Plastic Bags

Plastic bags are extremely versatile containers or carriers made of thin and often flexible polymeric films. Used to store, transport, ship and package goods in a number of industrial, commercial and residential applications, baggies such as these prove very useful as they are most often waterproof and provide some degree of protection from the elements. Commonly referred to as poly bags, the containers are constructed of processed polymer resins. You can find them here on IQS Directory.

Quick links to Plastic Bags Information

The History of Plastic Bags

There are multiple America and European patent applications for different plastic bags that date back to the 1950's. Most of them did not include handles. They had to be put on in a separate process. This made production more complicated and expensive.

In the early 1960's an engineer named Sten Gustaf Thulin, who worked for the Swedish company Celloplast, developed the modern plastic shopping bag. He developed a method to fold, weld, and die-cut, a plastic tube to form a one-piece bag with integrated handles.

Celloplast patented this development for a strong, lightweight, and flexible bag in 1965. The bag became incredibly desired worldwide and in 1977 Celloplast's U.S patent was overturned. This left the U.S market wide open and many plastic bag manufacturers rose up throughout the country.

The Dixie Bag Company was one of a host of companies that perfected the manufacturing and distribution of these bags. The Cincinnati based Kroger supermarket was one of the first to replace paper bags with plastic shopping bags.

From there plastic shopping bags spread like wildfire. The plastic bag has evolved through its 7 decades of existence but the basic principle remains the same: Strong, flexible, convenient, easy to manufacture.

Advantages of Plastic Bags

In the years before the process for manufacturing shopping bags was developed, paper bags ruled. Paper bags are suitable for carrying groceries but they are not as capable as plastic. Plastic bags are stronger and more flexible. Plastic will not rip as easily as paper. Additionally, the bottom of a plastic bag will rarely 'fall out' as paper bags tend to do when overloaded. Plastic bags are also less expensive to manufacture and are easier to ship.

In recent years the environmental concerns have led to a resurgence in paper bag usage. Despite what many think, paper bags also adversely affect the environment. They are less reusable and leave behind paper waste.

Reusable bags are often a good environmental choice. Many are made out of thick plastic or canvas. Additionally, compostable plastic bags were a major breakthrough in environmentally conscious plastic bags. They allow for the waste inside, and the bag itself, to return themselves to the earth. Over a period of time the waste is virtually gone. Plastic bag manufacturing utilizes less resources. Paper bags cost more to make and take longer to biodegrade than a compostable bag. Paper bags are also not as easy to re-use as they tear easily. Plastic bags typically have a much longer lifespan than paper bags.

How Plastic Bags Are Made

Plastic bags are deceivingly simple and inexpensive to manufacture. The process remains largely the same since their invention. Most retailers use polyethylene bags. Polyethylene is a strong plastic made from a film of resin. These bags are made in a two-step process.

The first step is to use a specialized piece of equipment, called an extruder, to heat polyethylene plastic to approximately 500 degrees Fahrenheit. The melted plastic is pushed into a die that determines how thick the bag will be. This plastic film is cooled by the outside air and cut into the desired size and placed on a spindle.

The spindle is sent to a conversion area where the film roll is unraveled and cut with a heated knife. The heated knife seals the sides of the bag together. After it is cut the manufacturer will add letters, graphics, or designs (if it is an order for printed poly bags).

The final step is the cutting of handles into the bag. The process is highly-efficient and can yield thousands of bags per minute, which helps to keep the price down. These bags remain flat which allows for easy, stack-able, bundles.

Uses for Plastic Bags

Specific materials for plastic bags abound, but polyethylene bags, polypropylene bags and vinyl bags are among the most popular and find great use as anything from medical plastic bags to plastic shopping bags. Beyond the basic material construction, plastic bags as a grouping may have little else in common due to the extreme variety in not only material choice, but also size, color, shape, closure and style which exhibit extreme variation. The selection often depends on the intended use of the bag. Clear plastic bags, for example, are a popular choice for plastic merchandise bags as they allow consumers to preview items before purchase. Resealable plastic bags and ziploc bags are also purpose driven as they provide users with a reliable closing and the option to reuse and reseal bags for extended use. You can find resealable bags on this site. While many of these factors are determined in manufacturing, post-production options such as custom printed plastic bags ensure the perfect fit, both functionally and aesthetically, for any application for all industrial, home or commercial locations.

