Flexible Shaft Couplings

Shaft couplings are a type of device used to securely join two shafts at their ends. Flexible shaft couplings specifically deliver torque, or rotational force, from one piece of rotary equipment to another. They can transmit power even if the shafts of the two devices are misaligned or aligned in a non-linear fashion. Flexible shaft couplings contrast with rigid shaft couplings, which are designed to connect well-aligned shafts linearly.

Quick links to Flexible Shaft Couplings Information

The History of Shaft Couplings

Historians believe that the first flexible coupling was invented along with the wheel, over 5000 years ago in Mesopotamia. The first documentation of flexible coupling use, though, comes first from the Greeks circa 300 BC, then the Chinese circa 25 AD.

The first flexible coupling that we might recognize today was developed in the 1500s by Italian polymath Jerome Cardan, also called Gerolamo Cardano. His invention was a Cardan shaft (driveshaft) joined with universal joints. It made it possible to transmit rotary motion at a wide variety of angles. Today, Cardan’s coupling is still popular in motor vehicles. In about 1650, a British polymath came up with a practical application for Cardan’s shaft; he installed it in a clock drive, where it acted as its rotating shaft. In 1676, in his book Helioscopes, Robert Hooke coined the term “universal joint.”

Flexible shaft couplings did not develop much after this until the Industrial Revolution. In 1886, for example, American Francis M. Roots shared the theory that, by thinning a rigid coupling flange, manufacturers could create a more flexible and resilient coupling. He believed, specifically, that a coupling designed this way would stop both the shaft and the equipment in which it worked from failing. He was right, and his idea eventually led to the invention of the diaphragm coupling.

As cars and other automobiles became more popular, couplings became more important. So, during those early years of the car, between around 1900 and 1930, the coupling industry boomed. In 1914, the Scientific American detailed the design of the first chain coupling. During the 1930s, engineers invented the gear coupling. Then, during the 1940s and 1950s, as manufacturers began using rotating equipment and cars became faster and faster, engineers needed to create better flexible couplings. To accommodate the breakneck speed at which things were advancing and machines were moving, they created power dense couplings that could deal with misalignment. Next, they focused on couplings that moved faster themselves.

During the 1960s, engineers created many new variations on the gear coupling, such as non-lubricated gear couplings and toothed gear couplings. They also sought to make couplings from lighter materials that absorbed weight and shock better.

Today, flexible shaft couplings are more diverse than ever. Some of the biggest changes that they have experienced in recent years relate to new materials, and CNC technology. As time goes on, we expect that engineers will continue to adapt to them.

Advantages of Shaft Couplings

- Maintenance of Proper and Effective System Function

- During operation, some types of shafts tend to shift, causing misalignment. In applications in which shaft misalignment is common, manufacturers use flexible shaft couplings that are able to maintain proper and effective function even if the shafts are not in perfect alignment.

- Efficient Accommodation of Misalignment

- Flexible shaft couplings provide efficient accommodation for moderate shaft misalignment which occurs when the shafts' axes of rotation become skewed. Also, flexible shaft couplings provide the means by which rotating equipment can continue to function during moderate displacement measuring up to 5° of misalignment.

