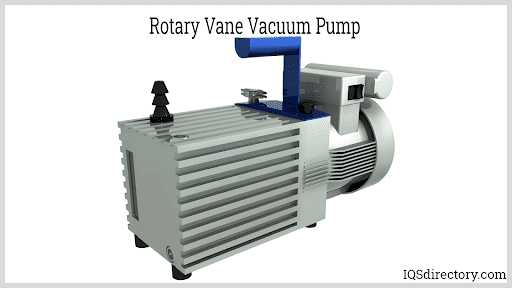

Rotary Vane Vacuum Pumps

Rotary vane vacuum pumps are vacuum pumps that generate low-pressure zones by rotating the moving parts against the pump casing. The mating surfaces of the rotor and the housing have very...

Please fill out the following form to submit a Request for Quote to any of the following companies listed on

This article gives industry insights into vacuum systems and vacuum pumps. Read further to learn more.

A vacuum pump is a device engineered to produce a partial or low-pressure vacuum by extracting gas or air molecules from a sealed environment. The word "vacuum" indicates a pressure condition where the chamber's pressure is lower than the atmospheric pressure or neighboring systems. This situation is distinct from an absolute vacuum, which describes a state with a pressure of 0 Pa (Pascal), completely free of gas particles.

Atmospheric pressure, the force exerted by air on the Earth's surface, is a central element in vacuum pump functionality. This pressure results from air molecules' weight and diminishes as one ascends to higher altitudes. Atmospheric pressure has a profound effect on machinery operations, including vacuum pumps. It seeks equilibrium by moving molecules from high-pressure areas to zones of lower pressure, in line with the tendency to fill vacuum or low-pressure gaps.

The primary goal of pumps is to transform energy into pressure. The energy needed for a pump's function is dependent on atmospheric pressure. Generally, increased atmospheric pressure enhances vacuum pump efficiency. Since atmospheric pressure greatly influences vacuum pump performance, it directly impacts operating expenses and can vary with temperature, humidity, and elevation changes.

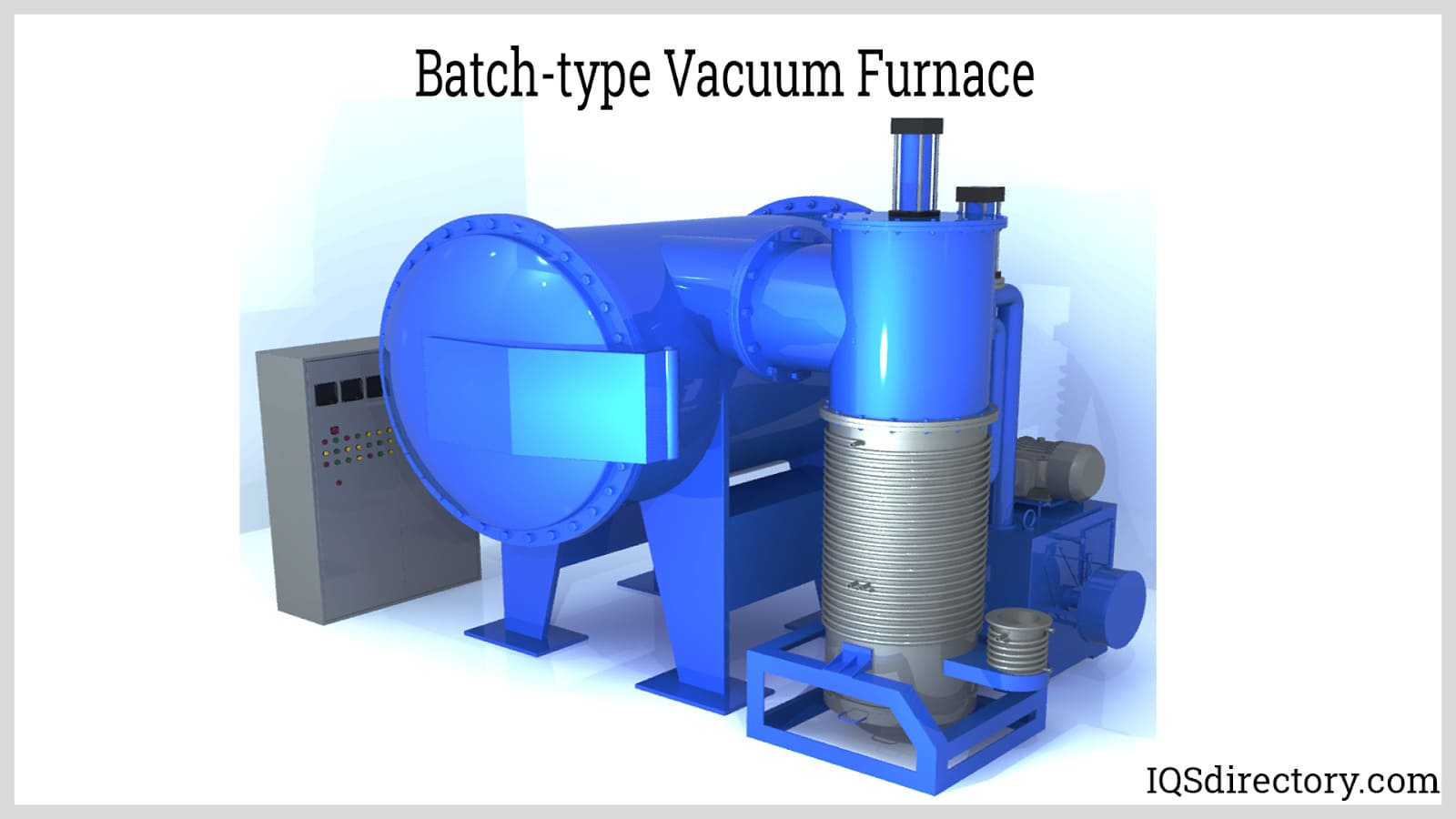

Diverse levels of vacuum are attainable, from low vacuums with absolute pressures of 1 to 0.03 bars to high vacuums that achieve pressures as minimal as a billionth of a Pascal. Low and medium vacuums are commonly employed in industrial settings such as vacuum grippers, vacuum cleaners, incandescent bulbs, painting, sandblasting, vacuum furnaces, and negative pressure ventilation. Conversely, higher vacuum systems are vital for specialized laboratory activities like particle accelerators and reactors.

Two main techniques for creating a partial vacuum exist: gas transfer and entrapment. Gas transfer approaches include positive displacement vacuum pumps, which employ chambers that cyclically expand and contract using check or non-return valves to intake and expel gases, and momentum transfer vacuum pumps, which accelerate gases, forming a low-pressure trail. Conversely, entrapment vacuum pumps trap gas molecules through various processes such as condensation, converting gases into liquid or solid states; sublimation, where gases shift directly to a solid; adsorption, involving adherence of gas molecules to surfaces; and ionization, wherein gases are ionized before capture. Each technique has particular benefits depending on the vacuum system's needs.

Vacuum ranges refer to the classification of vacuum levels based on the measurement of absolute pressure inside a sealed system. The absolute pressure indicates the number of remaining gas molecules—primarily nitrogen, oxygen, and water vapor, with traces of neon, helium, and hydrogen—within the chamber or process environment. Understanding these vacuum ranges is essential in applications requiring precise atmospheric control, such as laboratory research, semiconductor manufacturing, metallurgy, and industrial vacuum processing.

The process of creating a vacuum, specifically reducing the pressure and evacuating gas molecules from an enclosure, grows increasingly challenging as more molecules are removed. When working with advanced vacuum technology, the energy demand and system effort intensify at lower pressures, since fewer molecules remain to be evacuated. The lower the absolute pressure achieved, the closer the system comes to a "perfect vacuum"—an unattainable state, but one approached through powerful, highly efficient vacuum pump systems.

Different vacuum ranges require specialized vacuum pumps and techniques to achieve target pressure levels. Low vacuum (also referred to as rough or coarse vacuum) and medium vacuum are commonly achieved using positive displacement pumps, including rotary vane, diaphragm, and piston pumps. These vacuum pump types are ideal for most industrial vacuum applications, such as packaging, degassing, and filtration. However, when operations demand higher vacuum levels—classified as high vacuum or ultra-high vacuum (UHV)—more advanced vacuum pumps must be used.

Attaining high or ultra-high vacuum environments is critical in specialized applications like electron microscopy, mass spectrometry, surface science, nanolithography, and space simulation. These challenging vacuum ranges call for momentum transfer pumps (also called molecular pumps, such as turbomolecular and diffusion pumps), which work by accelerating gas molecules for efficient evacuation. For the most demanding ultra-high vacuum applications, entrapment pumps (including cryopumps and ion getter pumps) are used, relying on condensation, adsorption, or chemical reactions to capture and remove the last traces of gas molecules.

To select the appropriate vacuum pump or system for your operation, it’s crucial to match the target vacuum range to both the process requirements and anticipated contaminants. Other important considerations include pump throughput, maintenance, reliability, and compatibility with your process gases. Investing in the right pumping technology ensures consistent performance and process optimization across diverse industries.

| Vacuum Range | Absolute Pressure (Pa) |

|---|---|

| Atmospheric | 101,325 |

| Low Vacuum (Rough, Coarse) | 1.01 x 10⁵ to 3.33 x 10³ |

| Medium Vacuum | 3.33 x 10³ to 1 x 10⁻¹ |

| High Vacuum | 1 x 10⁻¹ to 1x10⁻⁷ |

| Ultra-high Vacuum | 1 x 10⁻⁷ to 1 x 10⁻¹⁰ |

Key Takeaways for Choosing a Vacuum Range:

For further guidance on vacuum pump selection, application requirements, or optimizing your vacuum system, consult with leading industry experts or trusted manufacturers. Leveraging the right vacuum technology elevates productivity, improves process reliability, and enables advanced research outcomes in science, manufacturing, and engineering.

The two main classifications of vacuum pumping principles are gas transfer and entrapment. Gas transfer mechanisms are further divided into positive displacement pumps and momentum transfer pumps. To fully understand industrial vacuum pumps and their applications in vacuum technology, it's essential first to grasp the three primary types of flow that gases exhibit under varying vacuum levels: viscous, transitional, and molecular flow.

