Overhead Cranes

Overhead industrial cranes, also called lifting cranes, are materials movement machines that are essential for many industrial processes including construction, loading and unloading of large objects, manufacturing and many other operations. Also known as hoist cranes, overhead cranes operate from an overhead steel beam or pair of beams bridged between two structural supports; a trolley runs along these beams carrying a hoist, which is used to lift and reposition heavy loads. They are powered by hydraulics, internal combustion or electric batteries.

Quick Links to Overhead Cranes Information

Construction of an Overhead Crane

Regardless of a crane's configuration, overhead cranes share three basic elements of construction: each uses a bridge, a trolley and a hoist. The bridge is the overhanging arm that bears the weight of the lift; in bridge cranes and gantry cranes, the bridge spans two supports, while jib crane and cantilever crane bridges are suspended in air from one support; in these cases, the load bearing arm is often called a boom. The trolley is the electrically or mechanically powered mechanism that moves the hoist and crane hook along the bridge. The hoist is the fixture responsible for lowering and raising the crane attachment, hook, grapple, fork or auger. Wire rope or nylon cables connect the crane attachment to the crane's main electric, internal combustion or hydraulic lift located at its base or at the top of its support, using electric motors for smaller applications and internal combustion or hydraulic power for doing larger, heavier work.

Components of Overhead Cranes

Overhead cranes are industrial cranes that have application in a variety of industries. Overhead cranes have a bridge, which runs on parallel runways and a hoist to which the load is linked. Since they are employed in different environments, a single design cannot fulfill all requirements. Therefore, for different needs, various configurations of overhead cranes are available, including the top or under running designs and single or double girder setups. However, before going into the details, let us discuss some components of overhead cranes, so it is easier to understand when those parts are mentioned in the discussion.

Overhead cranes travel on runway beams that have an I-shaped cross-section and elements called flanges that prevent bending. The beams are hot-rolled and can withstand high shear forces. The part of the bridge that travels on a runway beam is called end truck, which is a box girder that houses a bridge idler wheel. The bridge is the traveling structure of the overhead crane that spans the entire width of the facility, which consists of girder and two end trucks. The structure that holds the hoist around on the bridge girder is called the trolley. Bridge girders are the main traveling beam that contains the hoist and trolley. The equipment that performs the lifting function in an overhead crane is called a hoist. The hoist is fitted on the trolley and can be of two types: wire rope or chain hoist.

Overhead Cranes Images, Diagrams and Visual Concepts

Overhead crane, a type of heavy duty machinery capable of moving extremely heavy loads or equipment from one location to another in a safely and precise using an overhead space.

Overhead crane, a type of heavy duty machinery capable of moving extremely heavy loads or equipment from one location to another in a safely and precise using an overhead space.

Hoists for overhead cranes are either chains holders whichc is designed for load less than ten tons or wires which is capable of lifting over ten tons.

Hoists for overhead cranes are either chains holders whichc is designed for load less than ten tons or wires which is capable of lifting over ten tons.

Double bridge crane is built with two runways connected by a bridge and end trucks on the runway.

Double bridge crane is built with two runways connected by a bridge and end trucks on the runway.