Rigid, flexible, durable or tear away, plastic bags are a major part of the daily operations of many industrial and commercial outfits. Bags are practical and efficient for storage of parts, components and materials as they provide a safe and consistent barrier against moisture and other environmental contaminants. While some plastics are more susceptible to exposure to the elements, such as heat or UV light, others will last for extended periods of time with little to no change allowing their use in sterile and hermetic packaging of food and medical supplies as well as chemicals and biological materials. Pharmaceutical, retail, storage, sanitation, automotive, construction, electronics and chemical industries likewise take advantage of the many benefits afforded by plastic bags at a relatively low cost as compared to metal containment options. Big industry is not exclusive in its use of plastic bags which are also common household and office space goods. While the context and size may vary, plastic bags serve the same general purpose of storage, convenience and protection. No two plastic bags are alike. There are strong, well made, and environmentally friendly bags as well as flimsy, clumsy, wasteful, plastic bags.

Although the specifics are not always listed, plastic bags employ a large number of different materials to accommodate the growing needs of the aforementioned applications. The word ‘plastic' simply refers to the use of materials derived from polymer resins. These are long chains of molecules that consist of several smaller monomers held together by covalent bonds formed during calculated chemical reactions. This general description encompasses a diverse field of precise plastic compositions that may be synthetic, natural or organic. Polyethylene and polypropylene are two specific polymers that are commonly used in the production of plastic bags. Both thermoplastics, they provide the durable yet lightweight high-quality bag used in a number of industries. Vinyl bags are another popular option made of the polymer known as polyvinyl chloride. More rugged than polyethylene and polypropylene, this particular type of bag is well suited to harsher applications such as parts storage. Such use also requires a reliable seal, the design of which is most often a secondary step in the manufacturing of plastic bags. Before seams are heat-sealed, stitched or glued in place, the film encasement of the bag is formed through casting, winding, sheet extrusion or blown film extrusion with the latter being the most common. In this process polymer resins are melted into a viscous fluid which is then extruded through a die, producing a tube of plastic. Cool air is forced through the center of the die at uniform pressure to create a bubble of even thickness. Additional treatments may be applied after the material is cooled.

While material and necessary treatments are among the most important concerns to consider before selecting an application specific plastic bag, there are several other factors that come into play. The size of the bag must be suited to its potential use as bags can range from a capacity of several cubic inches to several hundred. The area of the bag is determined by length multiplied by height multiplied by diameter or width. It is important to look at specific dimensions and not just the total volume especially when dealing with irregularly shaped items. The style and closure type should also be considered as well as the overall cost. With increasing concerns for the environment, the recyclability of a plastic should also be considered. In the United States alone, four out of five grocery bags used are plastic, but less than 0.5% of such consumer plastic is recycled. Reusable plastic bags made of thicker and recyclable plastics are gaining popularity as is the development of biodegradable polymer films in many applications. The variability of plastic bags gives consumers much to consider prior to use and purchasing, but also ensures that the proper container or carrier will be available no matter the task at hand.

Plastic Bag Images, Diagrams and Visual Concepts

A plastic bag is an unwoven piece poly fabricated for packaging or storage.

A plastic bag is an unwoven piece poly fabricated for packaging or storage.

The material that is liquified to make plastic bags.

The material that is liquified to make plastic bags.

