Pressure Transducers

Pressure transducers are devices that convert any physical force being exerted on them into electrical energy. In the simplest and most general definition, a transducer is any device that converts energy from one form to another. Pressure transducers take energy gained from pressure and convert that energy into electricity.

Transducers are key components in pressure sensors (also called pressure transmitters), and though the terms sensor, transducer and transmitter are frequently used interchangeably, a pressure transducer is technically just one part of a pressure sensor. Nevertheless, mostly because pressure transducers are applied almost exclusively as pressure sensors, we will be describing a variety of pressure sensors throughout the course of this article as well.

Quick links to Pressure Transducers Information

The History of Pressure Transducers

- Pressure Transducers in the 1800s

- Transducers, sensors and transmitters have been necessary since the Steam Age. Pressure transducers in particular trace their history back to the 1800s, after others had discovered pressure, but before electricity had really taken off. First, scientists began discovering those materials that can transduce magnetic and electric fields. For example, in 1842, James P. Joule learned that a magnetic field will cause an iron bar to constrict.

- Also importantly, scientists of this century learned a lot about the workings of mechanical strain, resistance and the like. In 1843, Sir Charles Wheatstone performed experiments with a circuit now called the Wheatstone Bridge. (Though named after Wheatstone, he did not invent the Wheatstone bridge. Instead, it was invented 10 years earlier by a scientist named Samuel Hunter Christie. Wheatstone improved and popularized the circuit.) As a result of the experiments, Wheatstone learned that changes in the length and/or tension of his circuit changed its balance. Not long after, people began using the Wheatstone Bridge as a sort of pressure sensor, and today its primary use is to measure unknown electrical resistances.