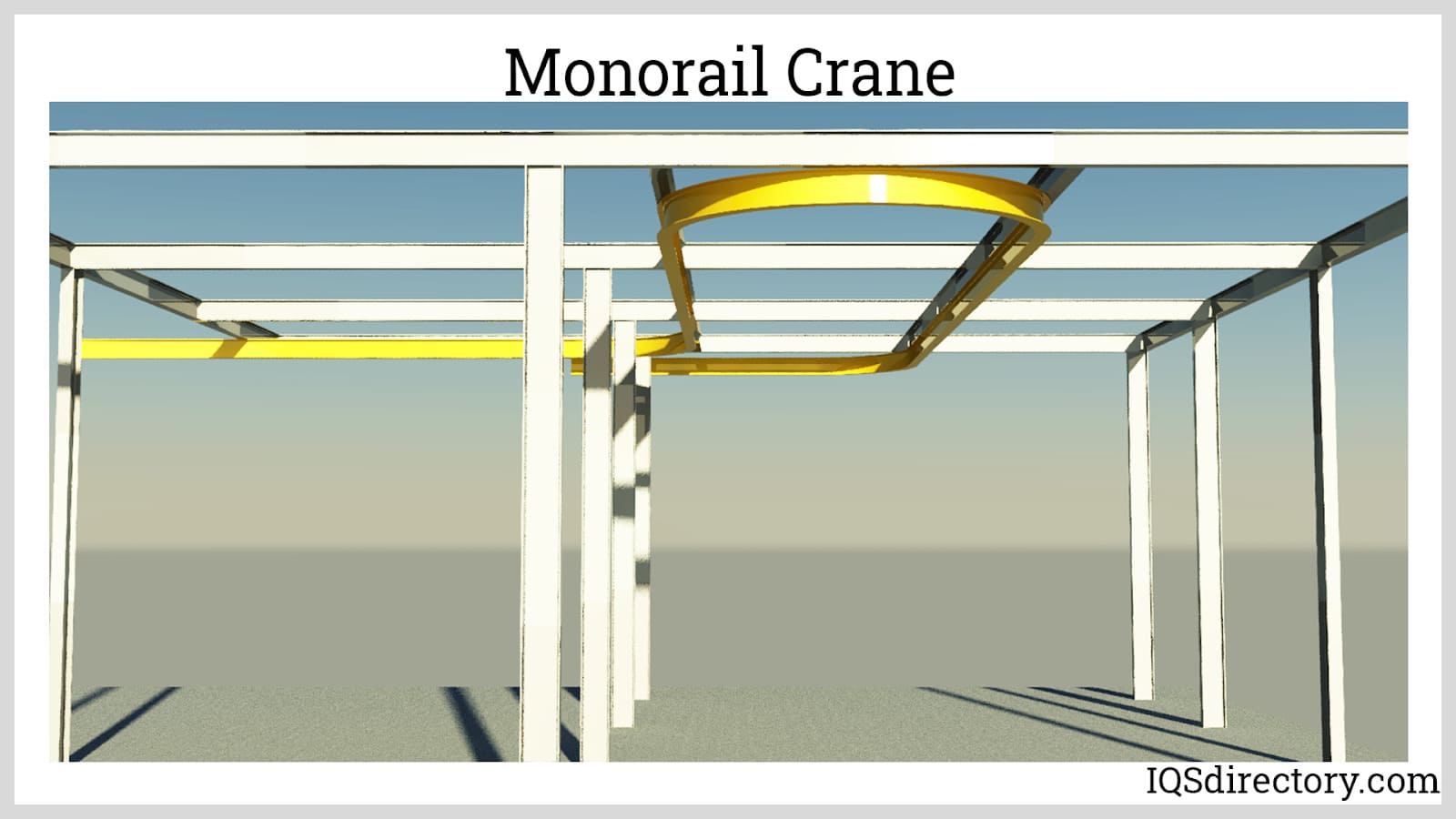

Monorail cranes have curves, branches, and switches to change its elevation and direction.

Monorail cranes have curves, branches, and switches to change its elevation and direction.