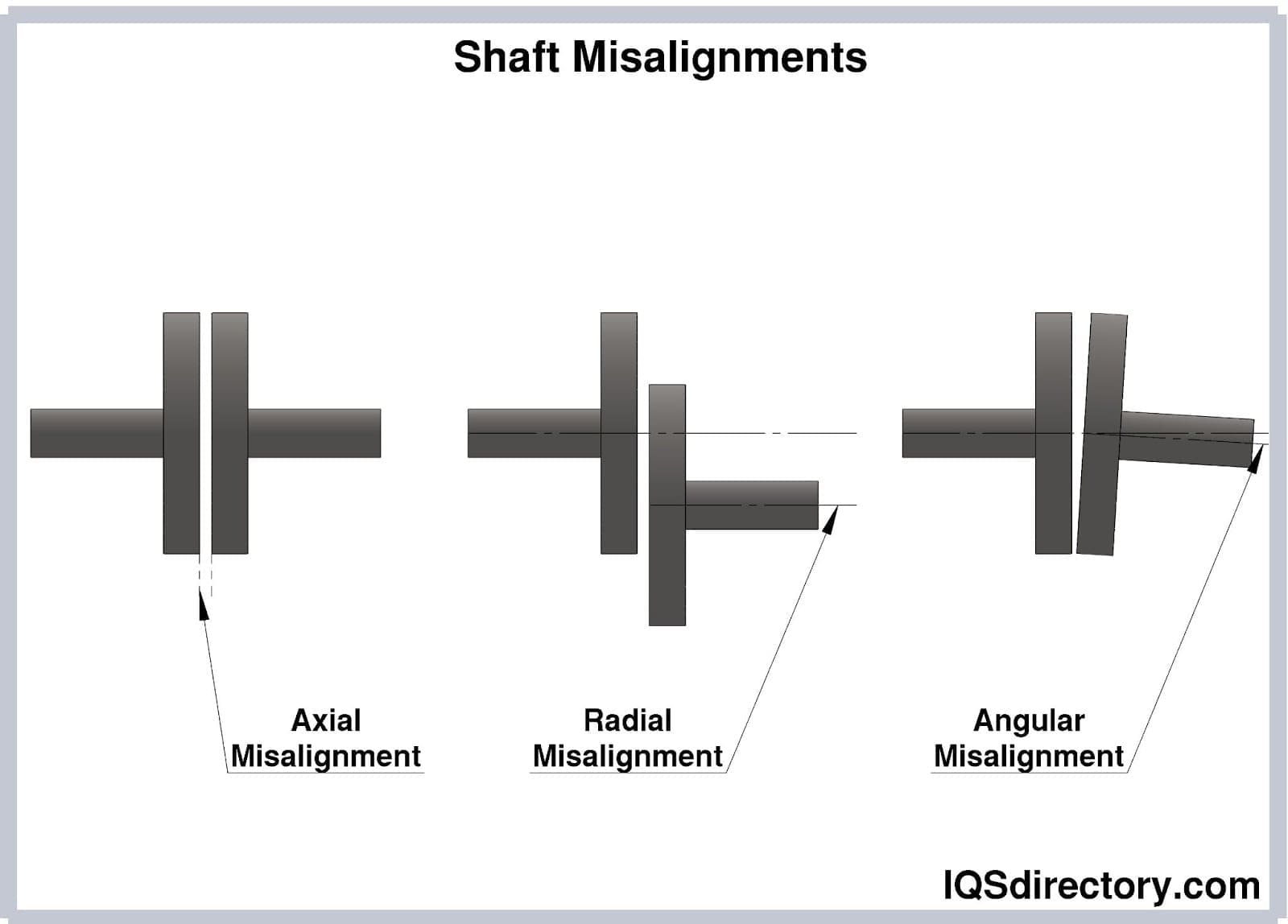

- Movement, bumps or vibration cause shaft movement, which results in parallel, angular or skewed shaft misalignment. Parallel misalignment occurs when shafts' axes are parallel to one another, but do not intersect with one another; angular misalignment occurs when the axes of shafts intersect with one another at an angle, and skewed misalignment occurs when axial and angular misalignment occur in conjunction with one another.

- Effective Accommodation of End Float

- Flexible shaft couplings accommodate axial displacement, also called end float, which occurs when the shafts move along the axis of rotation, either toward or away from one another.

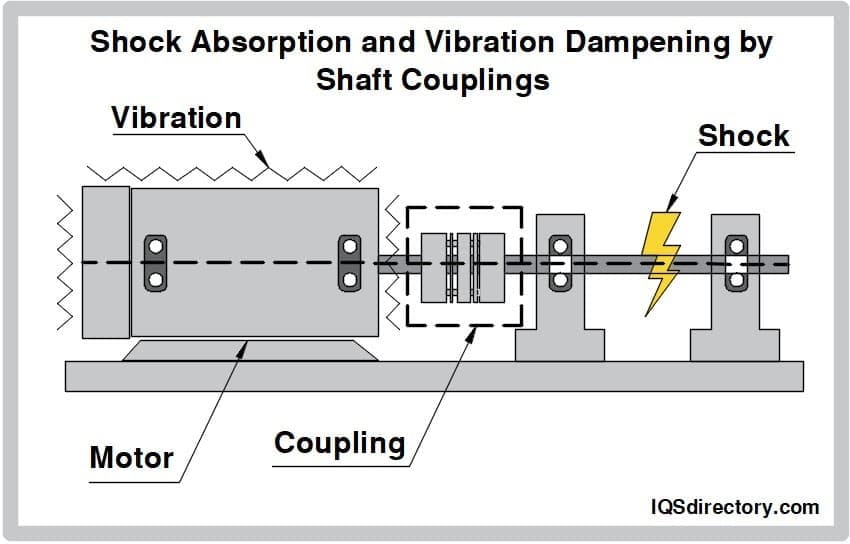

- Damping Advantages

- Flexible shaft couplings also provide shock absorption and lessen the intensity of vibrations, a process known as damping.

Shaft Coupling Design

Flexible shaft couplings typically consist of the shafts and mechanisms like gears or pulleys. If the coupling is to work with rotating machinery, it will also usually have a keyway and a keyway, which connect the rotating element to the shaft, and also regulate its rotation and torque.

To make the system work, engineers mount rotary equipment, such as wheels, onto rigid or linear shafts, using the shaft couplings. Couplings connect the shafts of rotating equipment in order to allow some axial and angular misalignment, while maintaining torque power. In certain industrial applications, shafts remain aligned with one another continuously, in which case rigid shaft couplings remain an effective choice.

