;

}

#clearstyles h4 {

margin-left: -1% !important;

}

}

@media screen and (max-width: 1199px) {

#clearstyles {

margin-left: 10% !important;

margin-right: 10% !important;

}

#clearstyles h2 {

margin-left: -5% !important;

}

#clearstyles h3 {

margin-left: -3% !important;

margin-top: 2em !important;

background-color: #2e5c692b !important;

}

#clearstyles h4 {

margin-left: -1% !important;

}

#clearstyles table {

display: none !important;

}

}

/*]]>*/</style>

<div id="clearstyles">

<h2>EMI Filters</h2>

<p>EMI (Electromagnetic Interference) filters, also known as RFI (Radio-Frequency Interference) filters or EMC (Electromagnetic Compatibility) filters, are electronic devices or components designed to mitigate or suppress electromagnetic interference in electrical and electronic circuits. Electromagnetic interference refers to unwanted electromagnetic emissions or radiation that can disrupt the proper operation of electronic equipment, cause signal degradation, and interfere with nearby devices.</p>

<h3>Quick links to EMI Filters Information</h3>

<ul>

<li><a href="#how-do-emi-filters-work">How Do EMI Filters Work?</a></li>

<li><a href="#types-of-emi-filters">Types of EMI Filters</a></li>

<li><a href="#advantages-of-using-emi-filters">Advantages of Using EMI Filters</a></li>

<li><a href="#choosing-the-right-emi-filter-manufacturer">Choosing the Right EMI Filter Manufacturer</a></li>

</ul>

<h3 id="how-do-emi-filters-work">How Do EMI Filters Work?</h3>

<p>EMI filters work by blocking or dissipating electromagnetic interference (EMI) and radio frequency interference (RFI) currents from entering or leaving an electrical device or circuit.</p>

<figure style="text-align: center;">

<img src="https://www.iqsdirectory.com/images/category/the-process-of-an-emi-filter.jpg" style="max-height: 20em;" alt="The Process of an EMI Filter" title="The Process of an EMI Filter">

</figure>

<p>Here are some key points about how they function:</p>

<ul>

<li>

<p><strong>Inductors and capacitors:</strong> EMI filters use a combination of inductors and capacitors to form passive low-pass and high-pass filters. This impedes the flow of interference currents at specific frequencies.</p>

</li>

<li>

<p><strong>Shielding: </strong>Ferrite magnetic cores and shielding enclosures are often used to enclose inductors and capacitors. This further blocks interference waves from propagating.</p>

</li>

<li>

<p><strong>Low-pass filtering:</strong> Low-pass filters using inductors and capacitors in series and/or parallel attenuate high-frequency interference currents attempting to enter or leave a device. This prevents emissions.</p>

</li>

<li>

<p><strong>High-pass filtering:</strong> High-pass filters using the same components block lower frequency noise and signals from passing through. This improves immunity.</p>

</li>

<li>

<p><strong>Common mode/differential mode:</strong> Filters are applied between signal wires and ground/earth to suppress both common mode and differential mode noise.</p>

</li>

<li>

<p><strong>Frequency selectivity: </strong>The component values determine the filter's cutoff frequency characteristics, blocking electromagnetic energies above or below certain thresholds.</p>

</li>

</ul>

<h3 id="types-of-emi-filters">Types of EMI Filters</h3>

<p>There are several common types of EMI filters, each designed to address specific aspects of EMI. The choice of filter depends on the application and the type of interference to be filtered. Here are some of the most common types:</p>

<ul>

<li>

<p><strong>Common Mode Choke Filters: </strong>These use chokes (coils) to block common mode interference produced by differential mode signals flowing in and out of a device. They work by creating opposing electromagnetic fields that cancel each other out.</p>

</li>

<li>

<p><strong>Differential Mode Filters:</strong> Also known as line filters or line impedance stabilization networks (LISNs), they suppress differential mode noise using resistive, inductive, and capacitive elements in series and/or parallel combinations. Often used at power connections.</p>

</li>

<li>

<p><strong>Radio Frequency Filters: </strong>Used to attenuate signals above a certain frequency threshold, usually in the RF range. Can be simple LC (inductor-capacitor) filters or more complex pi-filter or L-section filter designs.</p>

</li>

<li>

<p><strong>Power Line Filters:</strong> Block noise conducted along power cables. Usually make use of common mode chokes, Y-capacitors, and sometimes X-capacitors for improved high-frequency suppression. Used near power supplies or where devices share a power line.</p>

</li>

<li>

<p><strong>Buck-boost Filters:</strong> Specialized filters that provide adjustable voltage levels for circuits while also filtering noise. Often used in switched-mode power supplies and battery chargers.</p>

</li>

<li>

<p><strong>Multistage Filters: </strong>Combine various filter types (LC, pi, L-section, etc) in cascaded stages to achieve very high attenuation over broad frequency ranges. More effective but also more complex and costly.</p>

