Metal Fabrication

"Metal fabrication" is an umbrella term that refers to any and all metalworking processes. Some of the most common metal fabricating processes include metal bending, metal welding, stamping, punching and a wide variety of other metal forming processes.

Quick links to Metal Fabrication Information

The History of Metal Fabrication

The use of metals for adornment and tools has been a part of human history since prehistory. The oldest evidence we have of metalworking is from a copper pendant found in northern Iraq that dates to around 8700 BC. There is also evidence that, in the Great Lakes region between 5000 and 4000 BC, people processed copper using handheld hammers and heat. Other early peoples used metal fabrication techniques like bending and cutting using tools of stone, wood, bone and sinew.

Ancient civilizations knew of seven metal materials: iron, tin, lead, copper, mercury, silver and gold. Throughout the Bronze Age and the Iron Age, people around the world continued to fabricate metal tools, weapons and jewelry from these materials with heat and force.

In ancient Egypt, metalworkers became highly skilled and used their skills to create items such as weapons, adornments, religious artifacts and trade instruments. Their techniques spread and were imitated by artisans, blacksmiths, atharvavedic practitioners, alchemists, and other types of metalworkers around the world.

Since their development in antiquity, some of the most basic metalworking practices have endured and are still in use. Bending, stamping and engraving are, in principle, the same processes they have always been, though the processes have become more effective and efficient as time has passed.

As for the future of metalworking, the development of lasers and other advanced machinery that can cut metals without even touching them has made possible levels of precision fabrication that professionals even 20 years ago may never have dreamed of. For example, computer-assisted manufacturing equipment, or CNC machining, can fabricate products with virtually no mistakes. Complex designs can be created easily with Computer-Aided Design (CAD) software and created by computer-assisted equipment with tremendous ease.

Despite the surge of developments in metal fabrication technology, some metalworkers temper their enthusiasm for the future of metalworking. As advanced metalworking methods are developed, the possibility that older methods as well as workers will be displaced seems very real; automated production lines can make entire shifts of workers unnecessary. The only certainty about the future of metalworking is that no one can predict its course.

Metal fabrication is a valuable service, and choosing it over other services, such as plastic fabrication, offers a wide range of benefits. First, metal fabricated products offer superior heat resistance; they have higher melting points and it is less likely they’ll degrade when exposed to high temperatures. Second, metal fabrication services are incredibly versatile. Sheet metal fabricators have many options, and thus can produce incredibly diverse results. Next, metal fabricated parts are strong and tend to be harder and more durable than plastic parts. Finally, metal fabrication services are cost-effective. While prices vary from metal to metal and process to process, metal fabrication companies are usually able to offer fairly low prices. This is especially true if they are able to produce your products in their fabrication facility as a part of a high-volume process or long-term production run.

Manufacturers choose how to fabricate parts and products based on their applications and specifications. They consider factors like: shape, size, tolerances, metal thicknesses, complexity and more.

Because of the broadness of metal fabrication and the countless processes and techniques available to them, metal fabricators can customize your metal product in just about any way you need. This includes all of those factors we’ve mentioned above, as well as specifications like: color, texture and corrosion resistance. If you need metal with customized or unique properties beyond that which finishing can provide, manufacturers can reach out to their metal suppliers, and ask for the alloys you need.

- Before Fabrication

- Before these metals even reach metal fabricators, they are processed in some way. Freshly mined, unprocessed metals are almost never subject to fabrication processes. Instead, raw material is put through processes such as extrusion, in order to become the fully composed, solid stock metal parts that metal fabricators can use. This is also the time when applications like sheet metal fabrication take place.

- This metal processing step is known as primary metal forming. Common primary metal forming processes include: alloying, shaping, casting, extruding and forging, among others.

- During Fabrication

- Metals that have been made into stock forms, such as sheet metal, metal tubing, metal piping, etc. Using these stock forms, metal fabricators make products of all shapes and sizes, relying on metal fabrication processes including: welding, machining, roll forming, shearing, press braking, laser cutting, punching, stamping and more.

- Many metal fabricated products can only be completed in more than one fabrication process. For example, pipe elbows must be made using both mandrel bending and swaging or swaging.