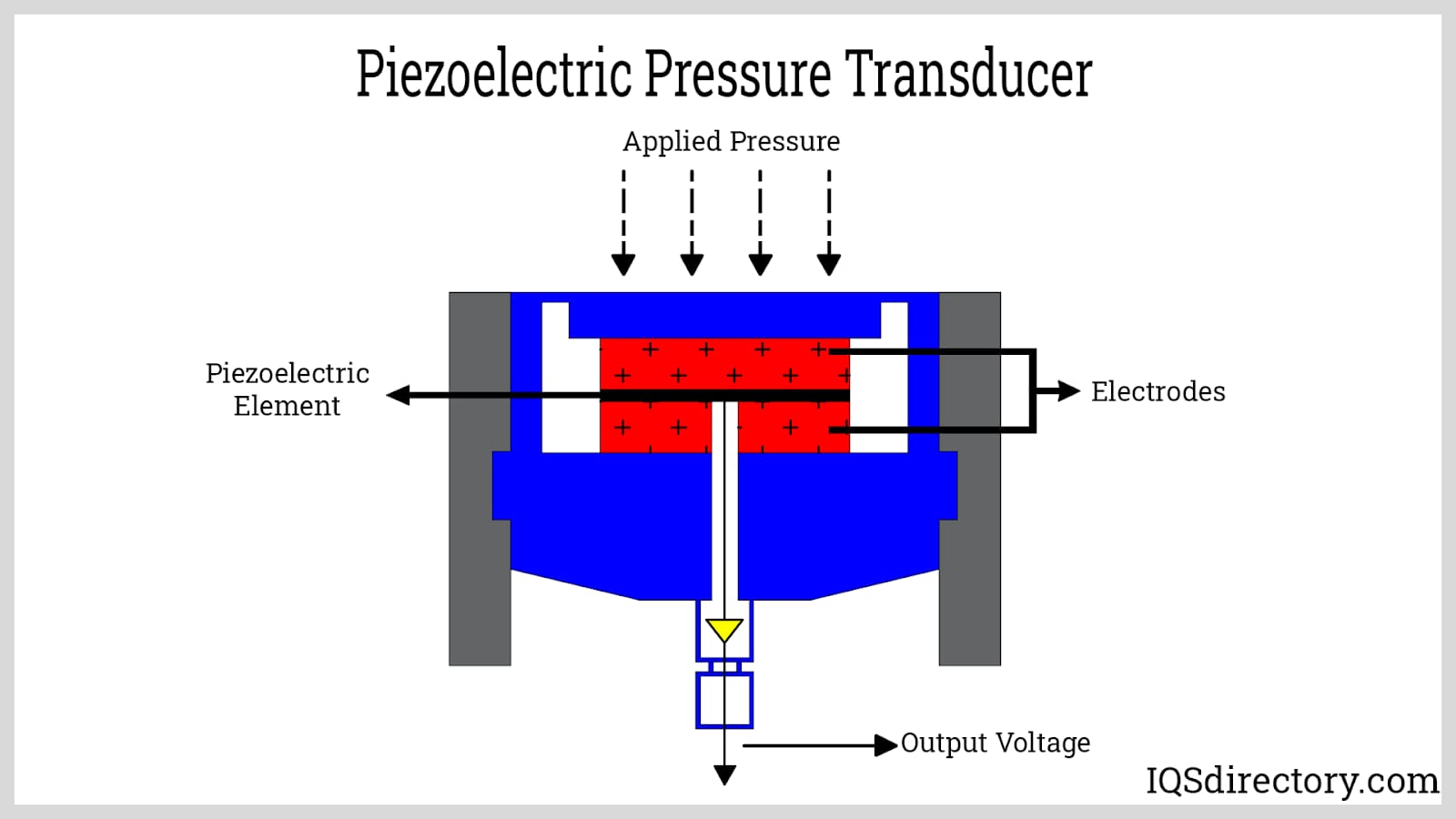

- Next, in 1856, Lord Kelvin similarly discovered that resistance will change as a result of strain. He lectured about his findings to the Royal Society of London, unaware of the already published findings of Wheatstone. Nevertheless, the work of Lord Kelvin lead to the invention of an instrument that uses pressure transducers, the strain gauge. In 1880, brothers Jacques and Pierre Curie discovered the piezoelectric effect, a way to create electricity. Basically, if you apply an external mechanical pressure to quartz crystals, an electric charge will follow. With this knowledge, the brothers were able to electrically polarize crystals at will. In 1881, they discovered that they, if one exposes a crystal to an electric field, it will mechanically strain and deform.

- Pressure Transducers in the 1900s

- During World War II, manufacturers relied on transduction via nickel materials in order to. In 1946, shortly after the war ended, researchers discovered another pressure transducer material, a ceramic material called barium titanate. In the 1950s, they followed up that discovery with the discovery of lead zirconate titanate, another transducing material. This one was better than nickel, especially when it came to sonar applications.

- Since the 1950s, pressure transducers have made substantial improvements. Today, advancements in materials and technology have allowed sensors and transducers to become smaller and more accurate. For example, a typical pressure sensor is about a cubic inch in size but miniature sensors can be less than 1/100th that size. Most are accurate with less than one percent margin of error. Modern materials include: ceramic, copper, stainless steel and various other metals.

Design of Pressure Transducers

When designing a pressure transducer, pressure transducers manufacturers think about factors like: the nature of the substance/system with which it will work (solid, liquid, slurry, corrosive, abrasive, etc.), the kind of pressure it will measure, the space available and the environment in which it will work (amount of vibration, heat, etc.) and how you want to measure and describe pressure.

Based on these factors, manufacturers can choose transducer details such as: the transducer pressure range (psi), as well as the operating temperature range. Depending on the variables of your application, pressure transducers suppliers may combine one device with another device or mechanism that maximizes the information it provides.

Pressure Transducer Features

Different transducers have different features and components. For example, to make sure you are aware of any danger, manufacturers often install features like alarms. They can also further safeguard your application with automatic shut-off switches, if appropriate. All pressure transducers, though, typically feature: a sensing element (in either direct or indirect contact with the process medium) and a transducing element that creates either an optical output signal or an electrical output signal. In addition, almost all pressure transducers today use an integrated circuit, also known as an IC microchip or silicon chip. The integrated circuit is a miniaturized electronic circuit. Many sensors and transducers use chips to maintain accuracy and to communicate with other equipment.

