Titanium

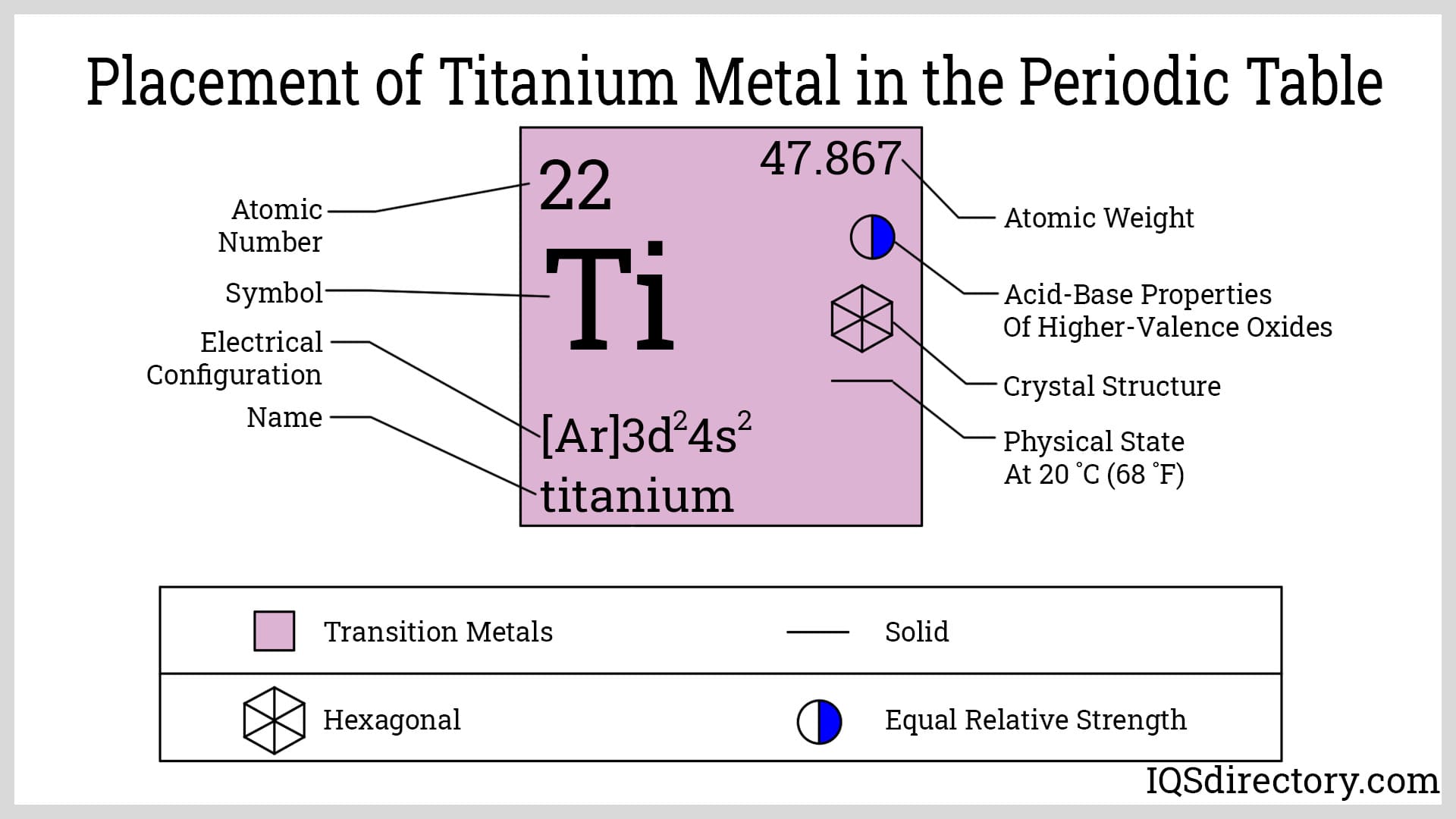

Titanium is a transition metal with the chemical element symbol Ti, atomic number of 22 and the atomic weight of 47.90. Titanium material is lightweight and silver in color. Although found in almost all living and natural conditions, titanium metal is the fourth rarest element on the Earth. According to geologists, titanium only contributes 0.62 percent of the earth's crust. Other than in earth crust, titanium as a raw material is found in minerals, water, stones, rocks, and several other natural settings. Titanium is naturally found in oxides, trichlorides, and tetrachlorides.

