Roll Forming

Roll forming is a metal forming process in which metal is shaped by a series of rollers. Roll forming produces some of the most widely used metal products in existence.

Roll forming does not involve heat, and rollers do not affect the surface properties of the metals. These features make it an ideal choice for shaping polished metals, coated metals, and other metals whose beauty and aesthetic properties need to be maintained.

Roll forming is used to bend metallic sheet metal in order to produce rounded shapes or frames known as roll formed parts. Roll formed parts are popular because they are precise with tight tolerances and can be made to conform to a variety of shapes, angles, and curves.

Roll forming services are utilized by a wide range of industries, including automotive manufacturing, building construction, architecture, carpentry, fences, appliance and utility, and more.

Quick links to Roll Forming Information

Roll forming is an excellent choice for the shaping of coated, finished, cured, or otherwise treated metals. Because roll forming processes don't involve heat, and because rollers can be coated with powders or oils that don't react with the metals they shape, roll forming can shape metals without affecting surface properties. This makes it an ideal shaping method for polished metals, coated metals, and other metals whose aesthetic properties must be maintained.

- Robust and Efficient

- The roll forming process does not take much time to complete, but it creates parts and products. A given roll former can shape anywhere between 30 and 600 feet of roll formed metal products per minute. Most roll formers are capable of using nearly 94% of stock metal material during forming operations, which minimizes waste, maximizes efficiency, and boosts profitability. Roll forming operations that involve punching or other surface area reduction services produce more waste than those that don't involve surface area reduction.

- Rapid Turnaround Times

- With the roll forming process, you can shape a complex design within a few hours. A roll former, depending on its type and configuration, can cut 30-600 feet of metal sheet per minute. In addition, because the coil used in forming is sourced in the desired cut, product manufacturers only have to complete the design conceptualization and implementation.

- Increased Consistency

- For large orders, roll forming creates pieces that are identical every time. You will find more accuracy, uniformity, and consistency in individual pieces as well as the entire production lot.

- Low Production Cost

- The coils are sourced from another manufacturer. No time and labor are needed to create metal strips. As a result, the roll forming process, with pre-cut metal strips, helps the roll forming plant keep their production cost low. Further, identical parts are created using strips of the same size, meaning there are fewer chances of material waste.

- Energy Savings

- In addition to this, the roll forming process does not involve heat to roll the metal strips. This helps save on energy or fuel costs. Other methods of metal part production need a heat source to bend the metal strip. However, the roll forming technique does not have such requirements.

- Higher Production Volume in Less Time

- The use of metal strips allows a manufacturing business to achieve a higher production level in comparatively less time. Also, roll forming is a continuous process, which means as long as a roll former is fed with a continuous supply of metal, it can continuously produce shaped products.These methods allow for highly accurate and efficient constant-profile parts to be created in large quantities.

- Flexibility

- Roll forming is a powerful yet flexible method. All metal, both ferrous and non-ferrous, can be rolled and formed with the roll forming method. Many complex designs that are impossible to form via the cross section cutting or stamping method can be easily created through the roll forming method. Creating C channels, J channels, U channels, metal rings, and many other metal trims is possible with this method. In addition, you can work on and roll form a pre-finished part that already has layers of paint, coating, and plating.

- Fewer Secondary Operations

- With roll forming, you can add extra touches that are normally reserved as a secondary operation, then and there. For example, during the initial production, you can cut, notch, perforate, punch, and otherwise change the metal. This also increases the structural integrity of the piece and results in superior parts joining.

Examples of roll formed parts and products include angle irons, aluminum angles, and steel angles (used in carpentry and building applications), metal trim and metal channels (used in construction and the manufacture of industrial, commercial, and consumer products), metal rings (used to embellish buttons on telephones, in elevators, and clothing to prevent hoses from disconnecting, to keep street signs from falling, and to secure lock hardware in doors), metal tube, and metal wall panels (used to improve the appearance of a wall in an office or to protect a wall in a factory from flying debris or sparks).

More specifically, metal roll forming produces items like: c channel frames, car frames, fence posts, angled posts, stabilizers, and railings.

History of Roll Forming

The earliest known examples of rolling technology were found in the Middle East and South Asia and date back to around 600 B.C. While they were quite rudimentary, they displayed the same basic principles as models drawn later by Leonardo Da Vinci.

