Plastic Fabrication

Plastic fabrication is the process by which manufacturers develop plastic products. Plastic fabrication processes include thermoforming methods like extrusion and molding, as well as mechanical forming processes like plastic machining and stamping. It even includes joining processes like welding. Note: the terms “plastic fabrication," “plastic machining" and “plastic manufacturing" can be used interchangeably.

Quick links to Plastic Fabrication Information

The History of Plastic Fabrication

Early Plastic Fabrication

Plastic fabrication can be traced back thousands of years, to the use of organic polymer proteins, derived from sources such as blood and egg. Some of the best examples we have of early polymer fabrication comes from the ancient peoples of South and Central America. By at least 1600 BC, the peoples of present-day Costa Rica and Mexico were fabricating balls, figurines and bands from natural rubber, which is a related polymer. During the Middle Ages, people had shifted to deriving polymers from milk proteins called casein. Casein was a key ingredient of the first plastics.

Plastic Fabrication in the 1800s

In the early 1800s, a couple manufacturers created rubber fabrication machinery that others later adapted for plastic fabrication. For example, in 1820 Thomas Hancock invented the rubber masticator, a system with which one could produce new rubber materials from used scraps. Sixteen years later, Edwin Chaffee invented a two-roll machine with which one could mix rubber. Plastic fabrication was rather insignificant and limited until after the invention of synthetic plastics. One of the first people to take this on was Charles Goodyear, the man credited with the discovery of vulcanization. In other words, he discovered that you can heat natural rubber with sulfur (or a similar additive) and turn it into plastic material. He received a U.S. patent for vulcanization in 1844.

In 1856, British citizen Alexander Parkes invented Parkesine, or nitrocellulose. He debuted it at London’s 1862 Great International Exhibition. Many historians consider this to be the first synthetic plastic. Parkes made it by treating cellulose with nitric acid, then dissolving it in alcohol, after which it transformed into a plastic. This plastic was transparent, hard and elastic. Manufacturers could form it by heating it up and molding it. They could also color it. Twelve years later, John Wesley Hyatt developed another plastic derived from cellulose, which he called celluloid. He created it by dissolving the cellulose in alcoholized camphor. His goal was to create a plastic with which manufacturers could fabricate pool balls. This was important because, up until that point, the balls were fabricated with ivory, obtained by slaughtering elephants. Manufacturers also began using this material to fabricate combs.

Plastic Fabrication in the 1900s

By the early 1900s, industrial plastic had advanced enough that manufacturers began using it to fabricate electrical insulation and wrapping for food products. After the 1908 invention of cellophane, for example, Whitman’s Candy Company began wrapping their chocolates in it.

Manufacturers kicked industrial plastic fabrication services up another notch during the First and Second World Wars, when they turned to the process for the production of food containers, acrylic bomber noses, fighter plane canopies, vehicle parts and more. One of the ways they created such products was through thermoplastic extrusion, a process that had been perfected in 1935 by a woman named Ashley Gershoff. Shortly afterwards, a man named Roberto Colombo invented twin screw extruders. Ironically, considering they were used by the Allied powers, these inventions came out of Germany and Italy, respectively.

During the mid-1900s, chemists came up with a slew of new industrial plastic materials for fabrication, which expanded their capabilities that much more. Examples of such materials include: polyvinyl chloride (PVC), polyethylene, polyethylene terephthalate (PET), polystyrene (PS) and, in 1954, expanded polystyrene (ESP). The invention of expanded ESP ushered in an era of plastic product fabrication that included building insulation, packaging and disposable cups. In 1957, manufacturers began using polypropylene, with which they could fabricate even more plastic packaging and parts.

Today, plastic fabrication services are as important and prominent in our world as ever. Manufacturers now use CNC machining technology during production so that, whatever process they’re using or product they’re making, their efforts yield consistent, accurate results. CNC machining also lets them fabricate products much more quickly and at higher volumes. Despite its popularity, plastic is a resource that, when disposed of, can really take a toll on the environment. Thus, one of the main focuses of the plastic fabrication industry today is sustainability. They are working hard to create marketable bioplastics that degrade properly and do not hurt the planet so much. However, until bioplastics are mass-produced, all users of plastic must make sure to recycle.

Benefits of Plastic Fabrication

There are many benefits to using plastic products and parts. First, plastic products are relatively easy and inexpensive to produce. Plastic fabrication services are affordable especially when compared to metal fabrication. Second, plastic materials are: durable, temperature resistant, shatter resistant, long lasting and resilient. They survive exposure to many different environmental conditions and substances, including: high and low temperatures, moisture, abrasive chemicals, pressure and high impact. Plastic products also provide vibration dampening, which is especially useful in the automotive industry, as well as the fact that plastic is durable and shatter resistant.

Plastic Fabrication Process

Plastic fabrication, as a whole, involves: product forming, product finishing, product packaging and product shipping.

In general, the forming part of the plastic fabrication process involves subjecting raw plastic resins (in the form of powder, flakes or small granules) to heat and pressure, in order to shape them into usable products. Some examples of common plastic forming processes are extrusion, injection molding, blow molding and vacuum forming.

After such a forming process, manufacturers will often send the product for additional fabrication processes. Examples of possible secondary forming processes include: punching, stamping, engraving, etching, bending, cutting, drilling, tapping and assembly (assembly inc. cutting, gluing, plastic welding, etc.). Different plastic parts require different kinds of attention, and plastic fabricators offer a wide range of processes to make whatever kinds of changes to a plastic part that may be necessary. After that, manufacturers package the product(s) and ship them off to the customer.

Plastic Fabrication Design

When designing plastic products and picking out custom plastic fabrication methods, manufacturers consider: size parameters, working temperature ranges, tensile strength, temper (hardness or softness) and color requirements.

