Flexible Shaft Couplings

Shaft couplings are essential components that connect two shafts at their ends to enable power transmission. Flexible shaft couplings efficiently transfer torque between rotating equipment and compensate for shaft misalignment. Unlike rigid shaft couplings, which connect perfectly aligned shafts, flexible couplings are designed to handle misalignment and provide more adaptability in a system.

Flexible Shaft Couplings FAQ

What is the purpose of a flexible shaft coupling?

A flexible shaft coupling connects two rotating shafts to transmit torque while compensating for misalignment, vibration, and end float. It maintains efficiency and protects equipment from stress during operation.

How do flexible shaft couplings differ from rigid couplings?

Flexible couplings handle angular, parallel, and axial misalignment between shafts, absorbing vibration and shock. Rigid couplings, by contrast, require perfect alignment and do not allow flexibility or movement between shafts.

What materials are used to manufacture flexible couplings?

Common materials include aluminum for lightweight designs and stainless steel for corrosion resistance and durability. The choice depends on performance needs, operating environment, and system requirements.

Which industries commonly use flexible shaft couplings?

Flexible couplings are widely used in automotive, aerospace, oil and gas, and water treatment industries to connect motors, driveshafts, pumps, and turbines, ensuring efficient power transmission and system reliability.

What types of flexible couplings are available?

Main types include mechanical, elastomeric, and metallic membrane couplings. Each provides unique benefits—mechanical for high stiffness, elastomeric for vibration damping, and metallic for durability in harsh conditions.

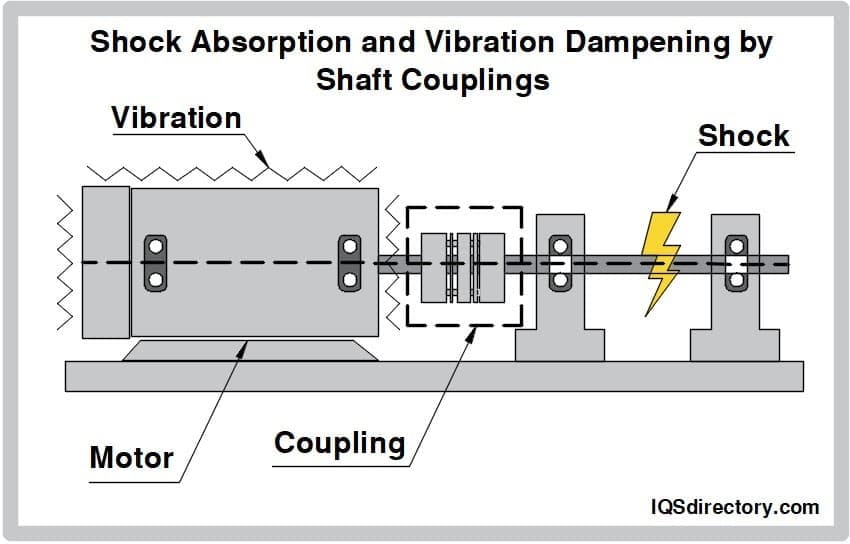

How do flexible couplings reduce vibration and shock?

They use elastomeric or metallic elements that absorb impact and dampen vibration, protecting equipment components and extending operational life in rotating systems.

What should be considered when selecting a flexible shaft coupling?

Selection depends on torque requirements, operating environment, expected misalignment, and maintenance needs. Evaluating these factors ensures the coupling delivers reliable and efficient performance for the specific application.

The History of Shaft Couplings

The development of flexible couplings dates back to the invention of the wheel in Mesopotamia over 5,000 years ago. The earliest documented uses appeared in Greek and Chinese engineering around 300 BC and 25 AD. In the 1500s, Italian polymath Jerome Cardan introduced a driveshaft with universal joints, enabling rotary motion transmission at various angles—a principle still used in vehicles today. By the 1650s, the Cardan shaft was applied to clock drives, and in 1676, Robert Hooke coined the term "universal joint."

Key innovations in flexible shaft couplings took place during the Industrial Revolution. In 1886, Francis M. Roots proposed that a thinner flange would create a more flexible coupling, leading to the diaphragm coupling. The automotive industry's growth in the early 20th century accelerated coupling development, with chain couplings described in 1914 and gear couplings created in the 1930s. The 1940s and 1950s brought couplings capable of managing higher speeds and greater misalignment, while the 1960s saw the introduction of non-lubricated and toothed gear couplings, as well as advances in lightweight materials.