The first rolling machinery, called a slitting mill, was manufactured in Europe in 1590. It worked by passing flat bars of iron in between a set of rolls to form a plate, then a set of grooved rolls to create slits. The slitting mill was later adapted to form roll hoops for barrels.

The modern roll forming process came along in the late 1700s, when a man named Henry Cort patented his use of grooved rolls for forming iron bars. As the years went on, engineers and manufacturers continued to revise the process, making it work with lead, then copper and brass, and, finally, with all the metals used today.

In the 20th century, manufacturers began using CNC technology. This technology allows manufacturers to design roll forms on a computer, then have that computer automate the process. This allows for the repeatable formation of a high volume of precision-made roll formed parts.

Roll formers can create shapes out of most ferrous and non-ferrous metals and alloy material. These include but are not limited to: aluminum, tin, steel, brass, titanium, zinc, and zirconium.

- Aluminum

- One of the world’s most widely used non-ferrous metals. It is valued for its properties of ductility and malleability, thermal and electrical conductivity, and corrosion resistance. It is also non-magnetic, resistant to fire, and a good reflector.

- Tin

- A naturally occurring element that has been in use in alloys for thousands of years. It is known for its softness, malleability, shine when polished, and resistance to corrosion from water. On its own, tin is susceptible to corrosion from acids and alkalis. Therefore, manufacturers typically alloy it with one or more other metals, such as copper.

- Steel

- The most frequently used material for roll forming. Manufacturers can use many grades and forms of steel, including galvanized steel, stainless steel, and carbon steel. In general, steel is hypoallergenic, durable, strong, corrosion resistant, and abrasion resistant.

- Brass

- Metallic alloy composed primarily of copper and zinc. There are many types of brass, all with different levels of properties like malleability, corrosion resistance, hardness, shine, and antimicrobial abilities.

- Titanium

- A material known for its extremely high strength-to-weight ratio. This strong metal also has a low density, high ductility, and high melting point. In addition, it’s resistant to fatigue, cracking, moderately high temperatures, and corrosion by fresh and saltwater.

- Zinc

- A naturally occurring element. As a metal, it is blueish-white and lustrous. It is a moderately conductive, fairly brittle, and weak material. However, it is combined with other elements, such as steel and copper, to create important alloys like galvanized steel and brass respectively.

- Zirconium

- A lustrous, soft, ductile and malleable element. As a metal, it is highly resistant to corrosion and highly reactive with oxygen.