- Finishing the Fabrication Process

- Once they’ve created the product they want, manufacturers can finish off their new metal fabricated part with secondary processing, or finishing. Manufacturers choose to finish their metal products for a myriad of reasons. Most often, they do so to impart advanced properties (better corrosion resistance, resistance to wear and tear, etc.) or improved aesthetics (color, tint, texture). Examples of popular finishing processes include: powder coating, sanding, deburring, annealing and polishing.

Metal fabrication starts with sheet metal no thicker than a quarter inch and must be malleable to be transformed into various shapes.

Metal fabrication starts with sheet metal no thicker than a quarter inch and must be malleable to be transformed into various shapes.

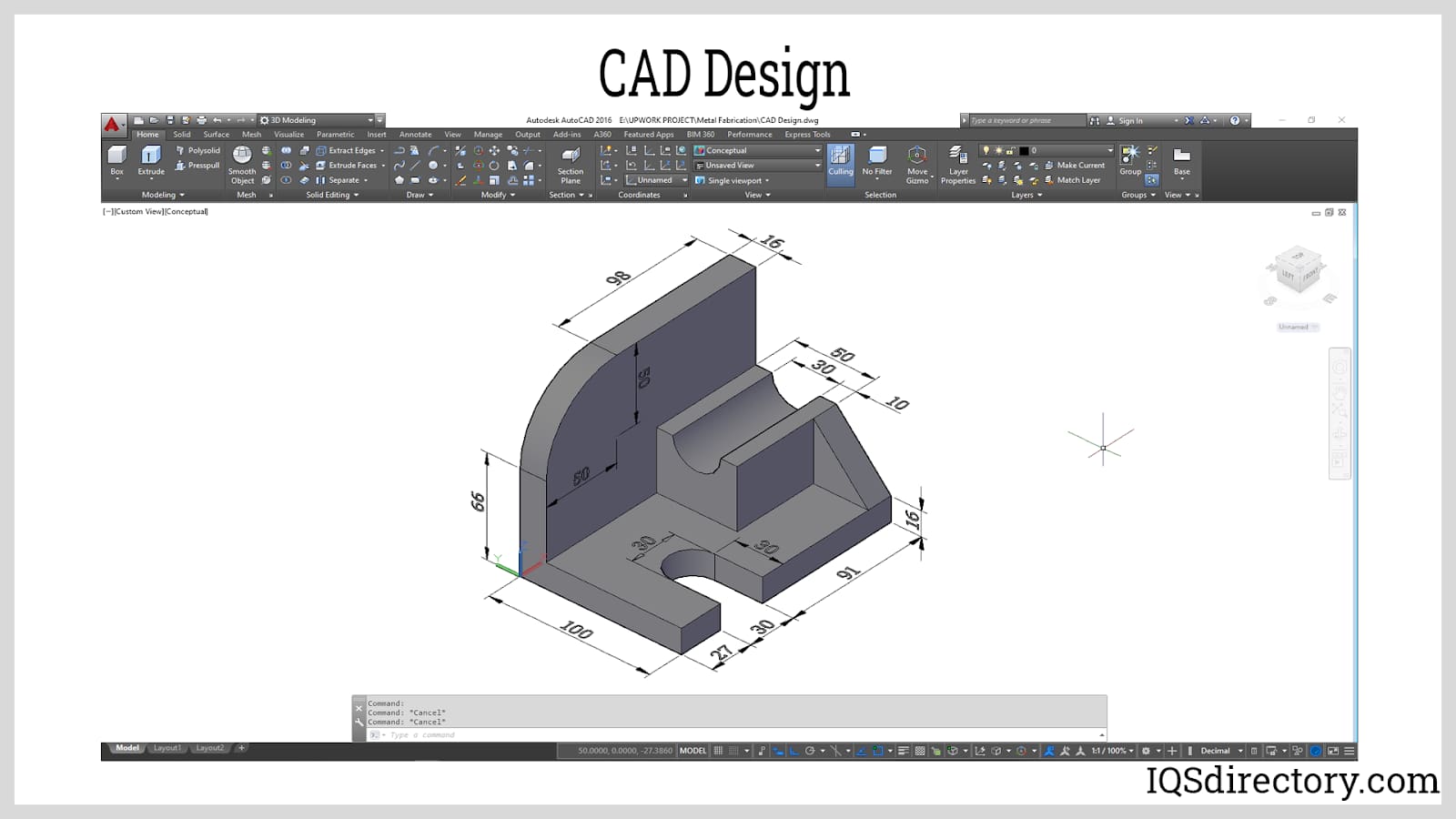

Designing the fabrication mainly uses a CAD drawing to identify the projects needs, improvements,and the strategies for manufacturing.

Designing the fabrication mainly uses a CAD drawing to identify the projects needs, improvements,and the strategies for manufacturing.