- Production

- The most common methods of construction for flexible couplings include electroforming, chemical deposition, mechanical forming and welding. All of these also typically involve CNC machining, so that manufacturers can more precisely produce the couplings.

- During electroforming, manufacturers add layers of metal on a mandrel until they reach the desired thickness and the mandrel melts away. This method is most common for creating bellows.

- During chemical deposition, shaft coupling manufacturers also add layers. The difference here though, is that manufacturers add the materials via electro-deposition.

- Next, mechanical forming includes roll-forming or extrusion.

- Finally, welded couplings are made when manufacturers weld a series of rings or washers on both the inside and outside of the couplings.

- Materials

- Manufacturers usually make flexible couplings from aluminum or stainless steel. Aluminum is a great option when you’re on a budget or you need a lightweight coupling. Otherwise, stainless steel is best, as it is strong, corrosion resistant and makes for couplings with a high torque capacity.

- Considerations and Customization

- Shaft coupling suppliers fabricate couplings for a broad range of applications. Thus, they take care before manufacturing one to carefully analyse the industrial application and environment in which the coupling will be used, as well as the performance of individual couplings. They also must consider specifications like shaft size. Based on these considerations, manufacturers can create a custom coupling.

Shaft Couplings Images, Diagrams and Visual Concepts

Shaft couplings, devices that connect two shafts to transmit power from a driveshaft to a driven shaft while absorbing some degrees of misalignments and mounting errors between the two shafts.

Shaft couplings, devices that connect two shafts to transmit power from a driveshaft to a driven shaft while absorbing some degrees of misalignments and mounting errors between the two shafts.

Shaft misalignments occur in different forms and usually exist in combinations.

Shaft misalignments occur in different forms and usually exist in combinations.

Flexible couplings can provide electrical isolation when sensitive electronic components driven in a high voltage.

Flexible couplings can provide electrical isolation when sensitive electronic components driven in a high voltage.

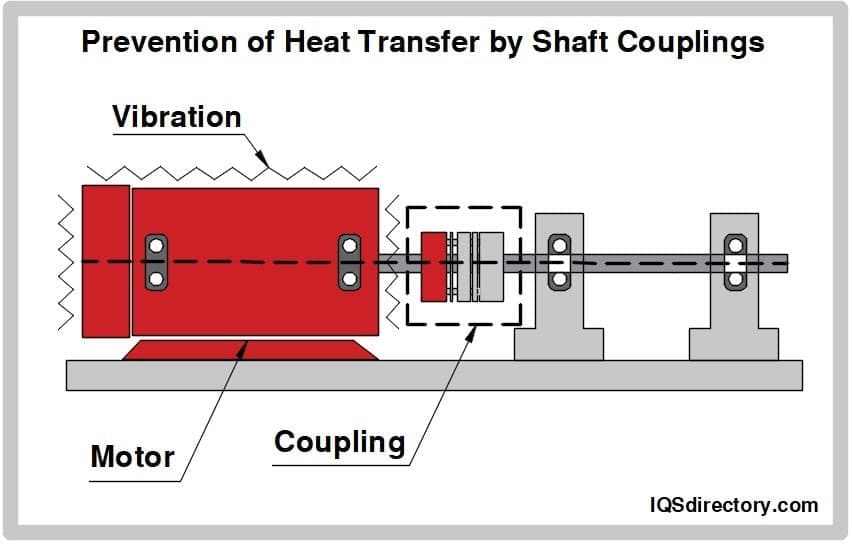

Shaft couplings prevent the transfer of heat from the power source to the driven shaft.

Shaft couplings prevent the transfer of heat from the power source to the driven shaft.

