Plastic Extrusions

Plastic extrusion is a continuous molding process that produces a wide variety of plastic shapes and products.

Note: The term polymer extrusion is sometimes used interchangeably with plastic extrusion. This is not incorrect, though it is not the most precise way to describe the process. Technically, a polymer is a large molecule made up of many similar monomers, which are small molecules. These are not the kinds of polymers to which the words "polymer extrusion" refer. Instead, when the words "polymer" and "extrusion" are paired together, they refer only to elastomers, rubber, and plastic.

Quick links to Plastic Extrusions Information

Applications of Plastic Extrusion

The purpose of plastic extrusion is to create products and shapes of all kinds. Customers turn to the plastic extrusion industry because the process is reliable, versatile, and fairly inexpensive.

Plastic extrusion is important to many industries, including automotive manufacturing, building and construction, HVAC, plumbing, chemical processing, appliance, food and beverage, electronics.

Plastic Extrusion Products

The plastic extrusion process is used to create plastic parts of all kinds. They range from engine components to electronic housings. Other examples of plastic extrusion products include plastic PVC channels, plastic strip, plastic profiles, PVC pipe, all-purpose plastic tubing, medical tubing, weather stripping, decorative trim, functional trim, fencing, deck railings, window frames, plastic films and sheeting, thermoplastic coatings, and wire insulation.

History of Plastic Extrusion

The earliest iterations of the plastic extruder were invented in the early 1800s. For instance, in 1820, Thomas Hancock invented a rubber "masticator," which was designed to reclaim processed rubber scraps. Not long after, in 1836, Edwin Chaffee developed a two-roller machine that allowed manufacturers to mix additives into rubber.

Plastic extrusion itself didn’t really take off until the mid-1900s, when the first thermoplastic extrusion took place. The extrusion was performed in Hamburg, Germany in 1935 by Ashley Gershoff and her husband, Paul Troester. Shortly after, in Italy, Roberto Colombo of LMP developed the first twin screw extruders.

Today, the plastic extrusion industry is alive and well, and showing signs of growth, as plastic products are trusted over counterparts like metal or wood. To meet the higher demands, many plastic extrusion manufacturers have been upgrading facilities to allow for faster and larger volumes of plastic profile extrusions, coupled with more accuracy during product cutting. Sophisticated products are equipped with more intricate parts so manufacturers must have the capabilities to adhere to exact specifications even down to the smallest measurements.

Materials Used in Plastic Extrusion

- Thermoplastics

- A thermoplastic is a plastic material that, when exposed to sufficient heat, becomes plasticized. A plasticized thermoplastic can be shaped into useful products and retain the shape once cooled. Thermoplastics are highly valued for this quality, and because they can be recycled at the end of their lifespans then reshaped by the same process.

- HDPE

- HDPE (high density polyethylene) is valued for its resistance to solvents, resistance to corrosion, high tensile strength, high strength-to-density ratio, durability, and safety.

- LDPE

- LDPE (low-density polyethylene), is tough and flexible, with excellent resistance to many acids, alcohols, bases, and esters. Manufacturers can extrude it as either translucent or opaque.

-

- PETG

- PETG (polyethylene terephthalate glycol-modified), known more commonly as polyester, can make rigid or semi-rigid plastic extruded parts. It is lightweight, impact-resistant, and strong. In addition, it can act as a good barrier to gas and alcohol (when treated) and a fair barrier to moisture.

- PVC (Vinyl)

- PVC (polyvinyl chloride), also called vinyl, is the world’s third-most produced synthetic polymer. PVC is hard and strong but has poor heat stability without the addition of a heat stabilizer. It also has good insulative properties and is resistant to acids, fats, alcohols, bases, and salts.PVC extrusion, using both rigid PVC and flexible PVC, is popular for products including pipes, PVC angle, small diameter tubing, floor coverings, and siding.

- Butyrate

- Butyrate is synthesized via the chemical modification of the natural polymer, cellulose. It is transparent, rigid, strong, and durable, with excellent dimensional stability and high impact strength. It is also easy to extrude.

- Polypropylene

- Polypropylene is the world’s second-most widely produced synthetic plastic. Polyethylene is the first. It offers low density and high resistance to many acids, bases, and chemical solvents. It is also thermal-resistant.