Manufacturers may make specialized custom plastic parts, or they may produce them for you using standard sizes and pre-engineered plastic designs. Many manufacturers offer a diversity of quality molds and product dimensions from which their customers can choose. Learn more about a manufacturer’s custom production capabilities by checking out their website and/or requesting a quote.

Plastic Fabrication Materials

Nylon, polyester, polystyrene, engineering plastics, polyvinyl chloride, polyethylene and acrylic plastics are just a few examples of the many plastic materials used by industry.

Nylon Material

Nylon is a thermoplastic known for its silkiness. It is often used for stockings, so much so that they are often called “nylons." It is useful for far more than that, though. Its usefulness derives from its characteristics, which include: sunlight resistance, superior weathering, colorfastness, high melting point, abrasion resistance, mold resistance, mildew resistance, insect resistance, rot resistance, moldability, high durability and high elongation.

Polyester plastics

Polyester plastics are polymers used mostly in clothing fabrication. Industrial polyesters are also used in the fabrication of plastic reinforcements, safety belts, conveyor belts, insulation, cushioning, coated fabrics, plastic bottles, filters, films, canoes and more. Polyester fabricated parts are known for their: heat resistance, stain resistance and durability. Polyester can also serve consumers as sanded, polished high-gloss finish.

Polystyrene

Polystyrene is an inexpensive polymer product, available in both foam and solid form. It is easy to extrude, and cools as a rigid material. Polystyrene has a low melting point and does not protect well against moisture or oxygen. It is also problematic due to its negative environmental impact. Nevertheless, it is popular for the plastic fabrication of packaging, especially clamshell containers, lids and bottles. It is also used to make throwaway cutlery, packing peanuts and models.

Engineering Plastics

Engineering plastics are plastic materials that are characterized by their high strength and durability, as compared to other plastics. As their name implies, they are used in engineering applications. A few good examples of engineering plastics include: polyetheretherketone (polyetheretherketone), or PEEK, and polycarbonate, or PC.

Polyvinyl Chloride

Polyvinyl chloride, also known as vinyl or PVC, is a popular plastic available in both flexible and rigid form. It is the third-most widely produced plastic in the world. PVC offers: high hardness, high elasticity, good (but not great) insulative properties, good flame retardancy and high chemical resistance (except for most solvents). PVC is popular for countless fabrications applications, especially: construction, pipe fabrication, sign fabrication, electrical insulation, furniture, flooring, clothing and wire rope fabrication.

Polyethylene

Polyethylene is the most commonly used plastic in the world. It has high ductility, high impact strength, low friction, superior chemical resistance and good insulation properties. Its main drawbacks are: low rigidity, low strength and low hardness. Mostly, polyethylene is used for packaging fabrication.

Acrylic Plastics

Acrylic plastics are thermoplastics and thermosetting plastics created from substances such as methacrylic acid or acrylic acid. They are available in paints, acrylic sheets, films and resin adhesives. In general, this group of plastics are: transparent, UV light resistant, weather resistant, stable, chemical resistant, colorfast and durable. Most often, manufacturers turn to acrylic fabrication when they want to make glass-like products, such as: headlights, taillights, window panes, signboards, LCD displays, cell phone screens, bathtub liners and aquariums.