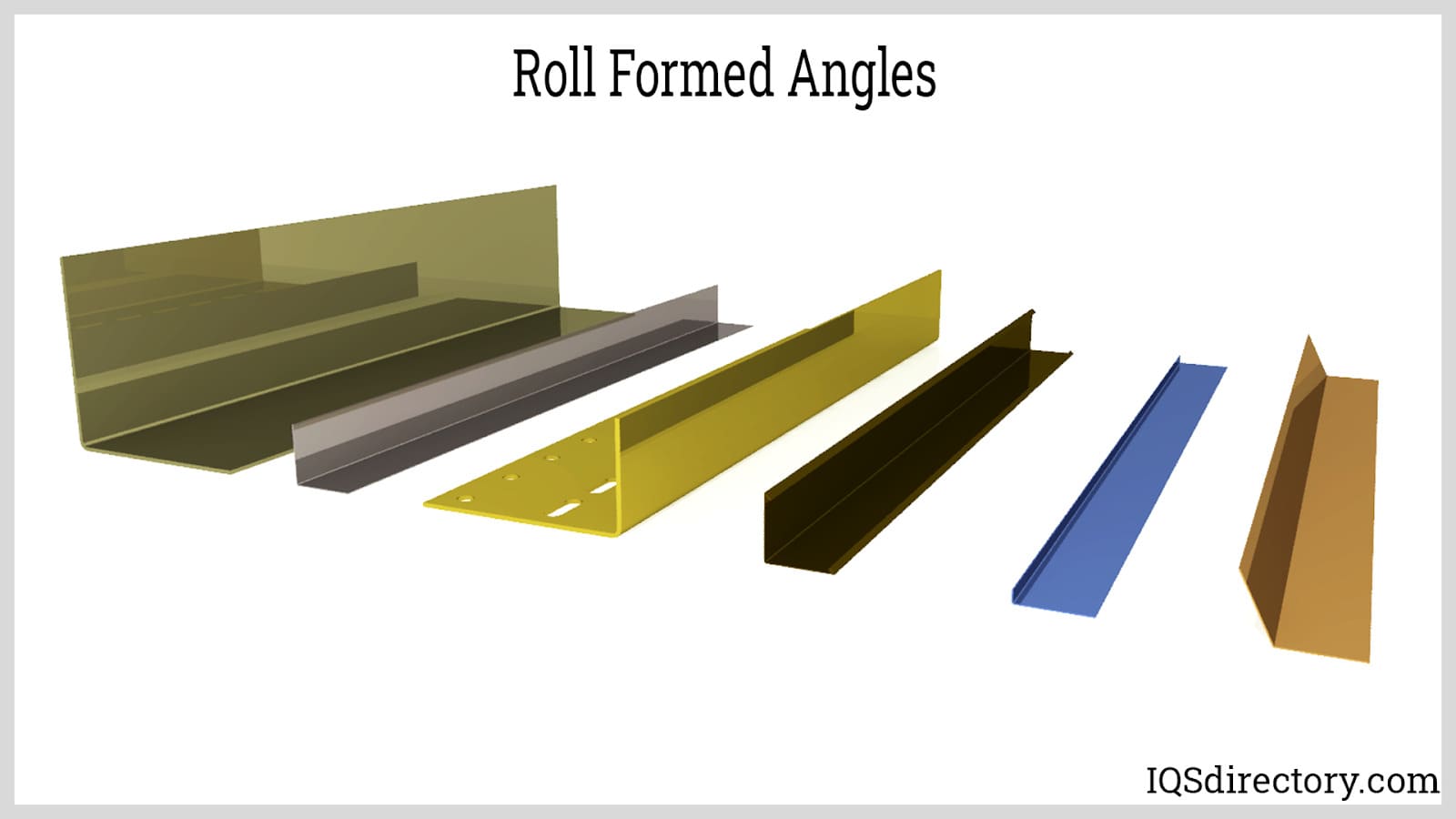

Roll forming process allows for the creation of different patterns or angles using an assortment of metals.

Roll forming process allows for the creation of different patterns or angles using an assortment of metals.

The steps of the roll forming process.

The steps of the roll forming process.

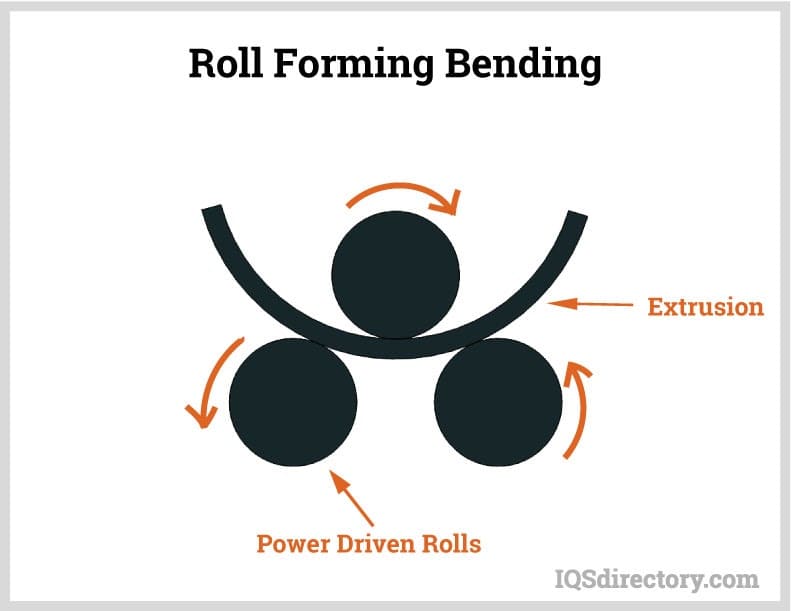

Roll bending uses three rollers bend a plate to produce a desired curve.

Roll bending uses three rollers bend a plate to produce a desired curve.