- Polystyrene

- Polystyrene can be formed in a variety of containers, cutlery, and packaging. While it is an inexpensive resin to purchase, it comes at a high cost to the environment. That is because it is slow to degrade and has become an abundant form of litter.

- Acrylic

- Acrylic extrusions are characterized by their optical clarity and durability. They are, for these reasons, often well suited to use as tubing in chemical processing because their contents can be easily visible when inspected by workers.

Plastic Extrusion Process

The plastic extrusion process is highly standardized, so there are few deviations between operations in terms of the basic principles of extrusion. Operating temperatures and output speeds may vary depending on the properties of the plastic material, but plastic extrusion processes closely resemble each other aside from these differences.

Here are the basic steps of the extrusion process:

- The extrusion process begins with a collection of raw plastic materials in a hopper suspended above a conveyance channel. These materials may be one plastic or a plastic composite.

- When a panel at the bottom of the hopper is removed or retracts, gravity directs the plastic into the channel.

- Inside the channel is a long shearing screw that forces the plastic down the channel as it turns. The friction caused by the turning of the screw causes the plastic to become molten. Some extruders feature supplementing electrical heating elements to aid in the melting of the plastic. By the time the plastic reaches the end of the channel, it is ready to be shaped.

- When the molten plastic reaches the extrusion die at the end of the channel, it is forced through, taking its shape as a result. The plastic emerges on the other side of the die as newly extruded plastic material.

- The plastic is quickly cooled, which causes it to harden and keep its shape.

- The extrusion can then be cut and prepared for shipment or sent for additional processing like labeling, painting, anti-static treating or another surface treatment.

Plastic Extrusion Design and Customization

When designing both standard and custom plastic extrusion products, manufacturers consider factors including best extrusion material, best manufacturing process, die shape, and die size. Material selection is based on matching up the required properties of an application with a material that exhibits those properties. The manufacturing process, whether that be hot extrusion, cold extrusion, or warm extrusion, is chosen based on the application requirements as well. Examples include tolerances, stress, and production volume.

Manufacturers offer a variety of custom extrusion options, including custom profile extrusion, custom tubing extrusion, custom plastic pipe extrusion, and extrusion coating lamination.

Machinery Used in Plastic Extrusion

- Extruder

- In this case, the extruder is composed of a hopper, where the material is held and heated, a conveyance channel, where the molten material is carried towards the die, and a shearing screw, which helps pressurize and push the material towards the die.

- Die

- At the end of the channel is a die, which is a specially-designed tool used to form raw materials into usable products. In the case of plastic extrusion, a die is a metal plate cut with a hole through which the plastic is forced.

- Every die is different; each is specially designed to accommodate an individual process. The simplest possible die designs are nothing more than simple shapes. A circle-shaped die produces a plastic rod, while a square-shaped die produces a continuous plastic square. Plastic profile extrusions, like pipes, require dies fitted with special pins that allow hollow places to form. Textured plastic sheets like floor mats can also sometimes be produced by extruders. Plastic sheet dies would be flat with grooves to create the texture.