Plastic Fabrication Images, Diagrams and Visual Concepts

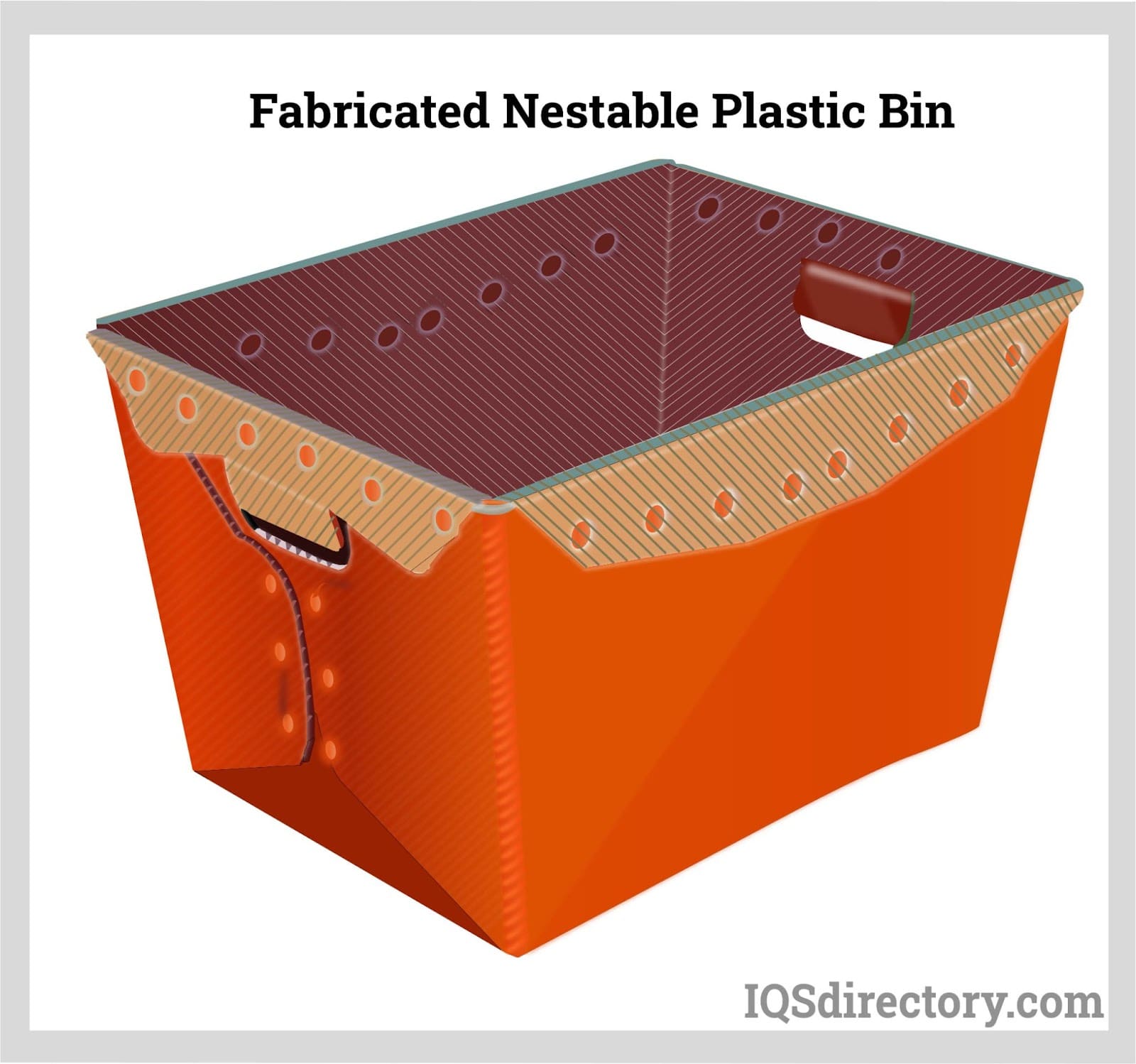

Plastic fabrication, the process of designing, manufacturing, and assembling a product out of plastic material or composites which contains plastic.

Plastic fabrication, the process of designing, manufacturing, and assembling a product out of plastic material or composites which contains plastic.

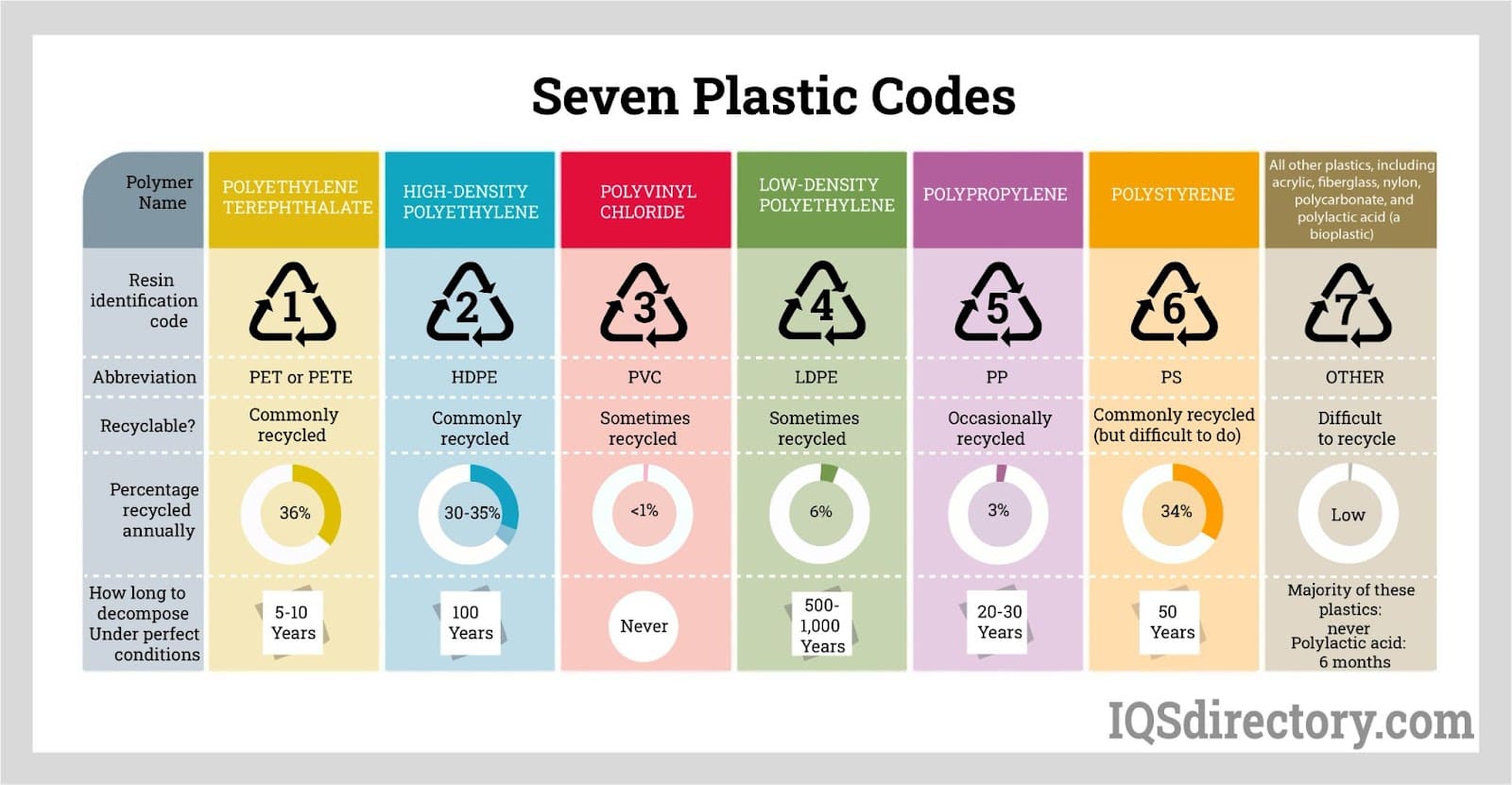

Thermosets and thermoplastics are divided into seven categories based on their molecular structures.

Thermosets and thermoplastics are divided into seven categories based on their molecular structures.