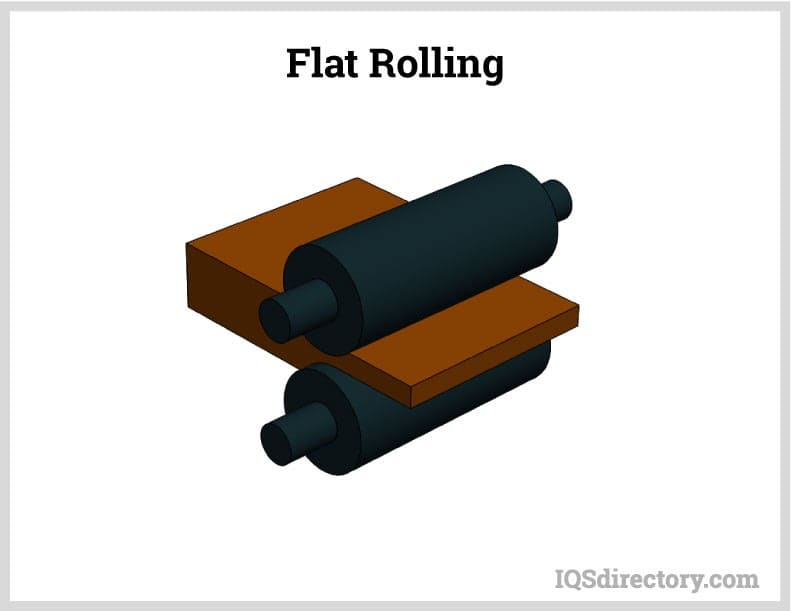

Two working rollers rotating in opposite directions which elongates the material due and creates the desired thickness of the material.

Two working rollers rotating in opposite directions which elongates the material due and creates the desired thickness of the material.

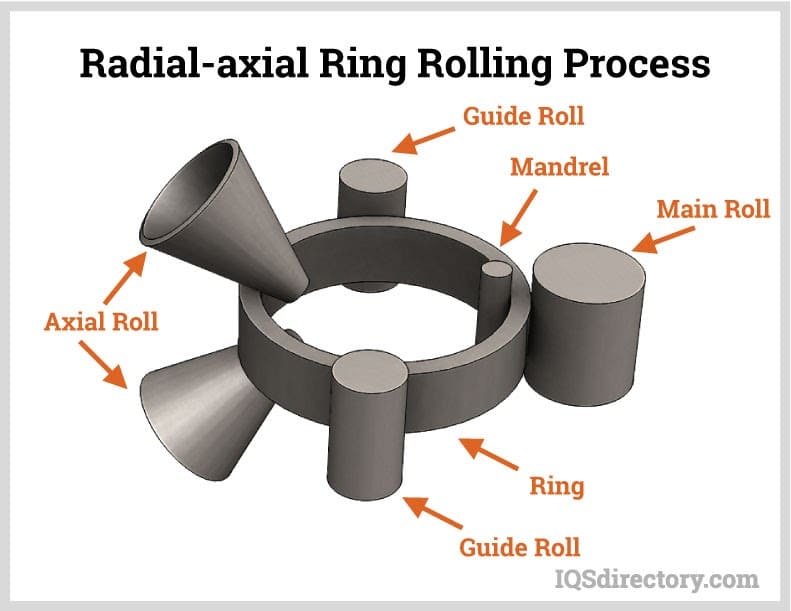

A ring of small diameter is rolled between two rollers to increase the diameter of the ring.

A ring of small diameter is rolled between two rollers to increase the diameter of the ring.

