Perforated Metals

Perforated metals, as their name implies, are pierced metal sheets that are fabricated from various processes (such as punching) to give them different patterns and shaped holes. These shapes are either decorative or functional, or both.

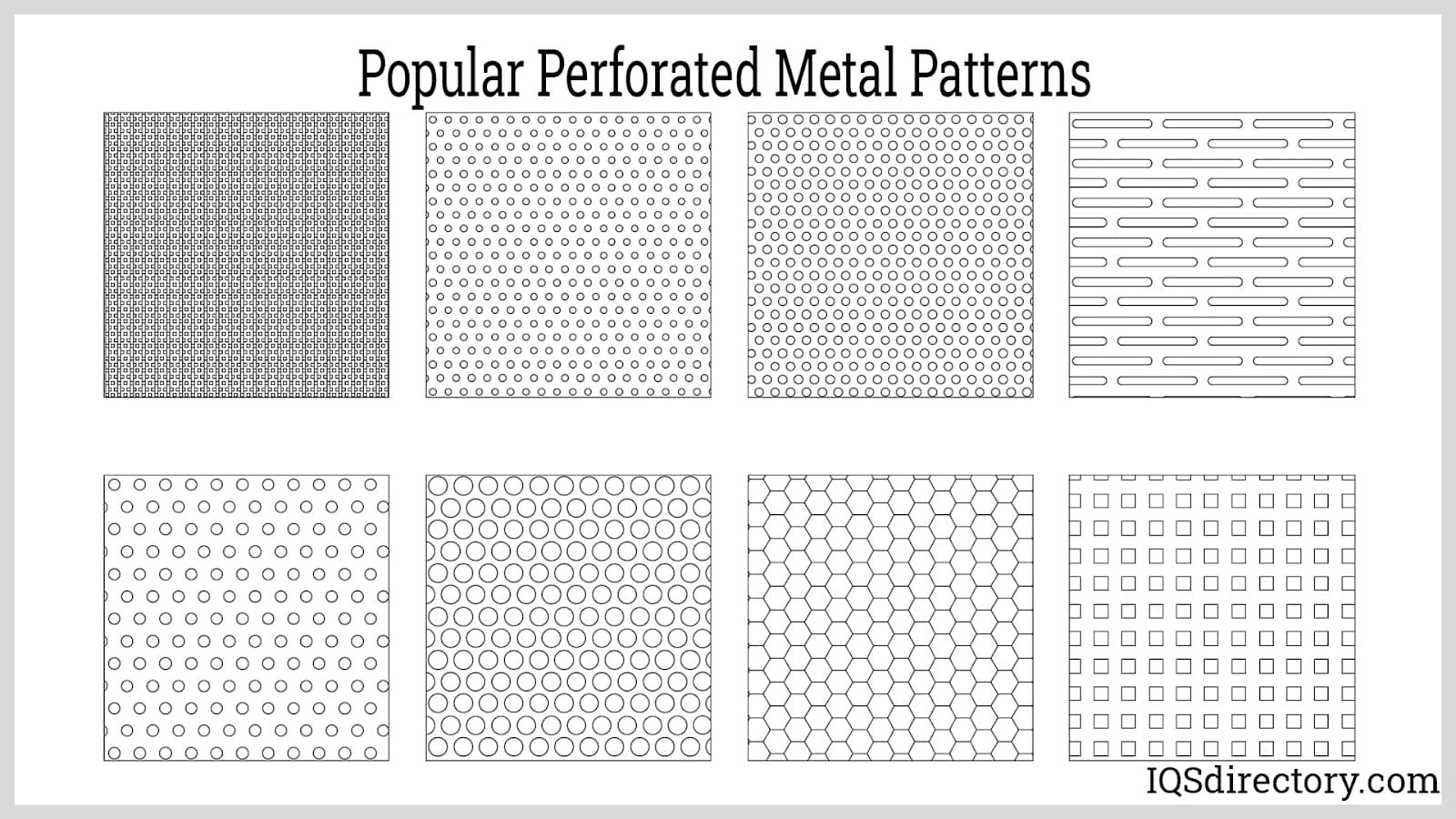

Types of hole patterns include: staggered round, staggered center, straight square slot, round and line square, round slot end, side staggered, square staggered diamond, chain link, cross, hexagon, center and square hole patterns, along with decorative cutouts like stars and flowers.