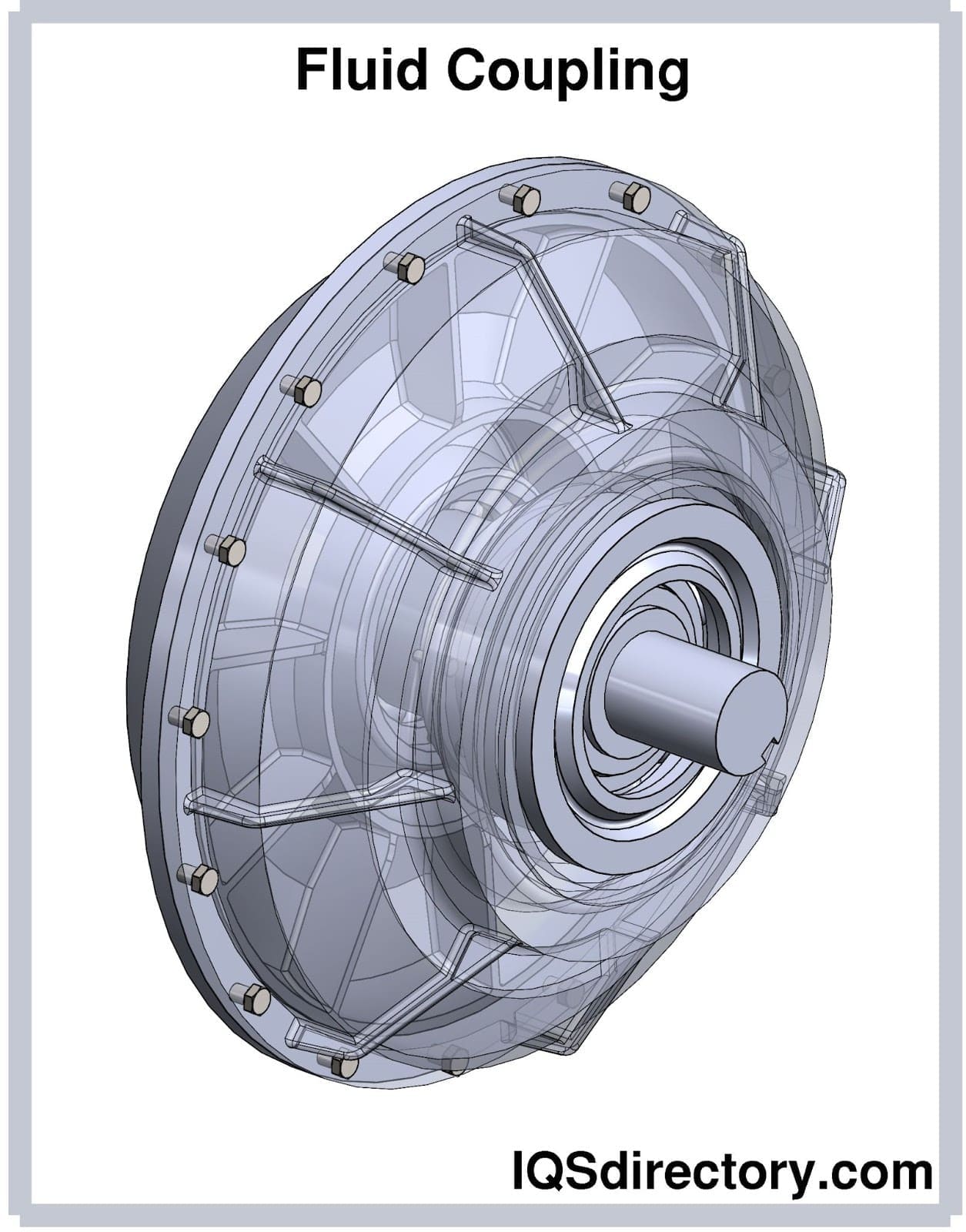

Fluid couplings, consist of an impeller attached to the driveshaft, which acts as a pump and a runner attached to the driven shaft.

Fluid couplings, consist of an impeller attached to the driveshaft, which acts as a pump and a runner attached to the driven shaft.