Modern sensors work based on the principle of piezoresistance, which is the observation that various amounts of pressure cause a material to conduct electricity at certain rates. The transducer receives the force from pressure and converts it to electrical energy. The charge is fed to a wire that reads it and can determine the pressure that was applied; a sensor then reads the information and displays it in a readable way. Usually, pressure transducers display information in psi (pounds per square inch) or bars (equal to Earth’s atmospheric pressure at sea level).

Pressure Transducer Images, Diagrams and Visual Concepts

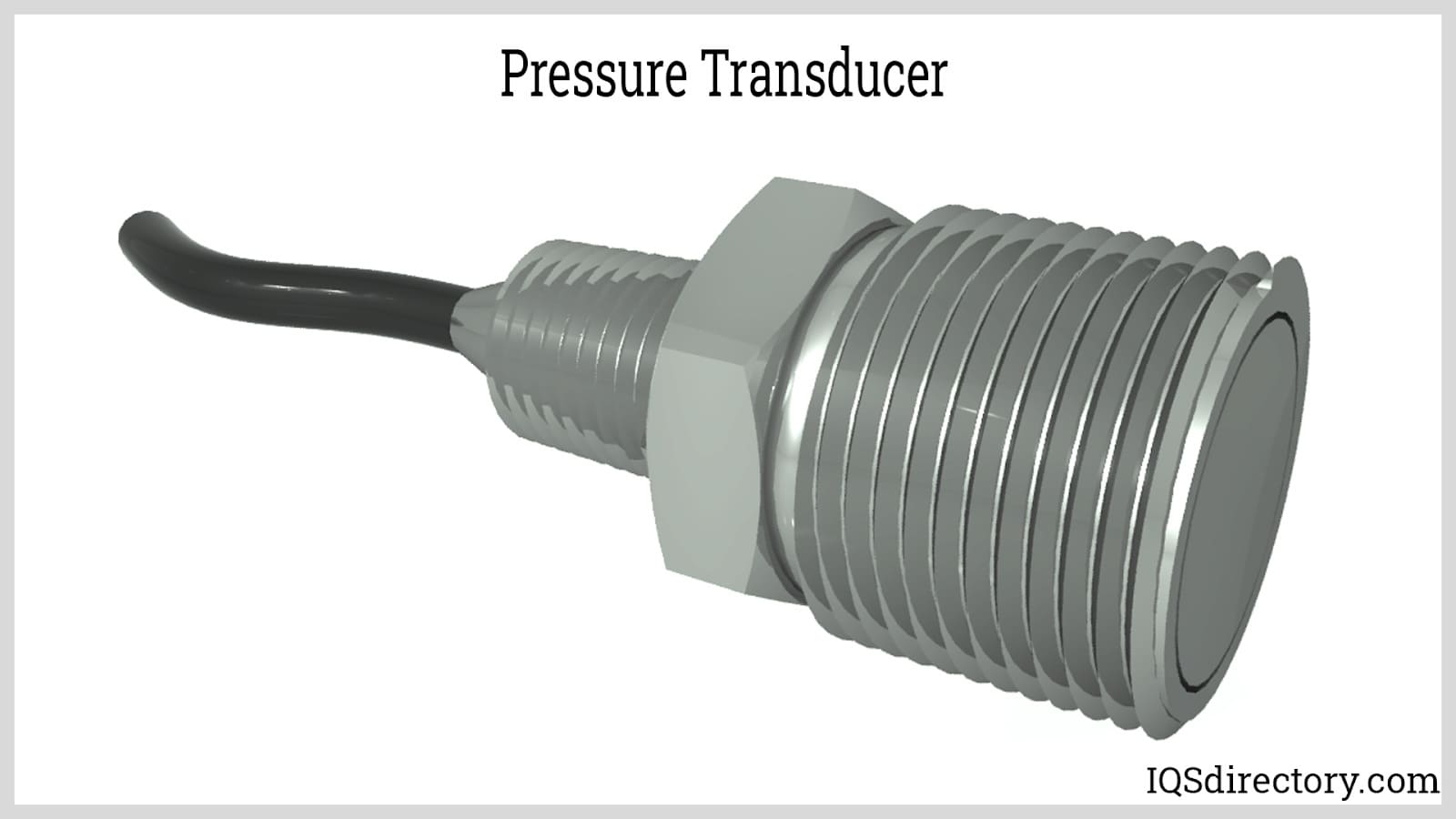

Pressure transducer, a mechanical device that converts applied pressure into a measurable electrical signal.