Quick links to Perforated Metals Information

The History of Perforated Metals

For decorative purposes, perforated metals have been in use for centuries. However, perforated sheets weren’t used industrially until the 19th century. At this time, manufacturers manually perforated screens so that they could use sift and separate mined coal. For a long time, the perforated metal screen was the main perforated product used in industry.

As new manufacturing techniques, fabrication methods, and technologies arose, perforated aluminum manufacturers adjusted their metal perforation practices accordingly. In particular, they began making custom presses using dies created specifically for perforated metals.

The manufacturing landscape changed once again with presses and related technologies like rotary pinned perforation rollers and laser perforation. These advancements made fabrication so efficient and consistent that perforated metals started to compete with other alternatives and were used in construction at a large scale, from access control sheets to acoustic control measures and heat saving facades.

Today, metal perforation continues to make a larger and larger imprint on the industrial world. They now assist not only with filtering important industries from aerospace to environmental impact.

There are many reasons to choose perforated metals over alternatives. First, they have more structural integrity and strength. Second, over the years, perforated metals have increased tenfold in functionality. Similarly, the aesthetic adoption of perforated metal sheets has also increased, as they are now integrated with building facades–not only adding architectural creativity but also helping to contribute to up to a 25% savings in energy consumption.

In addition, when it comes to acoustic applications, unlike other alternatives, metal sheets can be refurbished and cleaned without altering the absorptive properties of acoustic equipment. Plus, they’re resistant to the perils of mishandling and other damage.

Finally, based on the need, perforated metals can be fabricated into difficult shapes for visual purposes. This is because the fabrication methods used today add efficiency and give consistent results, all the while eliminating human error from metal perforation.

Materials Process

Metals most commonly perforated include: copper, stainless steel sheet, and aluminum. Alloy manufacturers may additionally manufacture a wide range of alloys, such as brass, and specialty grades (particularly steel grades). Manufacturers can use galvanized perforated metal or regular perforated metal. Each perforated material has specific utilities and characteristics. Read on for a few specifics about each.

Perforated Copper

Perforated copper has a reddish tint, which makes it good for decorative purposes. In addition, it works well in a variety of temperatures and resists rust when exposed to water. It’s also an excellent conductor of heat and electricity. These traits lend it to applications in interior and exterior design, tubing and shielding, among others.

Stainless Steel

Stainless steel perforated sheet is strong, lightweight, corrosion resistant, rust resistant and antibacterial. In addition, it is available in 15 different grades. Manufacturers also frequently use carbon steel. With these properties, perforated steel and perforated stainless steel are popular in virtually all industries, including healthcare and pharmaceuticals.

Aluminum Perforated Sheet

Aluminum perforated sheet presents favorable qualities including corrosion resistance, rust resistance, heat resistance, strength, durability and durability. Perforated aluminum sheet has applications in the refurbishment of offices, railings and stairways, and cutting technologies like Micro-Electro-Mechanical Systems (MEMS) capacitive microphones.

Perforated Brass

Brass, like copper, is an attractive metal; this alloy shines gold-like. For that reason, it’s quite popular as decorative perforated metal. In addition, it is relatively resistant to tarnishing, a good thermal conductor and an excellent thermal conductor. Perforated brass works well with heater and HVAC applications and electronics.

Process Details

- Find the appropriate material

-

Determine the appropriate sheet gauge

Sheets come in variable thicknesses and are measured in gauges-the larger the gauge number, the thinner the sheet. Determining the appropriate sheet gauge is as important as selecting the metal itself. Perforated metal sheet used for fabrication is mostly thin and flat.

-

Pick your perforation pattern

From staggered squares to flowers, you have a lot of pattern options.