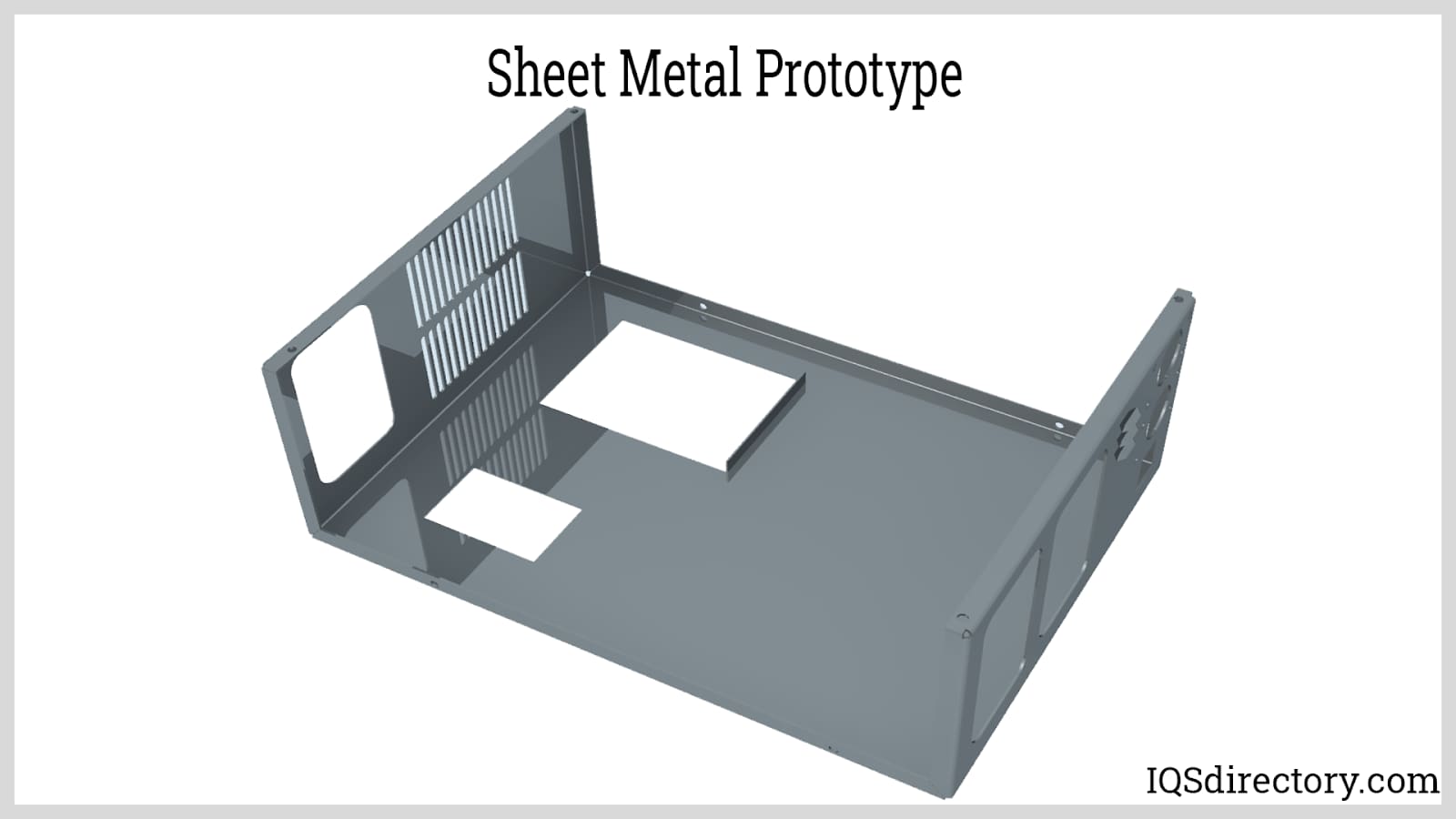

Prototyping allows for the manufacturers to test and adjust the design before the production phase.

Prototyping allows for the manufacturers