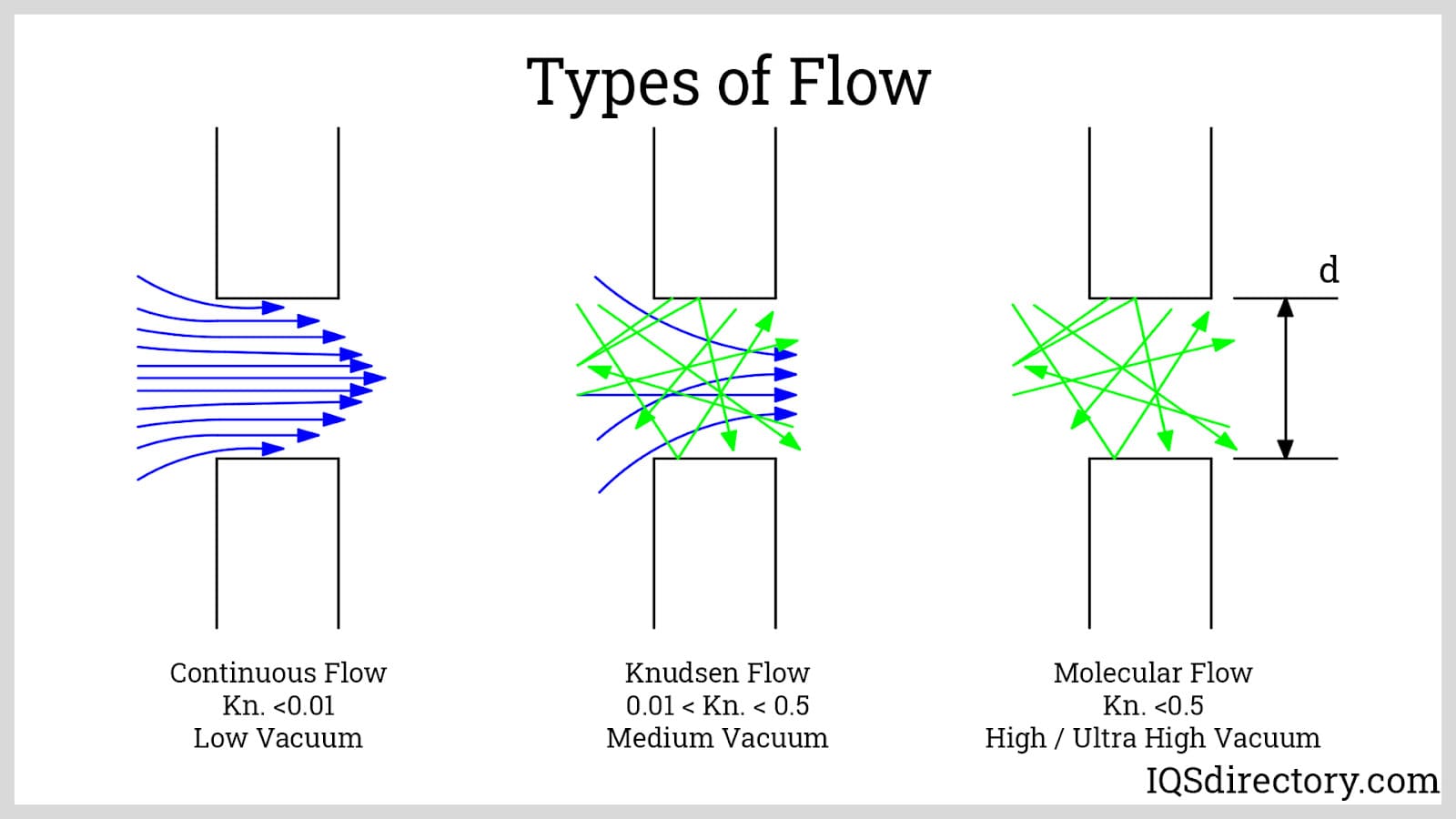

Viscous or continuous flow arises at high pressures and within the rough vacuum and medium vacuum range, where gas molecules are densely packed and frequently collide with one another. Here, the mean free path—the average distance a gas molecule travels before another collision—is much shorter than the chamber's physical dimensions. As higher vacuum levels are achieved and pressure decreases, the movement of gas molecules transitions toward more frequent interaction with the chamber surfaces instead of other gas molecules.

Transitional flow represents the intermediate regime between viscous and molecular flow, where both molecule-to-molecule and molecule-to-wall collisions occur with comparable frequency. Finally, in the molecular flow regime, typical of high vacuum and ultra-high vacuum applications, the mean free path greatly exceeds chamber dimensions, resulting in highly random molecular movement with rare intermolecular collisions. Understanding these gas flow behaviors is crucial for selecting and operating different vacuum pump types appropriately for laboratory, industrial, and scientific use.

In viscous flow, fluids can be effectively pumped mechanically by positive displacement pumps, which are commonly used for low vacuum and medium vacuum processes. As the system approaches higher vacuum and molecular flow conditions, positive displacement pumps become less effective, necessitating the integration of momentum transfer pumps (also called molecular pumps) or entrapment pumping systems. Most high vacuum systems used in research laboratories and manufacturing plants require a combination (or vacuum pump system)—with roughing pumps establishing low pressure and high vacuum pumps achieving deeper vacuum ranges. It's important to note that while positive displacement pumps struggle at ultra-high vacuum, momentum transfer pumps can be adversely affected if run in a viscous regime. Entrapment pumps, though capable of producing exceptionally clean vacuums, may require frequent regeneration if managing large quantities of condensable gas or vapor.

Positive displacement vacuum pumps operate by repeatedly expanding and compressing a sealed volume, with the intake and exhaust cycles regulated by high-performance one-way (non-return) valves. During expansion, a partial vacuum is generated, enabling air or process gas to enter the pump chamber. Upon reaching maximum chamber volume, the intake valve closes, the exhaust valve opens, and compression discharges the fluid. This rapid reciprocating action produces the characteristic pulsating flow and makes these pumps suitable for a broad range of industrial vacuum and laboratory vacuum applications.

These mechanical vacuum pumps are divided according to the design and motion of their internal chambers—single-acting or double-acting, and reciprocating or rotary configurations are the most common.

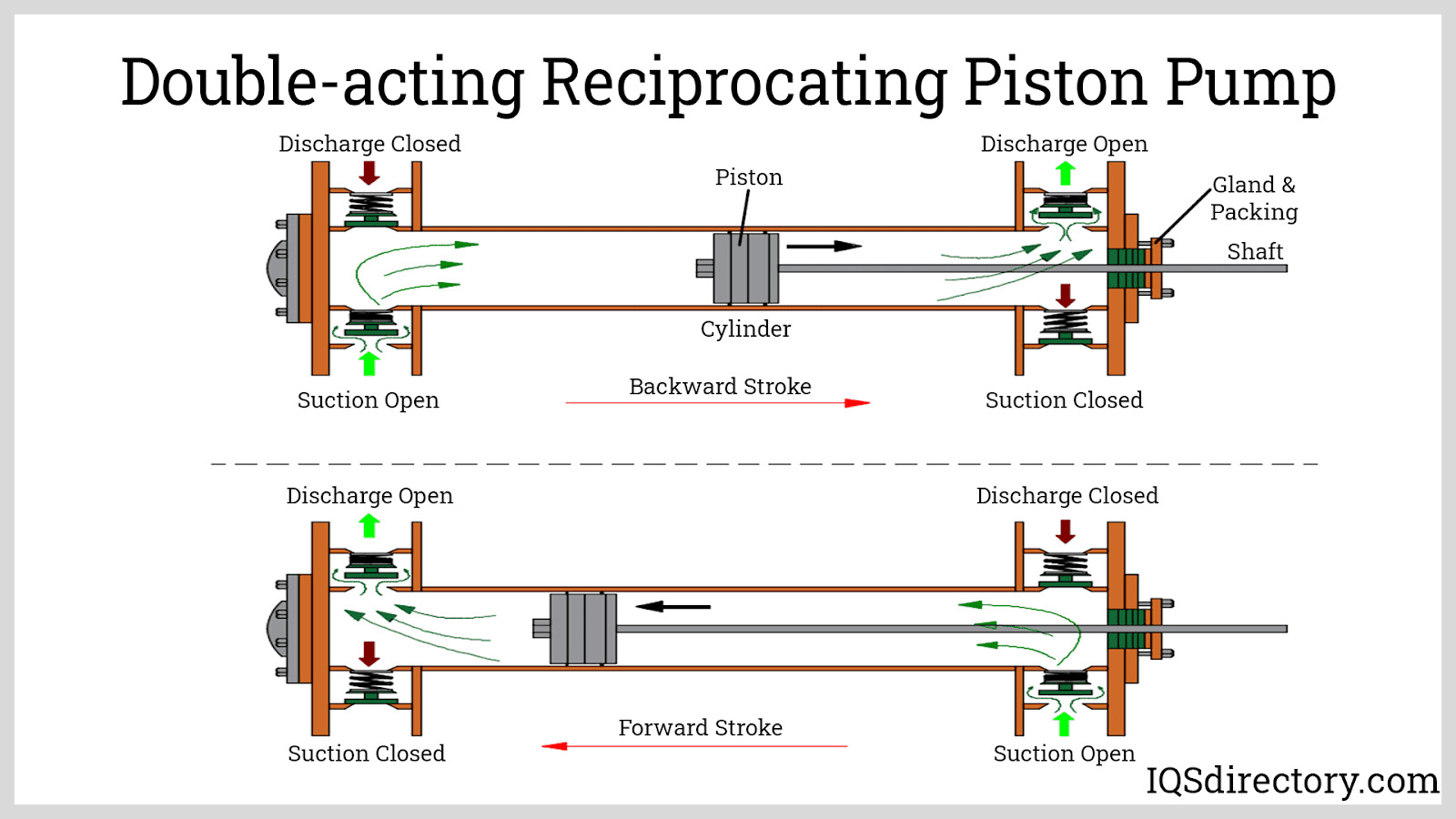

Reciprocating Piston Vacuum Pump: This classic pump uses a crankshaft-driven piston inside a cylinder, with piston materials selected for durability and chemical resistance. Cast iron, bronze, and steel pistons are common, especially for demanding industrial and research uses, where reliability and high volumetric efficiency are key.

Plunger Vacuum Pump: Similar in operation to piston pumps, plunger designs use a long, robust plunger (often ceramic for chemical compatibility and wear-resistance) with a fixed high-pressure seal, making these pumps advantageous for processes involving high differential pressures or aggressive process gases.

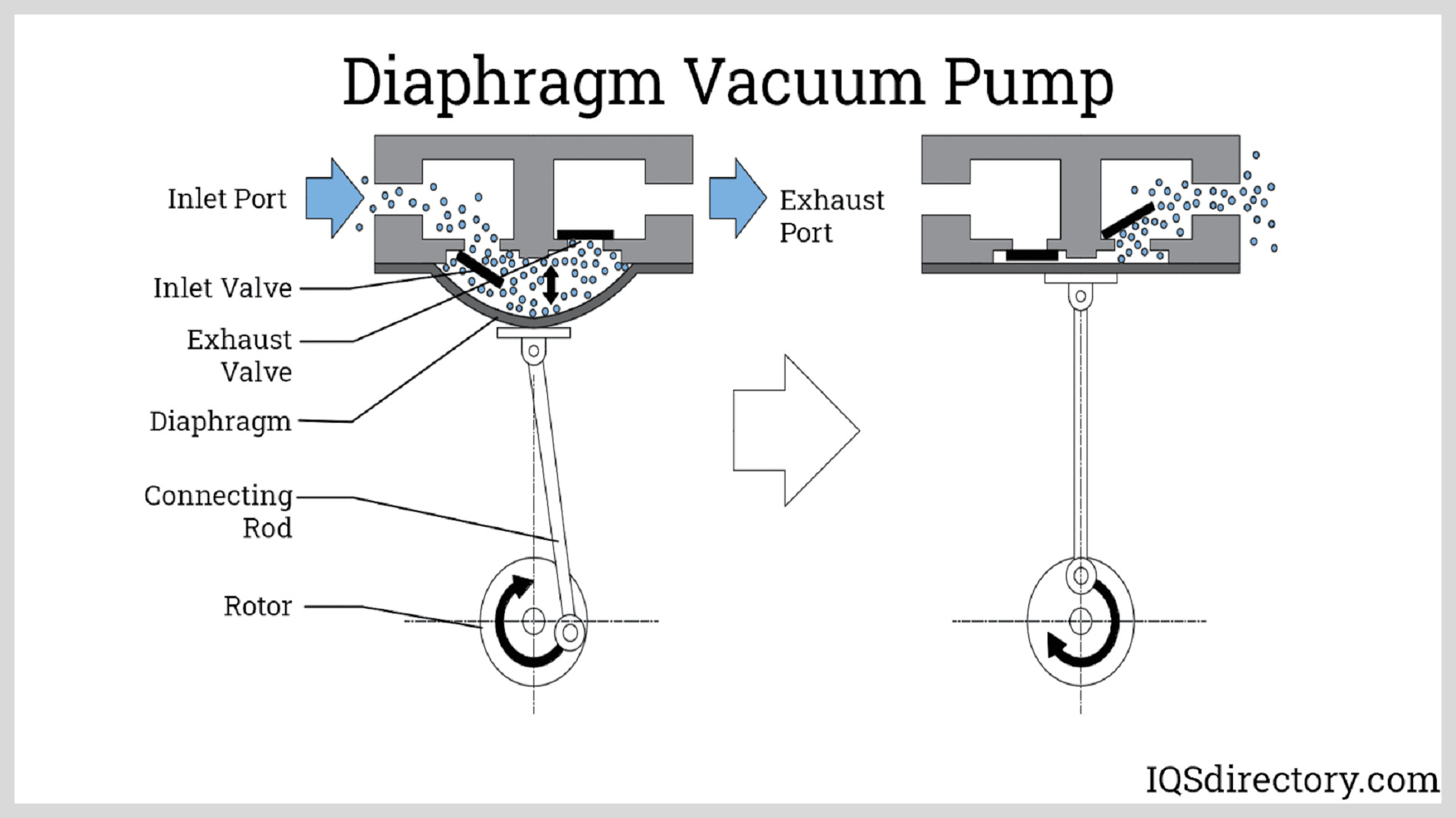

Diaphragm Vacuum Pump: These oil-free pumps employ a flexible membrane to separate the pumped medium from moving components, providing exceptional containment of corrosive or hazardous gases. As a result, diaphragm pumps see frequent use in laboratory vacuum systems, environmental analysis, and filtration processes requiring contamination-free operation.