Pressure transducer, a mechanical device that converts applied pressure into a measurable electrical signal.

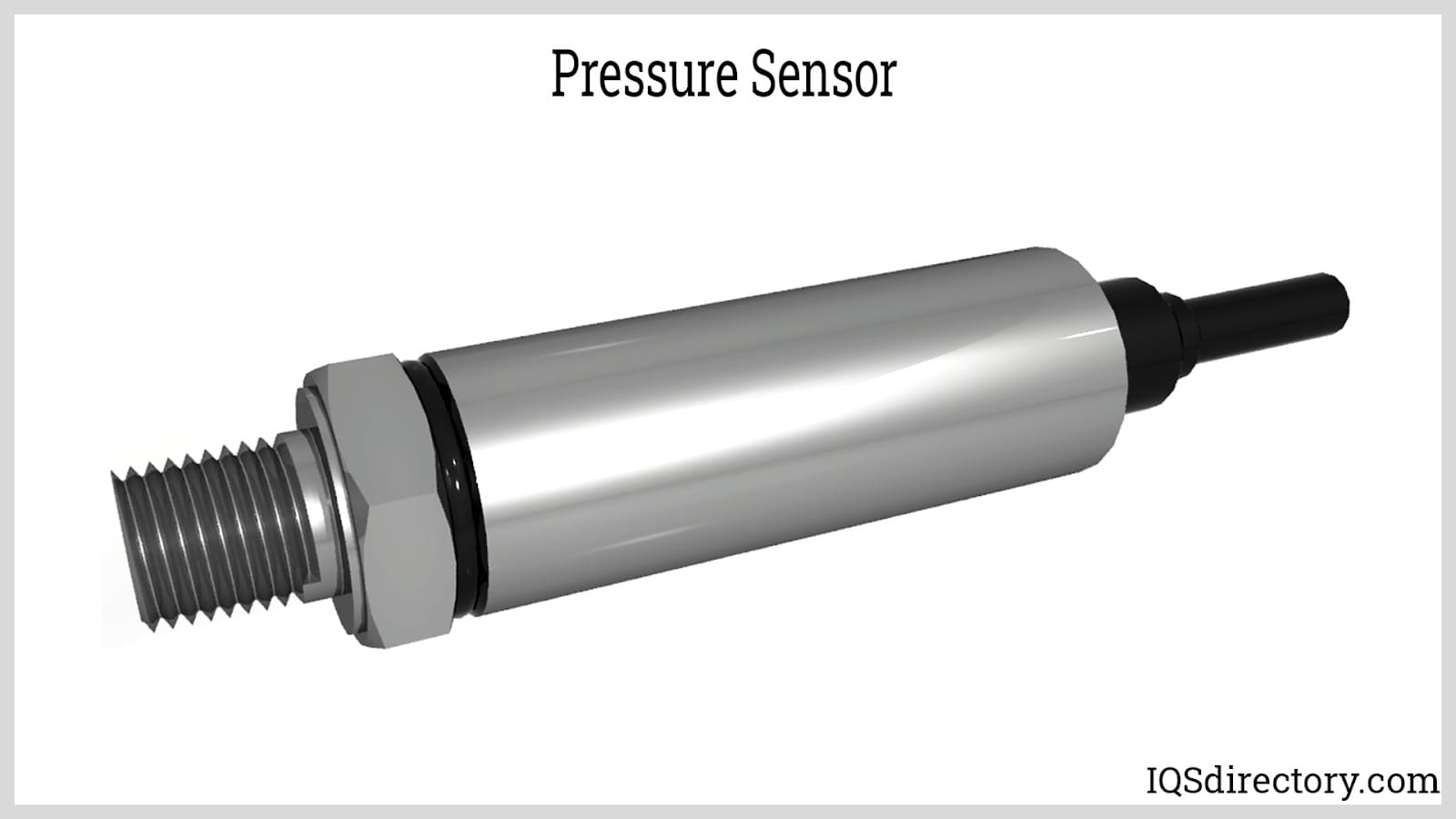

Pressure sensor is an element that directly receives the pressure exerted by fluids.