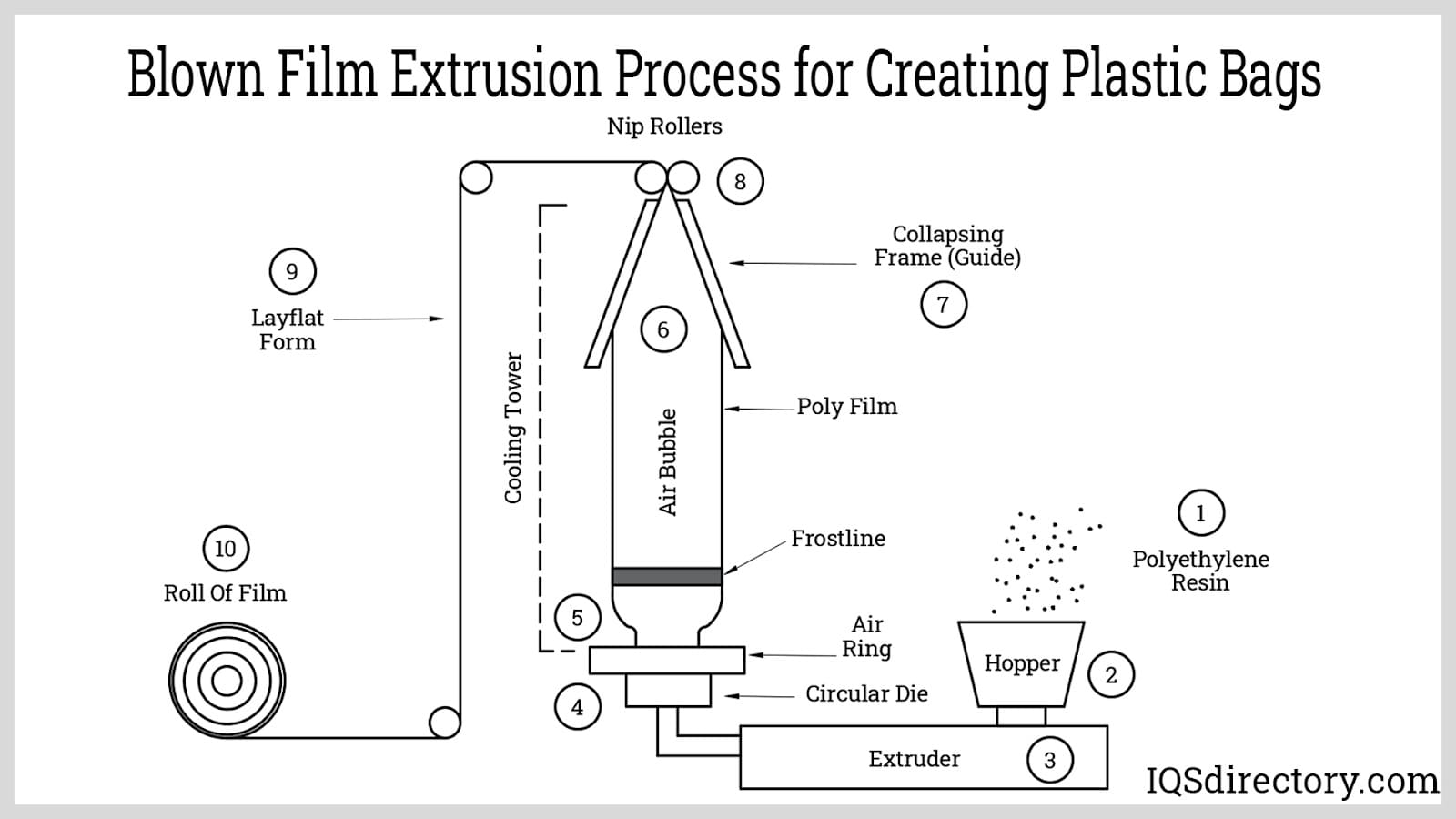

The process that turns the resin into a roll of material to produce plastic bags.

The process that turns the resin into a roll of material to produce plastic bags.

