Wire Forms

Wire forms consist of various shapes and parts that have been fabricated through the manipulation of wire; wire forming techniques include anything that alters the shape of the wire, such as wire cutting, bending, or heat treating. Wire forming is used to create wire products of all shapes, sizes and dimensions, including both 2D and 3D.

Quick Links to Wire Form Information

- Wire Displays

- Can refer to many different wire forms, including wire grids, wire racks, wire shelves, and wire baskets. Wire grids, also known as wire grid panels, are frameworks of crisscrossed horizontal and vertical wires. Wire grids are very similar to both metal gratings and wire mesh, however, they work on a much larger scale than wire mesh. Also, unlike metal grating, which is usually made from metal bars, they are formed from wire. Wire racks and wire shelves are very similar to one another; they both protrude from the wall in order to create a flat wire surface used for storage.

- Wire Basket

- Wire cages that are useful for both display purposes as well as storage and protective devices.

- Wire Hardware

- Can refer to any number of wire forms that qualify as equipment, accessories, or tools. Most often though, this term refers to wire hooks and wire screens.

- Wire Hooks

- Simple constructions of bent wire that can be shaped as s-hooks, c-hooks, j-hooks, and more.

- Wire Screens

- More complex wire screens consist of thin metal wires woven in a crisscrossed horizontal and vertical pattern that form open yet protective barriers that allow limited material flow as filters or protective barriers.

- Wire Guards

- Also used for protection, wire guards are a class of their own and are used for two main purposes: to protect the operator of potentially dangerous equipment and to protect fragile equipment from hazardous conditions. Wire guards can include fan guards, finger guards, window or flooring guards, face guards, fixture guards and more.

Vital to numerous applications, wire forms serve an extensive range of industries such as commercial and retail, medicine and healthcare, energy storage, maintenance, industrial washing, lighting, automotive, aerospace, construction, hardware, and storage. Below are brief descriptions of some wire form applications.

- Automotive

- An extensively used wire form in the automotive industry is the wire spring, which can be found in virtually any machine you come across. In vehicles, heavy springs, like the compression coil spring and volute spring, are widely used for suspension applications. More delicate springs, like torsion springs and tension springs, serve numerous purposes. A more specialized spring, a conical spring, has applications in the production of battery contacts.

- Healthcare

- In healthcare, stringent washing and sterilization procedures and standards are followed, and to comply with these standards, specialized equipment is employed. One piece of washing equipment is an ultrasonic washer; this comes with a metal basket (made from wire form). For proper functioning and longevity of washers, a basket is necessary as it holds the parts and keeps them away from transducers. In healthcare, wire forms are also used for gauged trays and hand-held pliers.

- Household

- Household items, such as music players, mouse traps, and hangers, use wire forms.

- Electronics

- Wire forms can be found in a range of electrical fittings. Antennas are wire forms. Similarly, spring mechanisms that facilitate opening and closing in many electrical appliances are wire forms.

- Commercial and Retail

- In commercial and retail industries, wire forms are used for product display. Point-of-purchase displays are the perfect example of this type of wire product. Similarly, wire racks and shelves are used for storing retail items and goods. Additionally, retail workers use wire guards to protect some equipment.

- Construction and Hardware

- Examples of wire form products used in construction and hardware include clips, wire hooks, springs and pins, wire hooks, and wire screens.

Wire Form History

The use of wire and wire forms spans centuries. Originally, people manually manipulated wire to create their wire products. The most common wire product of antiquity was jewelry, and while this tradition is carried on today by some artisans, it is only ever done on a small-scale.

In the second half of the 17th century, wire forming boosted with the introduction of the first wire mill in Great Britain. Once this mill was built, others were quickly constructed. In this time period, manufacturing processes continued to evolve, with more and more methods of fabricating wire forms.

A more recent development in wire forming processes is the use of computer numeric control (CNC) machines. CNC machines are able to program wire forming machines to perform operations automatically. Once programmed, automated wire forming machines are capable of continuously fabricating wire parts or complete wire forms, depending on the complexity of the wire form design. CNC machines ensure a higher level of precision, as manually operated machinery allows for a higher level of error and contamination.