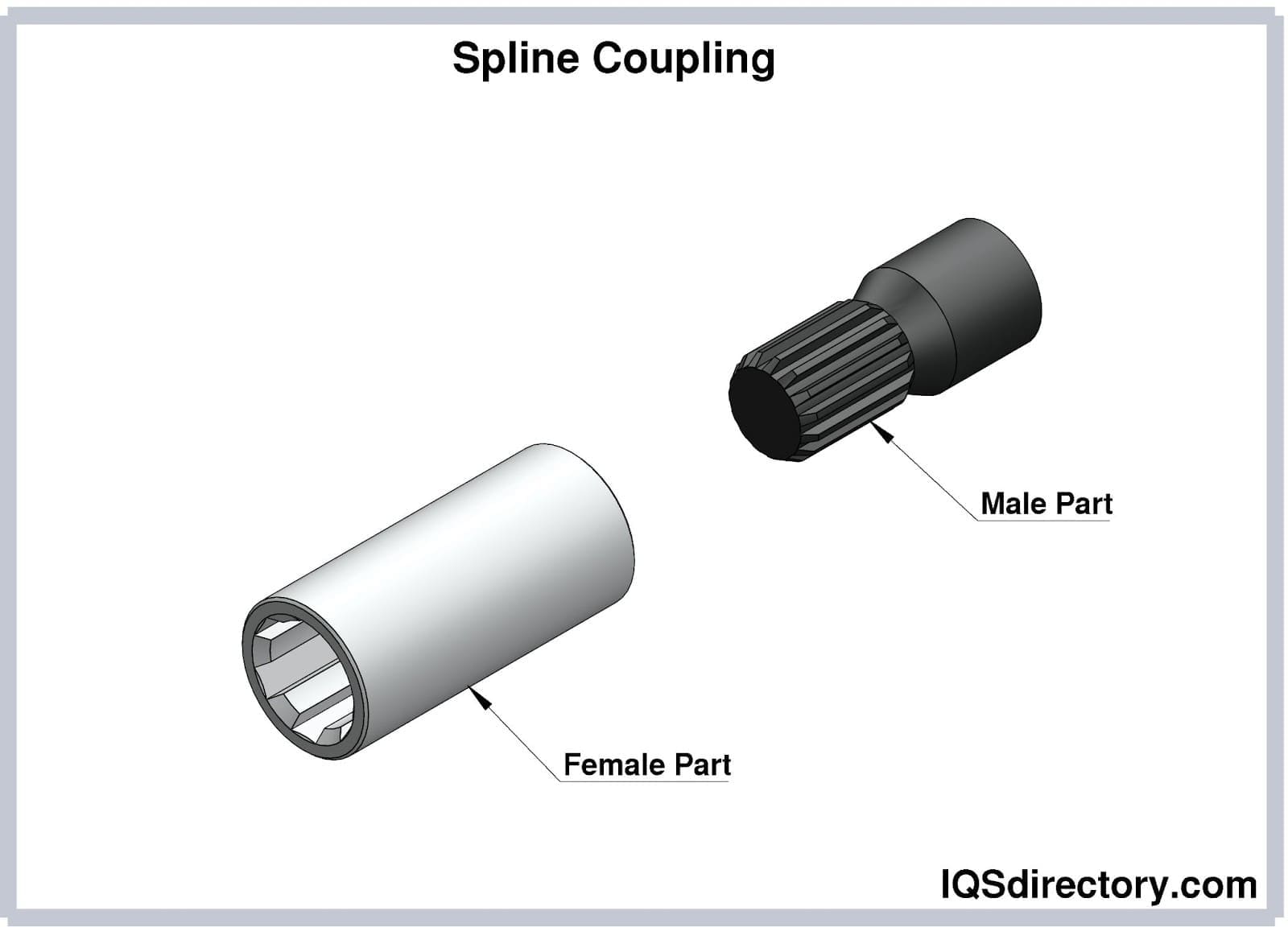

Spline couplings, the sleeve has internal teeth which matchs the external teeth of the spline shaft to prevent the shaft from slipping and becoming misaligned.

Spline couplings, the sleeve has internal teeth which matchs the external teeth of the spline shaft to prevent the shaft from slipping and becoming misaligned.