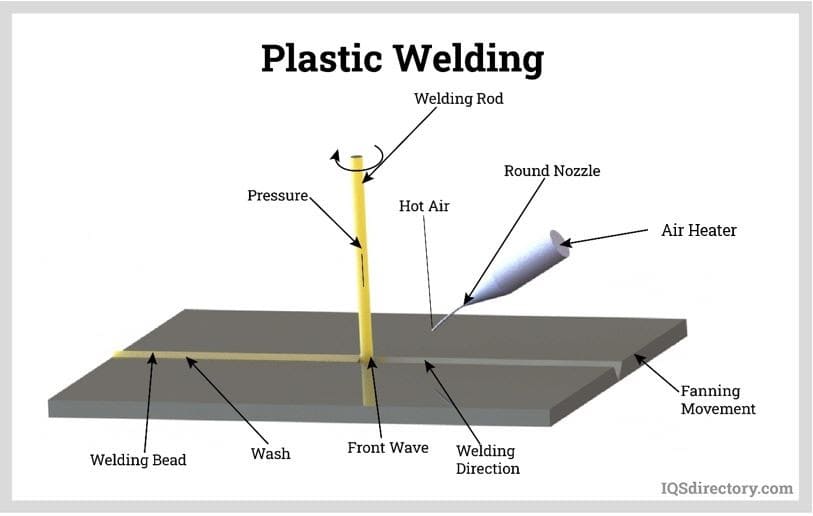

Plastic welding involves the melting of two or more workpieces to combine and a molecular bond them.

Plastic welding involves the melting of two or more workpieces to combine and a molecular bond them.

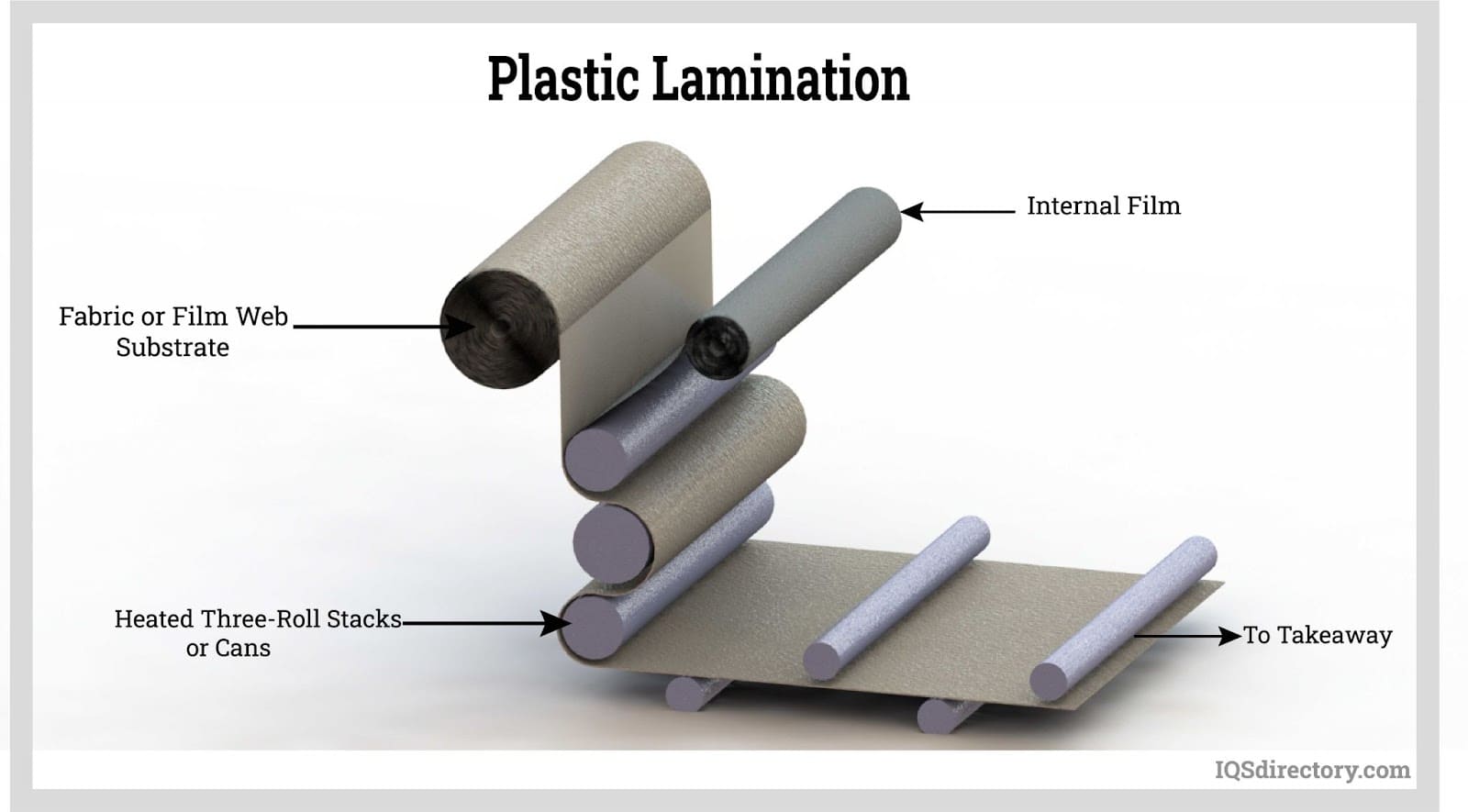

Plastic lamination, various layers of plastic are held together creating a barrier along the surface of another material.

Plastic lamination, various layers of plastic are held together creating a barrier along the surface of another material.