Today, flexible shaft couplings benefit from modern materials and CNC manufacturing processes. Ongoing engineering improvements continue to enhance these vital components to meet the evolving needs of diverse industries.

Advantages of Shaft Couplings

- Maintenance of Proper and Effective System Function

- Flexible shaft couplings are designed to handle shaft misalignment while preserving system performance, ensuring that machinery continues to function efficiently even when alignment shifts occur.

- Efficient Accommodation of Misalignment

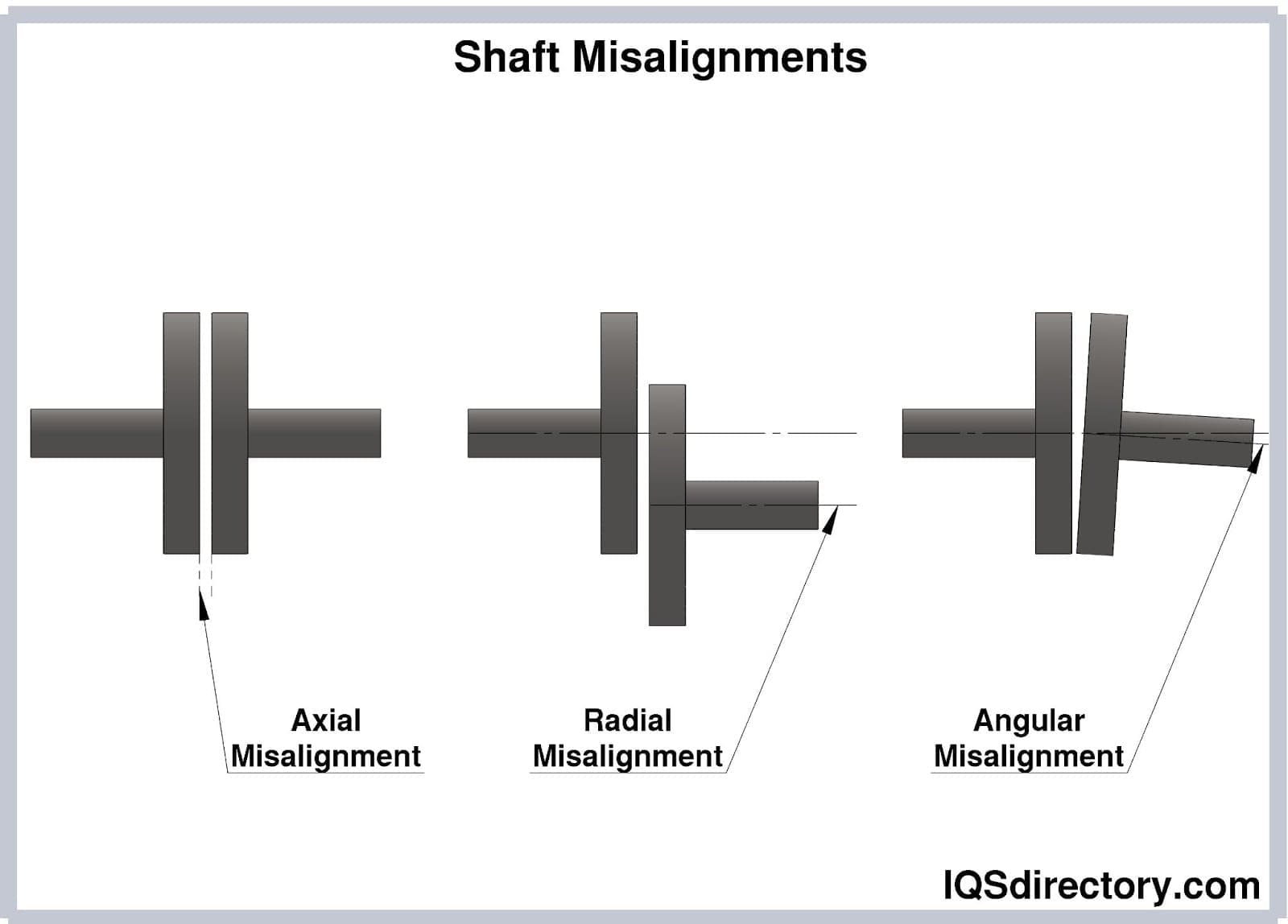

- These couplings effectively manage moderate shaft misalignment, such as skewed axes of rotation, and can accommodate up to 5° of misalignment. Types of misalignment include parallel (shafts are parallel but offset), angular (shafts meet at an angle), and skewed (a combination of both).