-

Bend, Weld, Punch and Cut

There are two main manners of punching perforations into sheet metal, and they vary based on the complexity, repetitiveness and design of the hole patterns. These methods involve standard punching and XY axis punching, respectively.

For simple perforations, manufacturers use a standard punching press. In this case, as they slowly feed the sheet metal into a large press, which contains the hole pattern that perforates it.

A sectional XY axis punching press perforated metal panels with decorative, complex designs in a non-repetitive manner. This punching press, which is usually CNC controlled, is best in terms of accuracy and precision. Like with the standard press, manufacturers use it by slowly feeding sheet metal though it. In this case, the metal is secured to the machinery and moved around underneath one or several stationary hole punching rams with a single shape. As the sheet moves in the direction of the hole design, the rams create a detailed and complex pattern on the metal.

-

Finishing

Manufacturers finish perforated metal products with processes like surface polishing and rounding. Sometimes, for different applications, they polish the plate either mechanically or with the use of electric methods, and then degrease and blast it with beads and sand. To post-process the surface of the plate, they also employ grinding and brushing techniques.

When designing perforated metals, manufacturers think about things like manufacturing speed. For example, if time is of the essence, they may choose to start with roll-formed coils. This is because this method is generally faster than perforating sheets.

They also think about perforation patterns as they pertain to your application. For example, for products used in audio applications, one of the ways that manufacturers determine the appropriate perforation hole pattern is sound transparency. The transparency index states that, when high transparency sound waves are involved, closely spaced perforation sheets work better. The transparency index usually increases as the open area increases. So, if they want high sound transparency, they will create a whole series with a greater open area. Conversely, if they want low sound transparency, they’ll create a hole pattern with a smaller open area.

Manufacturers also consider factors like industry requirements, space constraints and the general needs of your application.

Machinery Used in the Process

Wide Press

Wide press perforation is the most common perforation technique, as it is the quickest and most cost-effective. Using this method, in each strike of the die on a plate, the entire width of the plate is punched. As the plate moves through the machine, a punch row or an array of punch rows work simultaneously. Wide press perforation is a rapid process and it is common to find stress faults due to punching. Moreover, the tooling cost is high. Therefore, a wide press is considered the best option for processing high volumes of metal.

To rectify stress faults or distortions, a leveler is used. With a leveler, stress errors are removed by flattening the processed plates. The leveling procedure is not a standard procedure and depends on the location of non-perforated and perforated areas.

Sectional Press

When a machine works only on a specified area or section versus the entire width of a sheet, sectional punching is often a preferred technique. As the work is performed only in a small section, the production rate is significantly lower than with wide press processing. However, sectional press tooling is less expensive than the alternative. Sectional presses can be used when tailored products with specific perforation patterns are needed. With the advent of modern Computer Numeric Control (CNC) equipment, the perforation areas and patterns can be easily pre-programmed into press machines. The sectional press method is used when a plate is thick up to 20 mm, as fewer punches are required.