Quick links to Titanium Information

Benefits of Titanium

Titanium has a number of qualities that make it an excellent candidate for any application. These include its alloy-ability, durability, low conductivity and elasticity, high strength-to-weight ratio, ductility, corrosion resistance, heat resistance, high melting point and price.

- Alloy-Ability

- Titanium is an alloy metal, meaning it can be used for the formation of metal alloys. These blends can then be for a number of purposes.

- Strength and Durability

- This is probably the biggest advantage, and because of it, titanium is used in a large number of industrial applications that need rigorous support. Titanium is sixty percent denser than aluminum. Still, it is two times stronger and much more durable than aluminum.

- Conductivity (Or Lack Thereof)

- Titanium is a poor conductor of heat and electricity. At first glance, this may sound like a disadvantage, but actually it’s not. Instead, this specific feature makes titanium an ideal material for electric appliances and applications that work on extremely varying temperatures.

- Cost

- While maintaining better strength and corrosion resistance, titanium pipes and other fittings prove more economical than steel and stainless steel accessories.

The History of Titanium

Titanium was first discovered in 1791 in Cornwall, England by clergyman and amateur geologist William Gregor. This happened when Gregor observed that black sand by a stream was attracted by a magnet. Upon closer inspection, he realized that within the sand were two metal oxides. One he recognized as iron oxide, and the other 42.25%--an unidentified white metallic oxide--he could not identify. Inside this oxide, which turned out to be ilmenite, was yet another metal that he did not recognize. Gregor named it Manaccanite after his nearby parish, and reported his discovery to the Royal Geological Society of Cornwall and the German science journal Crell’s Annalen.

Titanium dioxide was again discovered shortly after in 1795, by a Prussian chemist named Martin Heinrich Klaproth. This time, it was found in a mineral called rutile, in the village now known as Bojnicky in Slovakia. He named the element titanium after the Titans of Greek mythology. When he heard about Manaccanite, he obtained a sample and confirmed that it was in fact titanium as well.

Pure (99.9%) metallic titanium was first properly prepared in 1910, at the Rensselaer Polytechnic Institute by Matthew A. Hunter. His method is now named the Hunter process. It involved heating titanium tetrachloride (TiCl4) in sodium at 700–800°C and under great pressure. In 1932, William Justin Kroll created the Kroll process, which reduced TiCl4 with calcium. In 1840, he updated this process to work with magnesium. Today, the Kroll process is still the most popular reduction process for commercial production, though engineers and scientists continue to search for more efficient methods.

- During 1900’s and Beyond

- In the 1950s and 1960s, the Soviet Union began using titanium in its military and submarine equipment, as a way to give them an edge during the Cold War. They used titanium most heavily in the construction of military aircraft, especially with high performance jet planes. Soviet engineers used titanium because they discovered that it was the only material that would not completely dissolve in the air. The U.S. Department of Defense responded to this by advancing early titanium commercialization efforts and stockpiling it strategically. This stockpile was not depleted for around 60 years; it didn’t run out until the 2000s. Since 2006, a two-company consortium, awarded a $5.7 million budget from the U.S. Defense Advanced Research Projects Agency (DARPA) has been working on developing a new process for making titanium powder. Titanium powder is important to this agency because it can be used to make incredibly strong and lightweight products in meaningful industries, including not only defense, but chemical processing, transportation and aerospace as well.

- Today, the titanium industry is booming. Every year, bioengineers, aerospace engineers, structural engineers and others find new and better ways to use titanium to advance their application. Industry members expect that in the coming years, titanium will become more and more important to healthcare, water desalination, sour and offshore hydrocarbon production, marine applications, chemical and petrochemical processing, automotive manufacturing and architecture.

Applications of Titanium

Manufacturers use titanium to make parts and products for a wide variety of low and high stakes applications. Many titanium parts are central to proper system functioning. Customers turn to titanium metal manufacturing for their applications because of its many superior properties.

Some of those industries in which titanium is ideal include those in healthcare, aerospace and defense. For example, because titanium has a very similar density to human bones, it’s perfect for orthopedics. In addition, the navy, marine, metal finishing and fabrication, aquarium, automotive, racing sport and jewelry industries all buy titanium to manufacture their products and materials.