To create smoother flow and minimize pulsation, reciprocating vacuum pumps can utilize multiplex configurations—combining multiple pistons or diaphragms in parallel to deliver more continuous and consistent vacuum at variable flow rates. This versatility makes them highly adaptable for diverse vacuum process requirements.

Reciprocating pumps also differ by action: single-acting pumps accomplish suction or compression only on one side of the piston during each stroke, while double-acting pumps produce vacuum and compression simultaneously on both sides of the piston or diaphragm during every revolution, improving overall efficiency and throughput—an important advantage for industrial and manufacturing vacuum applications where process speed and stability are critical.

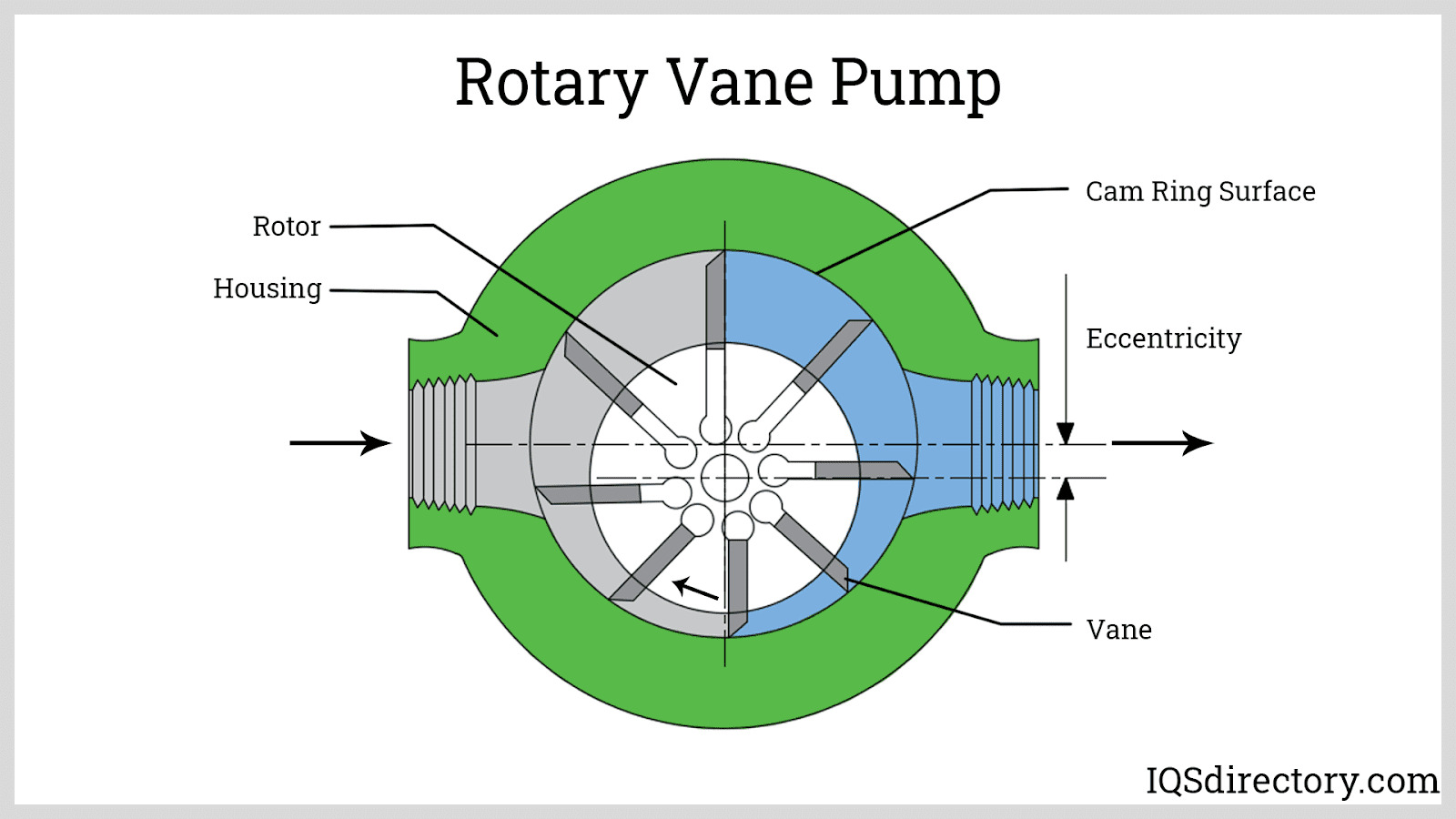

Rotary Vane Vacuum Pump: Among the most widespread positive displacement pumps, rotary vane models feature movable vanes housed within an offset rotor. As the rotor turns, chambers between vanes cyclically expand and contract, providing highly effective vacuum generation for applications from basic laboratory use to complex industrial systems. Rotary vane pumps can be oil-sealed for deeper vacuum or configured as dry vane pumps for clean environments.