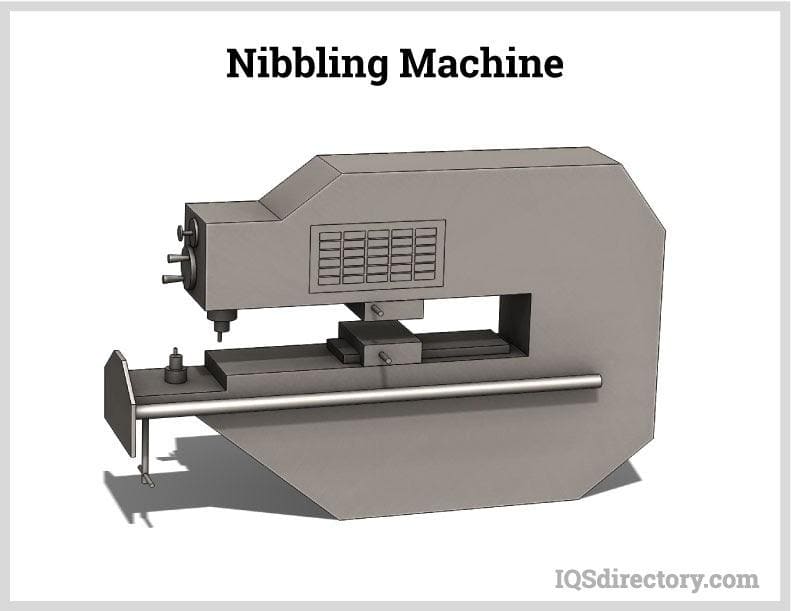

Automatic Nibbling Machines

This technique does not vary much from the sectional press method, as the machine works only on a section of the plate. However, the production is automated and the tools needed for perforations are changed without manual interference. The processing machine also nibbles the contours. With this machine, various perforations can be made economically. Moreover, the machine is competent at finishing the outer plate of contours if required.

Manufacturers use the various types of machinery at their disposal to create your perforated metal product with custom features related to: hole size (measured in mm), hole diameter, open area and strength-to-weight ratio.

The different metals that can be used for a perforating pattern, however the thickness of the mteal affects the amount of time to finsih the final product.

The different metals that can be used for a perforating pattern, however the thickness of the mteal affects the amount of time to finsih the final product.

Nibbling, a production process where the metal sheet is cut in stages using a punch using an electrohydraulic motor.

Nibbling, a production process where the metal sheet is cut in stages using a punch using an electrohydraulic motor.