Design of Titanium

While lightweight, titanium is one of the strongest materials found on the planet. The metal is very similar to zirconium and silicon. Just like these two materials, it is highly resistant to corrosion and heat. In addition, the density of titanium is very close to that of steel and aluminum. It is extremely low, at 4510 kg/m3. This type of density is ideal for robust applications used underwater and in the sky. Titanium can sustain very high temperatures, up to around 3,000F. In liquid state, titanium boils at around 6,000F.

Its high strength to weight ratio means it is as strong as steel but half the weight per volume. The titanium type used in manufacturing most often is titanium alloy.

Titanium's natural qualities of high tensile strength, low density, ductility and heat transference are often alloyed with various metals to create a hybrid of properties that better suit it to machining. Titanium steel is lighter and far more resistant to corrosion than regular steels; aluminum titanium alloys are finer and stronger; iron, copper and manganese titanium alloys also benefit from combining their strengths with titanium's properties.

Titanium Production Process

Titanium production and manufacturing consists of the following steps: extraction, reduction to sponge, ingot formation, primary titanium fabrication and secondary titanium fabrication.

- Extraction

- Although titanium is a naturally and abundantly occurring element (it is the ninth most abundant element on Earth), it does not occur in pure form. Instead, it is usually found in mineral deposits in the form of ilmenite, from which it must be extracted.

- Reduction to Sponge

- The next step is reducing the raw titanium into a sponge, which is a highly porous ore. To do this, titanium manufacturers most often use the Kroll or Hunter methods.

- Titanium Ingot Formation

- After creating the sponge, manufacturers either press it or melt it and a master alloying material, into blocks ready for fabrication, called ingots.

- Primary Fabrication

- The next step is turning the ingots into stocks shapes that end users and other manufacturers want. Examples include: titanium tubing/titanium tube, titanium pipes, titanium wire, titanium bar, titanium plate, titanium foil, titanium rods and titanium sheet, by hot or cold forming, flat rolling, extrusion or welding. These titanium materials are either used as parts, sold as products or sold as stock items in order to be further processed. Once processed into an ore in the form of foil, sheet, wire, granules, sponge, powder, mesh and rod, titanium is relatively easy to fabricate into products and is extremely useful.

- Secondary Fabrication

- During secondary fabrication, manufacturers use a wide variety of processes to fabricate finished shapes and products. The processes they use to make this happen include: cold forming (pressing, bending, shearing, etc.), welding (plasma, laser, resistance, electron beam, MIG, friction), machining (drilling, grinding), cutting (torch, waterjet, laser), cladding (explosive bonding, mechanical fastened loose lining, roll cladding, resistance weld lining, diffusion bonding), heat treating, annealing and surface treating (turning, grinding, polishing, etc). Sometimes, manufacturers also use titanium forging. Titanium forgings are especially strong.

- Titanium Metal Alloys

- So far, scientists have developed more than a thousand alloys of titanium. Different titanium alloy types can be organized in a number of different ways, including titanium grades and groups of structural alloys.

- Titanium grades define the properties and uses of individual titanium alloy types, and allow manufacturers to determine the most suitable grade for their applications. There are 38 grades of titanium classified by the American Society for Testing and Materials (ASTM). The first 5 grades are unalloyed, and the rest contain different ratios of elements such as aluminum, cobalt, vanadium, tin, molybdenum, palladium, zirconium, niobium, nickel, ruthenium, silicon and iron.

- The three groups of structural alloys are: Alpha titanium, Alpha Beta titanium and Beta titanium. Alpha titanium is usually alloyed with aluminum and tin, and is low to medium strength, non heat treatable and weldable. It is ductile, has high notch toughness, and good mechanical properties at cryogenic temperatures. It also has the highest corrosion resistance and is used in the manufacturing of airplane parts and chemical processing equipment. Alpha Beta titanium is medium to high strength, heat treatable and weldable. It is often hot formed and has limited cold forming abilities. Alpha Beta titanium is used to make marine hardware, aircrafts and prosthetic devices. Finally, Beta titanium, the smallest group, is the highest in strength, most dense, fully heat treatable and weldable. It exhibits high formability and is often extruded to make heavy duty aircraft parts which are required to maintain structure and shape even under extreme pressure.

Titanium Images, Diagrams and Visual Concepts

Based on the periodic placement makes it a transition metal and can explain chemical bonds of the element.

Based on the periodic placement makes it a transition metal and can explain chemical bonds of the element.