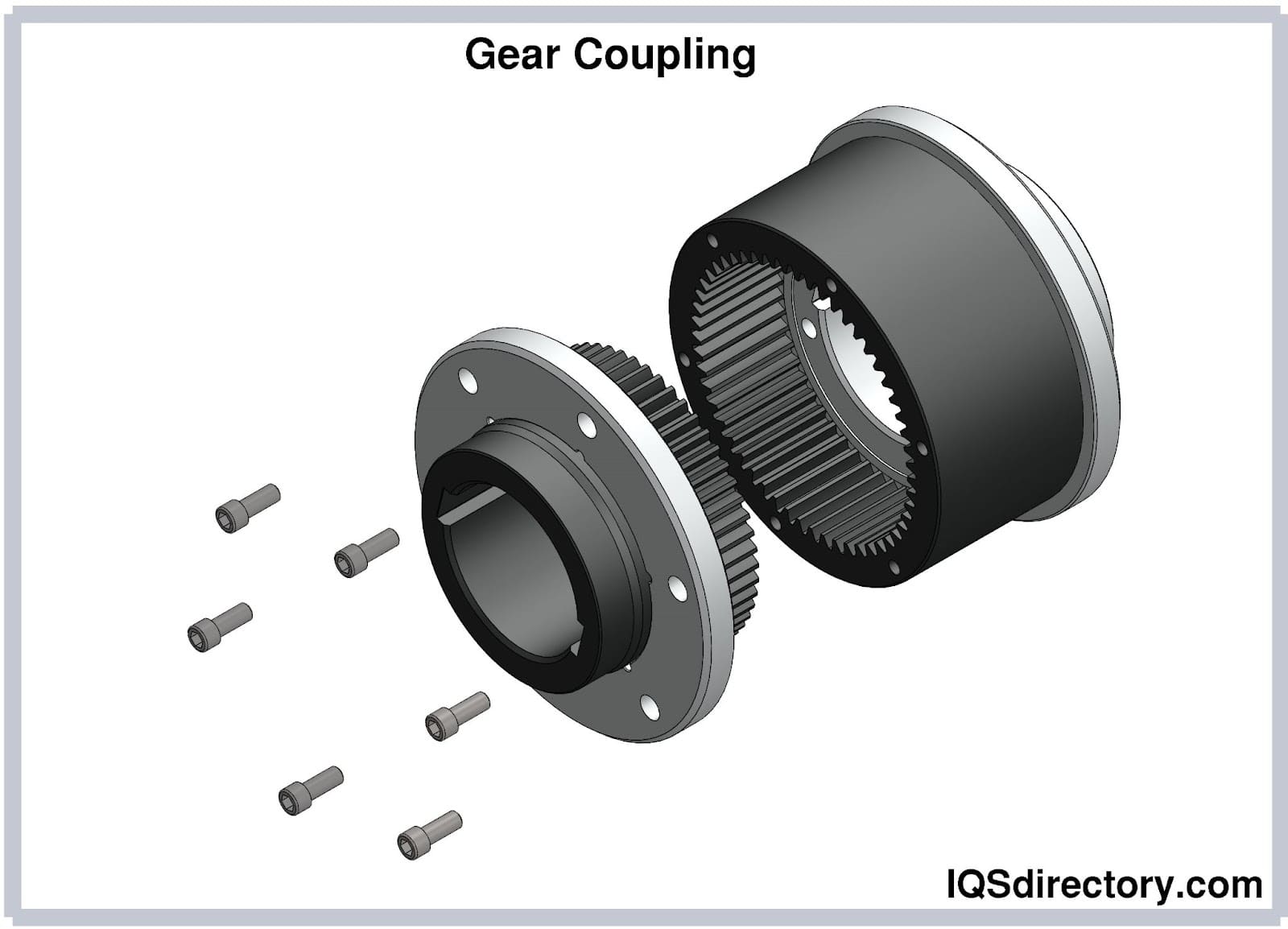

Gear coupling, where the flange and its hub are separate parts with protruding gear teeth on their external diameter that match the internal flange gear teeth.

Gear coupling, where the flange and its hub are separate parts with protruding gear teeth on their external diameter that match the internal flange gear teeth.

Roller chain couplings have radial sprocket hubs that are connected by a double-strand roller chain, which transmit the torque and compensate for the parallel, axial, and angular misalignments.

Roller chain couplings have radial sprocket hubs that are connected by a double-strand roller chain, which transmit the torque and compensate for the parallel, axial, and angular misalignments.