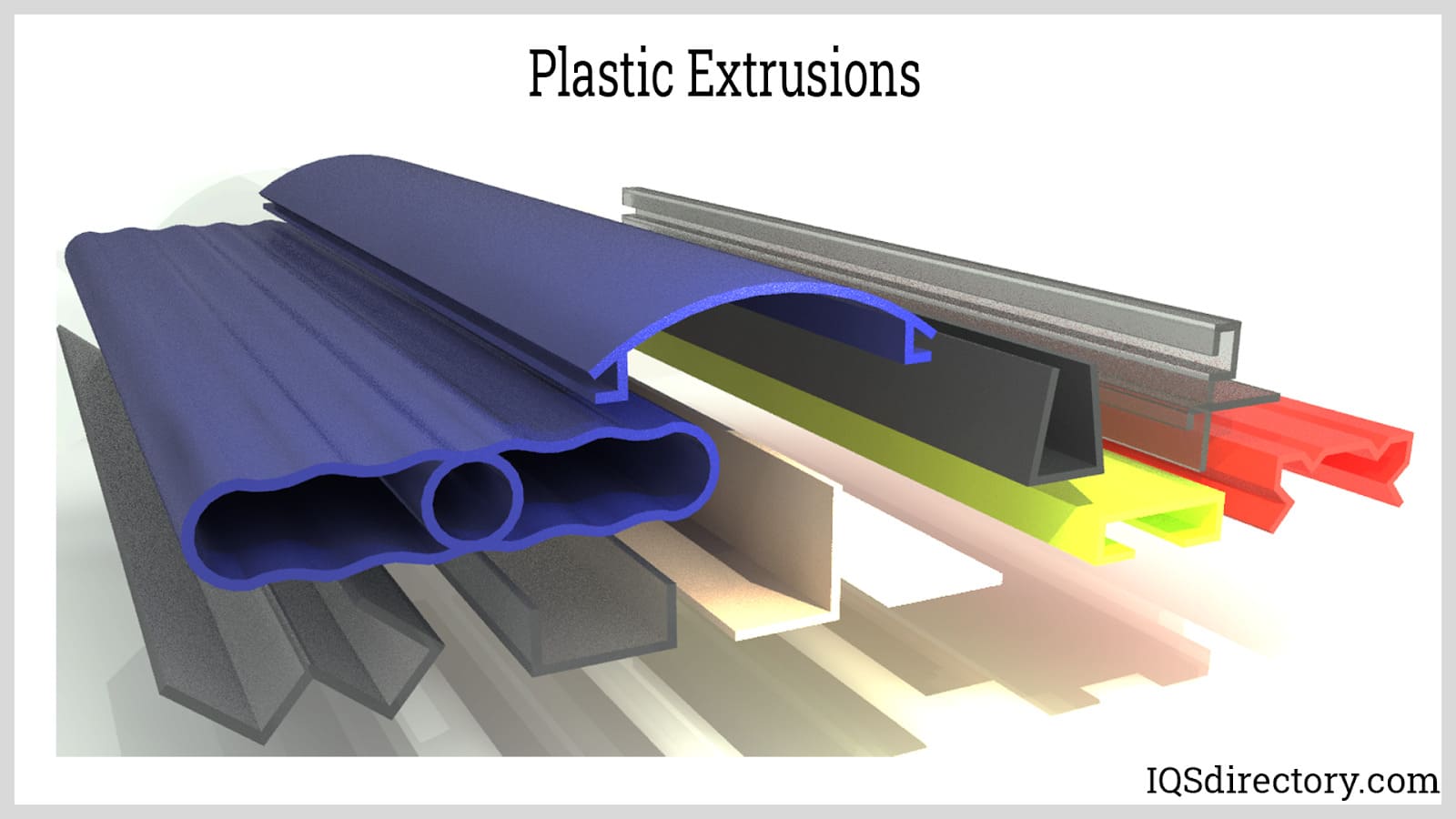

Plastic Extrusion Images, Diagrams and Visual Concepts

A continuous high volume manufacturing process in which a thermoplastic material is melted and then forced out of the shaping die with intense pressure.

A continuous high volume manufacturing process in which a thermoplastic material is melted and then forced out of the shaping die with intense pressure.