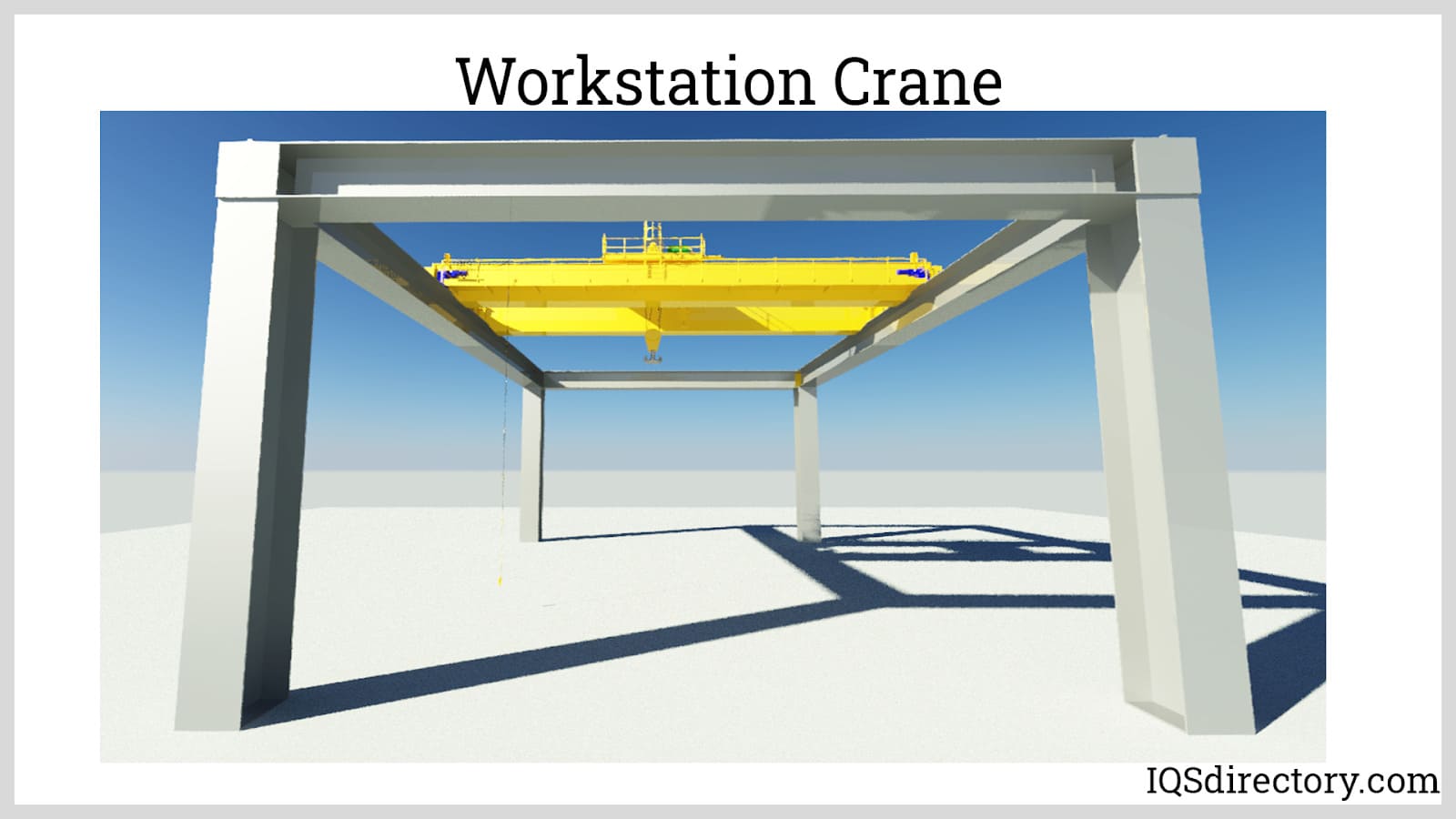

Workstation crane, a form of bridge crane designed for light to heavy production.

Workstation crane, a form of bridge crane designed for light to heavy production.

Types of Overhead Cranes

- Top Running Cranes

- Travel on the top of the runway beams. The top running overhead cranes have high load capacity. Since a top running overhead crane hauls heavy loads, it has two bridge girders to give additional structural strength and has better headroom than other options.

- Under Running Overhead Crane

- The end trucks move on the lower flanges of the runway beams. Also called under-hung cranes, they give more flexibility in an operation, as the hoist can get closer to the end truck in this type of setup. Moreover, it is cost-effective.