- Effective Accommodation of End Float

- Shaft couplings also compensate for axial displacement, or end float, allowing shafts to move along their axis without disconnecting the system.

- Damping Advantages

- Flexible couplings dampen vibration and absorb shocks, which helps extend the life and improve the reliability of equipment.

Shaft Coupling Design

Flexible shaft couplings are comprised of the shafts and elements like gears or pulleys, often featuring a keyway for controlled rotation. They allow for some axial and angular misalignment while reliably transmitting torque. For setups that require perfect alignment at all times, rigid shaft couplings are a viable choice.

- Production

- The fabrication of flexible couplings uses processes such as electroforming, chemical deposition, mechanical forming, and welding. CNC machining is also commonly used to achieve precision manufacturing.

- Materials

- Popular materials for flexible couplings include aluminum for its lightweight and cost-effectiveness, and stainless steel for its durability and resistance to corrosion.

- Considerations and Customization

- Manufacturers consider the application, operating environment, and required performance when creating couplings, offering custom solutions to meet specific project needs.

Shaft Couplings Images, Diagrams and Visual Concepts

Shaft couplings are devices that join two shafts to transmit power from a driving shaft to a driven shaft while compensating for misalignments and installation errors between the shafts.

Shaft couplings are devices that join two shafts to transmit power from a driving shaft to a driven shaft while compensating for misalignments and installation errors between the shafts.

Shaft misalignments can take various forms and often occur in combinations in mechanical systems.

Shaft misalignments can take various forms and often occur in combinations in mechanical systems.

Flexible couplings can provide electrical isolation for sensitive electronics in high-voltage environments.

Flexible couplings can provide electrical isolation for sensitive electronics in high-voltage environments.

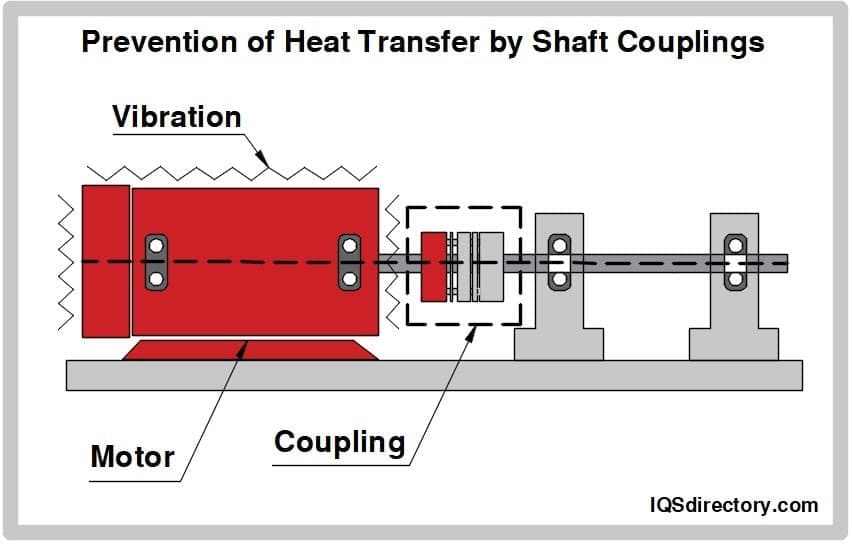

Shaft couplings help prevent heat from transferring from the power source to the driven shaft.

Shaft couplings help prevent heat from transferring from the power source to the driven shaft.