Pressure sensor is an element that directly receives the pressure exerted by fluids.

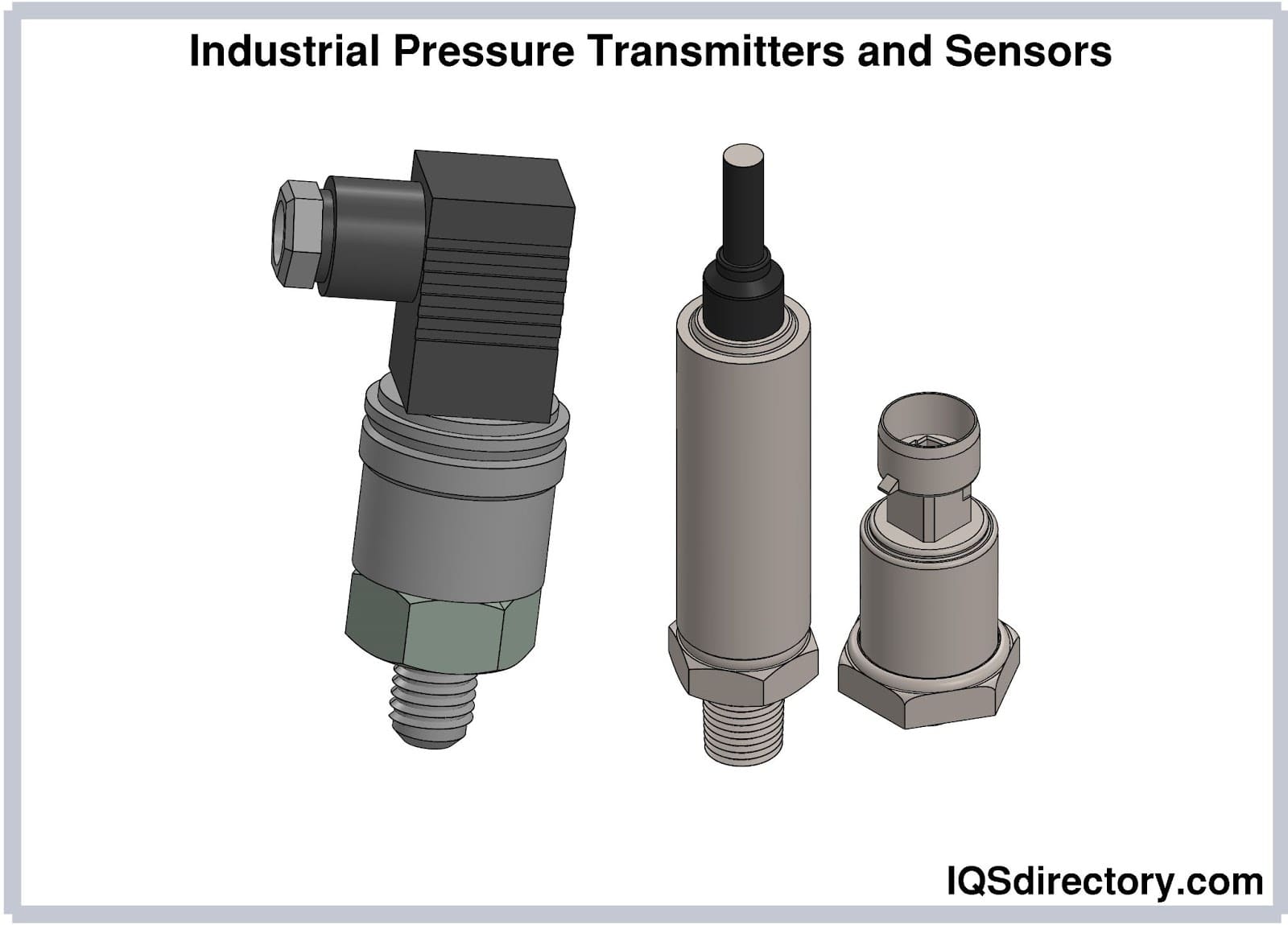

Pressure transmitters delivers a low-impedance current output that is typically designed to be connected to an industrial standard 4-20mA for sensing and control.