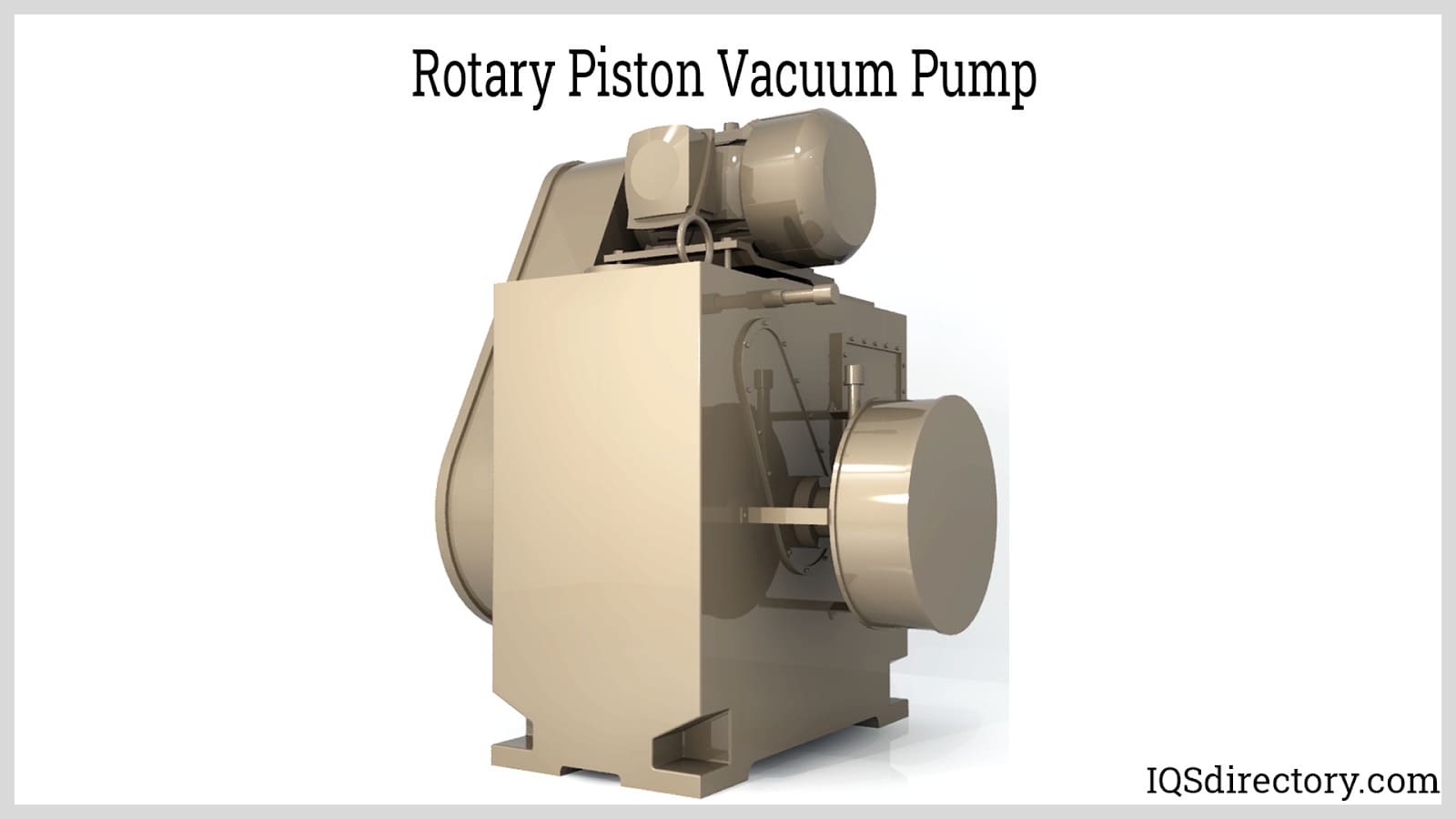

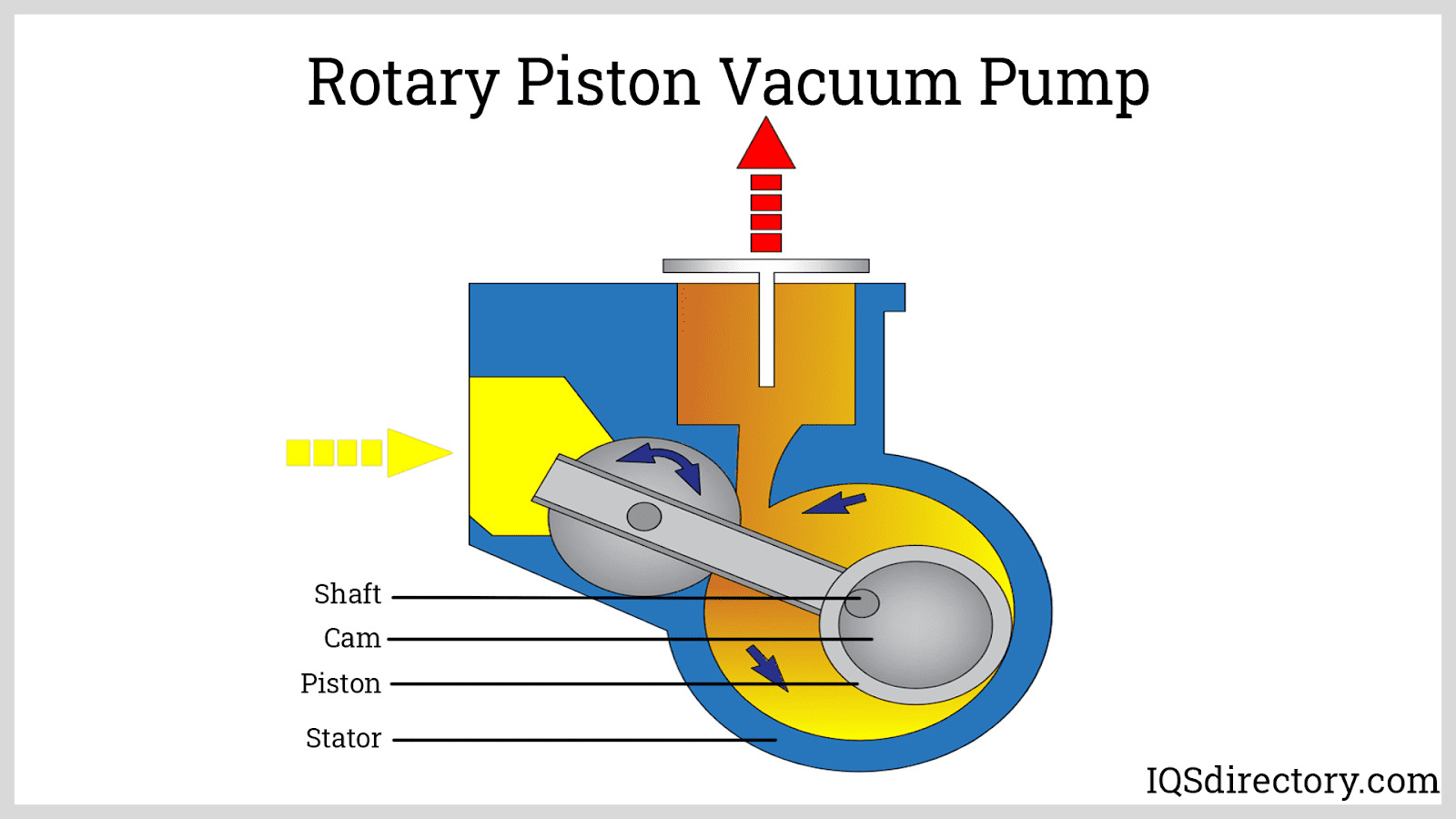

Rotary Piston Vacuum Pump: Featuring a rotating eccentric piston and slide valve system, these pumps achieve robust vacuum levels and are often used in demanding process environments where reliability and efficiency are required, such as plastic degassing, transformer drying, and metallurgy.

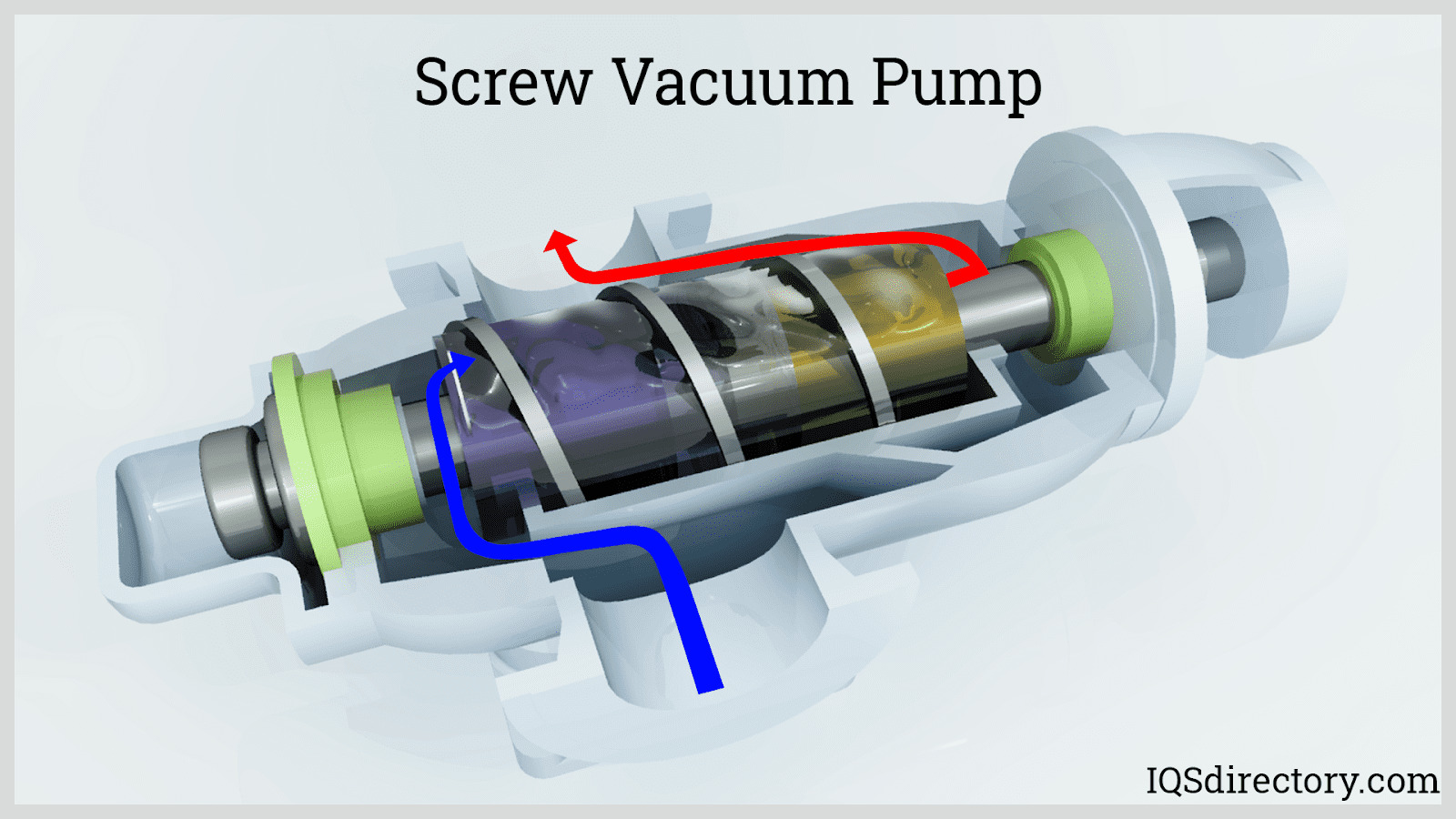

Screw Vacuum Pump: Embracing the principle of the Archimedes screw, modern screw vacuum pumps employ dual or triple intermeshing screws, providing oil-free, contamination-resistant operation capable of handling a range of gases and vapors, including applications requiring clean room compatibility and the management of light dust or particles.

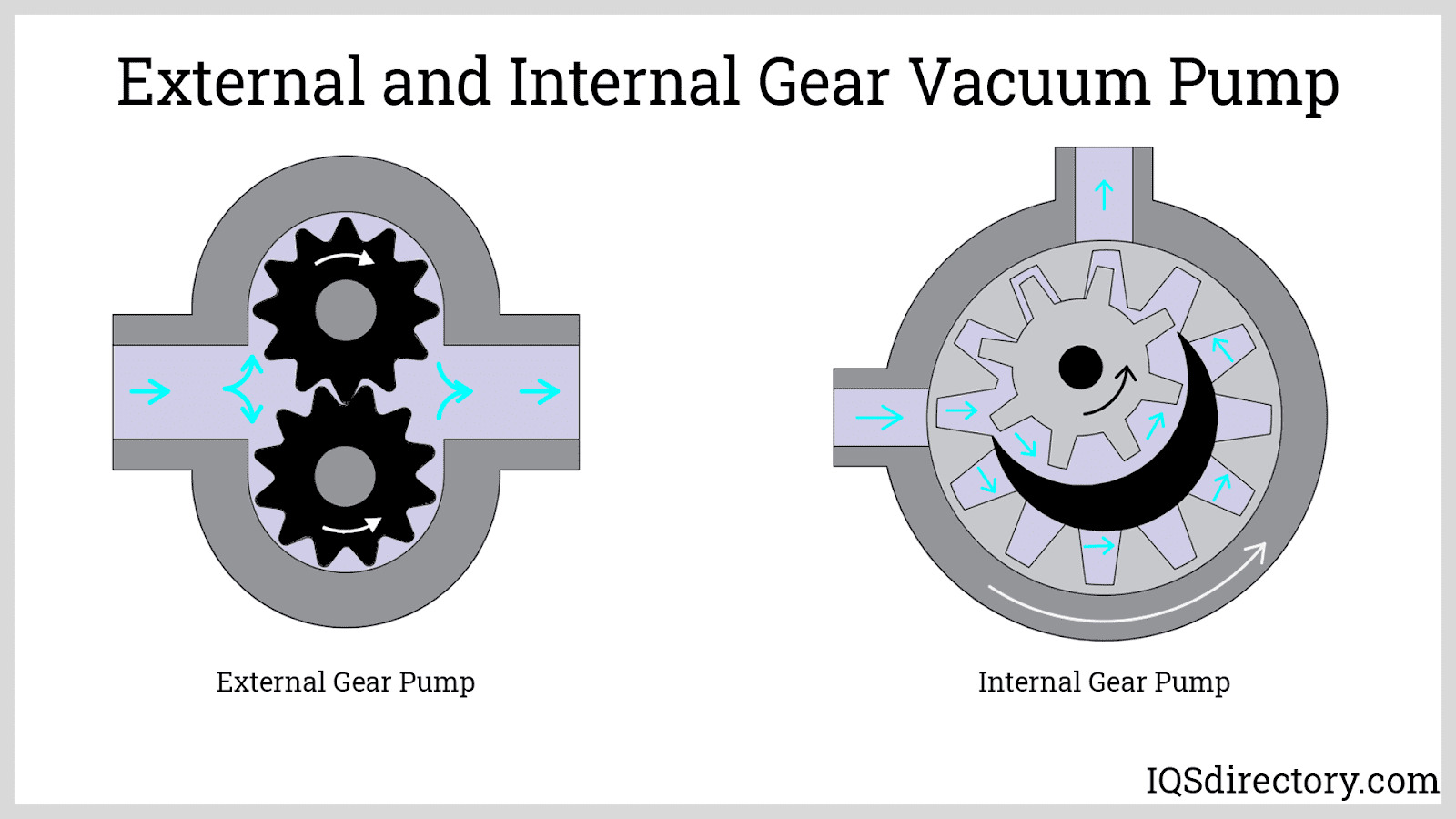

Gear Vacuum Pump: Utilizing precision-machined gears, these compact positive displacement pumps are effective for small volume, high-pressure vacuum or fluid transfer applications—ideal for instrument calibration, hydraulic test stands, or pilot-scale processing equipment.