Manufacturers can fabricate wire forms from a wide variety of materials, including steel, stainless steel, brass, copper, aluminum, and countless alloys. The most common material used in wire forming is steel.

- Steel

- An alloy, made up primarily of iron and carbon. It is fairly inexpensive and known for its high tensile strength. Sometimes, it’s known as carbon steel.

- Stainless Steel

- A steel alloy. It is strong, lightweight, corrosion resistant, rust resistant, and antibacterial; it’s available in 15 different grades.

- Brass

- Considered to be an aesthetic alloy; it has a gold-like shine. It is relatively resistant to tarnishing, and it is a good thermal conductor.

- Copper

- A naturally occurring element with a reddish tint. It works well in a variety of temperatures and resists rust when exposed to water. It’s also an excellent conductor of heat and electricity.

- Aluminum

- Has good corrosion resistance, rust resistance, heat resistance, strength, and durability.

- Wire Selection

- First, the type of wire best for the application must be selected.

- Wire Straightening

- Typically, wire forming starts with straightening wire; the output is in the form of a coil weighing anywhere from 5 pounds to 5,000 pounds.

- In the straightening stage, stress disfigurations that are accumulated in the wire are removed. There are essentially two types of stress; one is avoidable and the other is unavoidable. For high-quality wire forms, most avoidable stresses do not occur within processing. However, wire manufacturers can do very little to mitigate unavoidable stresses. The most common method of stress avoidance is machine rolling, where rolls are adjusted either by an operator or by machines. Sometimes, manufacturers employ a rotary arbor to straighten the wires.

- The wire straightening stage is very important, as any aberrations left at this stage will lead to faulty products. Therefore, only high-quality mill products should be selected and identified. The helix and camber of the wire should be consistent and are considered critical.

- Application of Force

- To produce wire forms, varying degrees of force (either manual or machine-made) is applied to wire, which changes the shape of the wire. The wire, depending on its intended application, can be hexagonal, triangular, round, oval, square, flat and even elliptical and D-shaped.

- The simplest method for shaping wire involves a hand-held lever and spindle. Other methods involve use of mechanized machines, such as hydraulic presses and benders with dies as well as air benders.

- For-high volume production, alternatives include four-slide machines and the modern computer numerical control (CNC) benders. CNC wire forming allows manufacturers to easily fabricate pre-programmed parts in three dimensions.

- Finishing/Secondary Operations

- To ensure the finished product is free from burrs or sharp edges, manufacturers finish wire forming with an array of secondary operations, such as cutting, stamping, forming, heading, and coining.

When deciding upon wire form design and fabrication method, manufacturers consider several factors:

- Volume Required (Large or Small)

- Tolerance Value Required

- Mechanical and Chemical Characteristics

- Configuration of the Design

- Intended Application

In selecting a desired wire form, these factors should be considered for both the end-product and the application of the product.

Two other things that manufacturers think about during design are wire form ends and wire form interior geometries. Machines make both wire form ends and interior geometries according to their intended use. The following are some of the most common ends and interior geometries that manufacturers choose.

- Machine Cut End

- This is a simple straight cut made by a machine die, such as a guillotine knife. The burrs in the cut are miniscule (0.13mm) and cannot be observed by the naked eye. Therefore, they are acceptable for most manufacturing applications.

- Chamfered End

- When burrs created during machine cuts are unacceptable for safety purposes, the end is deburred by grinding the edges off. With this cut, the wire is contoured marginally, just enough to remove sharp edges, using a machine such as a lathe.

- Winging

- This geometrical shape is also called swaging. To achieve a wing-type shape on a wire, a die is pressed on the wire and carves the wire by displacing the metal.

- Pierced Swaging

- Pierced swaging is a two-step process. First, the wire is pressed to give it a swaging shape, then a hole is pierced through the metal at the center.

- Custom-Shaped Hole

- This process is the same as pierced swaging, however, a custom hole is made at the end. First, the end is pressed by a die to carve and displace the material. In the second step, a custom die punctures the material to form a custom hole.

- Chisel Point and Turned End

- To get this shape, a die removes metal in a punch operation. The approach is considered coarse but is quite an effective method. Similarly, a turned end can be made. Diagonals are removed as the punch is made in a jagged manner.

- Ball End

- The ball end cannot be achieved with the use of a die. Instead, a lathe is typically employed. The process makes the end smooth with no edges.