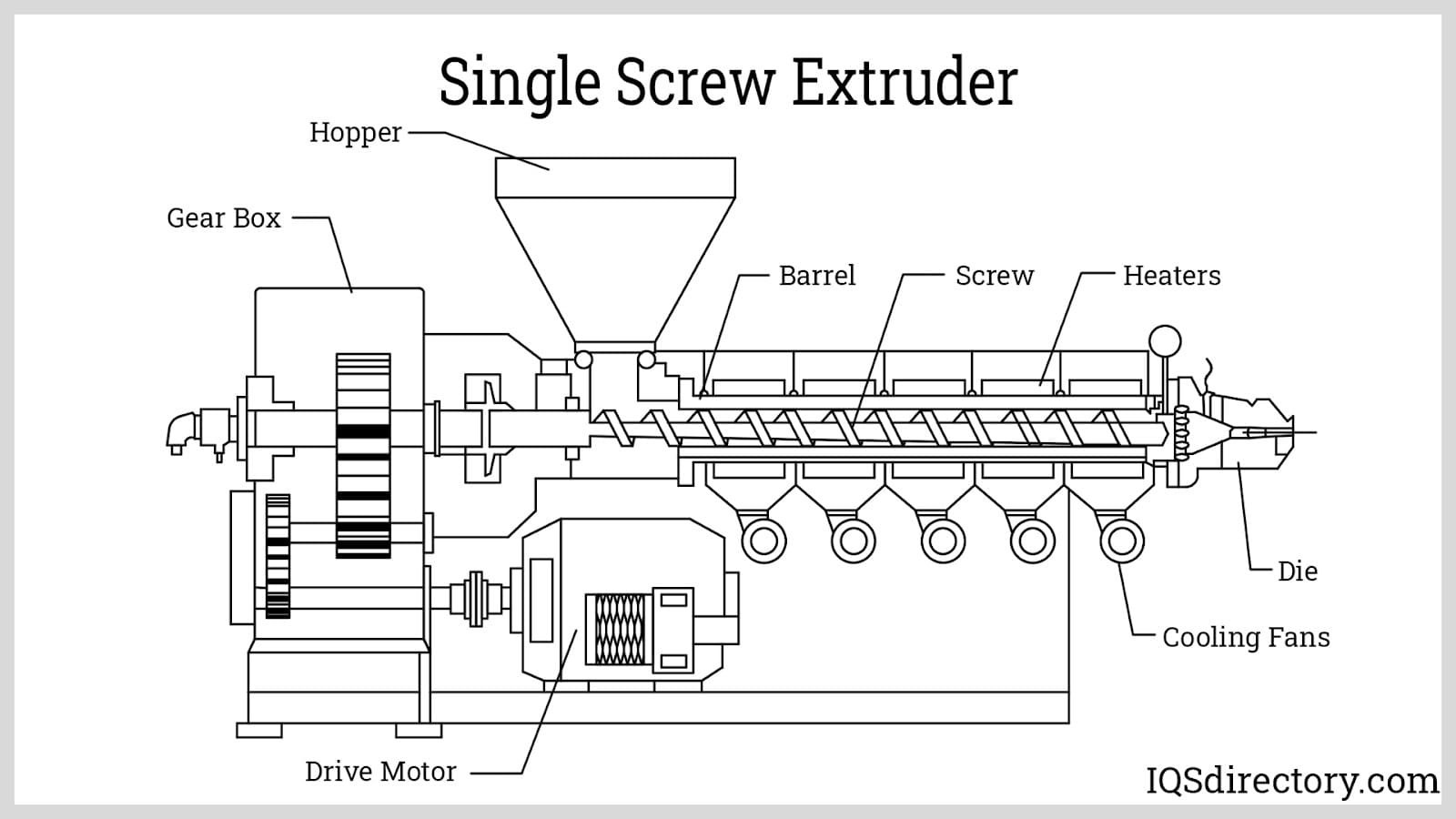

The most common continuous extruders.

The most common continuous extruders.