to test and adjust the design before the production phase.

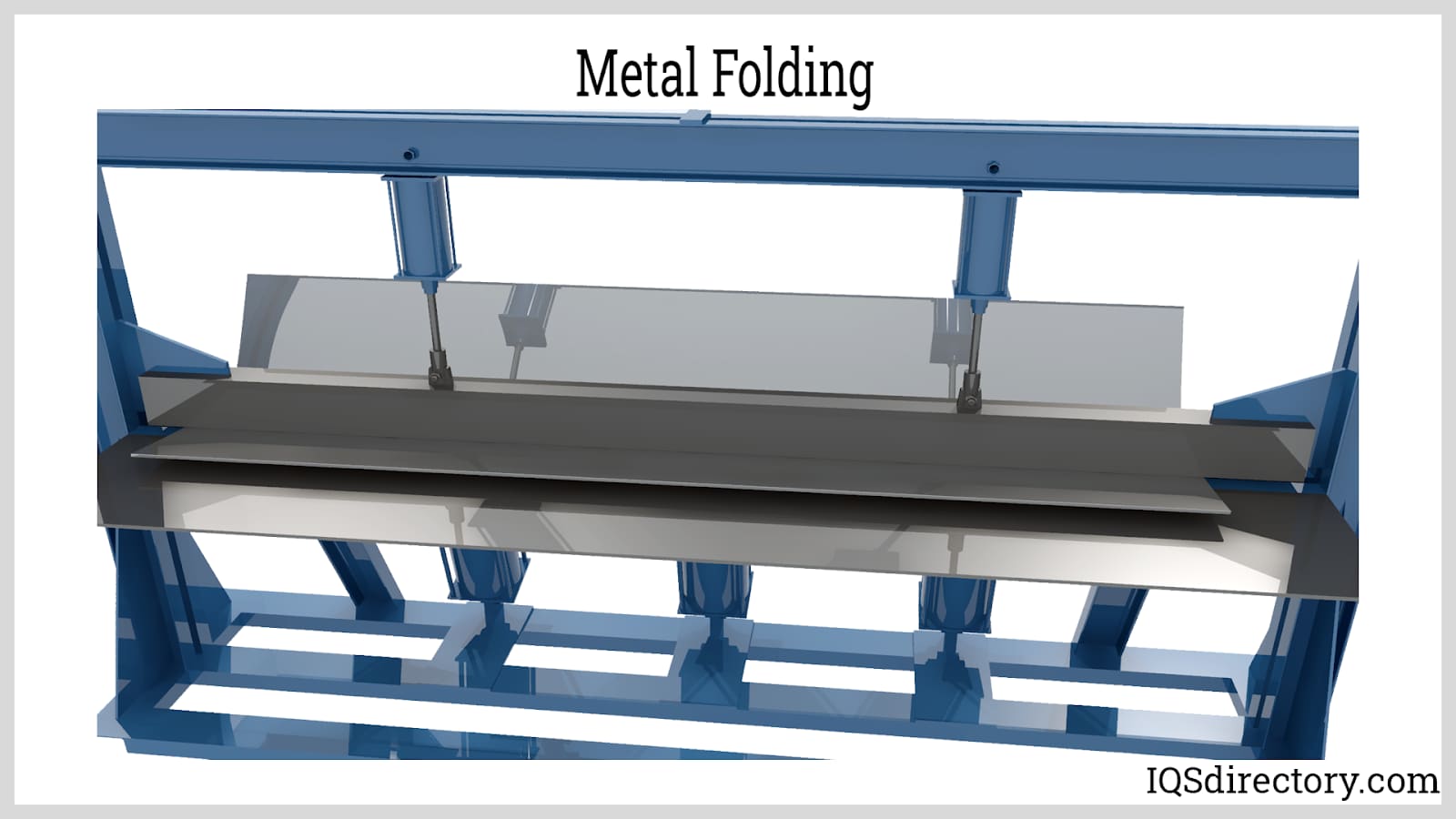

Folding the metal produces the desired shape of the metal required for production.