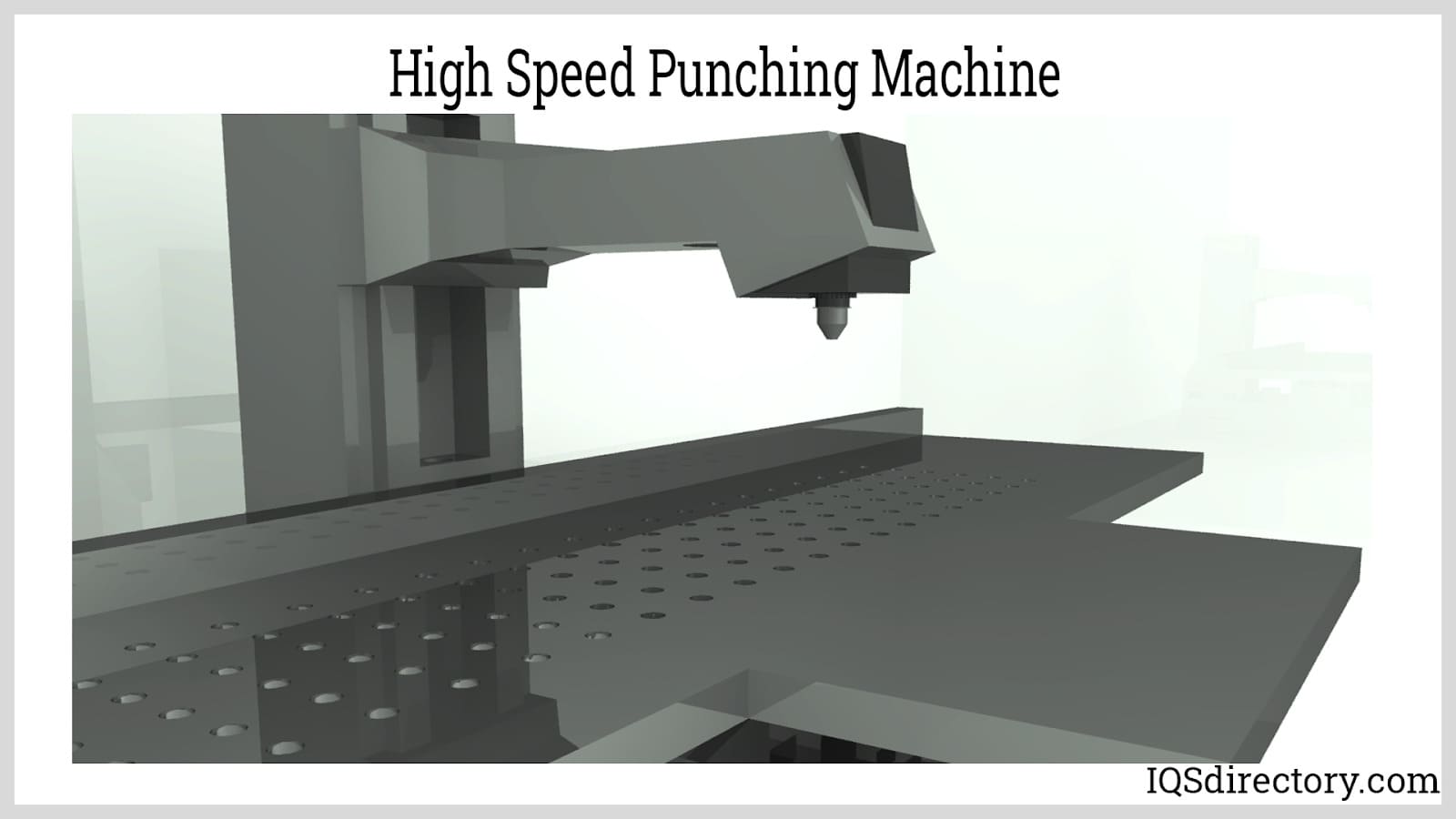

A punching machine functions much like a wide punch press that moves across the sheet metal placing symmetrical holes section by section.

A punching machine functions much like a wide punch press that moves across the sheet metal placing symmetrical holes section by section.