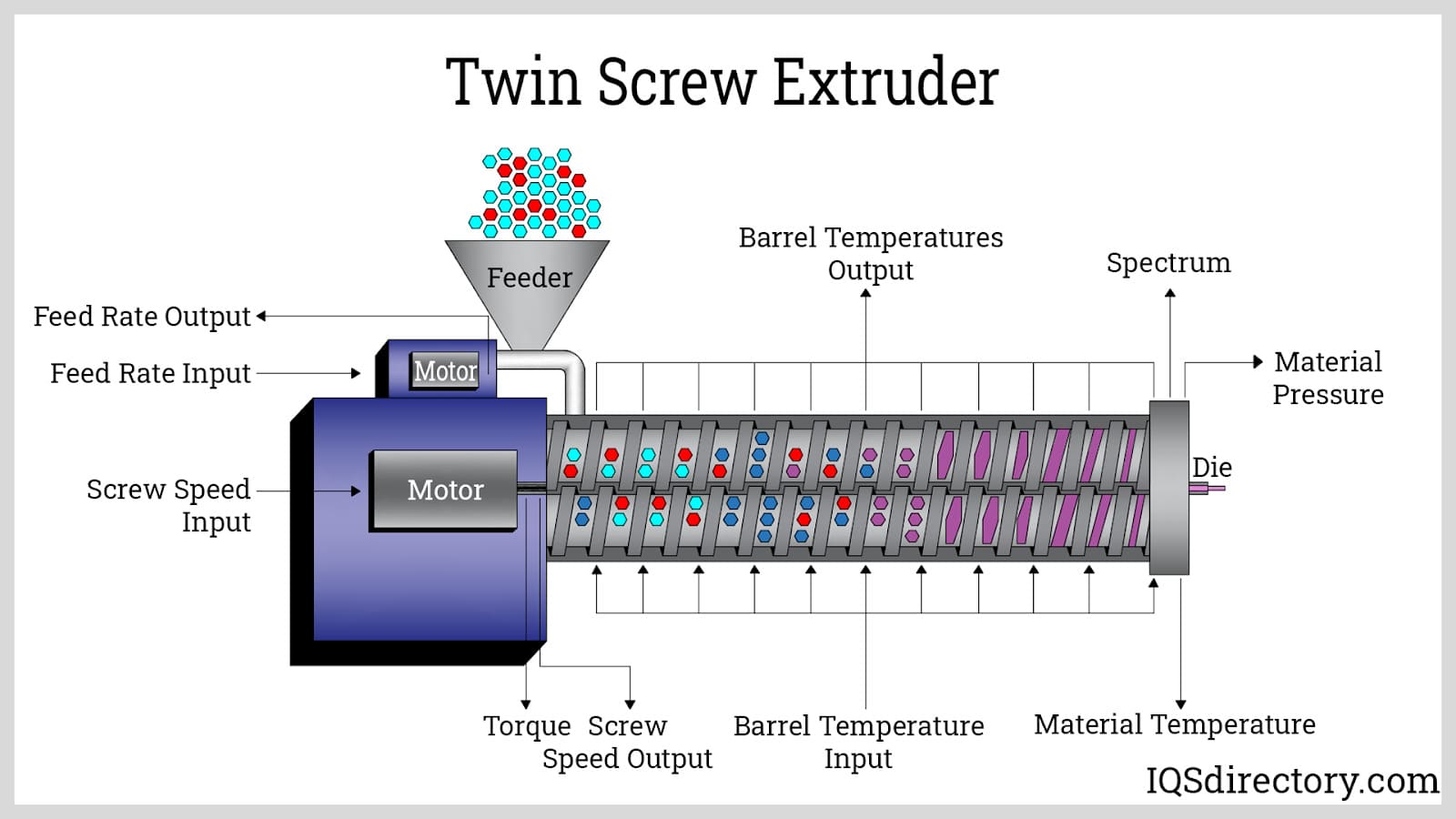

Twin screw extruders are continuous with multiple screw extruders.

Twin screw extruders are continuous with multiple screw extruders.