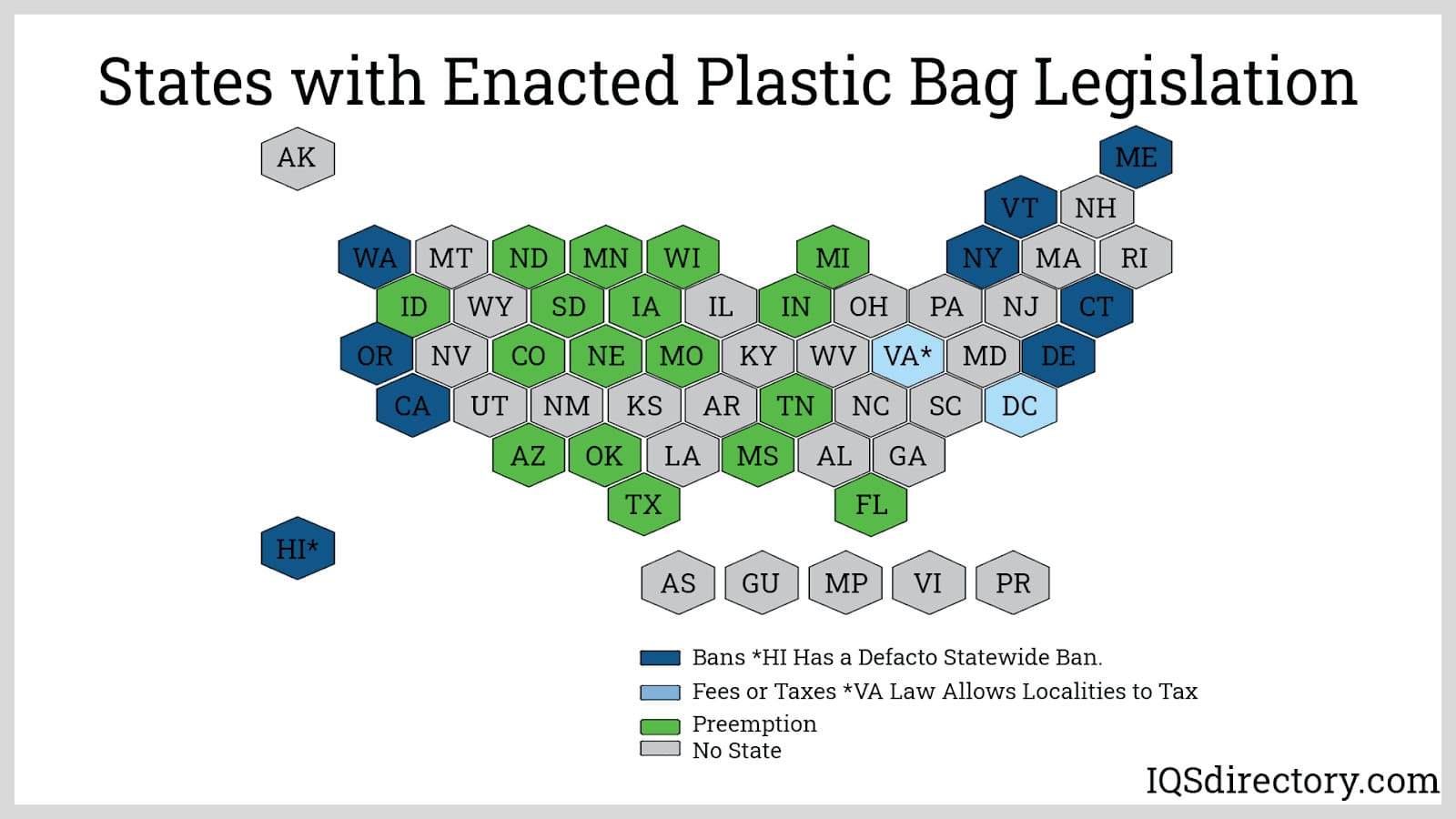

States that have passed plastic bag legislation to limit the usage of plastic bags.

States that have passed plastic bag legislation to limit the usage of plastic bags.

Plastic Bag Types

- Anti-Static Bags

- Contain an anti-static additive that disseminates static electrical charges. Anti-static bags are ideal for short-term storage.

- Baggies

- Sacks or pouches made of thin and most often flexible polymer materials commonly generalized as plastics.

- Clear Plastic Bags

- Sacks or pouches made with transparent polymers such as low-density polyethylene and polypropylene.

- Cellophane Bags

- Commonly referred to as cello bags, as they are made from cellulose. These thin, transparent bags are used in a number of applications such as gift bags or occasionally can be used as industrial and commercial packaging.

- Custom Zip Top Plastic Bags

- Primarily made from polyethylene plastic are versatile and easily customizable, and can be identified by the type of seals they have at the top. These types of seals allow for the bag to both protect its contents from outside elements and prevent spilling or leakage from the inside.

- Die-Cut Bags

- Flat bags containing a hole at the top of the bag for carrying. Die-cut bags are common in retail settings and trade shows.

- Drawstring Bags

- Contain either plastic or cotton drawstrings inserted inside the rim of the bag. The drawstrings allow for easy closure and provide handles with which to carry the bags.

- Electrically Conductive Bags

- Provide exterior protection from static charges, are made from carbon-impregnated polyethylene.