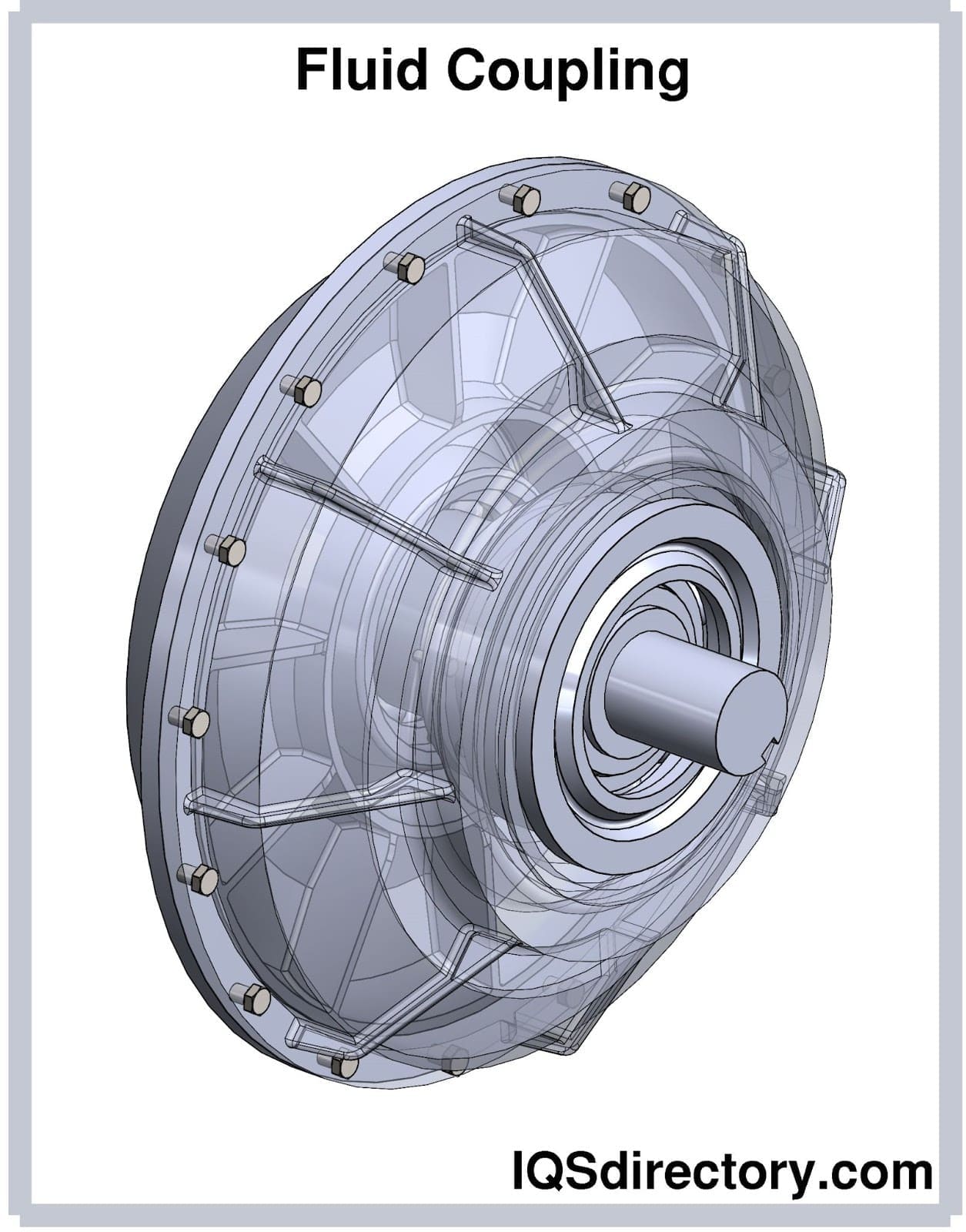

Fluid couplings consist of an impeller mounted to the driveshaft that acts as a pump and a runner attached to the driven shaft.

Fluid couplings consist of an impeller mounted to the driveshaft that acts as a pump and a runner attached to the driven shaft.