- Groove

- A lathe is utilized for a groove. A groove in the wire is used for holding a retaining ring.

- Cold Heading

- This process involves a couple of gripping dies. The first die grips the wire tightly, so the wire can withstand the next fairly rigorous die action. As the first die holds the wire, the die smashes the gripped wire, which results in either a flat or round head. The button heading, carriage heading, and collar heading are made using this method.

- Manufacturers can make custom wire forms that reflect any and all of your requirements. They can, for example, add a powder coating to protect your wire form or enhance it aesthetically. They can also create custom assemblies with different shapes, sizes and dimensions. They can work with virtually any wire diameter. In order to create the perfect custom wire fabrications, manufacturers turn to a variety of secondary services, such as nickel plating, painting, anodizing, and powder coating.

- Manual Lever

- Use of a hand-held lever and spindle is the oldest and most common method of wire form fabrication. Using this method, a professional manually bends wire around a past and an anvil—a solid iron block with concave sides and a flat top.

- Machine with Preset Pins

- Some wire forming equipment comes with preset pins for various bending operations. Machines such as these reflect some of the earliest attempts at semi-automated forming techniques. Technically, however, machines with preset pins still require manual bending. So, while this machine is more efficient than manual production, it still results in a variety of inconsistencies.

- Hydraulic Systems

- Another common method for wire form development involves a press and dies with a hopper. In this method, a resource manually loads material onto the die by moving wire from a straightening machine. The rest of the work is done by the hydraulic press under supervision of an operator. The straightening of the wire is a critical step wherein stresses that accumulated during the wiring process are removed. This step ensures the wire is consistent in its properties. With the development of technology, the hydraulic method has become an alternative to manual feeding. Pick-and-place robots are installed to eliminate the need for manually moving wires from the straightening machine.

- Fourslide Machines

- As an alternative to hydraulic presses, manufacturers utilize fourslide machines. These highly versatile machines, which also make stampings, work on a single work piece from four sides. This increases the production speed. Close to 3,500 simple wire forms can be made per hour. Modern fourslide machines come with multi purpose dies, so the production turnaround can be improved even further.