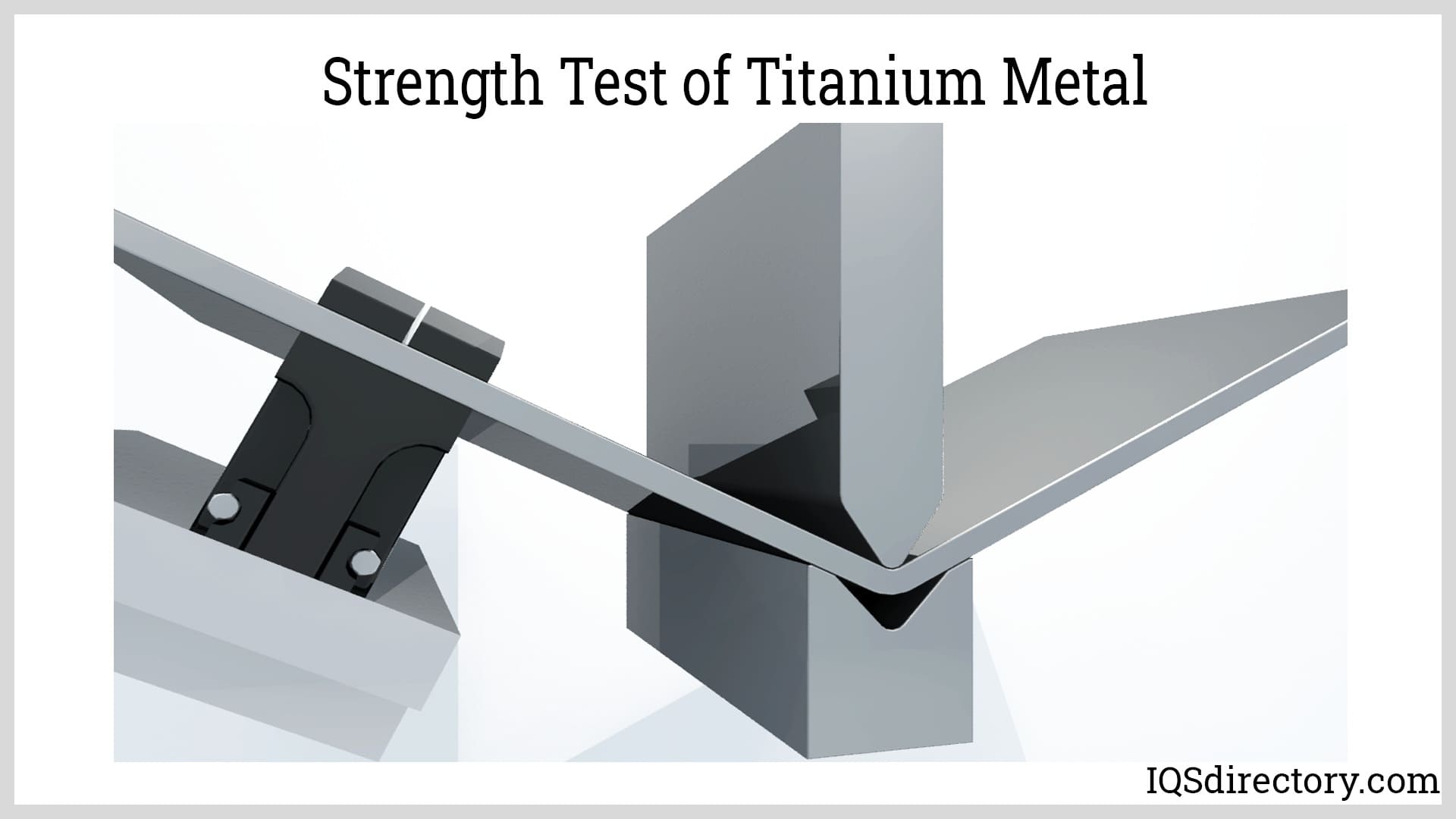

The tensile strength of Titanium is about 434 MPa equaling the strength of low grade steel alloy.

The tensile strength of Titanium is about 434 MPa equaling the strength of low grade steel alloy.