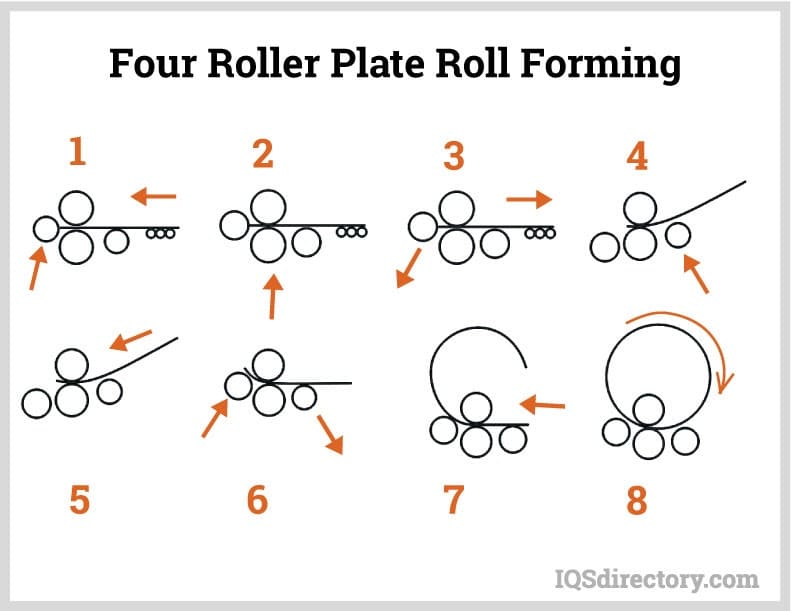

The four roller systems used in forming a cylinder.

The four roller systems used in forming a cylinder.

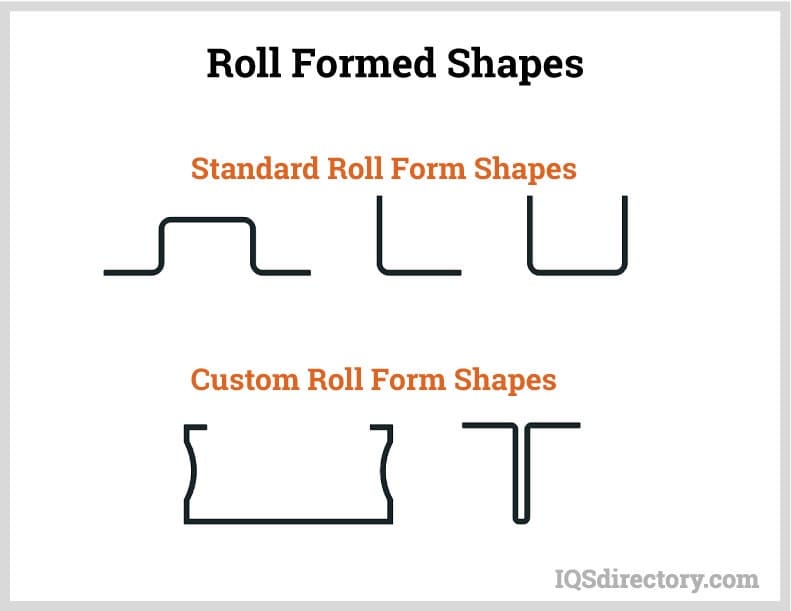

Shape rolling cuts different shapes which does not involve changing the metals thickness to produce irregular shaped channels and trim.

Shape rolling cuts different shapes which does not involve changing the metals thickness to produce irregular shaped channels and trim.

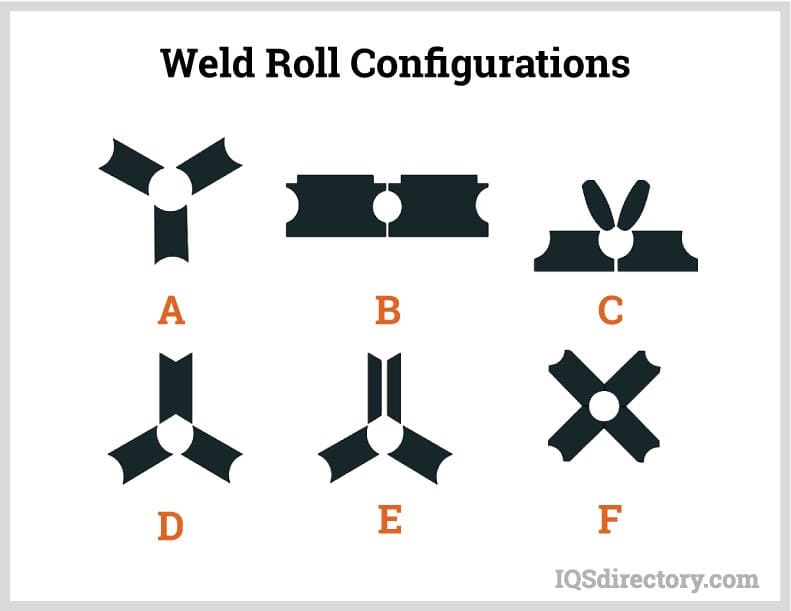

When roll forming tubes the process must include one of these configurations.