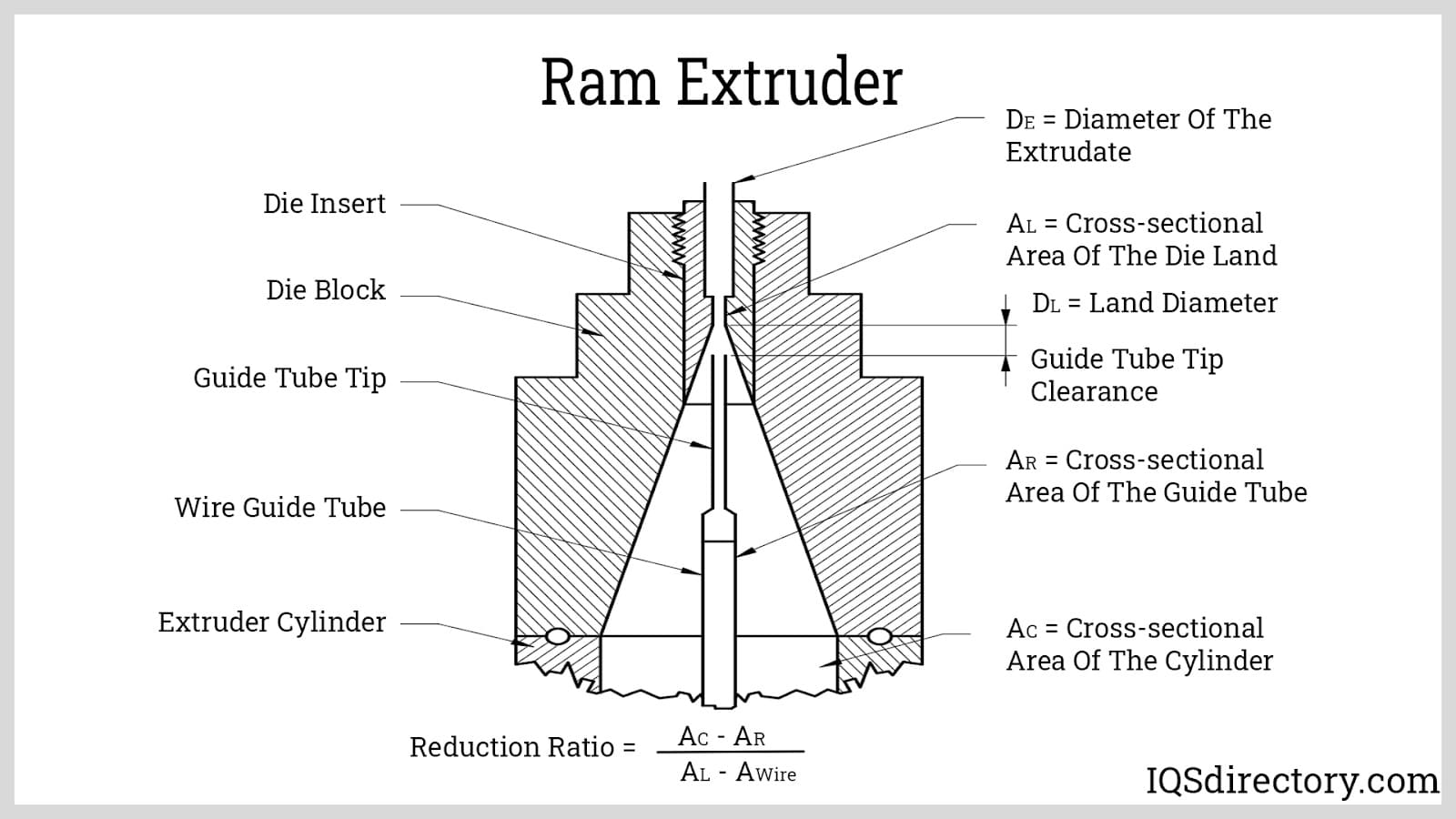

Ram extruders are advantageous in batch operations like injection molding and blow molding.

Ram extruders are advantageous in batch operations like injection molding and blow molding.

Plastic Extrusion Variations and Similar Processes

- Extruding Standard Profiles

- To make a plastic profile extrusion, manufacturers send resin through a barrel, which melts the plastics. Then, the molten plastic is molded by a different set of dies, based on the requirement. For instance, to make hollow sections, manufacturers place a mandrel within the die. Similarly, for multi-lumen tubes, manufacturers tool a couple of pins into the die, and, as it moves through the pins, the molten plastic extrudes two holes in the product. Sometimes, manufacturers apply positive pressure to supplant the whole process and to adjust the size of the lumen.

- Extrusion with Multiple Extruders (Coextrusion)

- When they need to extrude plastic in multiple layers, manufacturers turn to a process called coextrusion. Coextrusion allows for two or more types of plastic resin to be mixed together, so that they can create a product with both of their qualities. To do so, manufacturers use multiple extruders that melt the different resins at the same time and then deliver them together into a forked conveyance channel. Once on the channel, the different materials are directed, mixed together steadily, and delivered to a single die.

- Extrusion for Making Plastic Shopping Bags

- The method used for making shopping bags and plastic films is known as blow film extrusion. This method is similar to standard plastic extrusion, but it employs a different type of die, which is shaped as a cylinder with an annular opening. As the molten material leaves the barrel of the extruder, a couple of rolls pull the material, thus changing the gauge of the molten resin. Then, the die, which is tooled with an air outlet, blows air into the cylindrical plastic profile, giving it its final shape. At the end, a cooling mechanism, typically a cooling ring, is affixed to cool the film. To regulate the thickness of a product, the rate of revolution of the rolls is changed according to the needs of the product.

- Extrusion for Making Kernels

- Some machines make plastic pellets by extruding different types of resin together. The machines follow the same procedure as that of standard extrusion; however, the extruded products are not profiles or tubes, but rather beads, which act as raw material for manufacturing processes.

- Extrusion with 3D Printers

- Thanks to the development of modern 3D printers, plastic can now be extruded into elaborate shapes and structures. 3D printing gives fabricators the opportunity to fabricate any shape imaginable. In place of molten resin, this process uses a filament as feedstock.

- Plastic Injection

- Plastic extruded parts are considered a subsidiary of injection molded plastics, which are manufactured using another plastic molding technology: plastic injection. During plastic injection molding, plastic pellets are heated until molten in a hopper, then injected into two hollow cavities. Then the cavities clamp together under pressure and are left for a short amount of time to cool and solidify. Once solid, the two halves of the mold are separated, and the plastic product is ejected out of the mold by a set of ejector rods or pins.