- CNC Wire Bending Machines

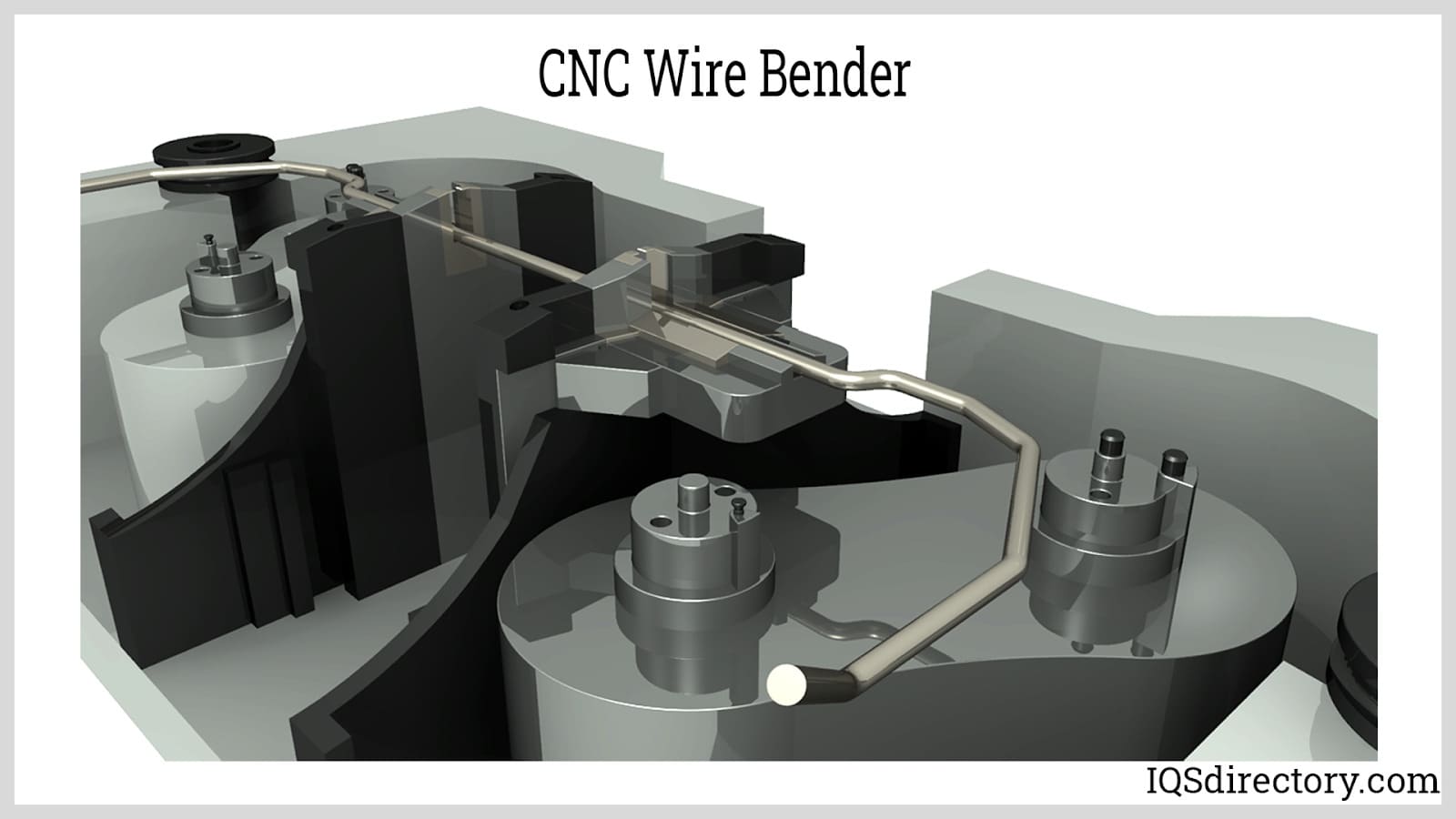

- The most advanced method of wire bending includes computer numerically controlled (CNC) machines, which have two-dimensional or three-dimensional bending abilities. The versatility of CNC wire forming is unparalleled, as in less than an hour, these machines can change from one project to another. These machines are especially useful in producing custom wire forms, as design, configuration and dimension can be pre-programmed easily in comparison to other methods.

To reach the variety of wire forms available, there are numerous wire forming processes; the most common of which include coil making, roll forming, metal stamping, and welding.