- Flap Lock Bags

- Commonly known as "sandwich" bags, have a lip that is folded back with side seals.

- Flat Bags

- Provide versatile plastic packaging for items of many shapes and sizes that are heat-sealed on either the side or the bottom of the bag. Bottom-sealed bags provide extra support for heavier items.

- Food Storage Bags

- Bags made from polyethylene resin to maintain the freshness of the food items and are often sealed with slider grips or zippers. Food storage bags, which include sandwich bags, freezer bags and produce bags, increase the life of perishable foods.

- Gusseted Bags

- Contain folds or pleats called gussets, which allow the bag and the bag opening to expand in order to accommodate large or bulky items. Gusseted bags include bottom-sealed, side-gusseted bags and side-sealed, bottom-gusseted bags. Gusset bags have specially designed sides and bottoms that allow for the packaging of larger, bulkier items. Their development was another branch in the evolution of the plastic bag. Small Gusset bags are often used to package candy assortments, hardware, garden soil, crafts, etc. They are very effective at preventing food spoilage. You can find manufacturers of them here on IQS Directory.

- Header Bags

- Side-weld bags that are loaded and sealed from the bottom. Header bags have a continuous seal along the top, which is 2-3" below the fold, and a hang hole.

- Medical Plastic Bags

- Used for a number of practical applications in hospitals, doctors’ offices, pharmacies, medical labs and other health-care facilities for the storage or containment of objects and materials. The medical industry uses plastic bags, usually clear plastic bags, of all sizes to contain medical specimens, or to dispose of certain types of hazardous and non-hazardous wastes. Plastics offer unparalleled protection from dangerous substances while maintaining a low profile and weight.

- Mulch Bags

- Top soil bags and landscaping bags in general have much more involved than a standard plastic bag as a lot goes into preserving the product that they contain.

- Patch Handle Bags

- Flat bags with a die-cut handle reinforced by a heat-sealed patch for added strength.

- Plastic Envelopes

- Flat laying pouches or bags that are usually produced with an adhesive edge for secure closure purposes.

- Plastic Ice Bags

- Come in a variety of shapes, sizes, designs and applications. Each bag must be manufactured in a way to ensure effectiveness within the desired application. One of these applications is dealing with ice.

- Plastic Merchandise Bags

- Sacks or pouches used in commercial and retail settings to store and protect goods and other items.

- Plastic Shopping Bags

- A cultural convenience product designed for the transportation of purchased goods from the store to home or other location. You can find suppliers of these bags for your business here onIQS Directory.

- Poly Bags

- Encompass a wide range of sacks, pouches and flexible containment systems made of organic, synthetic or processed plastic materials known as polymers.

- Polyethylene Bags

- Waterproof, translucent plastic receptacles employed in a number of industrial, commercial and domestic settings for the protection, storage or transport of goods.

- Polypropylene Bags

- Sacks or pouches made of completely transparent, strong, rigid material that doesn't stretch but provides a good vapor and moisture barrier.

- Printed Plastic Bags

- Mass manufactured or custom made storage containers to which permanent labels and designs are added.

- Reclosable Bags

- Revolutionized a few industries. This reusable bag is used as custom packaging in the food service industry instead of VC shrink bags, when something needs to be opened and closed multiple times. These bags preserve food and reduce food waste. The technology has been widely applied and has become a household necessity.

- Retail Bags

- Include all bags used to store and carry merchandise.

- Side Weld Bags

- Sealed on the side and have no bottom seal.

- Vinyl Bags

- Sacks or pouches made of a specific thermoplastic polymer known as polyvinyl chloride, or PVC. You can find companies that make them here.

- Waste Removal Bags

- Include all trash can liners and bags, as well as bags used to remove hazardous waste. Waste removal bags are often manufactured from high density polyethylene resin because of the strength and cost-effectiveness of the resin, but may also be made out of linear low density resin because of its stretching ability. Sanitation companies use these bags as convenient ways to store and transport wastes. They are used for this purpose in virtually every industry as most injuries have wastes that need to be dealt with. They are also used as drum liners to increase the sanitation of garbage pails.