- Plastic injection molding is chosen for both prototyping and mass production because it can create tight tolerance products at high-volume runs.

Benefits of Using Plastic Extrusion

- Efficiency

- Plastic extrusion is high speed, high-volume, and low-cost production. It is highly efficient, especially when compared with other molding methods.

- Low Wastage

- In plastic extrusion, the manufacturer can reuse plastic leftover after trimming or cutting again and again.

- Formability

- Plastic is easy to melt, which results in a quicker production run and low energy intake.

- Low Cost

- Because plastic extrusion machinery can run continuously, the process has low chances of inventory shortage, which keeps prices low. Moreover, cheap feedstock, reduced tooling costs, and low disposal expenditure mean this is the ultimate low-cost production method.

- Flexibility

- Plastic extrusion molding offers flexibility when products are required to have consistent cross-sectional profiles. Flexibility also comes in another form; manufacturers can easily tweak the process to produce plastic sheets or make products that mix plastic attributes.

- Allows Post-Extrusion Alteration

- Plastic takes time to cool down; it remains hot after it is removed from the precision extrusion machine. This makes it easy for manufacturers to implement changes to the plastic after the completion of the extrusion process, using a variety of tools like rollers, shoes, and dies.

- Versatility

- Plastic extrusion is an exceptionally versatile process which allows for plastic extruded parts that have intricate shapes with different thicknesses, hardnesses, sizes, colors, and textures; the only catch is that the cross-section needs to remain the same throughout.

Points to Consider When Using Plastic Extrusion

For the best results, you need to maintain stable head pressure, have consistent temperature at heating zones, and create uniform melt flow. Most problems originate from these three factors. We’ve outlined other factors you must consider below.

- Variations in Concentration of Raw Materials

- From the homogeneity of the molten resin to the finish of the product, all quality is directly determined by the raw material. For thin gauge extrusion, especially, process conditions need to be stable, without any major pressure surges (pressure oscillations). In a standard setting, pressure oscillations of ±50 psig are considered acceptable, but anything above that influences production. To achieve stable process conditions, avoid variation in concentration of raw materials in terms of virgin and regrind blends.

- Melt-bank Uniformity

- The lack of melt bank uniformity can cause many variations in the product, ranging from spotty finish to irregular polishing patterns. To check the presence of dull spots on the finished product, regulating the chrome-roll temperature is essential. The temperature should be kept high to discourage freezing of the bank. The other way is to shorten the distance between the die-lip exit and the primary nipping rolls; the ideal distance is 4 to 8 inches. However, there are factors that limit the distance between the die lip and primary rollers, such as area covered by the die, the die deckles, and appendages. To avoid this problem, the die should be tooled with contours to reduce the cross-section area.

- Design of Rolls

- When production of thin gauge is involved, rolls should have capacity to manage high roll loads. For this purpose, special rollers known as spherical tapered rollers are considered suitable. However, when spherical tapered rollers are installed in an extruder, additional equipment, such as bearing journals and roll shafts, also need to be designed appropriately in the extruder.

- Roll Deflection

- The common problem that all fabricators face is deflection of the roll. To rectify this problem, three solutions are available. The first involves a crowned roll, which has a pre-ground camber. This technique, however, limits the range of the production because the dimension and geometry of the camber remain fixed. The second method involves counter-bending rolls. Just like the first method, though, the technique limits the production window. The last solution involves roll skewing. The roll skewing method, unlike the first two solutions, is highly versatile and removes deflection in a wide range of operations.

Choosing the Right Plastic Extrusion Manufacturer

For more advice or for plastic extrusion services, reach out to a reliable contract manufacturer. Not sure where to start? No worries! To make your life easier, we’ve provided a list of our top plastic extrusion company picks. Find it by scrolling near to the top of the page. The best way to find the right manufacturer for you is by browsing their respective sites, picking out a few you like, and then reaching out to each of them with your questions and specifications. Be on the lookout for the one that provides the best customer service. Remember, the right manufacturer will work with you to create affordable solutions that adhere to all your requirements. There’s no reason to settle for subpar service.

Plastic Extrusion Terms

- Adiabatic Plastic Extrusions

- Plastic extrusions whose only source of heat is the conversion of the drive energy through the viscous resistance of the plastics mass in the plastic extruders.