- Top and under running overhead cranes can have a single girder or double girder formation. However, commonly, top running overhead cranes have double girders as they have to lift heavy loads.

- Single Girder Crane

- Designed for lower load capacity; however, they are less expensive than the double girder alternative. When a crane has a single girder, regardless of the configuration, the hoist always travels on the bottom of the crane girder.

- Double Girder Cranes

- Designed for managing higher loads, they tend to be more expensive than the single girder configuration. In this design, the hoist is mounted on the bridge rim, unlike single girder, where the hoist sits on the bottom of the girder, and due to this configuration, double girder overhead cranes offer greater hook height.

- To determine which configuration is suitable for your requirement, you need to know the load capacity and design of the facility. You also need to know the power source, service rating, and material to be handled.

Things to Consider When Purchasing an Overhead Crane

Overhead cranes are the most common plant and facility equipment found in the manufacturing facilities because they virtually have no footprint in the working area. They, as the name suggests, travel on a set of overhead tracks and have a hook that acts as a loading or unloading medium. They do not directly interfere with any machinery or equipment and can work around them without creating any obstacle to other operations.

If you are looking to install overhead cranes in your facility, then you have to consider a number of things before making the purchase. Here, we are discussing those things to help you make an informed decision.

- Materials Being Handled

- The first thing that you need to know is the materials that you will handle with the overhead cranes. You need to identify whether you will move finished products, solid coils of steel or liquid substance. For these specialized needs, a specific type of hoist and auxiliary equipment are required. Inform your manufacturer about your needs and get a quote for available options; the process will help you buy a crane that will minimize cost but maximize productivity.

- Girder Structure

- A girder is a structure that links the parallel running beams and, based on the application and load capacity, overhead cranes can be designed with single or double girders. To determine the girder design, you need to know the load rating, which is the amount of load you will pick up with your crane. A single girder design is preferred for the load capacity that ranges from 1 to 15 tons. When load capacity goes beyond this range, double girder designs are suitable.

- Service Frequency Rating

- You need to determine how often the crane will be used in your facility. The frequency of operation is called service rating, which, in other words, is the number of picks that will happen in a day at a specific load capacity. The rating scales go from Class A to F in the United States.

- Type of Crane Needed

- Generally, two types of overhead cranes are available -- top running and under running. Under running design is suitable for lower load capacities. Since the high loads are not involved in this design, the bridge of the crane can move on the flange of the runway beam. The beam is completely supported by the roof of the facility. Whereas in the top running design, the bridge, as the name implies, travels on the top of the runway beam, which either is supported by the roof or has its supporting structures independent of the facility. Evidently, the top run design has more load capacity than under running design.

- Required Power Source

- Overhead cranes can be driven pneumatically, electrically, or manually. Manually powered cranes have limited abilities and are used in small-scale operations. Most commonly, the cranes are powered electrically with a three-phase electric system. However, in operations that involve oil and gas, pneumatically driven cranes are considered suitable.

- All these factors should help you to make a right buying decision.

Proper Care for Overhead Cranes

Because cranes work with extremely heavy, dangerous loads, frequent inspections must be performed on overhead cranes for safety purposes. Every day the operating mechanisms must be checked for maladjustment, the pneumatic and hydraulic parts for leakage, the hooks for deformation or cracks and the hoist chains and end connections for wear, twist or distortion. The running rope and end connections should be checked on a monthly basis for wear, broken strands and other problems. Periodically, the overhead cranes should be checked for deformed, cracked or corroded components, loose bolts or rivets, cracked or worn sheaves and drums, other worn, cracked or distorted parts (e.g. bearings, gears and rollers) and excessive wear on brake system parts, chain drive sprockets and chains. Other components to be inspected include electric or fossil-fuel motors, indicators and electrical components such as pushbuttons and limit switches. OSHA has published a set of guidelines for the safe operation of overhead cranes.