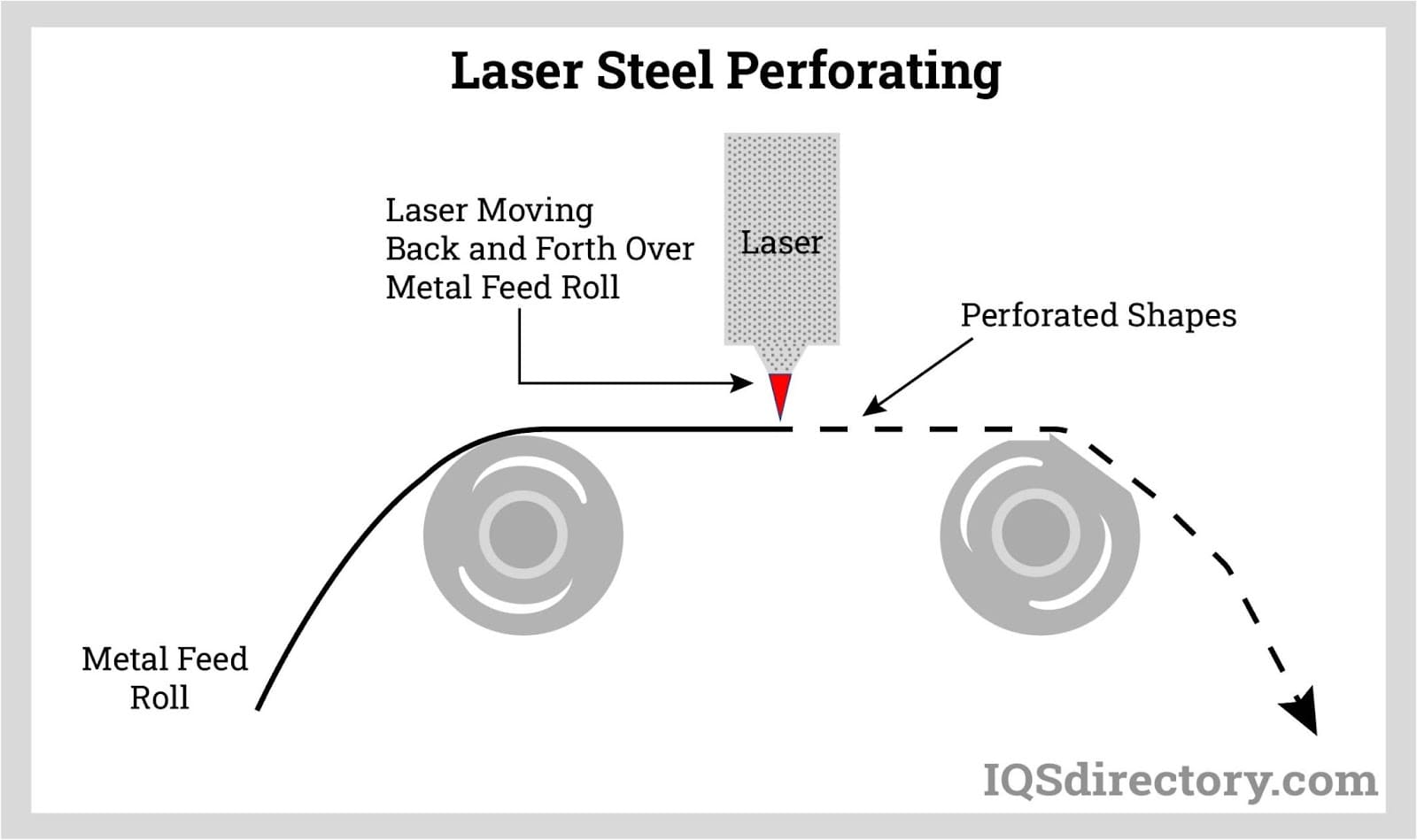

A laser perforating machine acts like an electronic pen for cutting complex and intricate patterns into steel metal sheets.

A laser perforating machine acts like an electronic pen for cutting complex and intricate patterns into steel metal sheets.

A perforated metal is a piece of sheet metal that has been stamped, fabricated, or punched to create a pattern of holes, slots, and various aesthetic shapes.

A perforated metal is a piece of sheet metal that has been stamped, fabricated, or punched to create a pattern of holes, slots, and various aesthetic shapes.

- Architectural Perforated Metal

- Products are punched metal planes that are used in building construction.

- Bar Grating

- Heavy-duty expanded metal with thicker bearing bars used for industrial flooring, stairs and transportation applications, such as street grating and railroad grating.

- Filter Screens

- Control the flow of fluids, sunlight and noise for light fixtures, window openings and acoustics.

- Floor Grating

- Grating consists of durable, expanded metal assembled in a grid configuration and used for flooring, stairs and catwalks in situations involving light to moderate traffic.

- Metal Panels

- Used for insulation, decoration and structural support in architectural and construction applications.

- Perforated Aluminum

- Aluminum sheet metal that has been perforated with a punch.

- Perforated Brass Sheets

- Sheets of brass that have been punched with holes or other shapes.

- Perforated Copper Products

- Sheets of copper that have been punched with holes or other shapes.

- Perforated Metal Panels

- Metal sheets or plates that have been punched with holes or other shapes and used in building construction, decorating and in several other applications.

- Metal Screens

- Block objects and substances from entering enclosed areas, providing protection and security.

- Perforated Plates

-

Metal plates that has been punched with a decorative shape.

- Perforated Sheet Metal

- Used as screens, tubing, panels and grating in a variety of different industrial applications.

- Perforated Sheets

- Sheets of metal that have been punched with shapes.

- Perforated Stainless Steel

- Products are sheets, plates or panels of stainless steel that have been punched with holes or other shapes.

- Perforated Steel

- Steel sheet metal that has been perforated with a punch.

- Perforated Tubes

- Used for filtration, light and fluid diffusion, shielding and dampening applications.

- Radically Cut Grating

- Annular-shaped panels cut out of rectangular grating and used in circular or annular areas.

- Reversible

- Grating that may be installed with either side facing up with no difference in appearance or carrying capacity.

- Riveted Grating

- Consists of straight bars and bent connecting bars that are joined by rivets at their contact points.

- Standard Expanded

- Begins as a solid metal sheet that is then uniformly slit and stretched to create diamond-shaped openings.

- Swage-Locked Grating

- Manufactured by applying pressure through dies to alter the cross sectional shape of a metal cross bar.