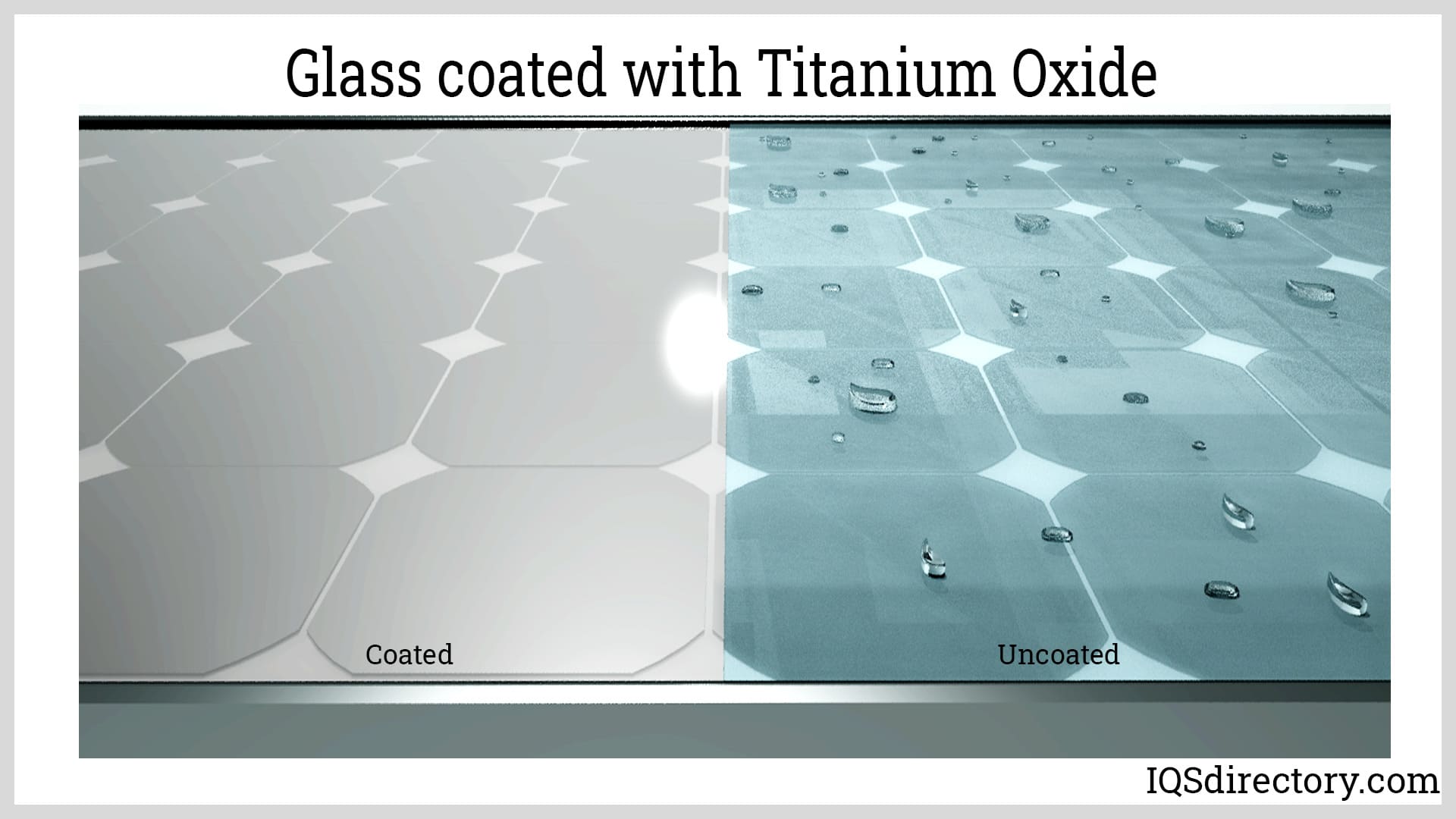

Titanium dioxide is a chemically inert compound that is corrosive resistant and does not fade in sunlight.

Titanium dioxide is a chemically inert compound that is corrosive resistant and does not fade in sunlight.