Folding the metal produces the desired shape of the metal required for production.

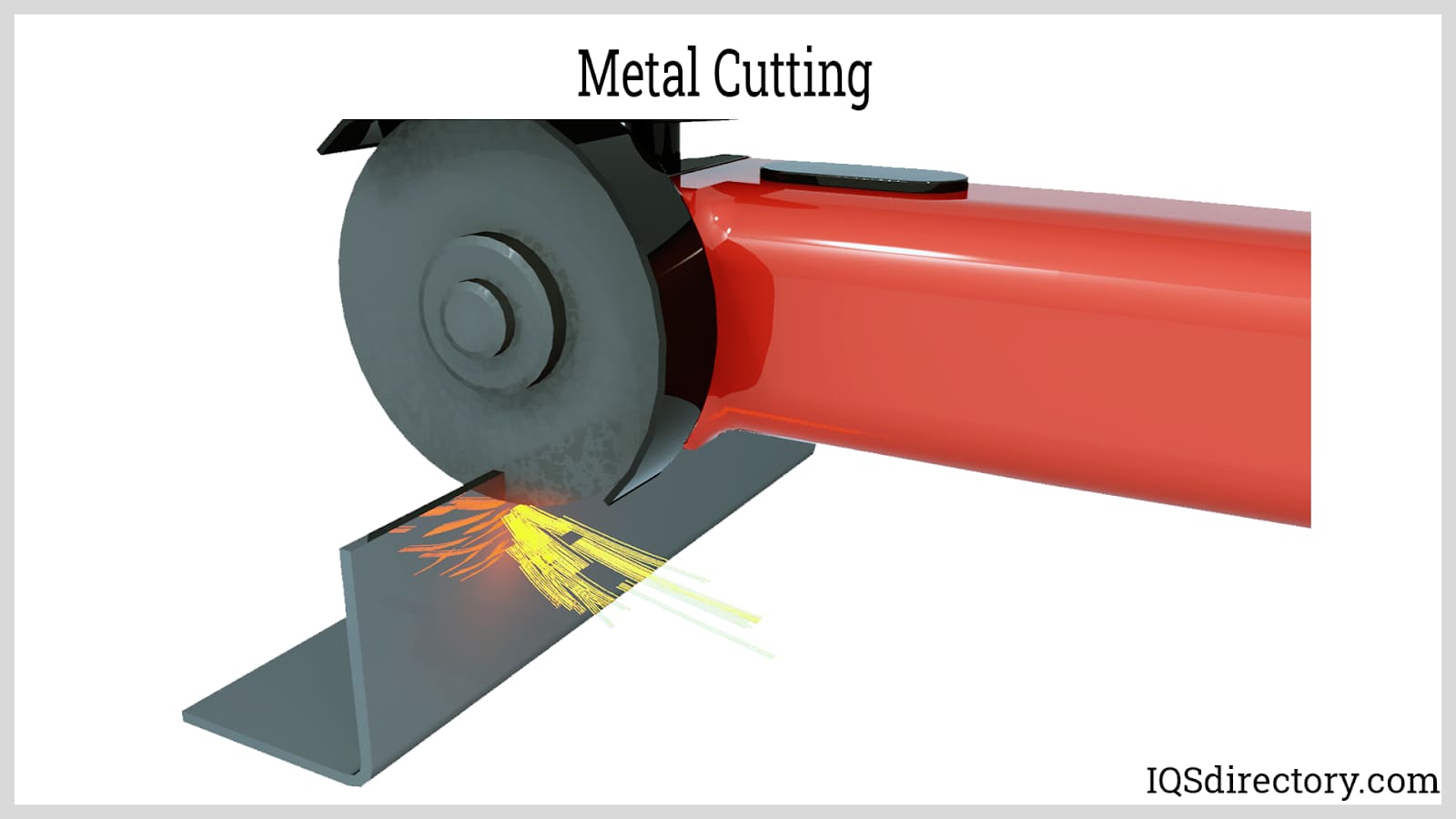

Cutting a workpiece to divide into smaller portions is a typical method of metal production.