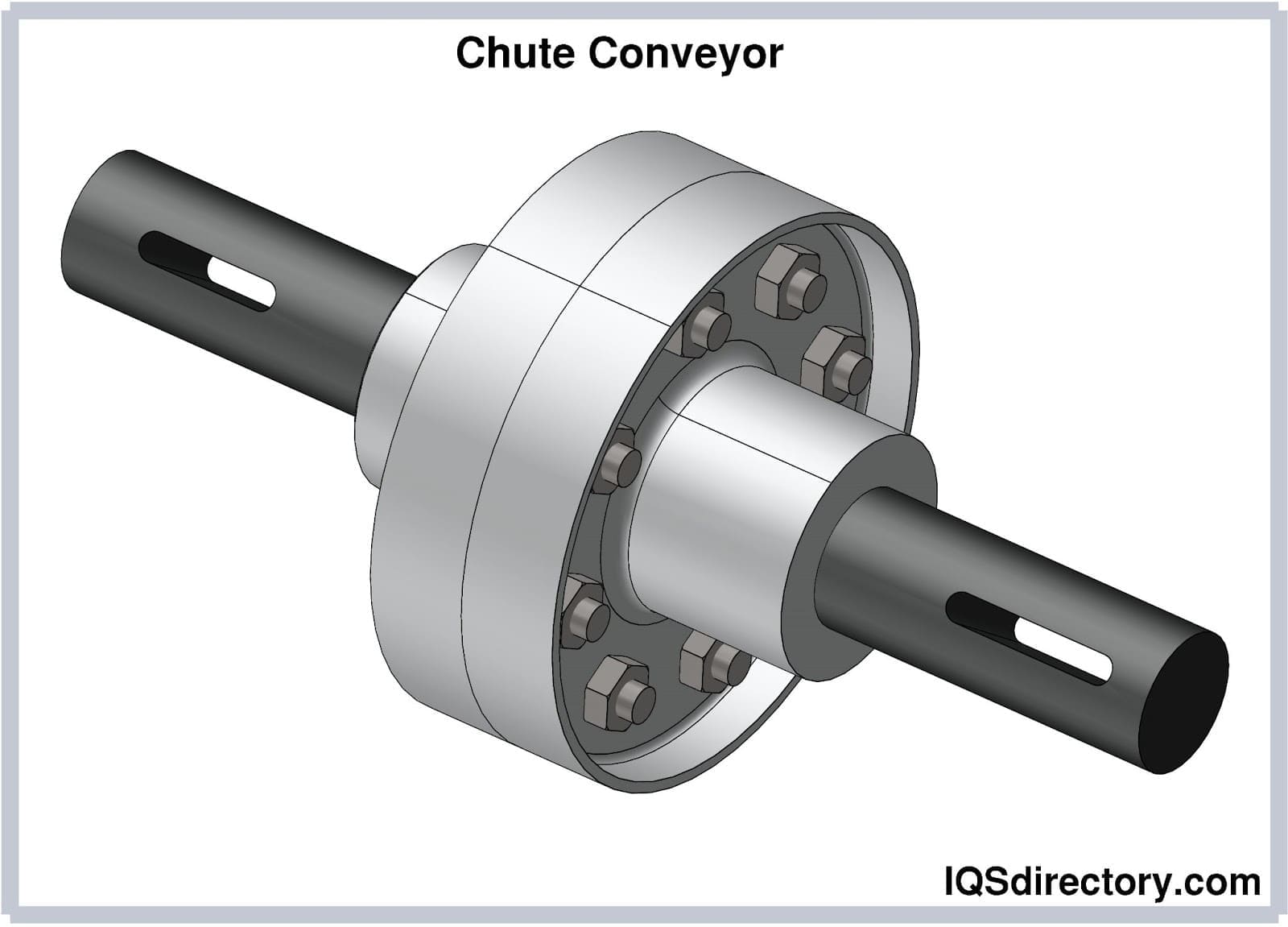

Disc couplings contain single or multiple flexible steel discs bolted between flanges.

Disc couplings contain single or multiple flexible steel discs bolted between flanges.

Types of Shaft Couplings

Flexible shaft couplings are categorized according to their means of flexibility and their application into three main categories: mechanical flexible shaft couplings, elastomeric flexible shaft couplings, and metallic membrane flexible shaft couplings.

- Mechanical Flexible Couplings

- Obtain flexibility through loosely fitted parts that move past one another. Mechanical flexible couplings maintain high torsional stiffness and accommodate a high degree of angular misalignment; however, mechanical couplings require lubrication and maintenance, and may not permit adequate axial movement.

- Elastomeric Couplings

- Contain a resilient element, such as rubber or plastic. Elastomeric couplings possess many advantages, including a high damping ability, high shock absorption, a high degree of misalignment accommodation, and do not require lubrication; however, elastomeric couplings are larger than metallic couplings, and possess sensitivity to ultraviolet light, chemicals and high temperatures.

- Metallic Membrane Couplings

- Or metallic element couplings, obtain flexibility through the bending of a membrane within the coupling. They do not contain a rubber or a plastic element. Metallic flexible couplings offer high torsional stiffness and great resistance to chemicals, ultraviolet radiation and high temperatures. In addition, metallic membrane couplings require low maintenance and no lubrication; however, these couplings may be more expensive than mechanical flexible couplings.

- In addition to these three main types, there is a wide variety of other flexible shaft coupling types. Keep reading for descriptions of a wide range of said types.

- Fluid Couplings

- Hydrodynamic devices that transmit rotational energy (measured in rpms) through oil by using pump and turbine construction. To get the rotation from one shaft to another, the pump and turbine accelerate and decelerate the hydraulic fluid.

- Motor Couplings

- Flexible devices that provide distance changes along a lateral axis between a motor shaft and a device. Motor couplings, like flywheel couplings and torque limiters, are found in transmissions and motors of many different vehicles.

- Flywheel Couplings

- A motor coupling type, connect two shafts together while absorbing vibration and shock and providing a steady dampening effect.

- Compression Couplings

- Elastomeric couplings used mostly to join plumbing elements. They offer several advantages, such as: efficient torque transmission, high overload tolerance and high torsional stiffness. Compression couplings include: jaw couplings, pin and bush couplings and donut couplings.

- Jaw Couplings

- A type of compression coupling that control motion by transmitting torque and damping vibrations that could cause damage to other system components. They offer zero backlash and, of all the couplings that provide vibration dampening, their service is the best.

- Bellows Couplings

- Connectors for shafts and equipment that require flexibility and non-linear alignment.

- Diaphragm Couplings

- Permit angular misalignment, but only a small degree of axial motion. A sub-type of metallic membrane coupling.

- Disc Couplings

- Accommodate angular misalignment, but do not accommodate parallel misalignment or axial motion. A sub-type of metallic membrane coupling.

- Driveshafts

- A type of rigid shaft coupling. They transmit torque from engines to moving parts.

- Fail-Safe Couplings

- Designed to continue operating for a certain length of time after the application of torque has ceased.

- Gear Couplings

- Identical in design to sprockets, using a gearhead in the same way sprockets move chains. Customers use them to connect shafts while providing efficient torque transmission in a compact mechanism. They also permit a high degree of axial movement. They transfer rotary motion at a 90 degree angle. However, gear couplings require piloting, and may malfunction at very high or very low torques.

- Grid Couplings

- Offer adequate vibration damping and shock absorption. However, significant axial movement may compromise coupling resilience.

- Oldham Couplings

- Constant velocity couplings used for connecting two parallel shafts that are close together and run at the same speed.

- Shear Couplings

- Provide a high degree of misalignment accommodation, produce low reactionary loads and offer high torsional softness. Shear couplings include tire, sleeve and molded-element couplings.