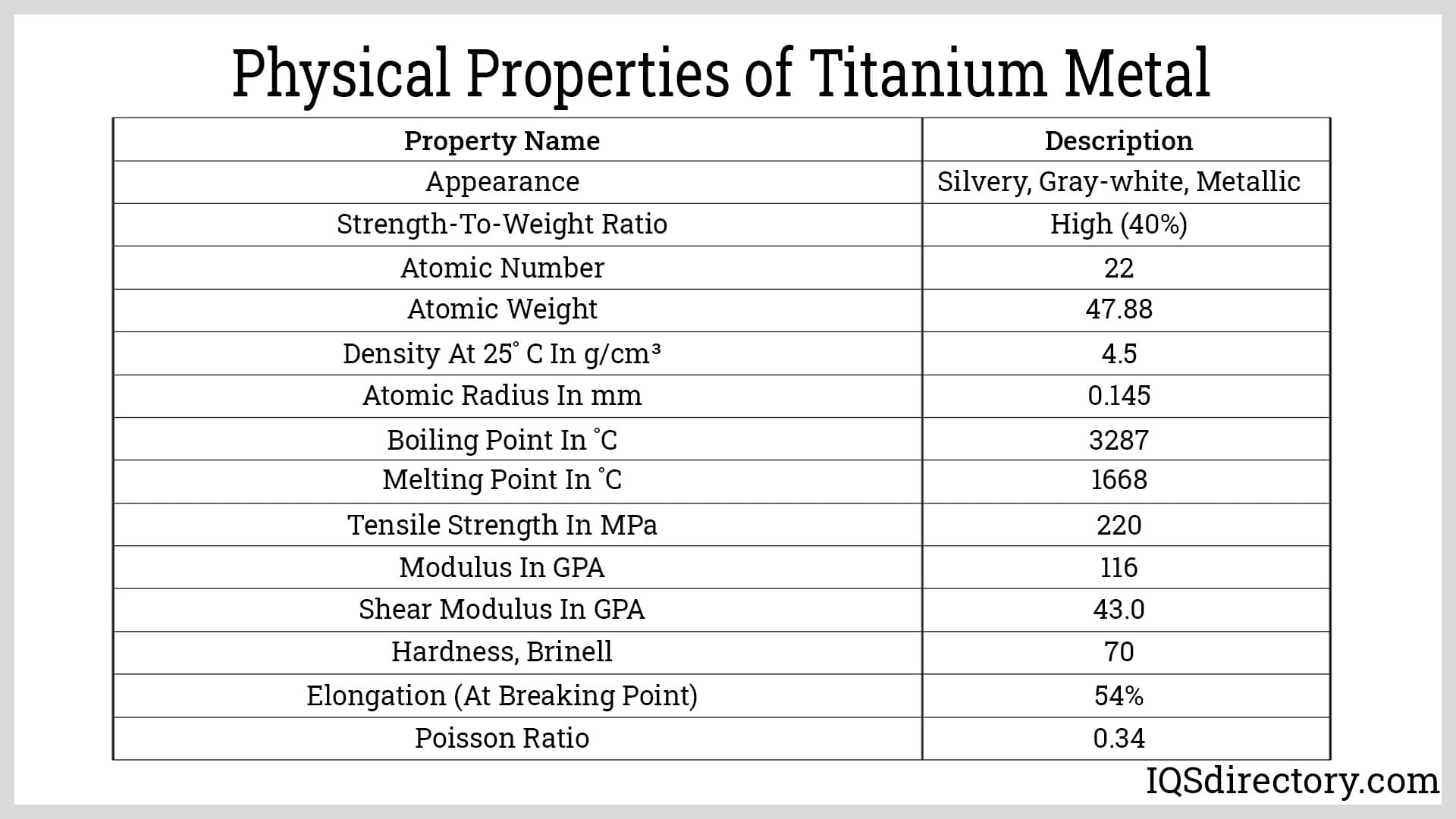

Titanium metal is considered to have superior physical properties and an element that is physiologically inert.

Titanium metal is considered to have superior physical properties and an element that is physiologically inert.

Types of Titanium

- 6Al-4V

- The most common titanium alloy, is composed of 90% titanium, six percent aluminum and four percent vanadium.

- Aerospace Metals

- Including aluminum beryllium, nickel-based superalloys and titanium, have basic metal properties that are enhanced by key elemental alloying additions.

- Bought Titanium

- Can be found in various stages of fabrication such as mill products or completed parts.

- Ferro-Titanium

- A mixture of titanium sponge and titanium scrap with iron. After being mixed, the titanium and iron are melted together, forming a single alloyed metal.

- High Temperature Alloys

- Materials that have unique strength and/or corrosion properties at temperatures exceeding 1,000ºF (537ºC), as well as high creep resistance and resistance to softening and metal loss from oxidation, sulfidation or carburization. High temperature alloys contain a large amount of nickel (from 25 to 60%) and critical amounts of molybdenum, columbium, chromium and titanium.