- Back Pressure

- The resistivity of molten plastic material to forward flow.

- Barrel

- The part of the plastic extruders encasing the screw or plunger.

- Barrel Liner

- The sleeve forming the inner surface of the plastic extrusion barrel.

- Calendering

- The plastic extrusion process of pressing or smoothing material between rollers.

- Cladding

- Extruded PVC-U boards that are used as outdoor weather-resistant fade panels. Sometimes referred to as sidings.

- Compound

- Any plastic material prepared for subsequent manufacturing processes, specifically plastic extrusion, molding, or calendering.

- Compression Section

- The transition section of a screw channel in which a reduction in the screw channel volume occurs.

- Cooling Tank

- A tank typically containing water through which plastic extrusions are constantly passed for cooling.

- Cure

- The technique of cross-linking a plastic material.

- Decompression Section

- The section of two-stage plastic extruders in which an increase in screw channel volume occurs.

- Die

- The component on plastic extruders affixed to the plastic extruder's head through which the melt is pushed to form the desired profile.

- Die Plate

- In moulds, the main support for the punch or mould cavity.

- Dry Blend

- A free-flowing blend of compound or resin and other ingredients as prepared for an additional manufacturing operation, specifically for plastic extrusion or molding.

- Extrudate

- The product or result of the plastic extrusion process. An extrudate is a product or material forced through a shaping orifice as a continuous body.

- Extruder Size

- The minimal inner diameter of the plastic extruder barrel

- Extrusion Coating

- A coating technique in which molten plastic feeds directly from plastic extruder dies into a nip-roll assembly combined with the substrate.

- Haul-off

- An apparatus used for the continuous removal of extrudate from the die. Also called a caterpillar.

- Heat Aging

- The unique process of aging a thermoplastic or thermoset product and examining the percentage of retained physical and chemical properties after exposure to heat for a prolonged period of time.

- Melt

- Any plastic extrusion material heated to a plastic condition.

- Melt Strength

- A term that refers to the strength of molten plastic.

- Outer Die Ring

- The element of tubing tie that shapes the outer surface of a tube.

- Pellets

- Resins or mixtures of resins with compounding additives in the shape of similar-sized tablets and granules that have been extruded or chopped into short segments to prepare them for molding or extrusion operations.

- Ram Extruder

- A barrel with a temperature control, wherein a plunger pushes material in a melted state to the die.

- Plastic Channels

- These versatile shapes can be extruded to any length and can hold, seal, direct, guard, and attach the flow of any liquid their material composition allows.

- Plastic J Channels

- Products of extrusion, these are “J" shaped plastic channels, used to support building trim material, provide a finished edge for profiles and assist in displays.

- Plastic Trim

- Plastic trim products are linear extruded profiles that can be extruded to any length. Plastic trim has many uses as a result of its ability to attach, hold, guard, and seal.

- Resin

- Any of several physically similar polymerized synthetics or chemically altered natural resins, such as thermoplastic materials (polyvinyl, polystyrene, polyethylene) or thermosetting materials (epoxies, polyesters, silicones used with fillers, stabilizers, pigments).

- Screw

- A helically-grooved rotating element inside the barrel of screw plastic extruders. The main purpose of a screw is to melt and feed raw material from the feeder to the die, but it also homogenizes, compresses, and pressurizes the material.

- Screw Extruder

- A machine consisting of a barrel with a temperature control. It houses one or more rotating screws, which pass plastic materials from the feed aperture and move them in the form of melt under pressure through a die.

- Take-up

- An apparatus for reeling extruded plastics material.

- Thermoset

- A term that refers to the family of materials that can be melted only once during the original processing and cannot be reprocessed after the original part is made.

- Thermoplastic

- Any material, such as polyethylene, Santoprene, and ABS, that can be remelted and reprocessed without considerable loss of properties or scrap loss.

- Torpedo

- An apparatus at the discharge stage of the screw for finishing homogenizing and blending of the melt.

- Trunking

- An extruded PVC-U channel used to contain and protect pipes or cables.

- Vacuum Sizing

- A procedure utilizing a sizing die with a vacuum applied to the outer surface of the extrudate.

- Vinyl

- A generic term for PVC. Vinyl is one of various compounds of ethylene polymerized to form resins and plastics (e.g., polyvinyl or polyethylene plastics).

More Plastic Extrusions Information