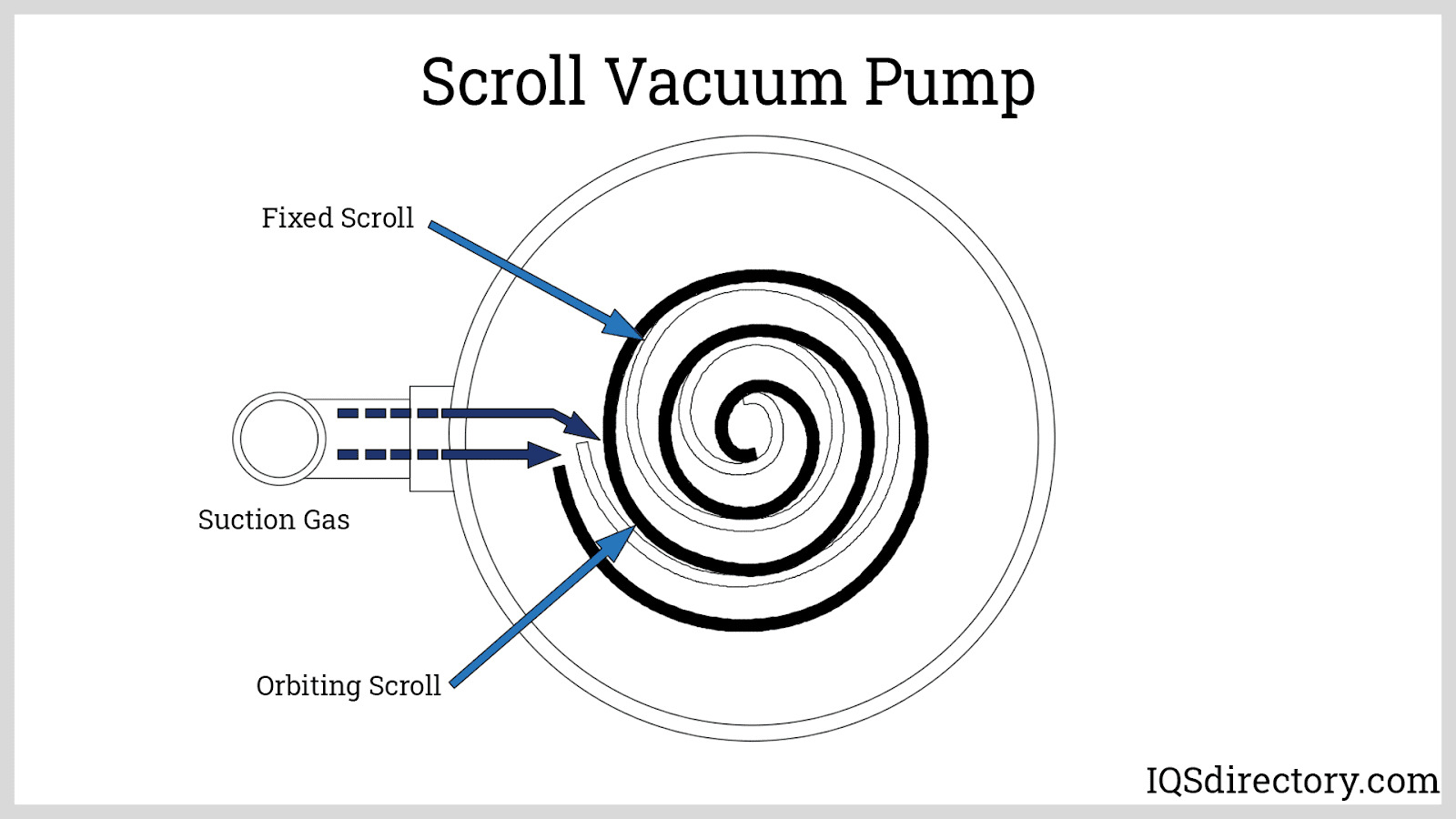

Scroll Vacuum Pump: Utilizing orbiting scrolls to compress and displace air, scroll pumps deliver ultra-smooth, oil-free vacuum suitable for sensitive laboratory and semiconductor device manufacturing, as well as in medical vacuum supply.

When specifying a positive displacement vacuum pump for your process, it is critical to consider ultimate vacuum (lowest pressure achievable), pumping speed or flow rate, serviceability, and compatibility with gases, vapors, or contaminants unique to your operation. For more detailed guidance, reviewing pump datasheets and consulting with pump manufacturers can ensure optimal system design and performance.

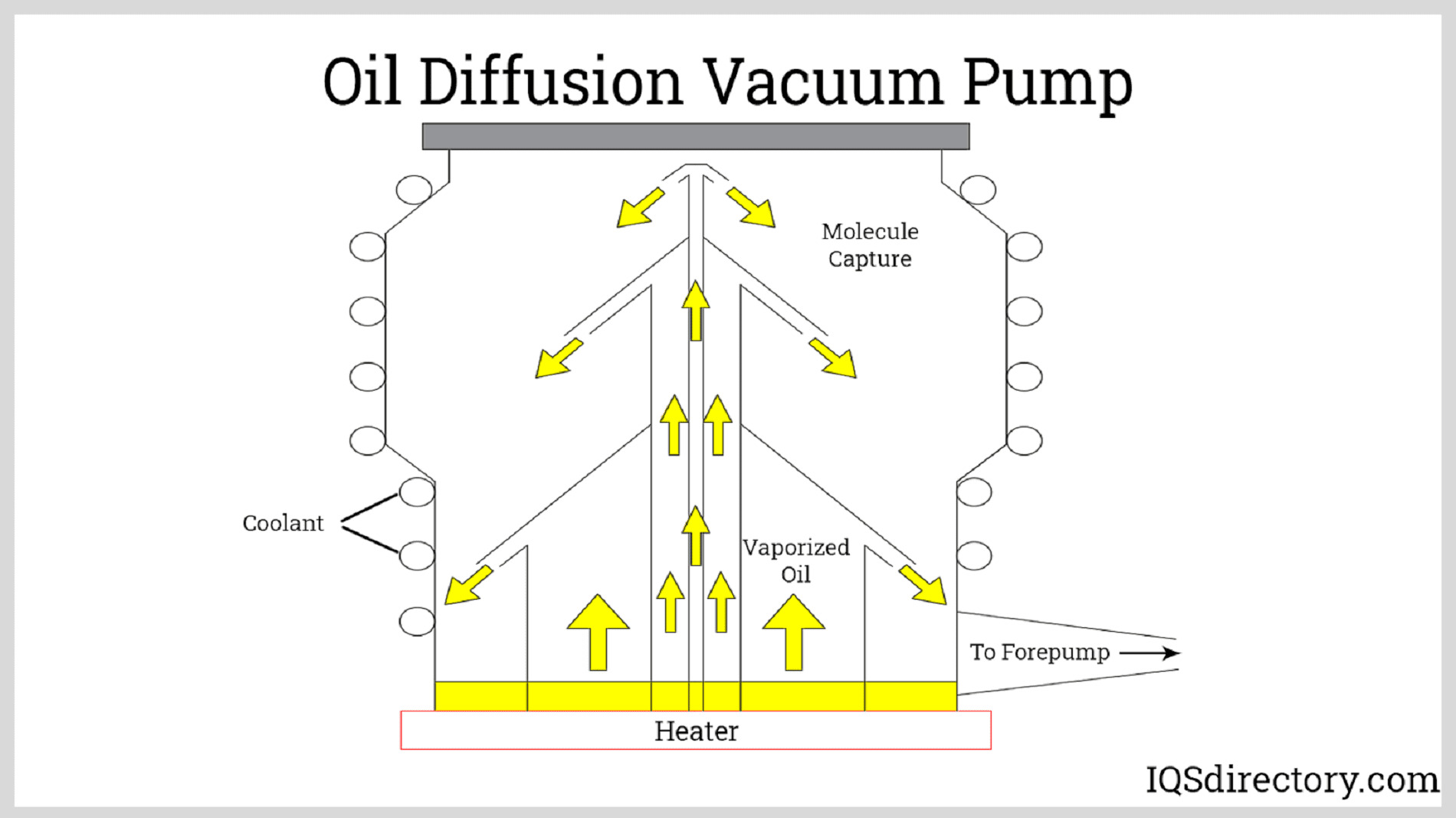

Momentum transfer vacuum pumps, or molecular pumps, achieve vacuum by imparting kinetic energy to gas molecules, propelling them directionally through repeated high-speed collisions or fluid jets. Unlike positive displacement pumps operating on viscous flow, momentum transfer pumps perform in the molecular flow regime, making them indispensable for achieving high vacuum or ultra-high vacuum (UHV) levels in fields like surface science, thin film deposition, and semiconductor manufacturing. Common types are turbomolecular pumps and diffusion pumps.

As these pumps require extremely low inlet pressures to function correctly, they are typically backed by roughing pumps (often rotary vane or dry screw pumps) to prevent backstreaming or performance loss. Proper configuration of your vacuum pump system—including appropriate backing pump selection and ensuring efficient foreline pressure control—maximizes vacuum integrity, increases system longevity, and reduces maintenance.

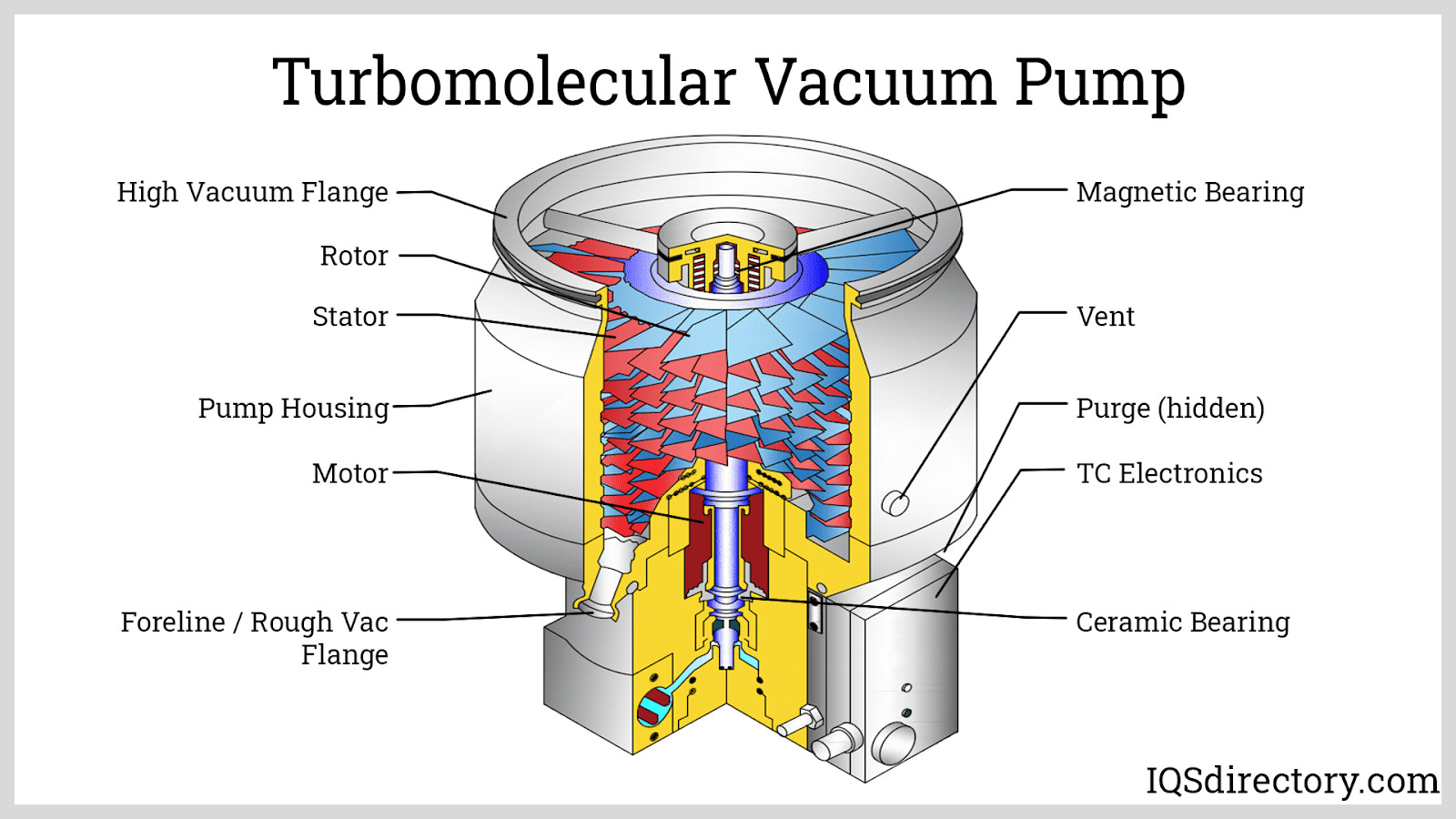

Turbomolecular Vacuum Pump: Characterized by multiple precisely engineered rotor and stator blade stages, turbomolecular pumps spin at ultra-high speeds (sometimes exceeding 60,000 rpm) to transfer energy to entering gas molecules. The blades' optimized angles accelerate gas in a preferred direction, resulting in exceptional compression ratios and ultra-clean vacuum—making these pumps ideal for sensitive analytical equipment and contamination-free processes.