- Super Alloys

- Have superior strength and corrosion resistance under high temperatures. Superalloys are used in applications such as jet engine components, valves and gas turbines.

- Titanium Alloys

- Composite materials that combine several metal components, with titanium being the predominant element, to create a hybrid metal.

- Titanium Bars

- Sections of titanium that have been machined down to a solid bar. The titanium bars are frequently shipped out and used by companies that manufacture titanium products.

- Titanium Billets

- Milled products that have been hot-worked by either the forging, extruding or roll processes, forming the material into round or round-corner squared products. Titanium billets, which have diameters starting at four inches, are mostly used as starting stock for subsequent forging or extrusion processes.

- Titanium Bolts

- Like other bolts, consist of a threaded pin or rod and a head at the opposite end. Titanium bolts are preferred over other materials for their superior strength and corrosion resistance.

- Titanium Castings

- Formed by pouring molten material into a mold in which it solidifies into the shape of the mold. The reactive properties of titanium makes the forming of titanium castings complex, though these products have been successfully used in a wide variety of applications.

- Titanium Foil

- A very thin flat mill product of varying size and thickness that is produced during titanium extraction, formed and sold to titanium parts and product manufacturers for secondary fabrication.

- Titanium Grades

- Used to distinguish between the different types of titanium and titanium alloys based on their different qualities and purities to ensure proper material selection.

- Titanium Ingots

- Large (sometimes more than 10 tons) masses, consisting of primarily titanium but including other alloying elements. Titanium ingots are large and mostly barrel shaped and are used primarily for heat exchangers and piping in such industries as petrochemical plants, nuclear power plants and seawater desalination plants.

- Titanium Manufacturers

- Provide various titanium products to many industries.

- Titanium Metal

- An extremely strong, low density and highly corrosion resistant substance used in a wide variety of industrial applications for which these traits and others, such as heat resistance, are desirable.

- Titanium Pipes

- Long hollow tube-like pieces of hardware used for the transport of fluid and gaseous materials in a wide range of industrial, commercial and domestic applications.

- Titanium Plates

- Widely used in the medical industry to correct skull defects or repair fracturing of the skull.

- Titanium Rods

- Have a superior strength-to-mass ratio. Titanium rods, if well-designed, are about 20% lighter than comparable steel rods.

- Titanium Sheet

- A thin, flat piece of titanium.

- Titanium Sponge

- Pure titanium, which has a porous cellular form.

- Titanium Tubing

- Offers superior strength, rigidity and lightness. Titanium tubing, largely formed from an alloy consisting of 3% aluminum and 2.5% of vanadium (3-2.5), is costly, due to the refinery, tooling and processing costs of the material.

- Titanium Wire

- A fine wire or braided cable that is becoming more popular in the biomedical and industrial fields for its small diameter and admirable strength. Common diameters range from 0.0015" with fine wire to over 0.2" with weld wire.

Products Produced by Titanium

Titanium is used to make a countless number of products. Let’s look at the groups, based on the industry in which they are used.

- Medicine and Healthcare Products

- Titanium is used to make catheters and a slew of orthopedic devices, such as: joint replacements, hip balls, rods for scoliosis surgery, bone plate, heart stents, dental replacements, bowl replacements and wire and bars for miscellaneous medical purposes. When manufactured with pure titanium, products such as these are less likely to cause an allergic reaction, or become corroded or contaminated inside the body.

- Homecare and Consumer Products

- Titanium alloys are a key ingredient in numerous products that we see or use in our day-to-day lives. Examples include: paints, inks, toothpastes, cosmetics, and a number of food products.

- Aerospace Products

- Titanium products are a staple of the aerospace industry. Titanium is involved in the production of missiles, spaceships, space stations, jet engines and aircrafts.

- Sports and Recreation Products

- A wide variety of sports equipment is made with or from titanium. One example includes bicycles, especially racing bikes.

- Marine and Naval Products

- These industries use titanium tubing and titanium sheet products for underwater ship parts and equipment. This is because it is resistant to salt erosion, stress, microbiological corrosion and pitting.

- Automotive Products

- Because it is such a lightweight material with high strength, automotive manufacturers rely on titanium plates to make: valve springs, rocker arms, connecting rods, exhaust systems, drive shafts, and steering gears.

- Chemical Products

- Titanium alloys are also used for the production of heat exchange coils and linings. They are also used to make pump units in various industrial and chemical plants.