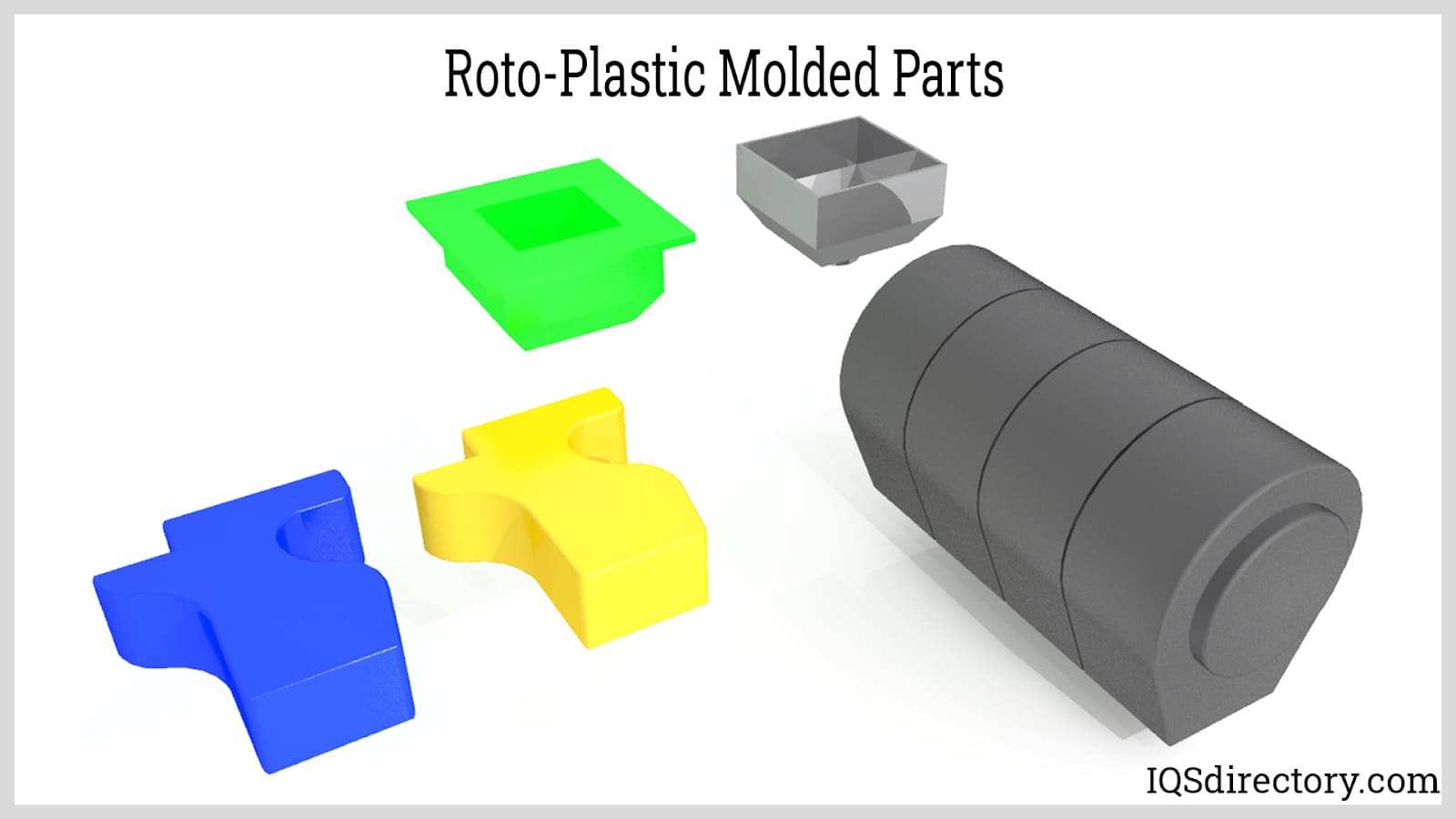

Plastic molding, the plastic is melted and poured into a mold to harden.

Plastic molding, the plastic is melted and poured into a mold to harden.