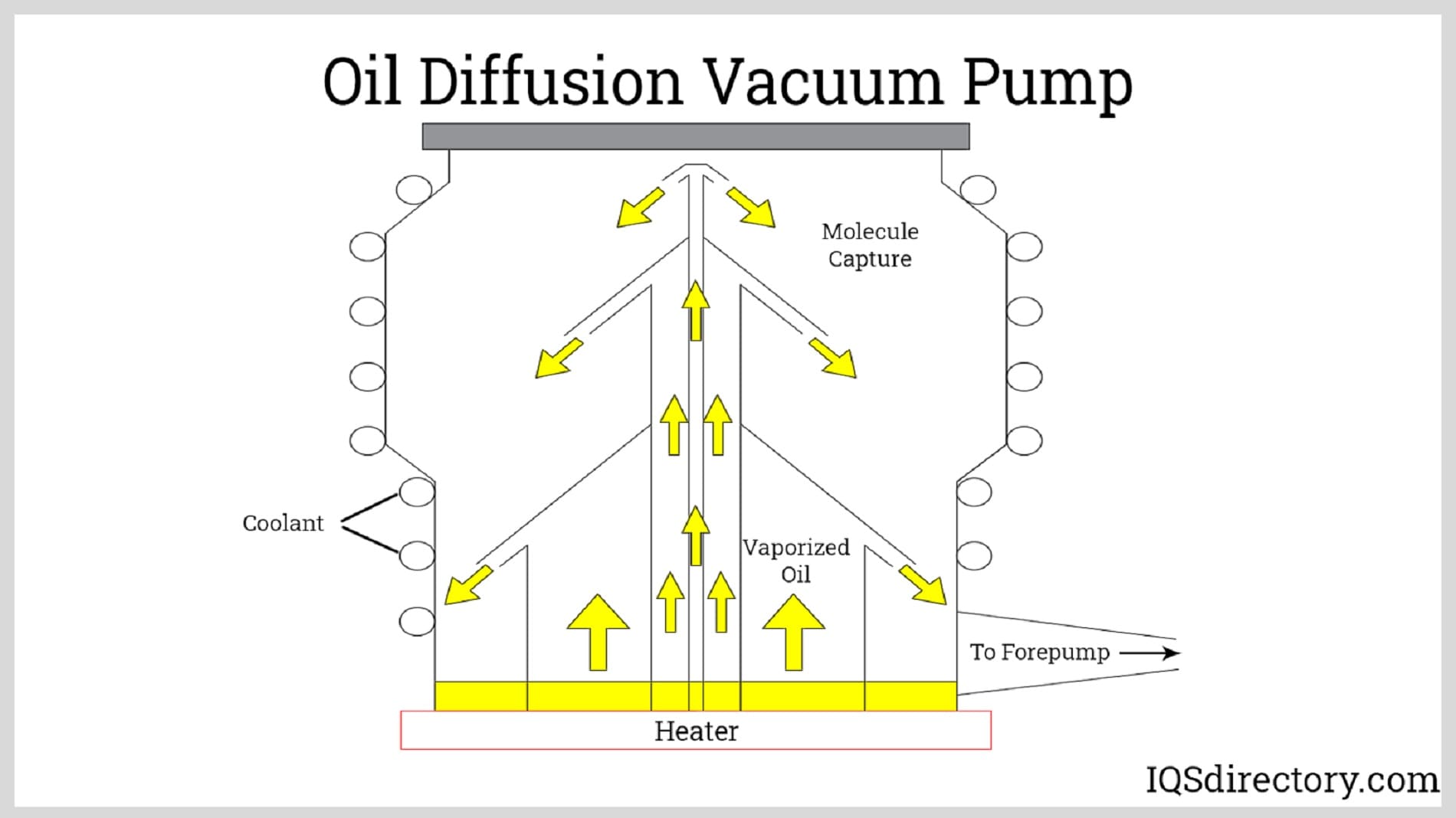

Diffusion Vacuum Pump: Leveraging vaporized oil or steam jets, diffusion pumps rapidly transfer momentum to residual gas molecules, driving them toward the exhaust at the pump base. Used worldwide for manufacturing, R&D, and coating operations requiring deep vacuum, diffusion pumps are recognized for high throughput, cost-effectiveness, and minimal vibration. For clean vacuum, oil traps or baffles can minimize hydrocarbon backstreaming. Steam-jet ejector types offer oil-free alternatives for specific ultra-pure applications.

When choosing between turbomolecular and diffusion vacuum pumps, consider base pressure requirements, contamination sensitivities, required pumping speed, and routine maintenance needs. Learn more about vacuum system design.

Entrapment vacuum pumps, also known as capture pumps, remove gas molecules by physically or chemically binding them to internal surfaces or adsorbent materials. These pumps introduce no oil or mechanical wear particles, delivering clean, high, and ultra-high vacuum environments critical for processes such as semiconductor production, surface analysis, and cryogenics. Common entrapment mechanisms include cryogenic condensation, adsorption, and gettering by ionization or chemical bonding.

With no moving parts, entrapment vacuum pumps are maintenance-light but must be periodically reconditioned when the capturing medium is saturated. Their main drawback is limited pumping capacity for light gases like hydrogen or helium, requiring hybrid vacuum systems for some applications.

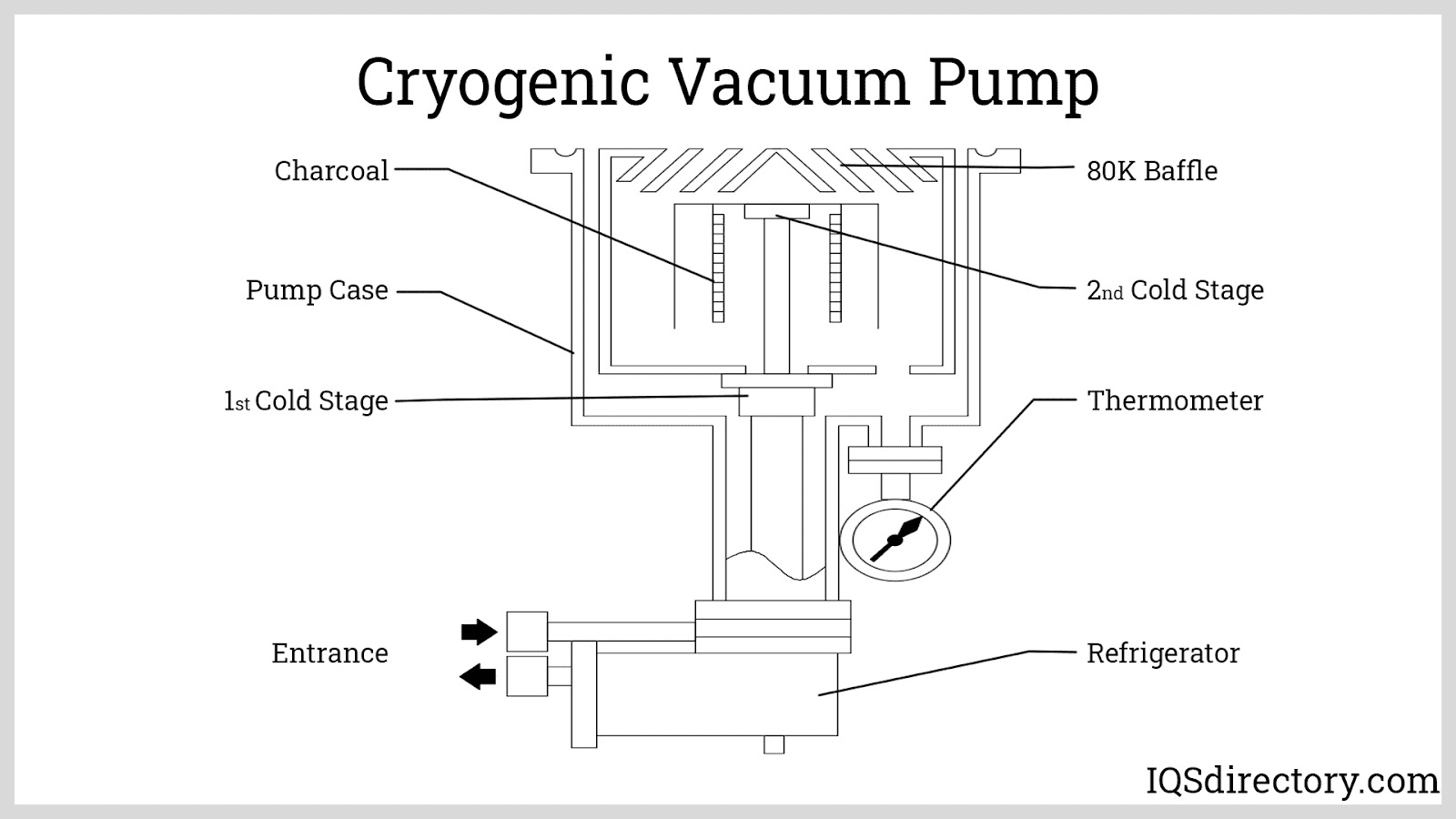

Cryogenic Vacuum Pump: Utilizing powerful refrigeration stages, cryopumps condense or freeze incoming gases onto cold surfaces—often reaching temperatures below 10 K for effective trapping of all but the lightest gases. These pumps excel in applications requiring ultra-pure vacuum, such as accelerator beamlines, semi-fabrication, and thin film deposition.

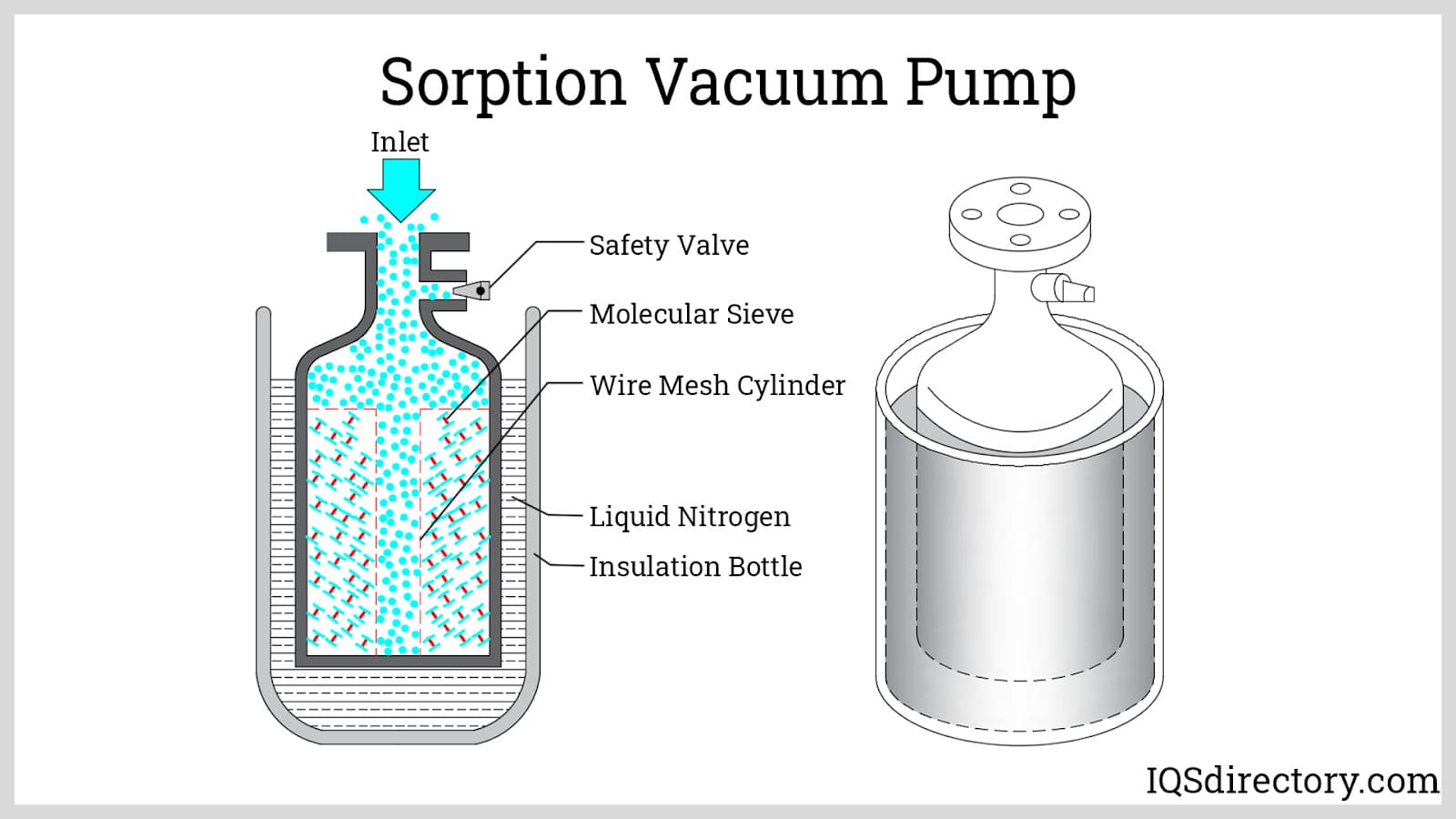

Sorption Vacuum Pump: By employing high-surface-area adsorbents—like molecular sieves, zeolites, or activated charcoal—sorption pumps trap gas molecules via physical adsorption. Frequently paired with cryopumps in vacuum isolation and instrument protection, these pumps are simple, clean, and widely used in small volume or backup applications.