- Gas and Oil Products

- Titanium is used as coolant in condenser tubes used in oil refineries.

- Industrial Products

- Constantly, new uses for titanium in construction are being discovered. It makes an excellent building material for outdoor applications since it is lightweight and resistant to corrosion.

- Miscellaneous Products

- Other titanium and titanium alloy products include: semiconductor and battery titanium wires, agri-food titanium tubing, paper, plastics, cement and jewelry.

Things to Consider When Choosing Titanium

Today, the titanium industry is flooded with manufacturers and suppliers looking to provide you with your product. While a few options are always nice, too many options can be a big headache. So how do you sift through the options out there, and discern between the good and the not so good? Well, you start with a directory, like this one. Here at IQS, we’ve already sifted through the riff raff for you. To find a high quality titanium manufacturer, scroll up towards the top of this page and check out the list we’ve compiled. Browse their individual websites and get a feel for what each offers. When you’re ready, reach out to three or four whom you believe could do the best work for you, and then discuss your specifications with each. Include topics such as: application, application requirements, industry requirements, price, lead times and delivery options. Once you’ve done that, compare and contrast their answers. Go with the manufacturer who you believe will deliver you the highest quality titanium product and serve you with the most integrity.

Overseas Market of Titanium

As of 2015, titanium sponge was produced in six major countries. They are, in order from largest to smallest output: China, Japan, Russia, Kazakhstan, the United States, Ukraine and India. While China is still producing more titanium than anyone else, its supply is not matched by demand. In addition, international companies like DuPont have lowered their prices over the last few years. Between these two factors, China’s price-performance superiority has dropped and its exports have gone down. Meanwhile, over the past 10 years or so, production and sale of American titanium has been climbing. Here in the USA, customers in the aerospace industry are clambering to innovate their airplane designs faster and better than one another, and every time they do, they use more and more titanium. So, there has never really been a better time to purchase titanium from an American supplier; the supply is ample and titanium prices are competitive.

Titanium Terms

- Alloy

- A uniform mixture or solid solution of at least two metals. Titanium is most often acquired as an alloy.

- Alpha Case

- A brittle, oxygen-enriched surface layer that is caused by the heat treatment of titanium at high temperatures in an oxygen atmosphere. Alpha case should be removed prior to any subsequent processing or finishing, as it can result in the embrittlement of the titanium material, making it susceptible to stress corrosion.

- Anodize

- To coat or cover a metallic surface with a protective or decorative oxide using electricity. The colors produced by anodizing do not fade, as they are not a dye or a pigment.

- Blasting

- A mechanical grit or abrasive blasting process used to remove scale from larger titanium products, such as ingots and billets. The grit, composed of silica, zircon and aluminum, leaves a fine dust that is removed from the titanium by a pickling process.

- Chromium

- An alloying element that is used in several titanium alloys. Chromium typically has an alloying weight percentage range of 2-12%.

- Density

- The amount of mass contained within a specific volume under standardized conditions. The density of titanium is 4,507 kg m-3, while the density of silver is 10,490 kg m-3.

- ELI (Extra Low Interstitials)

- The elements oxygen, nitrogen and carbon, referred to as interstitials, which have been reduced beyond the standard titanium alloy requirements in order to improve the ductility and fracture toughness of the alloys.

- Embrittlement

- A condition of metal that results in the metal’s losing a large quantity of ductility and/or toughness. Several sources—such as hydrogen pickup from water vapor, pickling acids and hydrocarbons and liquid metal embrittlement from liquid cadmium, mercury and silver—cause embrittlement in the susceptible titanium alloys.

- Grade

- The number given to the variety of types of titanium that distinguishes the different qualities and purities of that titanium and its alloys from those of other types. Grade 2 is the most common form of pure titanium, while Grade 4 is the strongest.

- Grains

- Microstructures that connect to form titanium. The changing of the size and shape of the grains through controlled processes results in the enhancement of the mechanical properties of titanium alloys.

- Inclusion

- A particle of foreign material, such as oxide, sulfide or silicate compounds, embedded within titanium products. If left unattended, inclusions may cause failure of the material.

- Laser Cutting

- A widely-used procedure for cutting thin gauge titanium products to close tolerances.

- Melting Point

- The temperature at which a solid liquefies at standard atmospheric pressure (SAP). The melting point of titanium is 3,034°F (1667.8ºC).

- Pickling

- A process that removes oxide film from the surface of titanium products through chemical bathing.