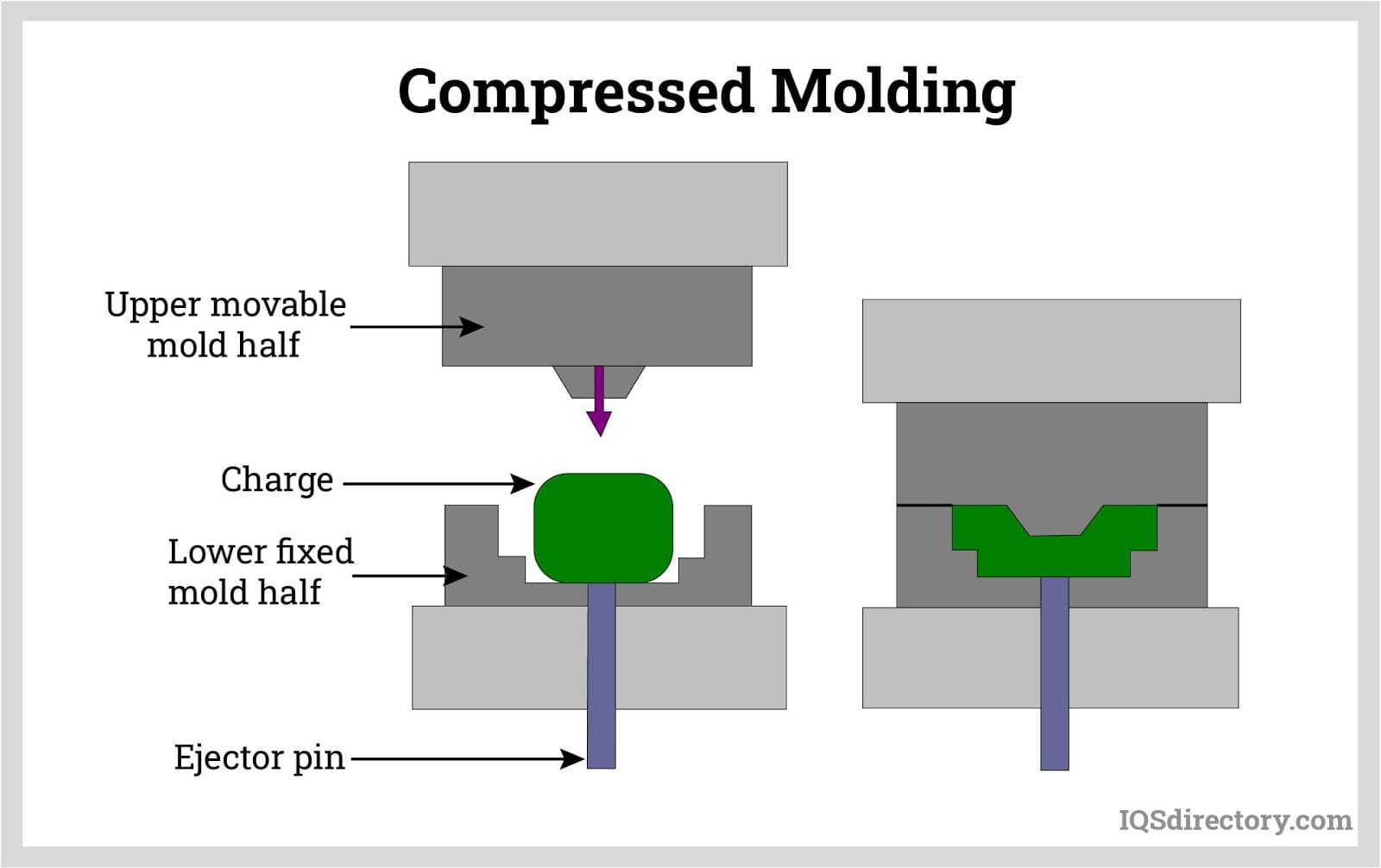

Compression molding, the plastic is heated, then compressed to obtain the desired shape, and cured to maintain its integrity and does not deform.

Compression molding, the plastic is heated, then compressed to obtain the desired shape, and cured to maintain its integrity and does not deform.

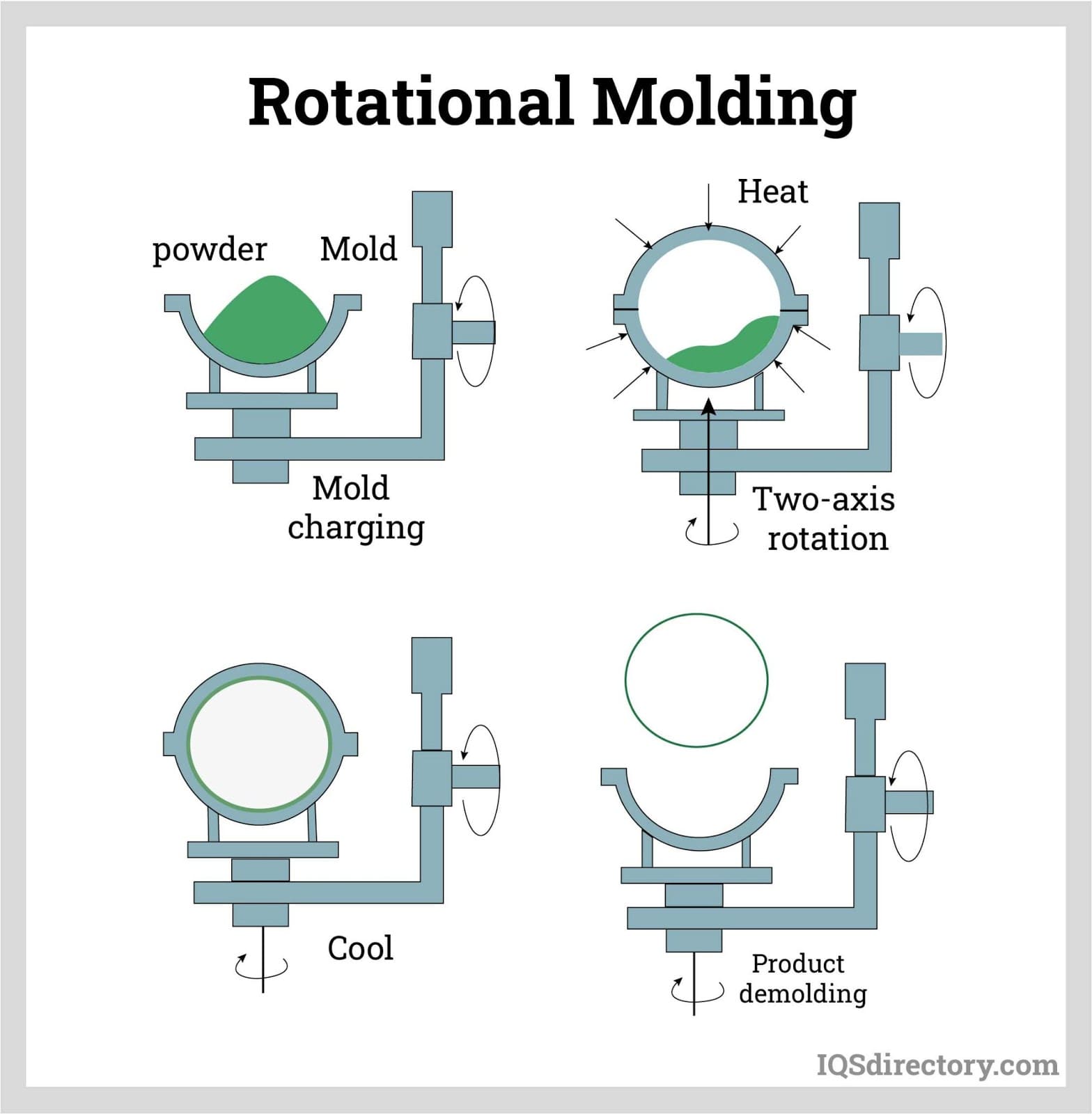

Rotational molding, uses rotational movements to coat the inside the mold with heated plastic to form the desired part.