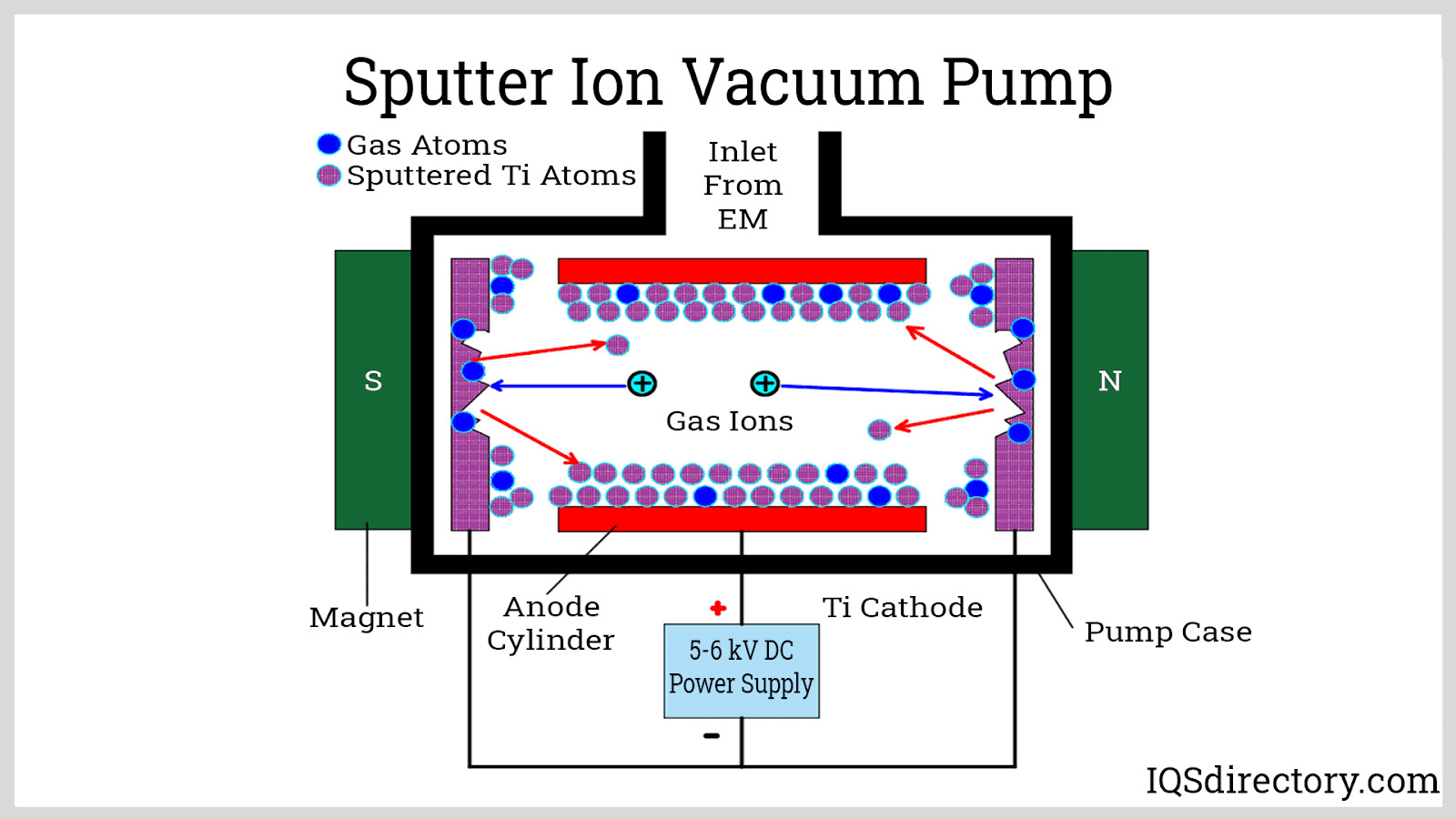

Sputter Ion Vacuum Pump: Sometimes called ion getter pumps, these devices ionize residual gases using a strong electromagnetic field. The resulting ions bombard a titanium cathode, embedding themselves or causing ejection of reactive atoms which permanently bond further molecules—a key technology in ultra-high-vacuum (UHV) scenarios like surface analysis and electron microscopy.

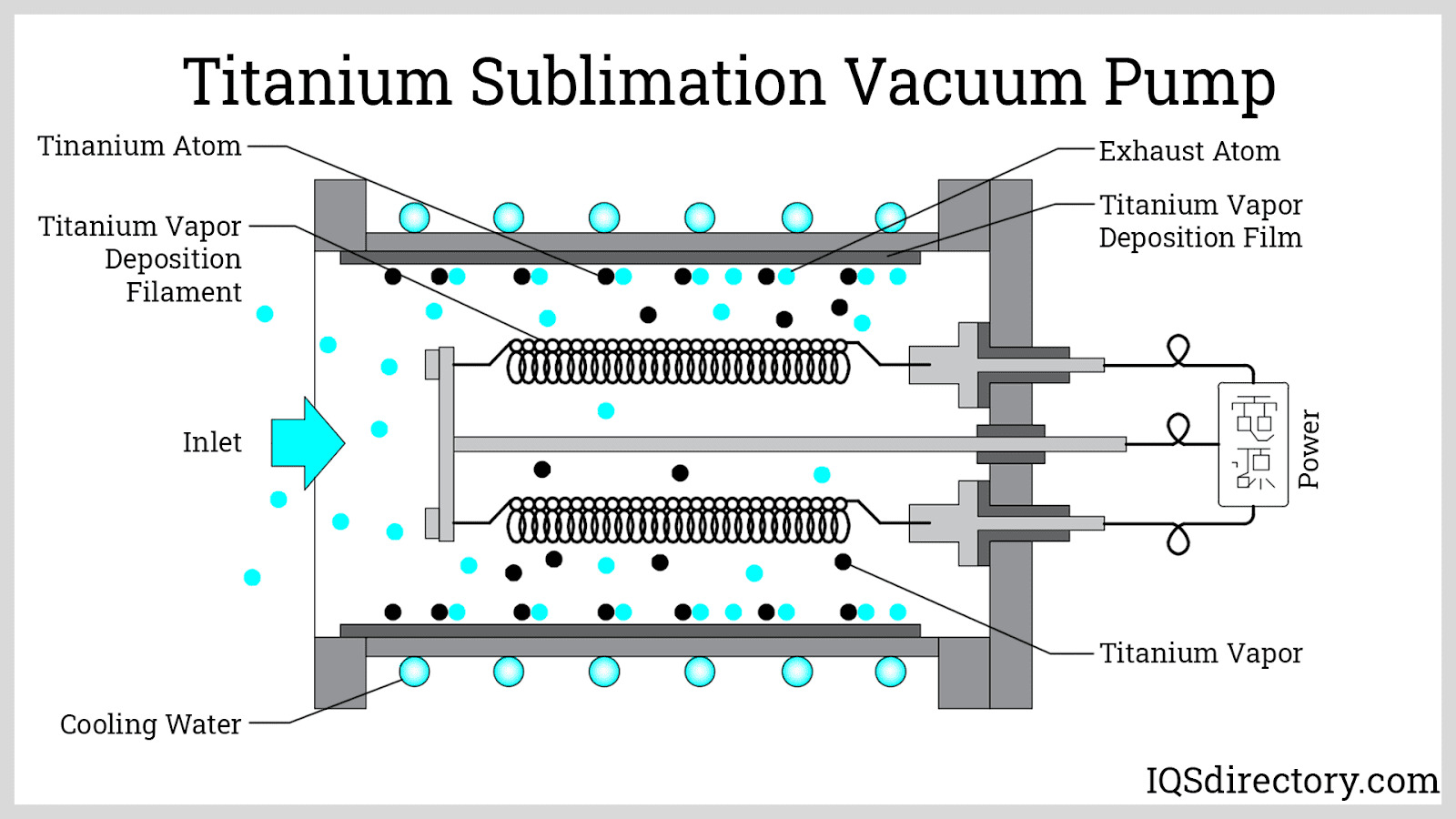

Titanium Sublimation Vacuum Pump: By heating a titanium filament, these pumps create reactive titanium vapor which coats internal chamber surfaces, chemically binding and capturing residual gases. Used as supplementary pumping in UHV chambers and scientific instrumentation, maintenance is minimal aside from periodic filament replacement.