When roll forming tubes the process must include one of these configurations.

- Select Metal Type

- Regardless of the type of material selected, manufacturers create roll formed parts from metal strips, which are often coiled for easy access by roll form machinery.

- Feed Metal to Rollers

- Roll formers work by forcing metal through a series of horizontal, rotating rollers, or roller dies. These roller die series help them produce a uniform and constant cross-section profile. At the beginning of a roll forming process, manufacturers feed a stock of metal into the first roller die set. Usually, manufacturers feed the metal to the machine at room temperature. This is called a cold roll form process.

- Let the Rollers do Their Work

- The first roller die sets in every roll former are designed in advance to fit tightly around the contours of the metal material. Each subsequent set of rollers is slightly different in terms of position, allowing for the gradual shaping of the metal as it passes through the rollers.

- For example, if a customer orders circular metal clamps, a roll forming company takes a long strip of horizontal metal stock. That strip is fed into a roller system that creates circular metal clamps. The first set of rollers will grip the metal strip horizontally in the middle. The position of each successive roller in the system will change so that the metal strip, whose horizontal cross section originally looked like a straight line, is slowly modified until it looks like a backwards C.

- Cut to Length:

- Once the metal strip has been formed into the shape manufacturers want, they cut the curved part according to the required length.

- Note: In pre-cut roll forming, materials are cut to length before entering the rolling machine; in post-cut roll forming, profiles are cut to length after the roll forming process.

If you’re interested in a custom roll form, you have many options available to you. Because roll forming is a modular process, manufacturers can configure a roll form machine to produce all manner of metal shapes. In addition, these shapes may have nearly any bend radius, size, and sheet thickness.

Choosing to customize your order of roll formed parts gives you pre-finished components that will come to you in pre-cut condition. The supplier gives you parts that are ready for assembling. You will simply have to begin with the production of your product or application using the custom roll formed parts.

The roll machine market is full of roll formers and roll former tools for every application. The basic roll former machine type consists of an entry section (where you insert the metal), the roller station (where the roller dies shape the metal), a cut off press (where the roll formed part is cut to length), and the exit section (where the part exits the machine onto a table or roller conveyor).

Some roll forming machines also feature laser or TIG welding capabilities. Including one or more of these roll form tooling options on the actual machine will result in a partial loss of energy efficiency. However, it will remove an entire secondary operation from the manufacturing process. They can also incorporate other functions, such as bend rolling and punching.

Manufacturers can further customize their machinery by choosing whether or not it will be an open loop system or a closed loop system. These systems help control the rolling.

The major drawback to roll forming as a metal shaping method is the labor intensity of roller configuration; this process requires a trained professional to precisely set roller systems to ensure a flawless finished product. Recent advances in computer control systems have made this process easier, but it can still be costly. Also, it cannot create sealed ring products; a roll formed metal ring must always be welded or connected with fasteners in order to become sealed. That said, these disadvantages are far outweighed by the advantages of roll forming.

If you want to leverage the expertise and experience of a top-notch metal form company, considering the following tips will enable you to make the right choice:

- Find a Certified Manufacturer from an Online Directory

- You will find a plethora of metal forming companies and manufacturers out there. However, not all will be able to cater to your needs and specifications. Hence, you should rely on an ISO 9001:2008 certified manufacturer who can provide you unmatched customer service at a competitive price.

- Evaluate the Competence or Capability of the Company

- Go through the company's online site and assess the competence and capability of the enterprise. Clients' testimonials, as well as reviews of the company, will give you a fair idea of the company's specialization as well as the quality of products and services they provide. It is very important that the manufacturer you choose has a history of excellent customer service.

- Discuss Your Industrial Requirements and get the Best Quote

- Whether you require rapid delivery of metal trims, hot-rolled or cold-rolled metal channels, metal rings or stainless-steel angles, you can discuss your needs with the experts at the company and get the best quote they have to offer. Collect quotes from several manufacturers, compare them, and settle on the company that best meets your requirements.

- Check to See if the Manufacturer Offers Customization

- Customizability is a key criterion for many industries. When your requirements are unique, a one-size-fits-all approach cannot serve your purpose. Your manufacturing partner should be able to provide you custom metal rolls or be able to create new prototypes per your fabrication specifications. Consider their turnaround time and delivery options to streamline your production process.