Cutting a workpiece to divide into smaller portions is a typical method of metal production.

Metal smoothing finishes the product by smoothing the surface and edges by applying different powder coating.

Metal smoothing finishes the product by smoothing the surface and edges by applying different powder coating.

The final assembly of the product would include electrical connections or welding.

The final assembly of the product would include electrical connections or welding.

- Aluminum Fabricators

- Manufacture components for industrial machinery or other products.

- Custom Metal Fabrication

- Any service that offers metal part assembly, stamping, welding or any other fabrication service according to customer specifications.

- Fabricated Metal Products

- Complete metal products that have been assembled, stamped, punched, welded or subject to any other fabrication process.

- Heavy Fabrication

- Any operations that deal with the creation of very large or complex fabricated metal products.

- Laser Fabrication

- Utilizes a device that produces a bright and intense light beam. The high-powered laser beam, depending on the total power output and beam diameter, is capable of cutting, marking and welding a metal.

- Metal Bending

- A metal forming process in which metal can be deformed through plastically deforming the material and then changing its shape.

- Metal Fabricating

- The act of creating or modifying a metal product. Examples of metal fabricating include welding, bending, laser cutting, etc.

- Metal Forming

- Encompasses a wide variety of manufacturing processes that are performed on metal parts and are used to fabricate metal components.

- Metal Welding

- The joining of two metals through coalescence, which is accomplished through heating the metals enough to melt into one another.

- Metalworking Process

- Assembling, stamping, punching or applying any other fabrication process to a metal.

- Robotic Welding

- The process in which robotic equipment performs welding tasks.

- Sheet Metal Fabricators

- Create custom-shaped or molded goods from metal sheets. Sheet metal fabricators are responsible for making body panels for automobiles, aerospace and aviation parts.

- Stainless Steel Fabrication

- The process of creating custom parts using various grades of stainless steel. Stainless steel offers excellent corrosion resistance, high strength and attractive aesthetic characteristics.

- Steel Fabricators

- Make or modify products made of steel. A steel fabricator offers varying services including steel bending, welding and cutting.

- Structural Steel Fabricators

- Manufacture steel components for the construction industry.

Manufacturers can fabricate virtually any metal material or metal alloy. Some of the most commonly commissioned to form include: aluminum, carbon steel, mild steel, stainless steel, brass, bronze, copper and titanium.

- Aluminum Metal

- A naturally-occurring, recyclable material, found inside minerals. Aluminum is soft, lightweight, highly ductile, and durable, corrosion and oxide resistant. Aluminum and aluminum alloys are important in aerospace applications. Purchase them from the manufacturers on IQS Directory.

- Carbon Steel

- A term that can either refer generally to non-stainless steel, or specifically to steel that is no more than 2.1% carbon by weight, no less than .4% copper, and no more than 1.6% manganese, .6% silicon and .6% copper. Note that, the higher the carbon level, the lower the level of ductility.

- Mild Steel

- Also known as low-carbon steel or plain-carbon steel, is a type of carbon steel. It is relatively inexpensive with a relatively low tensile strength, but it is still suitable for many applications. For that reason, it is among the most popular steels today. As it contains only .05% to .25% carbon, it is quite ductile and malleable.

- Stainless Steel

- Incredibly strong and durable, as well as hypoallergenic, corrosion resistant, oxidation resistant and resistant to most acids. Its strength quality comes from its composition, which is at least 10.5% chromium by mass. Stainless steel fabricators are especially popular with the medical and food processing industries.