- Wicket Bags

- Used in high speed industrial applications. Multiple wicket bags are placed on a 'U' shaped metal ring. Three sides of the bag are closed with one side open. The one side is blown open and products are inserted. This simple design maximizes speed in highly-automated manufacturing situations. They reduce handling time and are USDA approved for food storage. Their seals are very strong and provide a high level of protection for the contents.

- Zip Lock Bags

- Plastic sacks or pouches that have an interlocking or slide lock closure mechanism.

Plastic Bag Materials

There is a wide variety of plastic bags but there are two common types that you will see in most retailers.

High-Density Polyethylene (HDPE)

HDPE bags are the thin bags that are found at the supermarket. They are made with high-density film that give them strength and stability. They are easy to transport and store. HDPE is often used for trash drum liners and certain plastic wraps.

Low-Density Polyethylene (LDPE)

These bags are the thicker ones that are found at department stores. They’re slightly different molecular makeup makes them thick and strong. (Both of these bags are colloquially referred to as clear poly bags.) High strength black plastic bags are usually made from LDPE. Their thicker walls allow for disposal of a large amount of various materials.

Biodegradable LDPE

Some countries have issued a plastic bag ban in recent years. They are concerned that discarded plastic bags are the source of much pollution throughout the world. Environmentally conscious practices have become almost a customer requirement. They encourage different packaging methods, such as cardboard boxes. Biodegradable LDPE bags are made from materials that will eventually decay back into the earth. This biodegradable plastic bag reduces waste that would otherwise stay on the earth for generations.

This is curbing some of the trash that these bags leave behind. But their environmental impact is still an issue. Petroleum, a fossil fuel, is used to make these bags and their production can be harmful to the environment.

Standards and Specifications for Plastic Bags

Misinformation regarding the environmental effects of plastic bags have led to some legislation regarding their use. Many states and municipalities have issued regulations and offered alternative packaging options.

Some states have implemented effective recycling initiatives that help extend the life of plastic bags and reuse and repurpose them. Other states have completely banned plastic bags. California enacted a directive in 2014 that banned large retailers from providing plastic shopping bags.

The manufacturing process has remained the same over the last 60 years but plastic bag technology has not remained stagnant. Efforts are constantly made to find new uses for old plastic bags, as well as ways to decrease their environmental footprint.

Plastic bags may not be at the forefront of people's minds but they are something that we use virtually every day.

Plastic is stronger, easier and cheaper to manufacture, and more flexible. Their applications range from food service to sanitation.

Their strength is a result of the polyethylene plastic from which they are made. polyethylene's atomic arrangement affords it certain abilities that benefit a multitude of industries.

Choosing the right plastic bag provider is a decision that should not be taken lightly. Proper research and due diligence should be exercised when deciding upon a manufacturer. As with any product, there are many good plastic bags and there are those that are cheap and badly made. Going with the highest quality plastic bag may be worth the money for some businesses but not for others.

Even among good manufacturers there are many factors to consider. Customization options and available sizes are two important considerations. Finding the right manufacturer means finding the one that can satisfy all of your needs, not necessarily the most reputable. If you'd like to conveniently find a list of manufacturers of plastic bags, you can go to the top of this page.

The product must be able to withstand whatever is thrown its way. Many retailers like to customize their bags. Most manufacturers offer custom plastic bag orders, but some do not. Among those that do, some offer highly detailed, vibrant, custom graphics while others might only offer lettering.

Since plastic was created it has been used for almost every application. Its versatility allows it to carry goods from stores as well as save lives when used to make medical equipment.

Plastic Bag Terms

- Additive

- Substance added to a polymer to increase the effectiveness, but not the strength, of the polymer. Examples of additives include flame-retardants, anti-static compounds, pigments and lubricants.

- Alloy

- Also referred to as a "blend" or "hybrid," it is two chemically dissimilar polymers bonded together to form a new substance. However, each polymeric unit is representative of only one monomer.

- Blow Extrusion

- Common process of creating plastic bags in which compressed air fills an extruded plastic tube in order to enlarge and thin out the resin.

- Copolymer

- A polymer made up of two monomers in which each repeating unit in the chain consists of units of both monomers.

- Crazing

- Very thin cracks in a polymeric material caused by chemicals or other agents, such as ultraviolet radiation.

- Degree of Polymerization

- The length of the molecular or monomeric units in a polymer chain. This length determines the properties of the polymer.