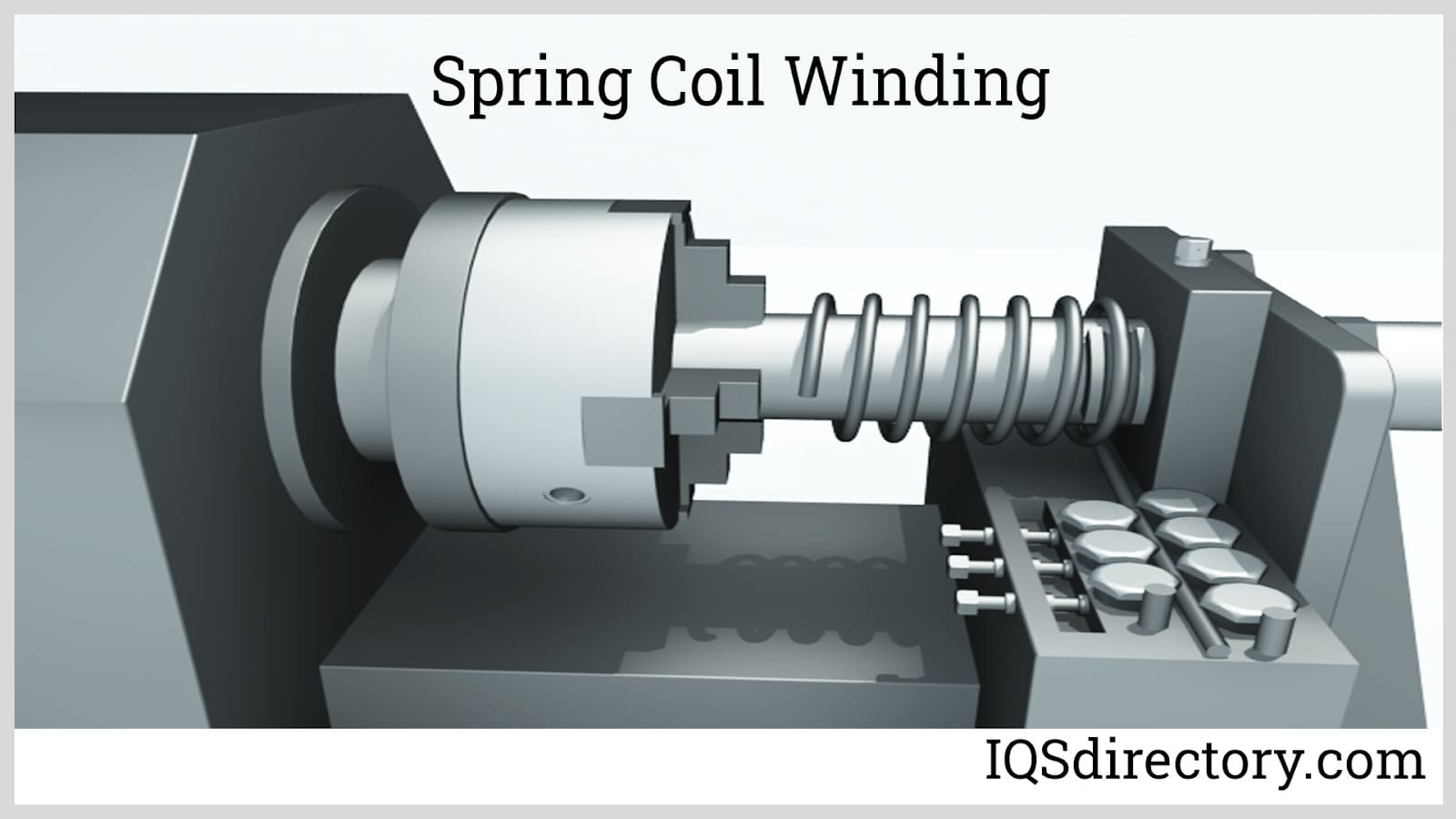

- Coil Making

- Also referred to as spring making or coil winding, is the process of winding wires around mandrels, or metal blanks, in order to create coils.

- Roll Forming

- As a less part-specific process, roll forming is used to produce flat, round, and shaped wire parts. A continuous process, roll forming uses calendars and die punches to shape the wire.

- Metal Stamping

- Another major wire forming process is metal stamping. Wire is precisely shaped into various forms through the use of a stamping press. A couple different methods of metal stamping are used for wire forms, including fourslide stamping and deep drawn stamping. During fourslide stamping, also referred to as multislide stamping, manufacturers use a metal stamp press with four horizontal forming slides to allow for forming in multiple directions. Deep drawing, on the other hand, gives a deeper depth to the wire form than is possible with other wire forming processes.

- Welding

- Can refer to various spot or seam welding processes, such as electric resistance welding (ERW), metal inert gas (MIG) welding, or tungsten inert gas (TIG) welding. ERW utilizes an electric current and the application of mechanical pressure to weld wire. As types of ERW, MIG and TIG also utilize inert gases to reduce any contamination; while TIG welding is the most accurate type, it is much more complex and requires a very skilled operator as well as longer production times, so MIG welding is often used instead. Weaving may also be used in order to create wire forms such as screens, grids or guards.

When you’re considering a wire form purchase, we recommend that you seek out a custom manufacturer. This is because custom wire form manufacturers can offer you the most in-depth and specialized options. However, it’s important that you look not only at a company’s capabilities, but also its customer service record. The most skilled manufacturing company is of no use to you if its staff does not work well with customers.

In addition, if you have a particularly complicated request, ask for prototype work. This way, you and your manufacturer can ensure you’re on the same page before you make a large investment.

To find the right manufacturer, check out the companies we have listed above. Every manufacturer we work with creates high quality work. Reach out to one or more to find out what they can do for you!