Pressure transmitters delivers a low-impedance current output that is typically designed to be connected to an industrial standard 4-20mA for sensing and control.

Piezoelectric pressure transducers do not use external voltage for their working principle.

Piezoelectric pressure transducers do not use external voltage for their working principle.

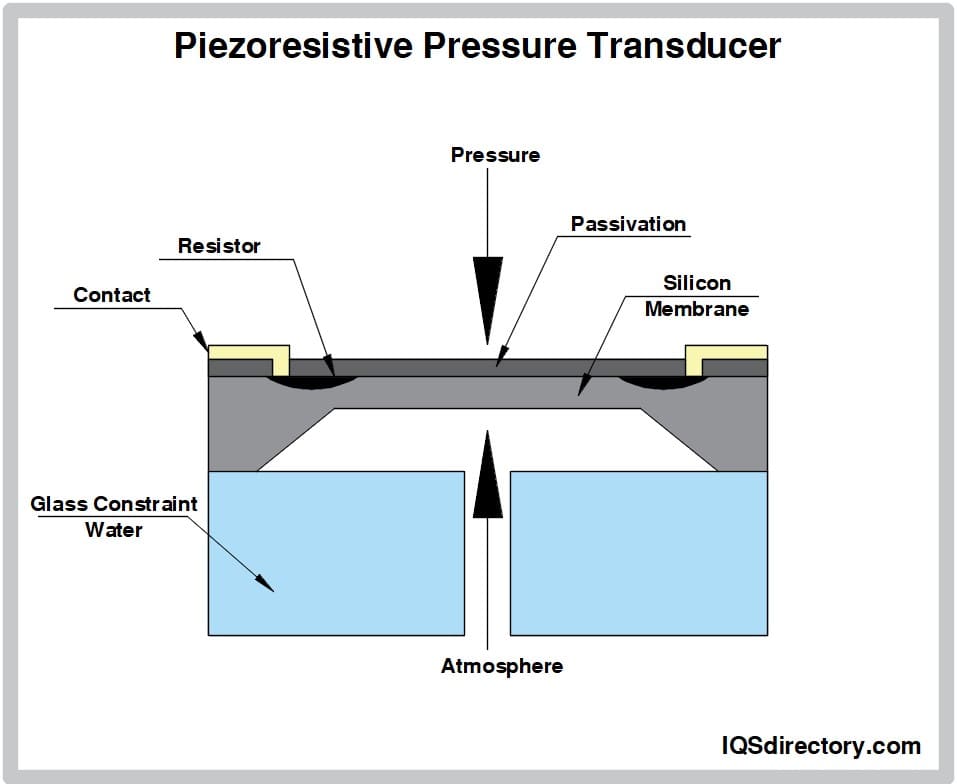

Piezoresistive pressure transducer, uses a resistance change of the semiconductor to measure the applied pressure.

Piezoresistive pressure transducer, uses a resistance change of the semiconductor to measure the applied pressure.

Pressure Transducer Types

There are many types of transducers, and there is a wide range of sensors and instruments that use pressure transducers.

Examples of those instruments that require the use of pressure transducers to measure and report pressure levels include: air pressure sensors, absolute pressure sensors, atmospheric pressure sensors, differential pressure sensors, miniature sensors, pressure calibrators, pressure regulators, pressure sensors, pressure transmitters, level transmitters, strain gauge based transducers, level transmitters, sealed pressure sensors, submersible liquid level transmitters and transducers, general-purpose transducers, industrial grade transducers, temperature transducers, torque transducers and vacuum pressure sensors.