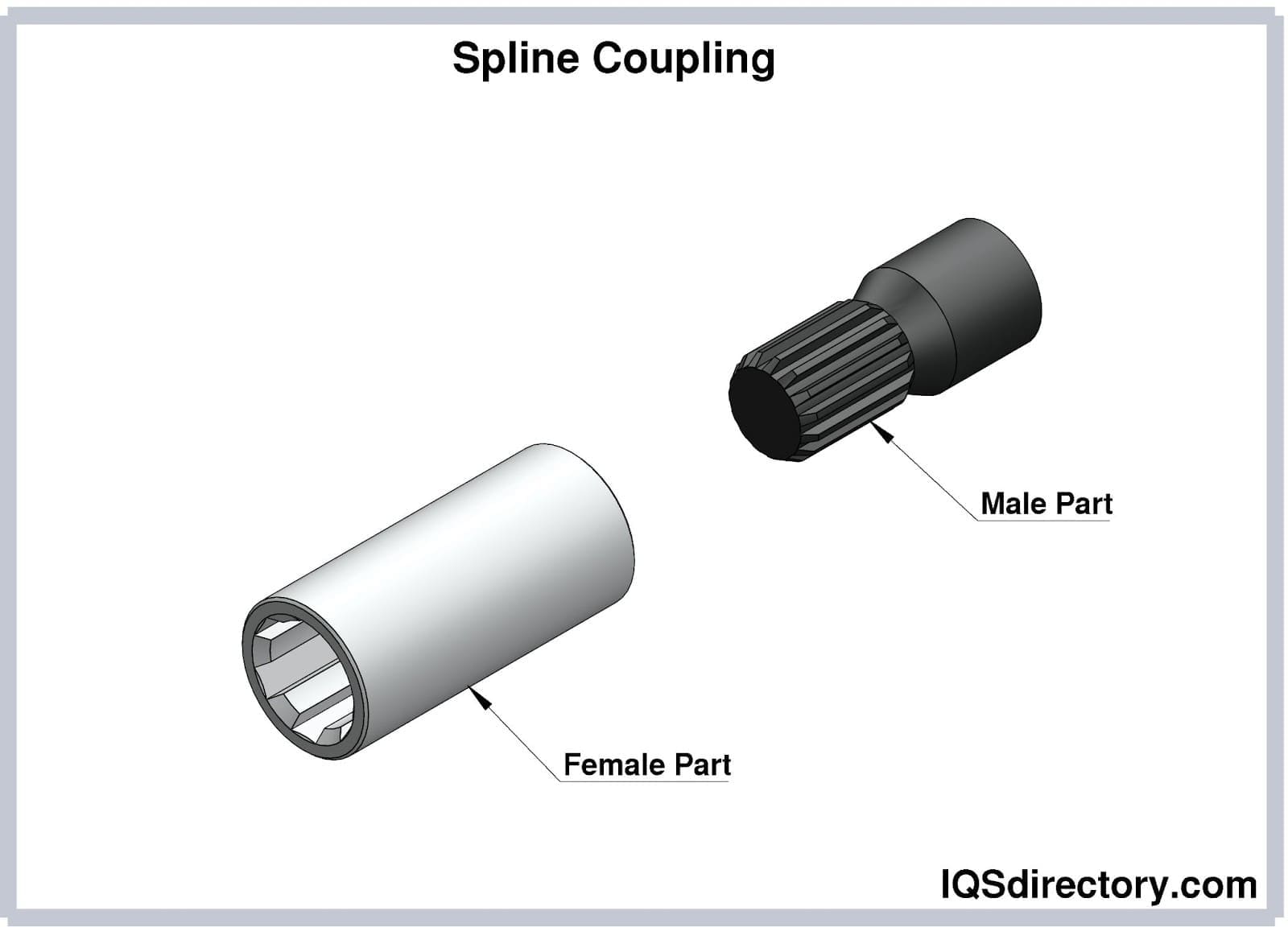

Spline couplings use a sleeve with internal teeth that match the external teeth of a spline shaft, preventing slipping and misalignment.

Spline couplings use a sleeve with internal teeth that match the external teeth of a spline shaft, preventing slipping and misalignment.