</li>

</ul>

<h3 id="advantages-of-using-emi-filters">Advantages of Using EMI Filters</h3>

<p>EMI (Electromagnetic Interference) filters are electronic components designed to mitigate and reduce electromagnetic interference in electrical and electronic systems. They offer several advantages when incorporated into electronic circuits and systems:</p>

<ul>

<li>

<p><strong>Reduce electromagnetic interference (EMI) emitted from electronic devices:</strong> EMI filters help control interference from devices that can disrupt other nearby electronics if left unchecked. This improves electromagnetic compatibility.</p>

</li>

<li>

<p><strong>Meet regulatory compliance standards:</strong> Filters allow devices to meet FCC and other regulatory standards for maximum allowed EMI emissions, which is important for selling electronic products legally.</p>

</li>

<li>

<p><strong>Improve signal integrity:</strong> Filters block interference from getting into a device's sensitive internal circuitry, keeping signal quality high and preventing noise from corrupting operation.</p>

</li>

<li>

<p><strong>Protect downstream equipment:</strong> Installing filters at the source of EMI helps protect any connected devices or cables from potential interference issues. This increases reliability.</p>

</li>

<li>

<p><strong>Lower fix costs:</strong> Adding filters upfront during design is cheaper than going back later and reworking a device's hardware to reduce EMI if issues emerge after production.</p>

</li>

<li>

<p><strong>Improve electromagnetic robustness: </strong>The device itself has enhanced protection against external EMI sources that could otherwise cause malfunctions or errors.</p>

</li>

<li>

<p><strong>Common mode rejection: </strong>EMI filters are particularly effective at rejecting interference that appears as a common-mode signal.</p>

</li>

</ul>

<h3 id="choosing-the-right-emi-filter-manufacturer">Choosing the Right EMI Filter Manufacturer</h3>

<p>When choosing an EMI filter from an EMI filter manufacturer, it is important to compare at least 4 or 5 manufacturers using our list of EMI filter manufacturers. Each EMI filter manufacturer has a business profile page that highlights their areas of experience and capabilities, and has a contact form to directly communicate with the company for more information or request a quote. Review each EMI filter company website using our patented website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple EMI filter companies with the same quote.</p>

<p>When choosing an EMI (Electromagnetic Interference) filter manufacturer, several important factors must be considered to ensure that you select the right partner for your specific needs. Here are some key factors to keep in mind:</p>

<ul>

<li>

<p><strong>Technical Expertise:</strong> Look for a manufacturer with a strong technical background and expertise in EMI filtering. They should have a deep understanding of electromagnetic interference, noise suppression, and the design of effective EMI filters.</p>

</li>

<li>

<p><strong>Customization:</strong> Consider whether the manufacturer can provide custom solutions tailored to your specific requirements. EMI filter needs can vary significantly depending on the application, so the ability to create bespoke filters is essential.</p>

</li>

<li>

<p><strong>Quality and Certification:</strong> Ensure that the manufacturer adheres to high-quality standards and has relevant certifications, such as ISO 9001 and ISO 14001. EMI filters may also need to meet specific industry standards (e.g., CE, UL, or military standards).</p>

</li>

<li>

<p><strong>Product Range: </strong>Look for a manufacturer with a comprehensive product range that covers different types of EMI filters, including common mode, differential mode, feedthrough, and power line filters. Having a wide selection ensures you can find the right filter for your application.</p>

</li>

<li>

<p><strong>Lead Times: </strong>Check the manufacturer's lead times for product delivery. Quick turnaround times can be crucial, especially for industries with tight production schedules.</p>

</li>

<li>

<p><strong>Supply Chain and Availability:</strong> Evaluate the manufacturer's supply chain and stock availability. It's important that they can consistently provide the required filters without significant delays.</p>

</li>

<li>

<p><strong>Cost and Pricing: </strong>Compare the pricing of filters from different manufacturers. However, don't make cost the sole determining factor, as the quality and performance of the filters are more critical.</p>

</li>

<li>

<p><strong>Support and Customer Service:</strong> Consider the level of technical support and customer service provided by the manufacturer. They should be responsive to your inquiries and provide assistance with selecting the right filters and troubleshooting issues.</p>

</li>

<li>

<p><strong>Reputation and References: </strong>Look for reviews, testimonials, and references from other customers who have used the manufacturer's EMI filters. A good reputation and positive feedback can be indicative of a reliable manufacturer.</p>

</li>

<li>

<p><strong>Longevity of the Company: </strong>The manufacturer's longevity and financial stability are important factors. You want to partner with a company that will be around for the long term and can support your ongoing EMI filter needs.</p>

</li>

</ul>

<p>By considering these factors, you can make a more informed decision when choosing an EMI filter manufacturer that best suits your specific requirements.</p>

</div>