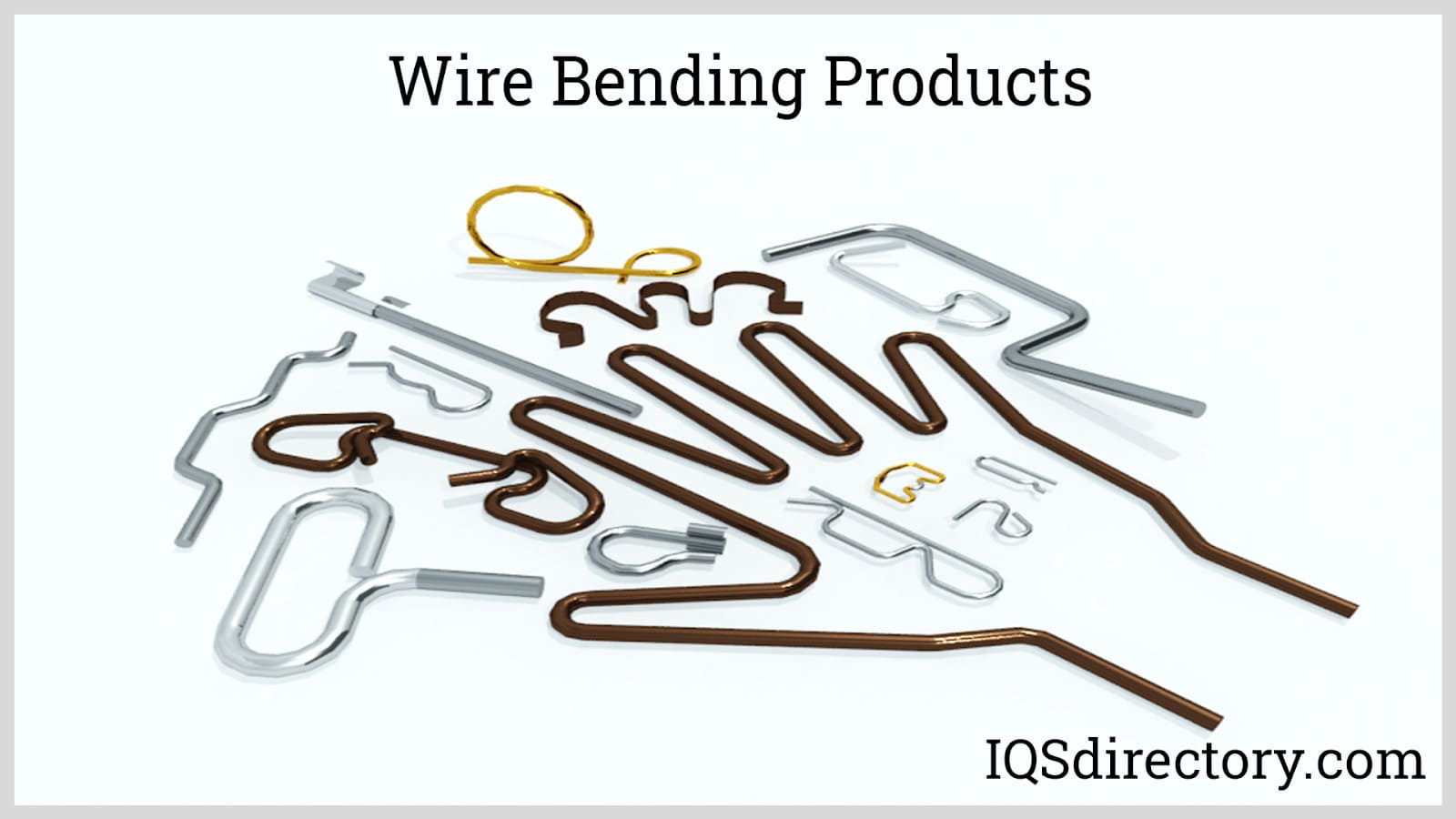

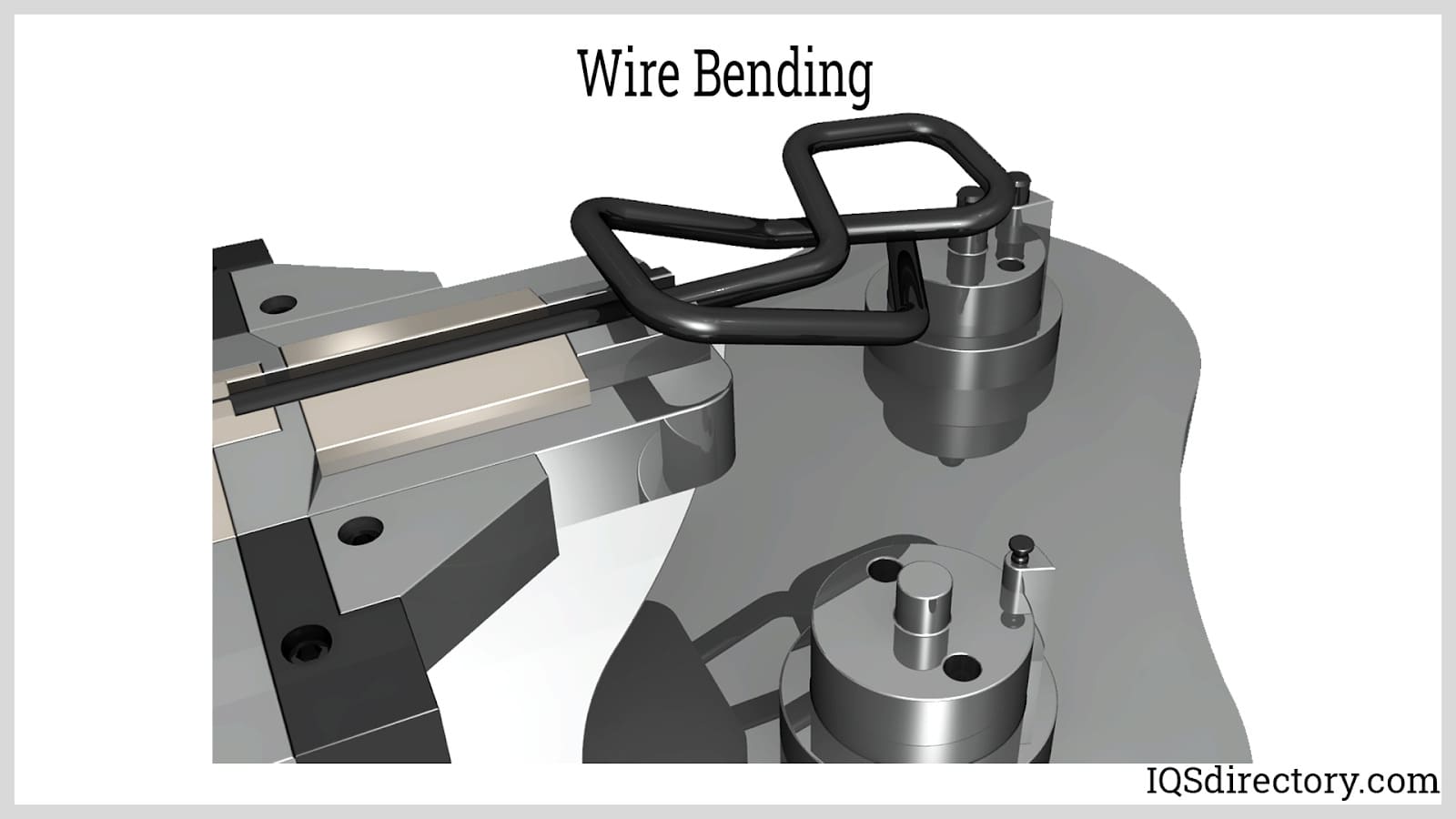

Wire bending process, wire can be shaped into unlimited configurations to fit any application.

Wire bending process, wire can be shaped into unlimited configurations to fit any application.

Wire baskets are made from a series of wires woven together or welded to form a shape of a basket.

Wire baskets are made from a series of wires woven together or welded to form a shape of a basket.

Wire racks are made from the wire forming process of acquiring a wire, from either a blank length or spooled coil, and bending it into definite forms.

Wire racks are made from the wire forming process of acquiring a wire, from either a blank length or spooled coil, and bending it into definite forms.

Wire bending produces a wide array of shapes and configurations and creates no scrap or waste sicne the wire is bent before cutting..

Wire bending produces a wide array of shapes and configurations and creates no scrap or waste sicne the wire is bent before cutting..

CNC bending is an abbreviation for “computer numerical controlled” bending are extremely accurate.