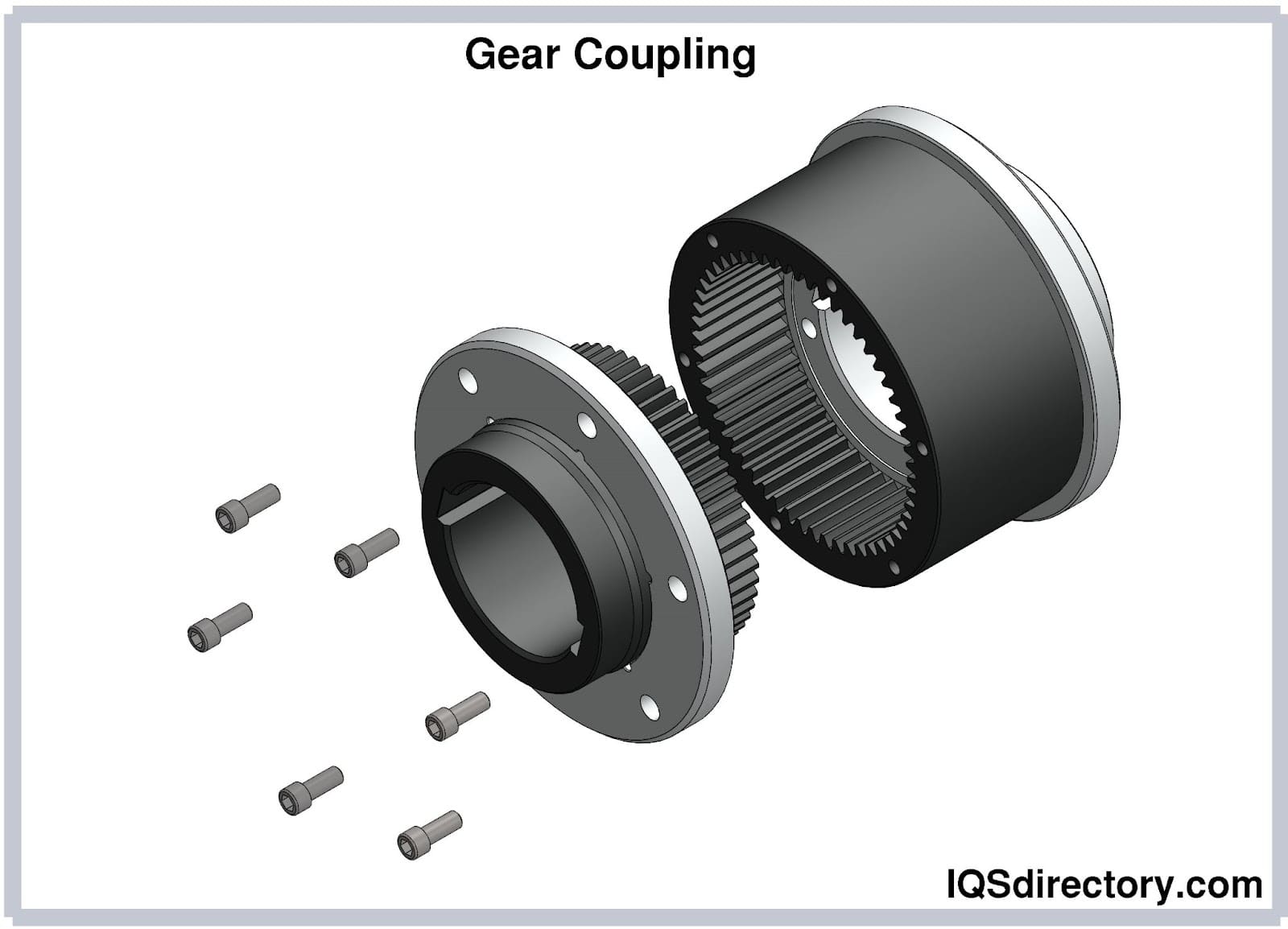

Gear couplings feature a flange and hub with external gear teeth that mesh with the internal teeth of the flange to transmit torque.

Gear couplings feature a flange and hub with external gear teeth that mesh with the internal teeth of the flange to transmit torque.

Roller chain couplings use sprocket hubs connected by a double-strand roller chain to transmit torque and accommodate parallel, axial, and angular misalignments.

Roller chain couplings use sprocket hubs connected by a double-strand roller chain to transmit torque and accommodate parallel, axial, and angular misalignments.