- Aluminum Angles

- Bent or conjoined pieces of aluminum that form an angle.

- Aluminum Channels

- Open or closed rectangular tubes made of aluminum.

- Angle Irons

- Bent or conjoined pieces of heavy-duty metal that are often used to support a structure.

- Angles

- Created by roll forming various metals, commonly stainless steel, and provide support in two directions. Angles often contain holes or slots for connecting parts; this increases strength and firmness.

- Channels

- Provide a support system for numerous roll formed products, such as frames and rails.

- Custom Roll Forming

- A roll forming service that offers the fabrication of custom products.

- Metal Channels

- Roll formed products that provide support system frames and rails.

- Metal Rings

- Circular, roll formed parts used to join and seal.

- Metal Trim

- Fits around the edge of a product or part.

- Metal Wall Panels

- Sheets of roll formed metal that are used to cover walls.

- Outboard Mills

- Roll forming machines which have housings that support both ends of the roll tooling shafts.

- Post-Cut Roll Rorming

- A process that uses continuous rolls of metal and does not cut the piece to size until after it has been roll formed. This process is the most common, efficient, consistent, and least troublesome roll forming method.

- Pre-Cut Roll Forming

- A process that uses material that has been cut-to-length before entering the roll forming machine. This method is primarily used for low-volume applications.

- Roll Formed Products

- Metals that have been passed through a series of rollers in order to take on a shape.

- Roll Formers

- Machines that are used to roll form metals.

- Steel Angles

- Roll-formed products made by bending a piece of steel sheet metal.

- Steel Channels

- Roll-formed products made of steel that provide support system frames and rails.

- Rings

- Often roll formed from other shapes and commonly function as container seals and lids. Stainless steel is the preferred alloy.

- Accumulator

- Piece of equipment that holds metal coil, so the roll forming process may continue uninterrupted while new material is attached to the coil.

- Auxiliary Operations

- Secondary processes performed in conjunction with roll forming.

- Camber

- A deviation from a straight line in a roll formed piece.

- Coiling

- Procedure in which heated flat sheet metal is transformed into spiral coils.

- Cold Work

- The process of deforming metal at room temperature in order to increase strength and hardness.

- Drive System

- The system responsible for providing the roll forming machines with power and moving the metal coils through the machines.

- Ductility

- The ability of metal to bend or form without fracture.

- Elastic Limit

- The maximum amount of stress a metal can accept without succumbing to permanent deformation.

- End Flare

- Deformation at the end of a roll formed part.

- End Joiner

- Piece of equipment that connects two coils to permit the continuance of metal coils into the roll forming machine.

- Ferrous Metal

- A metal in which iron makes up a significant component.

- Hat Channel

- Similar to a C channel, except it has edges that form the “brim” of the hat.

- Levelers

- Mechanism that maintains flatness of metal being fed into the roll forming machine.

- Non-ferrous Metal

- A metal that does not contain iron.

- Plastic Deformation

- Permanent changes in the shape of a metal that occur after pushing a metal piece past its elastic limit. Deformation is accomplished through the application of stress.

- Pickling

- The process of cleaning steel coils in preparation for metal forming processes, such as roll forming. The coils are subjected to hydrochloric acid that removes impurities, such as rust, from the metal.

- Reel Kinks

- Imperfections in the metal coil.

- Roll Changing

- The process of changing the rolls on roll forming equipment. This is a long, costly procedure.

- Slit Edges

- In reference to the edge of sheet or strip metal that results from cutting to width by rotary slitters.

- Springback

- Deformation in a roll formed part that occurs when the roll forming process fails to stretch a part past its elastic limit.

- Sweep

- Deviation from a straight line in the horizontal plane measured after the part has been formed. Sweep is caused because of incorrect horizontal roll alignment and/or uneven forming pressure.

- Tolerance

- The acceptable variation from product specifications, such as cross-sectional dimensions.

- Trimming

- Removing metal scrap from a metal formed part in order to maintain consistency among metal parts.

- Twist

- Deformation in a roll formed part that resembles a corkscrew. Twists are caused by extreme pressure levels created during the roll forming process.

- Yield Strength

- The maximum stress which can be applied to a material without lasting deformation of that material.