Rotational molding, uses rotational movements to coat the inside the mold with heated plastic to form the desired part.

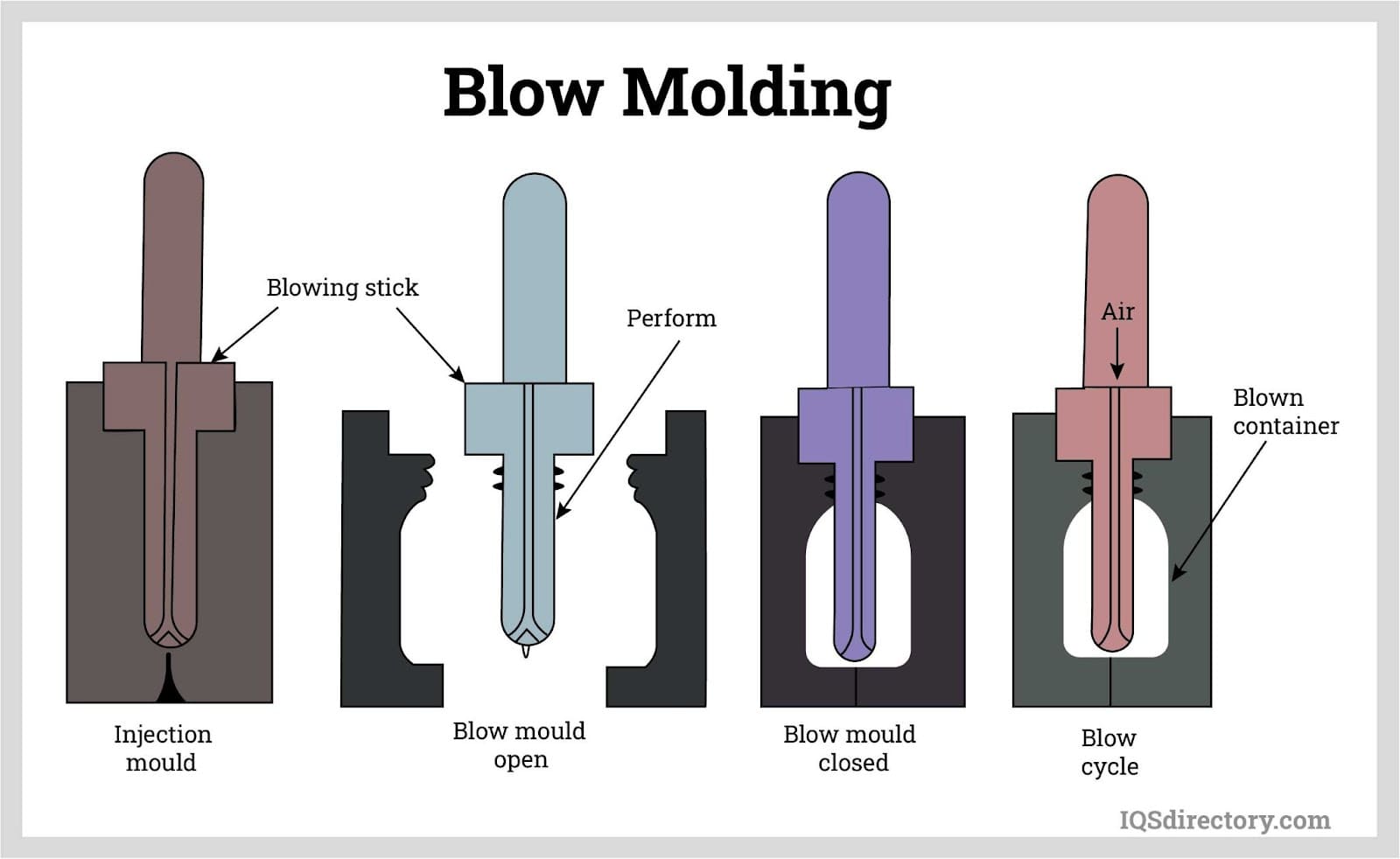

Blow molding is where air is blownto inflate the tube into the desired shape of the plastic.

Blow molding is where air is blownto inflate the tube into the desired shape of the plastic.

Machinery Used in Plastic Fabrication

Plastic fabrication processes can be performed manually by technicians or automatically by computer controlled machining equipment. Most plastic fabrication processes are operated by computer numerically controlled (CNC) software, which uses a computer to carry out the custom fabrication process. Automated machining equipment all but eliminate human error, are very fast and efficient and can produce high volumes of complex, identical products.

Plastic assembly is the plastic fabrication process that involves bonding or connecting one or more pieces. This process may involve cutting the pieces to the precise shape and size before assembling them; the assembly itself could consist of welding or bonding adhesives.

Plastic CNC machining is the machining of plastic parts through a computerized, numerical control machine. It is common to machine parts through a CNC machine, as it assures precision and accuracy.

Plastic Fabrication Applications

Because plastic fabricators are the source of all plastic products, every consumer of plastic components relies on them for the creation of the quality products they need. Everything, from stock products like plastic washers to custom products for specialized electronics, must be created by a fabricator. Also, plastic is often used outdoors because it can often withstand both high and low temperatures, and unlike many metals, will not oxidize when exposed to water.

Some specific examples of industries that use plastic fabrications include: chemical processing, construction, cosmetics, electronics, sign making, pharmaceutical, medical, consumer goods, toy manufacturing, packaging, shipping, automotive, agriculture, architectural, food and beverage processing, restaurant, engineering and lighting industries.