CNC bending is an abbreviation for “computer numerical controlled” bending are extremely accurate.

Hand machines, which features a spindle and hand lever may be rotary die or drawn and have gears that increase the facilitated bending pressure.

Hand machines, which features a spindle and hand lever may be rotary die or drawn and have gears that increase the facilitated bending pressure.

Coil wire forming, involves winding wire around a metal blank which takes different forms depending on the final product.

Coil wire forming, involves winding wire around a metal blank which takes different forms depending on the final product.

- Coil

- Wire wound into rings or spirals.

- Flat Springs

- Flat or curved pieces of steel shaped into a coil; flat springs have a nearly constant force.

- Medical Wire Forms

- Used primarily in orthopedic and prosthetic devices, and they provide a positive closure.

- S Hooks

- Wire hooks used to connect or hang components.

- Spring Washers

- Springs that store the energy used to tighten the nut or bolt they are under.

- Springs

- Coiled material that deflect when load is applied. Removing the load will cause the spring to return to its previous position.

- Wire Baskets

- Used in various industries to store and display products.

- Wire Displays

- Often used to display books, food, clothing, and other products. Wire displays can be custom designed for manufacturer needs and desires.

- Wire Fabrications

- Include various forms of wire that can meet a wide range of needs.

- Wire Forming

- Refers to numerous processes that manipulate wire into various shapes, referred to as wire forms.

- Wire Grids

- Also referred to as wire grid panels, are frameworks of crisscrossed horizontal and vertical wires.

- Wire Guards

- Protective equipment used to shield various parts and machinery from damage.

- Wire Hooks

- Curved pieces of metal used to hold things.

- Wire Parts

- Commonly referred to as wire forms, are formed from wire that has been manipulated into a specific shape or design.

- Wire Products

- Consist of a wide variety of shapes and items composed of wire.

- Wire Racks

- Available in various materials and are used in many retail situations, including those dealing with food and clothing.

- Wire Screens

- Thin metal wires woven in a crisscrossed horizontal and vertical pattern to form open yet protective barriers.

- Wire Shelves

- Produced for both industrial and consumer use because they are versatile and sturdy with a variety of load strengths and wire densities.

- Active Coils

- Coils that freely deflect when under a load.

- Closed Ends

- The ends of the coils touch because the pitch end is reduced on a compression spring.

- CNC (Computer Numerical Control)

- Machines with a computer memory, often used in manufacturing and production of wire forms.

- Deflection

- The motion of the spring arms or ends during the application or removal of the burden.

- Elastic Limit

- The strain and manipulation a material can endure without a lasting effect.

- Fine Blanking

- A technique of precision blanking in which the material is cut smoothly and accurately without the need for secondary operations.

- Free Angle

- The slope between the torsion spring arms at the unloaded position for the spring wire form.

- Gauge

- The measurement of the thickness of a wire used in wire forms.

- Helix

- In open or closed forms, the spiral shape of the spring.

- Hooks

- The open ends of extension springs.

- Hysteresis

- Lost mechanical energy during a spring's cyclic loading and unloading.

- Hysteresis is relative to the space among the loading and unloading deflection curves.

- Load

- Applied force that causes deflection with a spring.

- Multislide Stamping

- Stamping or forming from multiple directions in pieces and segments.

- Pitch

- In the wire of active coils, the measure of the distance from the center of one adjacent active coil to another.

- Rate (R)

- The modification in load for each unit deflection, typically expressed in pounds per inch (N/mm).

- Rod Bending

- A broad term that applies to forming machine tools that assemble bends on any workpiece. Rod bending tools range from small, handheld devices to automated machines.

- Set

- Permanent deformation that happens from the stressing of a spring past the material's elastic limit.

- Spring Index

- The ratio of mean coil diameter to wire diameter.

- Stress Relief

- Exposing a spring to a treatment of low heat, which results in the reduction of residual stresses.

- Torque

- Equation measurement of torsion spring's twisting action relative to the distance from the axis of the spring body.

- Wire Forming

- The forming of wire forms.

- Wire

- A single, flexible, cylindrical rod or strand of metal created via the metalworking process known as drawing. It can be made in a variety of materials and thicknesses; wire is highly useful and is used to create countless parts and products.