- Structural Steel

- A special kind of steel, used in the construction industry for houses, bridges and other structures. Structural steel manufacturing safety and quality requirements vary by region. Because of this, custom fabrication of structural steel is often necessary.

- Note: There are many different types of steel. For special applications, such as structural steel fabrication, your manufacturer can reach out to a primary steel fabricator or primary sheet metal fabricator, and request custom steel fabrication.

- Brass Alloy

- Made up primarily of copper and zinc. With a low melting point and high malleability, brass is easy to cast. It’s usually used decoratively, for its attractive reddish-yellow color, but it can also be used for its antimicrobial effect on pathogens and microorganisms. Brass metal formers can alter its composition to change its characteristics, like strength, corrosion resistance, machinability, etc.

- Bronze Metal

- Another copper alloy that primarily features tin. It is resistant to metal fatigue and corrosion, especially corrosion from seawater. It is also a good conductor of heat and electricity. Finally, it is ductile and durable.

- Copper Metal

- A naturally occurring element that can be found in its metallic form, ready for immediate use. It is the main ingredient in both brass and bronze. Copper metal is known for its electrical and thermal conductivity, ductility, malleability and softness.

- Titanium Metal

- A transition metal that is very strong, but lightweight. It is also resistant to corrosion from chlorine, saltwater and aqua regia. On top of that, it has good thermal conductivity and electrical conductivity.

Metal fabrication services are important to all sectors of industry, commerce and consumer markets. Examples of some of the industries that rely on these services include: architecture and building construction, furniture, HVAC, office supply, home appliance, manufacturing, electronics, aerospace and aviation, automotive and transportation and sports and recreation.

The most basic hand tools and the most complicated electronics feature fabricated metal products. Examples of metal fabricated products used in an office building include: fabricated metal furniture, shelving, HVAC components like ductwork and grating, desktop paper trays and a host of other products. Industrial operations require stamped metal racks for product storage, bent metal hoods for fluorescent lighting and welded stairwell railings. Domestic utilities like kitchenware, scissors, animal cages, bed frames and appliances can all be products of metal fabrication processes.

Fabrication services like heavy fabrication and robotic welding are used to assemble the structural supports of large buildings and the airframes of planes. The steel skeletons of the largest bridges are assembled by metal fabricators, and the smallest inscriptions on complex electronic components are engraved during laser fabrication. For all of the needs in between, custom metal fabrication services allow for the creation of irregular fabricated metal products.

Typically, manufacturers use a combination of tried-and-true machinery and state-of-the-art equipment to achieve precision metal fabrication. Examples of some of the machinery you might see in their shop include: CNC machines, roll formers, laser cut machinery, hydraulic press brake tools and welding machinery.

It is easy to customize metal fabrication machinery. For example, to change cut patterns, manufacturers can reprogram laser cut machinery, which typically work with CNC machinery. They can also manually adjust machine outputs like speed, pressure and angles of force.

Not sure if metal fabrication is right for you? Ask yourself the following questions: What is your product’s purpose? What kind of appearance would you like it to have? What other characteristics are important to you? What is your available budget? Metal fabrication offers some specifications quite different from plastic fabrication. For example, while many metal products can be designed and finished for chemical resistance, plastic products are more naturally and effortlessly resistant to chemicals. If this is your main focus, it may be better to go with plastic fabrication. On the other hand, if you’re looking for wear resistance, metal fabrication is likely a better fit for you. Think about questions like these and determine if metal fabrication services are right for you.

If you’ve determined that you would like to pursue metal fabrication services, the next step is to locate a custom metal fabricator. To guide you in your search, we’ve compiled a list of our top choices, which you can find towards the top of this page. To get a feel for what these different service providers offer, peruse their respective websites. Make sure to take note of secondary services, standard certifications and lead times. Choose three or four in whom you’re most interested, then reach out to each with your specifications. As you talk to them, try to get a feel for not only the fabrication services they offer, but also the interpersonal services they offer. Will they be attentive to your needs? Will they make sure that they work within your budget while ensuring that you get a high-quality product? In essence, do they have your best interests in mind? The fabrication company that offers the best fabrication and customer services is the right supplier for you. For the highest quality, go with them.