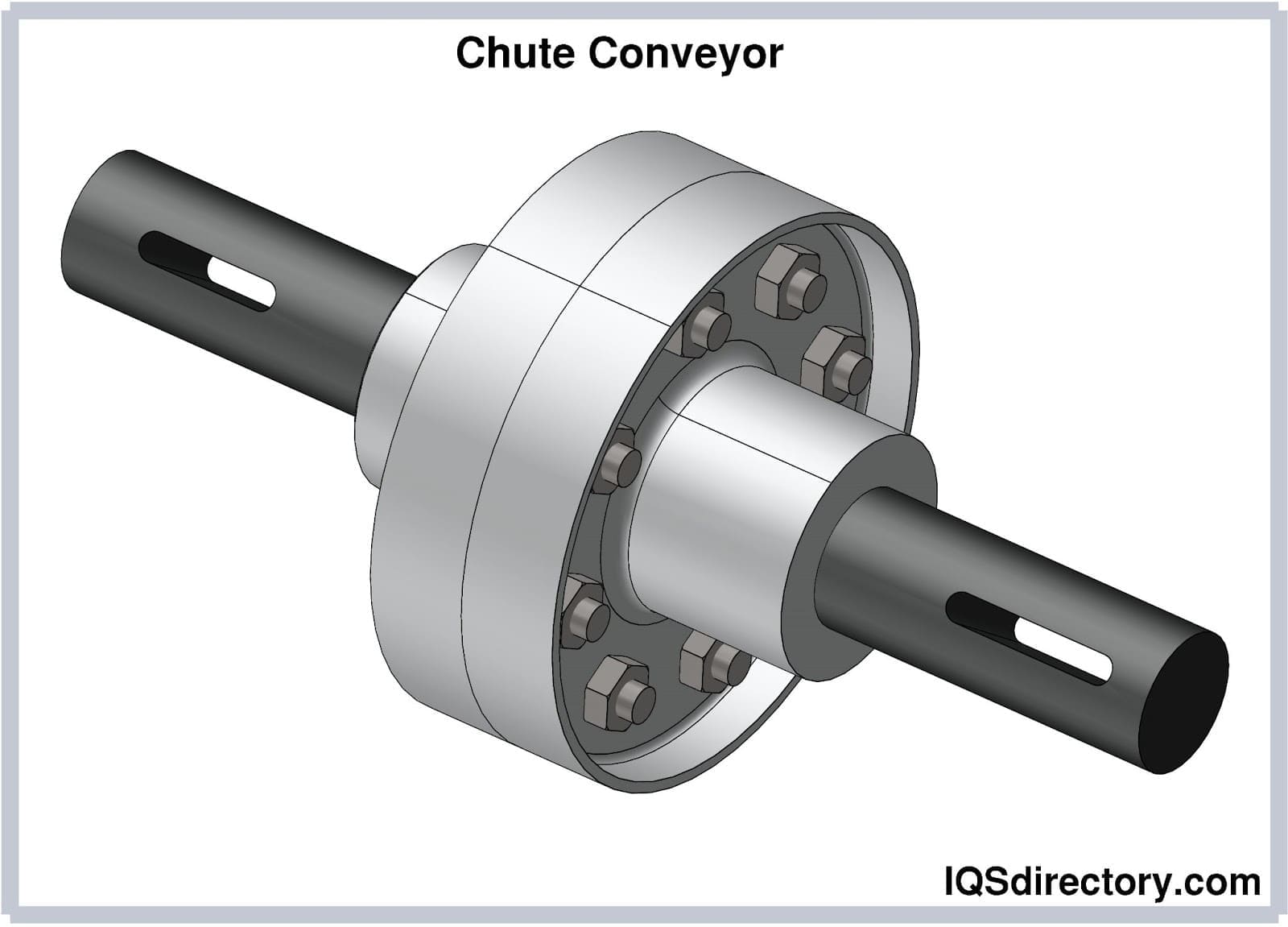

Disc couplings utilize one or more flexible steel discs bolted between flanges to transmit motion.

Disc couplings utilize one or more flexible steel discs bolted between flanges to transmit motion.

Types of Shaft Couplings

Flexible shaft couplings are categorized by their flexibility and function into three main types: mechanical flexible shaft couplings, elastomeric flexible shaft couplings, and metallic membrane flexible shaft couplings.