- Air Pressure Sensors

- Among the most common pressure sensors. They measure the force of air exerted on the device and then convert the information into a readable display. These sensors are typically used with air compressors or pneumatic tools.

- There are three main air pressure sensor categories: absolute pressure sensors, atmospheric pressure sensors and differential pressure sensors. They distinguish themselves from each other based on how they measure air pressure relative to ambient pressure.

- Absolute Pressure Sensors

- Measure pressure regardless of ambient pressure conditions. In other words, absolute pressure sensors measure pressure in reference to an absolute vacuum as opposed to in reference to ambient air pressure. Absolute pressure is measured against a perfect vacuum, which is 0 pounds per square inch (PSI). Atmospheric pressure, for example, is ~14.7 PSI at sea level as measured by an absolute pressure sensor.

- Atmospheric Pressure Sensors

- Also known as barometric pressure sensors, measure the force exerted by the weight of air. They convert the information from electrical energy to a readable display. They are most often used in meteorology.

- Differential Pressure Transducers

- Calculate the difference between two or more pressures as measured by various inputs in the unit. They measure drops in pressure and the rate of flow within enclosed or pressurized vessels. In response to fluid pressure, they produce an electrical, mechanical, or pneumatic signal.

- Miniature Pressure Sensors

- Designed to unobtrusively measure the pressure of gases or liquids, and then display the results in an understandable way. Manufacturers mainly produce them for use in critical medical or biological applications where instruments should provide a very low intrusion volume (ex. medical pressure sensors, blood pressure sensors, etc.).

- Pressure Calibrators

- Devices that determine how accurately sensors are measuring pressure in order to keep them operating safely and efficiently. They receive input from an established system and compare that information with what the system's gauge reads. Allowing the operator to quickly determine whether the gauge pressure is reading correctly or not is an important step in maintaining safe conditions.

- Pressure Regulators

- Monitor and control the pressure of gas and liquid passing through a system by opening and closing valves in order to match the flow of the fluid to the demand for it. Typically, they can be programmed to alert operators if the pressure exceeds a certain point in order to maintain safe conditions.

- Pressure Sensors

- Used to measure the psi of gases or fluids. They are designed to monitor changes in pressure and are often connected to safety devices that activate shut-off switches. Pressure sensors use their pressure readings to send a message to another mechanism.

- Pressure Transmitters

- Used to measure, monitor, and transmit the pressure of liquids or gases.

- Strain Gauge Based Transducers

- Convert pressure into an electrical signal by physically deforming strain gauges, which are bonded into the diaphragm of the pressure transducer. This introduces strain to the gages, which then will produce an electrical resistance change proportional to the psi.

- Level Transmitters

- Devices that measure the level of a solid, liquid or slurry within a container then convert the information into a comprehensible form. Level transmitters usually provide feedback in the form of an alarm or shut-off switch.

- Sealed Pressure Sensors

- Designed to measure variable pressure against a fixed, constant pressure.

- Submersible Liquid Level Transmitters

- Specifically designed for municipal liquid level measurements and a range of other applications. Specifically, these transducers are used for water and wastewater treatments, well depth measurements and offshore water depth measurements and therefore use a watertight, high-strength vented polyurethane cable, which is capable of complete submersion.

- General-Purpose Transducers

- For the purposes of pressure measurement perform well for a wide range of electronic psi measurement applications. They have a high accuracy rate.

- Industrial Grade Transducers

- For the purposes of psi measurement fit most industrial pressure measurement applications. The printed circuit board is potted in silicone gel for protection against shock, vibration and humidity, and uses state of the art surface mount technology.

- Temperature Transducers

- Manufactured to measure heat content by changing an input of energy into a temperature reading. To measure temperature, these sensors can be placed directly into a substance, or they can make a reading based on thermal radiation. To help meet your needs, manufacturers produce these with wide temperature ranges.

- Torque Transducers

- Instruments that measure torque on rotating systems. Specifically, they measure the twist (rotational movement) in rotating systems, both static and dynamic. Like other transducers, they do so by converting input energy into measurable electrical energy.