Plastic Fabrication Products Produced

Machined plastics, engineering plastics, custom plastics and all other plastic products are created by plastic manufacturing operations.

Plastic components like industrial machine parts and hardware are often used within manufacturing and industrial applications. Examples of these and a wide variety of other products that plastic manufacturing can produce include: washers, adapters, bearings, bushings, guide rings, insulators, shims, spacers, o-rings, wear rings, hardware such as screws, nuts and bolts, plastic tanks and containers, display racks, toys, enclosures, carts, carrying cases, powder coatings, fiberglass sheet and signs.

In addition to providing plastic fabrication services and formed plastic products, the plastics industry provides a variety of commercial and consumer plastic shaping products, such as plastic cutters (metal blades used to cut plastic).

Things to Consider When Choosing Plastic Fabrication

Successful plastic fabricators are sensitive to the varied needs of industry. For example, in the medical and food industries, plastics must be contaminant resistant and non-toxic. They must be watertight and fabricated to withstand exposure to many different substances, including abrasive chemicals, fats and oils, as well as bodily fluids. To find a quality plastic manufacturer who is sensitive to your needs, check out those we have listed on this page. They all have something different to offer, and we believe the right plastic fabrication company for you is among them. Before discussing your needs with a potential supplier, we recommend you write out a list of your specifications (including your budget), so that you’ll be able to have fruitful conversations when you’re seeking a quote.

Plastic Fabrication Terms

- Acrylic

- A manufactured plastic material that provides transparency, color-fastness and weather resistance. You can find this material type on IQS Directory.

- Additive

- Substances that modify the characteristics of polymer resins. The different types of additives include viscosity modifiers, pigments, fillers and reagents.

- Binder

- A substance, such as a resin, that binds materials together. Binders provide mechanical strength solidification and adhesion to surface coatings or guarantee consistency.

- Bond Strength

- The quantity of adhesion that connects bonded surfaces.

- Brightener

- An additive that enhances plastic coatings to make them brighter or smoother used in the plastic fabrication process.

- Catalyst

- A material that alters the pace of a chemical reaction so that it does not undergo any permanent changes in its own structure. This term also refers to a substance that significantly increases the curing of a compound when introduced in small amounts, contrasted with the quantity of primary reactants.

- Colorants and Pigments

- Additives that alter the color of plastic. Colorants and pigments include resin color premix or a powder.

- Color Stability

- The capability of a surface coating to resist deterioration normally caused by environmental conditions.

- Compounding

- The necessary procedure for blending the polymer with all the required substances to make a final plastic fabricated product.

- Composite

- A plastic structural substance that is a blending of materials, usually a thermoplastic resin or thermoset and a reinforcing element. Composite also refers to a strengthening fiber within a polymer resin; in either case, the collective result is greater than the isolated elements.

- Compressive Strength

- The capacity of any material to withstand any crushing forces.

- Continuous Service Temperature

- The maximum temperature in which a material is able to function reliably for multiple applications and extensive periods of time. Manufacturers do not consistently define the long term period.

- Coupling Agent

- A material that functions as an interface to create a chemical bridge between the resin and mineral fiber or fiberglass. Coupling agents enhance bonding.

- Cure

- The process of altering properties of polymers into a state of greater stability and usability. Curing is achieved through radiation, heat or reaction with chemical additives.

- Delamination

- The process of disconnecting the layers of a composite.

- Flexural Strength and Yield

- The calculation of a plastic material's ability to resist fracturing in the event of bending.

- Flow Line

- Also called a "weld line," it is a score on molded plastic that occurs from the contact of two flow fronts in the molding process.

- Forming

- The procedure in which an existing shape of a plastic is changed to another preferred one.

- Hardener

- A substance or substance blend that, when added to a material, enhances or controls the curing reaction by participating in it.

- Heat Stabilizers

- Additives that enhance the capability of a material to resist any negative effects of exposure to heat. Heat stabilizers are utilized to enhance the overall service temperature of the material.

- Impact Modifiers

- Additives utilized to increase capability of a material to resist the force of an impact.

- Laminate

- The process of putting a sequence of layers of polymer and reinforcement into a mold. The resulting product is called a laminant.

- Layer

- A single layer of laminate or lay up.

- Lay Up

- A process in which layers of polymer resin and other reinforcements are applied to a mold to produce a part.

- Light, UV Stabilizers and Absorbers

- Additives that enhance the capability of a material to resist the harmful effects of UV and light exposure, consequently enhancing the life of the material.

- Molded Part

- Plastic parts produced by primary processing. Molded parts often do not need a finishing operation.

- Polymer

- A chain molecule that is typically found in plastics and made up of long molecular chains created from monomers, which occur as repetitive building blocks.

- Reinforced Plastic

- Material of plastic with increased mechanical properties, resulting from the embedding of high-strength fillers in the composition.

- Sandwich Construction

- A composite of two laminate layers with a structural core material between them. Sandwich construction produces stiff, lightweight structures.

- Sheet

- Continuous phase plastic that is formed in such a way that the thickness is extremely low in proportion to the length and width. Specifically, a sheet is more than 0.25 mm.

- Stress Crack

- An internal or external crack that results from tensile stresses lower than the short-time mechanical strength.

- Tackifiers

- Additives that increase the bonding capability or adhesiveness of a material.

- Tensile Yield Strength

- The highest stress a material can resist when exposed to a stretching load before yielding.

- Tensile Break Strength

- The highest stress a material can resist when exposed to a stretching load before breaking.

- Thermoplastic

- A category of plastics that are able to be softened or hardened through heat and cold. These materials, which include PVC, nylon, polystyrene and polycarbonates, undergo a change that is primarily physical as opposed to chemical. You can find thermoplastic materials here.

- Warpage

- An inconsistent alteration in internal stresses, which causes deformation or distortion of the material.