- Mechanical Flexible Couplings

- These couplings achieve flexibility with moving components that slide against each other. They provide high torsional stiffness and can handle large angular misalignment, but they require regular lubrication and maintenance and have limited axial movement.

- Elastomeric Couplings

- Using resilient materials like rubber or plastic, these couplings deliver flexibility, vibration damping, and shock absorption, and can tolerate misalignment without needing lubrication. They are generally larger and may be affected by UV light, chemicals, or extreme temperatures.

- Metallic Membrane Couplings

- These couplings use a thin metallic membrane for flexibility, without rubber or plastic parts. They offer high torsional stiffness, withstand harsh chemicals, UV radiation, and extreme temperatures, and require little maintenance. However, they may be more expensive than mechanical couplings.

- Additionally, other flexible shaft couplings are available for specialized applications.

- Fluid Couplings

- Hydrodynamic devices that transfer rotational energy through oil, using pump and turbine elements to regulate shaft speeds.

- Motor Couplings

- Flexible couplings designed for motors, allowing for lateral movement between the motor shaft and connected equipment, common in many transmission setups.

- Flywheel Couplings

- A motor coupling type that joins two shafts, providing consistent vibration damping and torque transmission.

- Compression Couplings

- Elastomeric couplings commonly used in plumbing for their efficient torque transfer, overload tolerance, and torsional stiffness. Examples include jaw couplings, pin and bush couplings, and donut couplings.

- Jaw Couplings

- Compression couplings that transmit torque and minimize vibration, offering zero backlash and excellent vibration damping properties.

- Bellows Couplings

- Flexible connectors used to join shafts and equipment requiring compensation for misalignment.

- Diaphragm Couplings

- Allow for angular misalignment with limited axial movement, classified as a type of metallic membrane coupling.

- Disc Couplings

- Engineered to handle angular misalignment but not parallel misalignment or axial movement, these are a type of metallic membrane coupling.

- Driveshafts

- As rigid shaft couplings, driveshafts are essential for transmitting torque from engines to mechanical parts.

- Fail-Safe Couplings

- Designed to sustain operation for a period after torque input stops, providing temporary continued function.

- Gear Couplings

- Similar to sprockets, these couplings use a gearhead to connect shafts for efficient torque transfer in limited spaces, allow significant axial movement, and transmit rotary motion at right angles. They require precise alignment and may not perform well at extreme torque levels.

- Grid Couplings

- These couplings are valued for vibration damping and shock absorption, though they may be less durable with extensive axial movement.

- Oldham Couplings

- Used to link parallel shafts that are close together and rotate at the same speed, ensuring constant velocity.

- Shear Couplings

- Known for accommodating significant misalignment, low reactionary loads, and high torsional softness, shear couplings include types like tire, sleeve, and molded-element couplings.

- Universal Joints

- Also called universal couplings, these joints allow rigid shafts to rotate and bend through a full range of motion while transmitting torque. Common in driveshafts, they feature central hubs for greater bending than flexible couplings, making them ideal for applications needing more than five degrees of misalignment or extensive angular movement.

Applications of Flexible Couplings

Flexible couplings are used across a wide range of vehicles, machines, and industrial equipment to connect shafts such as tube shafts, driveshafts, and line shafts. They are crucial for providing secure, reliable connections in rotary systems, whether the coupling is rigid, flexible, or accommodates non-linear alignment.

As a result, flexible shaft couplings are commonly found in industries like automotive, oil and gas, aerospace, water and wastewater treatment, and construction, where they connect rotary equipment such as transmissions, driveshafts, generators, wheels, pumps, and turbines.

Things to Consider When Purchasing Shaft Couplings

Not all manufacturers produce every type of flexible coupling; some specialize in gear couplings, bellows couplings, or other industry-specific types. Many suppliers also offer driveshafts, line shafts, and custom fabrication to meet specialized coupling needs.

To select the best manufacturer, assess your specific requirements, including the intended application, operating environment, performance expectations, and any unique features necessary for your system. Knowing these details will help you choose a coupling that ensures reliable and efficient operation.

Shaft coupling accessories include items such as shaft collars, dripless shaft seals, and coupling encoders. Consult your supplier to determine the best accessories for your specific application.