- Vacuum Pressure Sensors

- Measure psi lower than atmospheric pressure. They also display the difference between the measured temperature and atmospheric temperature. Though similar, they are not the same thing as absolute pressure sensors.

Pressure Transducer Applications

Pressure transducers and pressure sensors are used in critical situations. Examples include: navigation, leak testing, altitude sensing, pressure monitoring and high pressure sensing. These scenarios are important to applications such as: chemical processing, automotive operation, aerospace and airplane operation, weather instrumentation and more.

Standards and Specifications for Pressure Transducers

Your standards depend on your application, industry and location. So, always talk it over with your industry leaders so you know what to look for when shopping around. However, in general, it is always a good idea to get pressure transducers that have been certified by ASTM International.

Choosing a Pressure Transducer Manufacturer

If you’re looking for high quality pressure transducer products, you need to work with a high quality manufacturer. To assist you in this endeavor, we’ve put together a comprehensive list of manufacturers we trust. Before checking out their offerings, we recommend you put together a list of your specifications. Make sure to include things like: psi required, size available, standard requirements, budget, required delivery date and post-delivery support preferences. Then, as you browse, frequently compare and contrast the services listed here with the services on your list. Pick out three or four you believe have the most potential for you, and discuss your application. Finally, decide which one is right for you.

Proper Care for Pressure Transducers

Pressure transducers are kept reliable through proper calibration and backup systems. Learn about the best systems and procedures for the care of your particular transducer by talking it over with your pressure transducer supplier.

Pressure Transducer Accessories

Most, if not all, pressure transducers require accessories. The answer to the question of what accessories are best for your transducer depends entirely on your application. Some examples of common pressure transducer accessories include: digital displays, connector cables, connector conduits, mounting adaptors, installation tool kits and junction termination boxes.

Pressure Transducers Terms

- Accuracy

- The combination of the error of nonlinearity, repeatability and hysteresis, expressed as a percentage of full scale output.

- Axial Load

- A load applied alongside or parallel to and concentric with the primary axis.

- Best Fit Straight Line

- The sensitivity of a sensor that is preferably in a straight line but also usually has minute non-linearity. BFSL takes all the data points from the curve and describes a straight line through these data points so that the divergence (and thus the error) between the curve and the straight line is at a minimum.

- Burst Pressure

- The maximum amount of pressure that may be applied to an object without the object rupturing.

- Calibration

- A test in which known values of pressure are applied to the instrument and output readings are recorded under specific conditions.

- Dead Volume

- The volume of the pressure port of a transducer at room temperature and barometric pressure.

- Differential Pressure

- The difference between the actual measured pressure and a fixed reference point.

- Error

- The difference between the true value of the pressure that is sensed and the value indicated by the transducer.

- Excitation

- The voltage or current applied to the input terminals of the transducer to supply its proper operating conditions.

- Gauge Pressure

- Pressure measured relative to ambient pressure.

- Hysterisis

- The maximum difference in output within the range when the value is approached with increasing pressure and then with decreasing pressure for full range traverses.

- Linearity

- The maximum deviation of the calibration curve (average of upscale and downscale readings) from a straight line positioned to pass through the upper and lower range values.

- Noise

- Undesirable signals that can increase the amount of error. Examples of noise include radio frequency interference, electromagnetic interference, hum from power lines and broadband or white noise.

- Output

- The electrical signal that results from applied pressure to the transducer.

- Peak Pressure

- The greatest pressure desired that is sensed during a measurement session.

- Pressure Rate

- An orderly change in pressure over a specific time.

- Repeatability

- The closeness of agreement among a number of consecutive measurements of the output for the same value of the input under the same operating conditions, approaching from the same direction, for full range traverses.

- Sensing Element

- The part of the transducer that reacts directly as a response to pressure.

- Variable Pressure

- A change in the pressure that is being measured or controlled.

- Zero Balance

- The rated output signal of a transducer without a load applied and rated excitation, typically articulated as a percent of rated output.