Below are just a few examples of some of the most common of the many metal fabrication variations out there.

- Cutting Process

- The goal of cutting processes is to remove excess material from a workpiece in order to meet shape and size specifications.

- Forming Process

- Involves pressing or bending material at certain angles. Forming uses deforming equipment like hydraulic brakes. Types of forming, among others, include: roll forming and press braking.

- Roll Forming

- A continuous, high volume bending process. Roll formers can take textured, extruded, finished and other kinds of metals and bend them into useful products like channels and trim. Roll forming is particularly important to operations that produce sheet metal and paneling.

- Press Braking

- A metal forming process that produces bent metal on a much lower scale than roll forming. Press brakes involve a flat working surface with a specially formed indentation in the shape of the bend to be imparted into the metal. Above the working surface is suspended a pressing tool with an edge that fits perfectly into the indentation in the working surface. A sheet of metal is then placed in between the surface and the pressing tool; when a technician presses the tool into the metal, it forces the metal into the indentation in the working surface.

- Welding Process

- One of the most important metal fabricating methods. It is used to join metal pieces in so many contexts that welding methods have been developed for applications in outer space and underwater. Welding services are essential to the continued maintenance of industrial facilities like power plants, the manufacturing of vehicles, the fabrication of furniture and many other operations and processes.

- Variations on welding include: TIG welding, arc welding, solid-state welding, resistance welding and oxy fuel welding.

- Alloy Steel

- A steel to which one or more alloying elements—with the exception of carbon and the commonly accepted amounts of manganese, silicon sulfur and phosphorus—have been added to attain specific physical properties. Common alloys include chromium, nickel, molybdenum, etc.

- Aluminum

- A nonferrous metal that is commonly used in the creation of light, strong and corrosion-resistant alloys. Aluminum is an element that is primarily found in bauxite.

- Annealing

- A process that involves the heating and cooling of a cold-rolled substrate, making it softer and easier to form.

- Bending

- The changing of the shape of sheet metal by utilizing pairs of forming rollers in succession. Bending changes the thickness of the metal only at the bend radius, at which point a slight thinning occurs.

- Brazing

- A high-heat, metal-linking method that uses a filler material to make a bond between two metals. The filler is melted to a temperature just below the melting points of the materials being joined.

- Chemical Treatment

- A solution of chemicals often applied to various metals in order to inhibit corrosion.

- Computer Numeric Control CNC Machining

- A manufacturing process that automatically shapes or forms metals or other materials into highly precise parts. CNC machines utilize specialized software in conjunction with CAD/CAM software systems to instruct the tooling to execute the exact movements necessary to create the part.

- Cold-Rolled Product

- A flat-rolled metal sheet whose final thickness was achieved by rolling it at room temperature.

- Conversion Coating

- A chemical film that is applied to a metal prior to the painting process.

- Corrosion

- The deterioration of a metal due to a chemical reaction or oxidation. Rust is a common form of corrosion.

- Cutting

- A process in which a metal is penetrated or opened using a sharp edge. Metal sheets are almost always cut from a larger source prior to fabrication.

- Die Cutting

- The application of a powerful die to a metal blank. Pressure from the stamping device is often applied by a mechanical or hydraulic press.

- Ductility

- The ability of a metal to endure change without fracturing. Hardness and the tensile strength of the metal often determine its ductility.

- Forming

- A term that encompasses many processes, which are used to shape or mold a metal piece into a desired configuration.

- Hot Rolled Sheet

- A metal sheet processed to its absolute thickness by rolling on a specialized hot-rolling machine.

- Leveling

- Eliminating distortions of a rolled sheet by flattening the material.

- Powder Coating

- The process of applying a powder consisting of solids to a material surface and then heating the powder above its melting point to create a uniform film.

- Roll Forming

- A process in which sheet metal is continually deformed by passing it through a series of rolls.

- Stainless Steel

- A wide variety of corrosion-resistant steel that contains at least 10% chromium and to which varying amounts of other elements, such as nickel, molybdenum, titanium and niobium, have been added.

- Tensile Strength

- Also referred to as "ultimate strength," it is the maximum amount of stress a material can endure.