- Ethylene Vinyl Acetate (EVA)

- A copolymer produced through the chemical reaction of ethylene and vinyl acetate. EVA is often added to plastic resins to increase the strength of the resin in temperatures below freezing.

- Gauge

- A term referring to the thickness of the material. The smaller the gauge number, the thinner the material.

- Glass Transition Temperature (Tg)

- Term that reflects the temperature when a substance changes from a hard glass to a rubber consistency. Polymers become weak at temperatures below their transition temperature.

- Grade

- Polymers originating from the same chemical family and produced from the same company. However, they vary in weight, additives, reinforcements and the manner in which they are processed.

- Heat Sealing

- Fusing together two or more thermoplastic films, such as low density polyethylene, through the application of heat and pressure.

- High Density Polyethylene (HDPE)

- A plastic material whose thickness ranges from .941 -.965 g/cm3. HDPE is more expensive to process, but maintains greater strength, resistance and stiffness than either LDPE or LLDPE.

- Light-Weighting

- The process of decreasing the weight of plastic by using less resin, while retaining the strength and effectiveness of the plastic.

- Linear Low Density Polyethylene (LLDPE)

- A plastic material that is produced at lower temperatures and pressures than LDPE through copolymerization, resulting in a crystalline structure responsible for greater stiffness and a higher melting point than LDPE. Although it is more difficult to process, LLDPE maintains greater tensile strength and a greater resistance to stress cracking than LDPE.

- Lip

- The longer side of the bag that allows the bag to be opened more easily.

- Low Density Polyethylene (LDPE)

- The most common and least expensive plastic bag material that maintains a density of .910-.925 g/cm3. LDPE maintains its durability, flexibility, water resistance and clarity under low temperatures, and its low melting point makes it ideal for heat sealing.

- Melting Point

- The temperature at which a substance converts from a solid into a liquid.

- Metallocene

- A puncture resistant material that is thinner and stronger than LDPE.

- Monomer

- The most basic polymeric unit, usually a liquid or a gas, consisting of molecules from the same organic substance. When chained together, monomers form solid polymers.

- Plasticizer

- A chemical added to plastic resins to increase the flexibility of the plastic.

- Polyethylene (PE)

- The most common plastic resin, it is a light, chemically resistant thermoplastic used in packaging and insulation. PE resins used in the production of plastic bags include low density, linear low density and high density resins.

- Polymer

- Two or more monomers bonded together through a chemical reaction. Each polymer consists of a chain of repeating monomers.

- Polypropylene (PP)

- Light, durable thermoplastic with a high melting point that is often used in packaging. PP contains polymers consisting of propylene, a colorless, combustible gas found in petroleum.

- Reinforcement

- Substance added to a polymer to increase the strength of the plastic. Examples include clay, mica and glass fibers.

- Resin

- A class of polymers, or plastics, chemically different to naturally occurring resin, a sticky substance obtained from certain trees and plants. Examples of resins include polyethylene, polyurethane and acrylics.

- Slip

- An additive that aids in decreasing the slippage of stacked packaged goods and prevents bags from sticking together.

- Star Seal

- A bottom seal for liners that combines four sections into a star design. Star seals are the strongest seals, and they maximize carrying capacity.

- Stress Cracking

- Cracking that occurs as a result of mechanical stress. In most cases, tiny cracks caused from exposure of the plastic to chemicals or ultraviolet radiation are already present.

- Terpolymer

- A polymer made up of three monomers in which each repeating unit in the chain consists of units of all three monomers.

- Thermoforming

- The process of applying heat, pressure or suction to create plastic sheets, according to specified sizes and shapes.

- Thermoplastic

- Category of plastics that has the potential to soften and reform when heated and to harden again during cooling. During the process, the physical makeup of the plastic does not change.

- Thermoset

- A category of plastics that cannot be reformed upon reheating. Thermosets remain permanently hard.

- Ultraviolet Inhibitor (UVI)

- A plastic additive that increases the resistance of the plastic to the harmful effects of ultraviolet radiation, such as fading of color and strength decrease.

- Vapor Corrosive Inhibitor

- Thermoplastic coating or film that safeguards sensitive items from harsh environmental conditions through the release of a vapor that forms a protective layer on the surface of the thermoplastic.