- Wire Cloth

- Available in a variety of different weave patterns for use in air filters, ventilation covers, animal cages, window guards and clothes dryers.

Applications

The purposes of perforated metals are many. Among their most prominent applications are: filtration, screening, structures, acoustics, insulation, building construction, waste management, furniture elements, and security and barriers.

The industries that make the most use of perforated metals include architecture, food and beverage, chemical and energy, material development, automotive engineering, and acoustics.

Products Produced

Perforated sheet metal is often made into screens, filters, strainers, piping inserts, trash cans, tubing, light fixtures, vents, audio speaker covers, patio furniture, and many other products.

Architectural Products

Architectural perforated metal products include: perforated metal panel, sunshades, cladding, eco-friendly aesthetic fittings, decorations, signage, fencing and other access control elements, and column covers.

Food and Beverage Products

Examples of perforated metal products in the food and beverage industry include grain dryers, fish screens, silo ventilation screens, perforated metal strainers, juice press screens, wine vat screens, cheese mold screens, and man made beehives. (Before the advent of modern technology and perforated sheets, bees were harvested in containers without movable frames. Bees used to make their own hives within these structures; however, a single harvest could destroy a whole enclosure, and bees had to start from scratch. Modern beehives made from perforated metals solve this issue.)

Chemical and Energy Products

The most extensive use of perforated sheets is as filter mechanisms. There are a multitude of equipment types that contain filters made from perforation techniques, including centrifuges in laboratories; drying baskets in washing machines; separator plates in batteries; screens in gas, water, and air purifiers; and conventional coal washing and mine cages.

Material Development Products

Perforated metal, along with wire forms, is utilized for strengthening glasses used in extreme manufacturing environments. Similarly, they are used in the manufacturing of screens of cement slurry, textile printers, felt mills, dyeing machines, as well as blast furnace screens, which are specially designed to withstand high temperatures.

Automobile Products

The most common use of perforated metals, other than on building facades, is in the automobile industry. Grills, running boards, and silencers all are manufactured with perforated sheets of different metals, based on need. Moreover, almost all filters, whether they are oil filters, air filters, or ventilation grids, are made with perforated sheets.

Acoustic Products

In acoustics, perforated metals serve as diffusers, protective coverings and sound absorbers.

- Protective Covering

- Today's architects are realizing the capabilities of perforated sheet metal as a decorative covering for acoustical materials that can reflect, scatter, and absorb sound waves. Perforated metal sheets uniquely suit this purpose, as the perforations let the sound waves pass through the covering and reach acoustic equipment installed behind them. Perforated metal sheets allow varying sound frequencies to pass through.

- Sound Absorbers

- Sometimes, perforated metal sheets are used for absorbing sound waves of specific frequencies. When you need to selectively filter out sound waves of specific frequency, resonant sound absorbers made from perforated sheets can be used. Unlike the first application, where they are used for sound transparency, the sheets play an active part in the sound cancelling process. When perforated metals are used as resonant sound absorbers, they are fabricated in a way that traps a layer of air and modifies their performance. There are other materials that have been used as alternatives, however, perforated metal makes resonant sound absorbers efficient-especially when tuned to 120 Hz. The use of metal sheets has eliminated the need of large spaces and thick layers of absorptive materials in acoustical settings.

- Diffusers

- To provide acoustical properties, perforated metal sheets are occasionally used in aerodynamic test facilities, including wind tunnels. The perforated metals break up the turbulence of the airflows.

Perforation Variations

Rotary Pinned Perforation Rolling

Many manufacturers consider the process of rotary pinned perforation rolling as the most efficient method for fabricating perforated metal sheets. In this method, as the name suggests, a rotary pinned perforation roller is used, consisting of a large cylinder with sharp and pointed needles. Using the needles, holes with varying diameters can be punched into the metal sheets, as the sheets move across a perforation roller. To reinforce the perforation, the needles on the roller are sometimes heated continuously, causing the metal to melt and form a ring around the hole. As this process is streamlined, the holes are punched continuously, making the method cost effective and efficient. For making holes of varying circumferences, different needles are used.