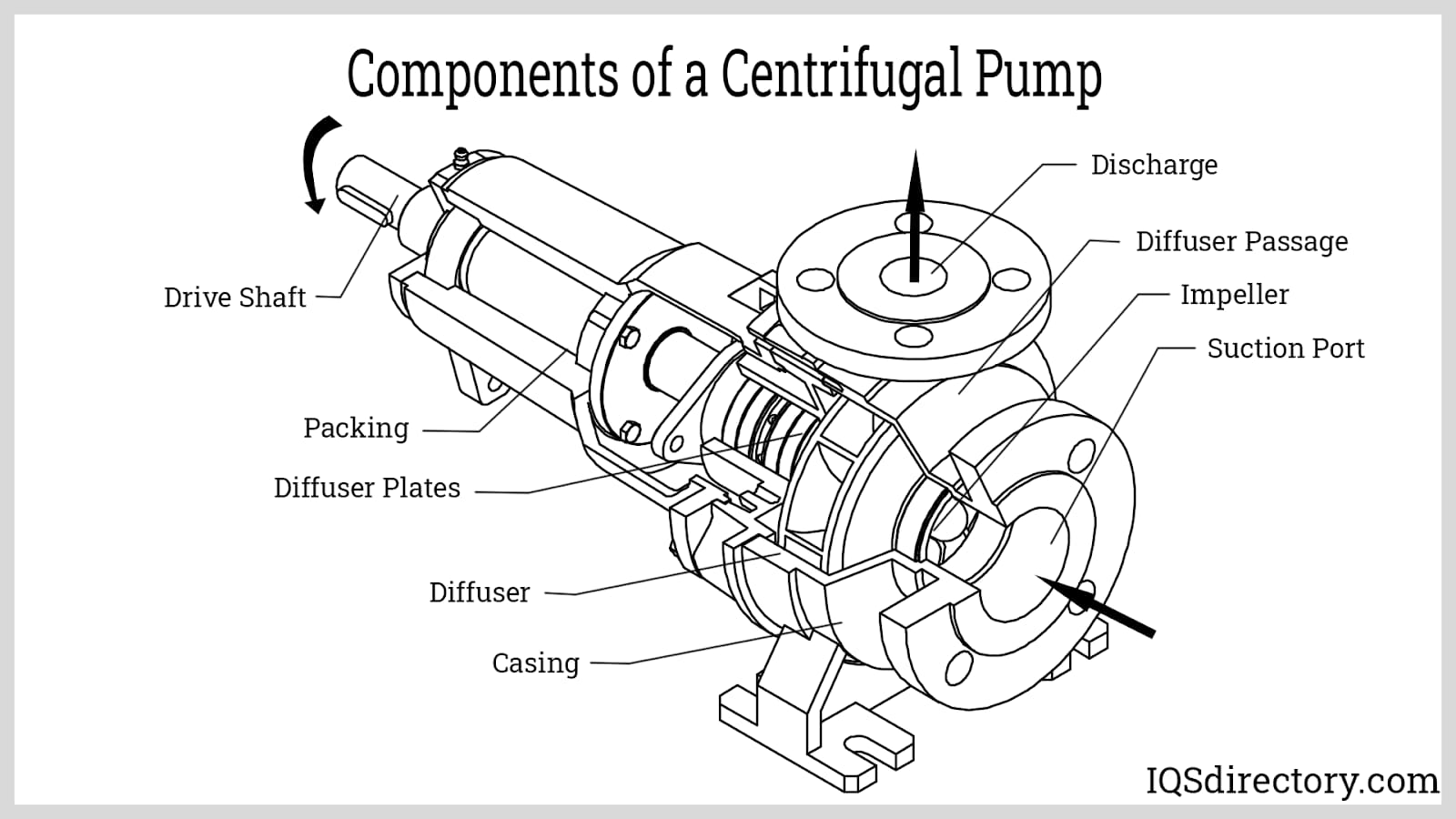

Centrifugal Pumps: While primarily used for moving liquids rather than creating vacuum, centrifugal pumps utilize rotating impellers to impart velocity and pressure to fluids—a principle leveraged in vacuum-assisted liquid transfer and certain hybrid vacuum systems. Their adjustable flow rates and robust design make them indispensable in chemical processing, water treatment, and industrial liquid handling, but they are not used for generating true vacuum in gas-phase systems.

The impeller, driven via a precision shaft, generates the dynamic force needed for continuous liquid movement—a fundamental concept in fluid mechanics and a cornerstone of pump engineering.

Choosing the Right Vacuum Pump: Selecting an appropriate vacuum pump involves careful evaluation of required ultimate pressure, flow rate, gas compatibility, contamination tolerances, and service conditions. Modern vacuum technology offers an array of options tailored for specific industrial, laboratory, and scientific needs. Consider overall lifecycle cost, maintenance frequency, energy efficiency, and integration with control systems when designing your vacuum solution for optimal performance and long-term reliability.

A vacuum pump extracts gas or air molecules from a sealed environment, reducing the pressure below atmospheric levels. It operates by either transferring gases out (gas transfer) or capturing them (entrapment), enabling various industrial and scientific processes requiring controlled low-pressure environments.

Vacuum ranges are classified by absolute pressure: low vacuum (1.01×10⁵ to 3.33×10³ Pa), medium vacuum, high vacuum (down to 10⁻⁷ Pa), and ultra-high vacuum (as low as 10⁻¹⁰ Pa). Each range requires specific pump technologies and is suited for particular applications.

For industrial applications, positive displacement pumps such as rotary vane, rotary piston, or diaphragm pumps are widely used for low and medium vacuum tasks. For high or ultra-high vacuum, turbomolecular, diffusion, or entrapment pumps are preferred for their advanced vacuum capabilities.

Key factors include required vacuum range, compatibility with process gases, contaminant handling, pumping speed, energy efficiency, maintenance frequency, and integration needs. Each application may demand specific pump technologies tailored to its requirements.

Entrapment pumps remove gases by condensing, adsorbing, or chemically binding them, offering oil-free, clean high or ultra-high vacuum. They have minimal moving parts and low maintenance, making them ideal for ultra-clean processes like semiconductor manufacturing and surface analysis.

Yes, higher elevation and changes in atmospheric pressure directly impact a vacuum pump’s efficiency. Increased atmospheric pressure enhances pump performance, while lower pressure at high altitudes can reduce vacuum effectiveness and influence operating costs.

In addition to their operating principles, vacuum pumps can be categorized based on their lubrication and sealing systems. They can be either wet or dry lubricated. The choice between these lubrication types impacts various performance factors, including wear resistance, pumping speed, and fluid contamination.

Vacuum ejectors and Venturi vacuum pumps utilize the Venturi principle, where a Venturi nozzle accelerates materials at high speeds. These devices operate based on Bernoulli’s principle and have no moving parts.

A vacuum ejector, also known as a venturi vacuum pump, operates on the Venturi effect, which is derived from Bernoulli's principle. This principle, based on the law of conservation of energy for fluids, states that as a fluid's velocity increases, its pressure decreases, and vice versa. Vacuum ejectors use compressed air as their energy source, rather than electricity.

Inside a vacuum ejector is a Venturi, a jet nozzle that expels high-pressure air across a chamber and out through a receiver nozzle. The Venturi nozzle features a constricted orifice that narrows and then gradually expands, accelerating the air and decreasing the pressure. The high-velocity stream of air between the nozzles creates a region of lower pressure. As a result, outside air is drawn into the chamber and is carried out through the receiver nozzle along with the compressed air.

Venturi pumps are housed within a vacuum ejector, which includes a port between the nozzles that allows the pump to provide vacuum for various applications.

The advantages of a vacuum ejector:

However, a disadvantage of using a vacuum ejector is the unavoidable mixing of the motive fluid with the fluid from the vacuum connection. If recovery of the fluid drawn from the evacuated chamber is desired, additional separation techniques are required.

Vacuum ejectors are typically used in applications involving the drawing of liquids such as water and steam, where the mixing of the motive and vacuum streams is not problematic. They are commonly employed in power plants, petroleum and petrochemical facilities, and water treatment plants.

Venturi vacuum pumps feature an inlet and an outlet, with a nozzle positioned between them. The nozzle restricts the flow of fluids, which increases the velocity of the fluid and decreases its pressure. This pressure drop creates a vacuum, drawing fluid into the nozzle and then expelling it through the outlet.

Unlike many other vacuum pumps, Venturi vacuum pumps do not require an external power source; instead, they operate using compressed air. They are compact, lightweight, and can run continuously for extended periods without issues. Because they don't rely on a power source, they do not generate heat and thus do not risk overheating. Additionally, Venturi vacuum pumps can be tailored to specific applications by adjusting the nozzle diameter, which optimizes pressure loss and differential pressure to meet the application’s requirements.

Advantages of a Venturi Vacuum Pump:

Venturi vacuum pumps are employed in applications where precise control and minimal pressure loss are crucial. They can handle both wet and dry materials and fluids, transporting them through pipelines. Similar to vacuum ejectors, Venturi vacuum pumps are often used in conjunction with conventional vacuum pumps to aid in the transportation of materials over long distances.

Rotary vane vacuum pumps are vacuum pumps that generate low-pressure zones by rotating the moving parts against the pump casing. The mating surfaces of the rotor and the housing have very...

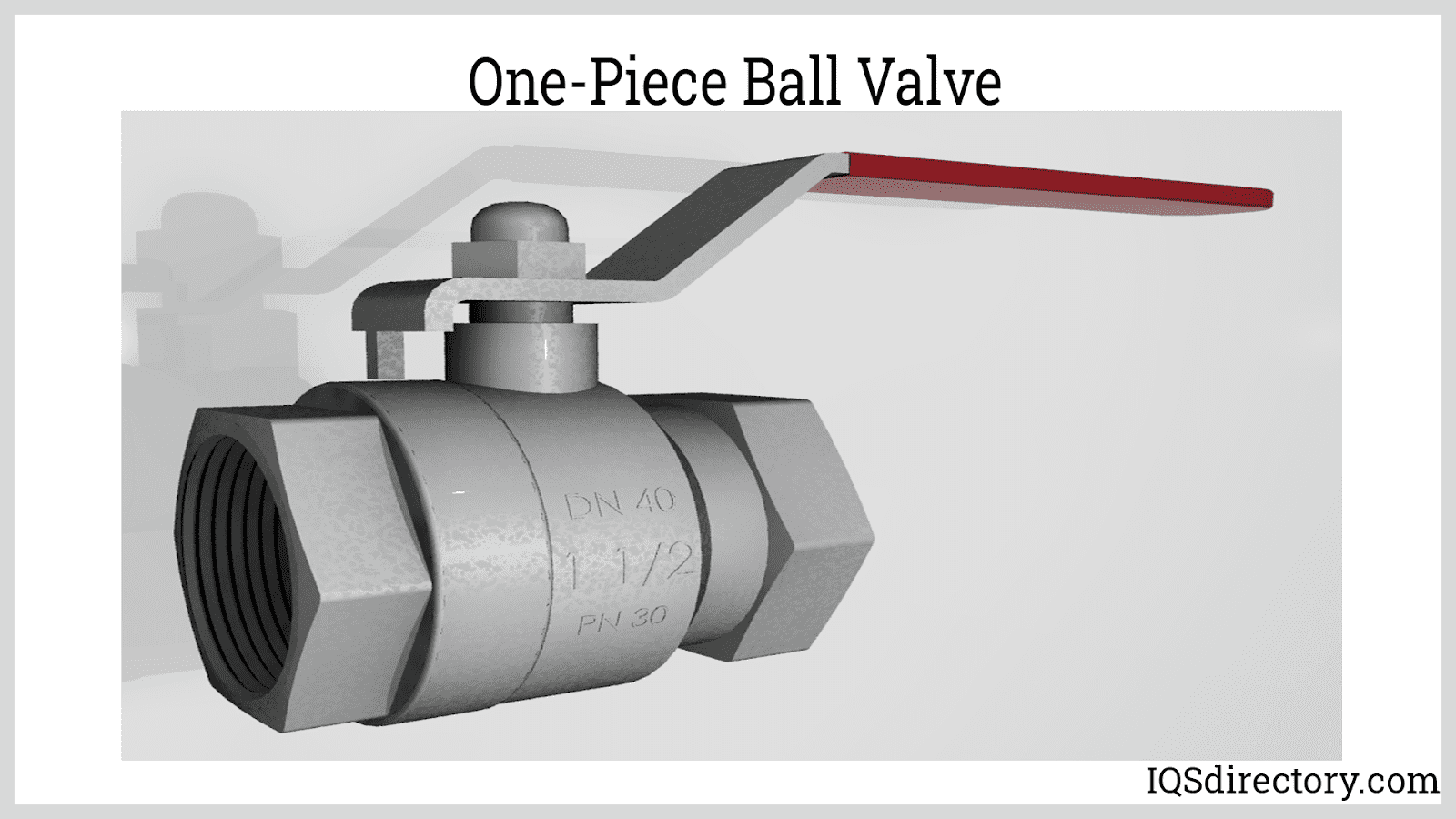

A ball valve is a shut-off valve that allows or obstructs the flow of liquids and gasses in a piping system by rotating the ball having a bore inside the valve for 90°. The ball is mounted against two seats and has a stem that connects it to the operating and control mechanism that rotates the ball...

A butterfly valve is a quarter-turn rotational motion device that utilizes a rotary disc to allow, obstruct, or control the flow of fluids in a piping system. It features a rotating disc that is situated on the passageway of the flowing media...

A check valve is a safety device designed to allow fluids and gasses to flow in one direction. Under pressure, fluids enter the valve at the inlet and exit through the outlet. Uninterrupted flow continues until the pressure drops, or the pump is shut down...

A PVC or polyvinyl chloride ball valve is a plastic on and off valve that has a rotary ball with a bore where turning the ball a quarter turn can stop the flow of a fluid. They are highly durable, cost effective and can be...

A spring check valve is a valve that ensures unidirectional flow and prevents reverse flow. They have a single inlet and outlet and must be placed in proper orientation to function correctly. On the side of a spring check valve, and all...