- Universal Joints

- Sometimes called universal couplings, are hinges that enable rigid shafts to rotate and bend to a full range of motion, while still providing torque. Found in driveshafts, they have central hubs where the shafts are joined to a third element. Their arrangement allows the joint to bend to a higher degree than in flexible shaft couplings. For this reason, manufacturers turn to universal joints when shafts or equipment require a wider range of motion or more than five degrees of misalignment.

Applications of Flexible Couplings

Flexible couplings assist shafts in their endeavors and the endeavors of the machines in which shafts are installed. Shafts, such as tube shafts, driveshafts and line shafts, are used to provide rotary motion to a wide spectrum of vehicles, machines and equipment. Shaft couplings are critical for providing secure rigid, flexible or non-linear connection between shafts, wheels and rotary equipment.

Flexible shaft couplings are utilized therefore by manufacturers to connect rotary equipment such as: power transmissions, driveshafts, line shafts, generators, wheels, pumps and turbines in a variety of automotive, oil and gas, aerospace, water/waste treatment and construction industries.

Things to Consider When Purchasing Shaft Couplings

Not all coupling manufacturers fabricate all types of flexible couplings; some specialize instead in gear couplings, bellows couplings and other industry-specific types. Many coupling manufacturers also manufacture various types of shafts, such as driveshafts, line shafts and bearing supported stub shafts, offering custom fabrication for unusual coupling applications.

To make sure you have found the right manufacturer for you, you need to know what you need. To help focus your search, we recommend you start by jotting down a list of your application specifications, as well as your budget, questions and concerns. That way, as you browse the list of high quality manufacturers we’ve provided on this page, you can figure out more quickly which ones offer the right services for you.

Shaft Coupling Accessories

Examples of shaft coupling accessories include: shaft collars, dripless shaft seals, coupling encoders and more. Learn what accessories are best for your application by talking to your supplier.

Shaft Coupling Terms

- Angular Misalignment

- The condition in which the axes of shafts intersect with one another at an angle; angular misalignment is calculated by measuring the angle at the intersection of the connected axes, expressed in degrees.

- Axis of Rotation

- An imaginary line in the center of an object around which the object rotates.

- Axial

- Characterized by movement along the axis of rotation.

- Axial Displacement

- Condition in which shaft's move axially; also called end float.

- Axial Freedom

- The amount of movement along the shaft axes that a coupling can permit.

- Axial Stretch

- The change in a shafts length, whether an increase or decrease in length, upon the application of a load.

- Backlash

- The extent of shaft movement.

- Bending Flexibility

- Measurement indicating the comparison of flexibility between shafts.

- Bending Stiffness

- The shaft's resistance to the application of torque.

- Bore

- The hole on the shaft onto which the coupling is mounted.

- Burst Pressure

- The pressure at which a device fails and loses ability to retain fluid.

- Damping

- The reduction of vibration between shafts; this reduction is caused by an elastomer in the coupling.

- Field Repairable

- In such cases the entire coupling does not have to be replaced and only certain components are repaired on site of the coupling.

- Horsepower (hp)

- Measurement unit indicating the time rate of work a piece of equipment produces. With regard to mechanical power, horsepower equals the movement of 33,000 pounds one foot per minute or the movement of 550 pounds one foot per second. Horsepower equals 746 watts of electrical power.

- Hysteresis

- A delay in the response of an object to forces, especially magnetic forces, acting upon the object; often observed in elastic and magnetic objects.

- Inherent Balance

- Balance of the coupling found in the original design of the coupling itself. This also can be a factor of the materials used in construction of the coupling, as certain stocks of metal are better for equilibrium.

- Keyway

- Rectangular opening in the coupling bore in which a key may be inserted to lock couplings and shaft parts into place.

- Parallel Misalignment

- The condition in which shafts axes are parallel, but do not intersect with one another; also called parallel offset or radial misalignment.

- Piloting

- The process of guaranteeing that shafts and couplings maintain the same axis of rotation.

- Reactionary Load

- The coupling's exertion of force upon shafts during parallel misalignment, which causes the shafts to bend.

- RPM (Revolutions Per Minute)

- Measurement of operating speed indicating the number of full rotations a shaft completes in one minute.

- Shear Pin

- A protective pin used in some couplings to prevent cut off.

- Shrouded Bolt

- An optional bolt found on some flexible couplings, which are used during high speed applications. Installed with a socket wrench.

- Thermal Expansion

- Lengthening of shafting caused by change in environmental temperature.

- Torque

- The measurement of the extent to which a force applied to an object causes the object to rotate.

- Torsional Softness

- The low resistance of a shaft to twisting motion, opposite of torsional stiffness.

- Torsional Stiffness

- The measurement of a shaft's resistance to twisting during operation. High torsionsal stiffness indicates minimal shaft twisting; low torsional stiffness indicates little resistance to twisting.

- Torsional Vibration

- The change in a rotational system's torque.