Die and Punch Perforation

To make perforated sheets, die and punch perforation is as common as rotary pinned perforation rolling. The method is simple, a die punches a hole in the sheet driven by a press, which can be mechanical or hydraulic. Unlike the first process, which has a single point of operation and eliminates secondary procedures, die and punch perforation requires secondary processing, as the remaining metal is sheared off to make the surface smooth. However, the method is preferred when large surfaces of sheets need to be punched.

Laser Perforation

The most modern method of perforated metal production includes the use of laser technology. Since this method is quite expensive it is used only when precision is a factor. Laser perforation gives high consistency.

Among the technologies employed for producing perforated metals, the most effective and efficient is press and punch perforation forming. With the most modern perforation presses, it is now possible to produce any conceivable perforation pattern since computer programming has been integrated into machine operation and offers extreme precision.

Metal Expansion

Like perforated metals, expanded metals are also used for filtration, reinforcement and decoration. Expanded metals are similar to perforated metals, but they have been cut and stretched into a shaped framework rather than punched.

Using expanded metal can be both cost-effective and ecologically sustainable, as the expanded metal fabrication process creates very little waste material and can expand a metal sheet's surface area by up to 70%.

Applications for expanded metals are often similar to those of perforated metals; they include enclosures such as lockers and cages, supportive structures such as grating, shelves and catwalks, and protective structures such as guards and fencing.

Although expanded metal is sometimes a cost-effective alternative to perforated metal, perforated metal is capable of being fabricated with much finer holes in a wide variety of configurations, making it an optimal choice for many metal screen applications as well as filter, design and construction applications. The decision whether to expand metal or perforate metal depends upon the industrial application, budget and specific design requirements. Perforated metal remains useful because it is easy to manufacture, cost-effective, versatile and suitable for a wide range of metals.

There are a lot of good perforated metal manufacturers out there. So, how do you choose one to perform this service for you? Well, the best way is to focus on that word–service. The right manufacturer will treat you with deference, seek to put you at ease and work to give you the best solution possible. They’ll consider your specifications, requirements, budget, ideal time frame and any and all standards to which your perforated metal product needs to adhere. Find the manufacturer for you by browsing the sites of the many more than capable companies we’ve listed above.

- Anchor

- A device that attaches the perforated metal grating to its supports.

- Band

- Flat metal bars connected to each end of the bearing bars of a perforated metal grating.

- Bearing Bars

- Individual strips of metal that make up perforated metal grating panels; they support the load applied to the perforated metal grating.

- Bond

- The point of intersection between two strands of expanded metal.

- Carriers (Punched Plate)

- Angles or flats that get welded to the perforated metal grating.

- Cold Rolling

- The process of moving unheated metal through pairs of roller dies to increase strength and reduce thickness. Expanded metal is flattened in the cold rolling process.

- Cross Bars

- The bars perpendicular to the bearing bars of expanded metal grating.

- Deflection

- The amount of deformation that occurs upon the application of stress to perforated metal grating. Acceptable deformation usually measures about 0.25.

- Finish

- A coating applied to perforated metal grating. This coating is typically paint or galvanizing.

- Open Area

- The openings or gaps in expanded and perforated metals that are surrounded by metal strands.

- Pressed-Locked

- A manufacturing method for perforated metal grating in which a specialized press, fit with cross-bar deformation, locks the bearing bars in position. The press-locked method is an alternative to riveting and welding.

- Random Sheared

- A shearing method that leaves prongs or jagged edges on the expanded metal.

- Serration

- The inclusion of a row of notches on expanded metal grating to provide slip resistance.

- Shearing

- Process of trimming metal to meet size and shape design requirements.

- Slitting

- Process whereby metal strip width is reduced to meet design criteria.

- Strand

- In expanded metal, the metal strip creating the pattern framework.

- Tread

- A panel of grating to which carrier end plates and nosing are welded. Tread is designed specifically to be used as stairs.