Investment Casting

Investment casting is a manufacturing process used to produce a wide range of lightweight industrial parts. Investment casting takes its name from the ceramic slurry that is used to form a ceramic shell around a wax pattern. Because it yields such precise and reliable results, this process is also sometimes known as precision casting. In addition, it is also called a "lost-wax process," "lost wax casting," or even just "wax casting." This is because, after the wax cast part is ready, the remaining wax is melted down, or "lost."

In non-industrial terms, lost wax casting and precision investment casting both refer to a method in which a duplicate copy of a metal sculpture is made. However, in industrial terms, the investment casting process is not about sculptures; it is solely about creating machine parts following the practices of wax cast sculpturing.

Many manufacturers depend on the investment casting process to produce dimensionally accurate precision cast parts. Investment casting is a diverse process that allows for the usage of all sorts of alloys and specifications. Investment castings can be found in the aerospace, automotive, chemical, defense, food processing, electrical, railroad, mechanical, marine, electronic, textile and engineering industries.

Quick links to Investment Casting Information

The History of Investment Casting

Investment casting is a very old industrial process. In fact, it’s the oldest known industrial process, and the earliest known description of investment casting was written around 1100 A.D. by a monk who wrote under the pseudonym Theophilus Presbyter. By 1100 A.D., though, it had already been around for a long time. In practice for over 5,000 years, the earliest examples of castings hail from the tombs of King Tut and the ancient civilizations of Harappa, Mesopotamia, Aztec and Mayan Mexico and the Benin civilization of Africa.

Originally, people used natural honeycomb or beeswax for the wax pattern, clay for the molds. They manually operated bellows as stoking furnaces. In contrast, today, people make the wax pattern using a variety of pure and synthetic waxes, and they make molds using a variety of refractory material types and alloys. Instead of handheld bellows, they use a cast foundry.

Investment casting entered the modern era in the late 1800s. At that time, dentists were beginning to use it to make crowns and fillings. The investment casting process was ushered into the industrial world during World War II, when it was used with alloys and other materials in precision net shape and near-net shape manufacturing.

Today, investment casting is a staple of industrial manufacturing.

Advantages of Investment Casting

Choosing to make investment cast parts has a host of advantages. These include its low production costs, efficiency, lack of waste, reliability and environmental friendliness. In addition, investment cast parts have superior tolerances, excellent surface finishes, no seams and no lines. Also, the investment process allows manufacturers to create complex parts with extra fine details that match the exact specifications of the original design.

- Low Production Costs

- Investment casting has lower production costs than many comparable methods, such as metal fabrication. Requiring less manpower, it slashes capital-consuming labor costs. It also requires the use of fewer resources, and it takes less time. Precision investment casting also saves money because it does not require welding, assembly or finishing work. All of these factors add up to lower production costs that allow you to earn a substantial margin.

- Low Wastage and Fewer Time Delays

- Investment cast parts are much better than machined parts for a number of reasons. For example, if you are considering using machines to prepare your parts, then there are chances that it will lead to a great deal of wastage. Wastage also adds to your production cost, and subsequently, your losses. Furthermore, machining processes can easily become prolonged and delay on-time delivery. On the contrary, investment casting prevents the waste of material and time.

- High Reliability

- Investment casting, along with other similar techniques such as brass investment casting, aluminum investment casting, and forging, stands as one of the most reliable methods of creating machining parts. Engineers have strong control over the process throughout the process.

- Environment Procurement

- Last but not the least, investment casting offers great environmental procurement. In other words, investment casting takes and uses resources in a way that is sustainable for the environment. For example, manufacturers can make most investment cast parts using just 9 wax patterns, most of which can be used time and time again.

- Complexity, Details, and Quality

- Investment casting is effective at producing lightweight, complex and detailed parts that other methods cannot. It allows for a greater design flexibility and metal alloy selection, as well as a superior surface finish. In addition, because the part is made as one whole piece, investment cast parts have no joints or flash lines. This means investment cast parts are more durable and less susceptible to breakage than other products.

Design of Investment Casting

Castings are created either from the original wax model or from wax replicas of an original pattern. The first method is called the direct method. The second one is the indirect method, in which it is not important for the model to be of wax. In the following descriptions, we discuss the various stages of investment casting.

- Creating the Master Pattern

- In the first stage, the engineers create a master pattern for the component that they have envisioned. Creating the master pattern itself is a tedious task, as it may take several hours and even days to come to a perfect pattern that exactly fits into their requirements. The master pattern is crafted on paper, based on the calculation of the artist or the engineer.

- Creating the Mold

- Once you are done with the pattern, it is time to create a temporary mold or permanent mold, based on the measurements from the pattern. The mold is shaped from wax, clay, or plastic, depending upon the preferences of the artist or engineer, or the type of component. However, if an original component has been made from a metal such as steel or alloy steel, you can create its mold using that molten metal alloy. This mold will not only be strong but also highly precise. Rubber and frozen mercury are also used as materials to prepare the mold.

- Producing and Assembling the Pattern

- The wax or the molten waxing material is poured into the mold and is allowed to stay in it until an even and hard coating is accomplished. Per your requirements, you can make numerous wax patterns, and you can also create a large cluster of patterns.

- Applying the Investment Materials

- Investment is the industry term for a ceramic mold, which is a thick result of multiple coatings. During this stage, you create the ceramic mold by coating, stuccoing and hardening a wax pattern cluster over and over again until you reach the thickness you want. This particular stage may take up to a few days.

- Dewaxing Staging

- After the ceramic mold or molds are ready, the most intricate stage, dewaxing, occurs. For a wax mold, this stage may be a straightforward process. But, for the ones that have been created using the metal melt, you will need electric appliances and careful hand motions.

Features of Investment Casting

Investment casting is a straightforward concept: form a mold around a wax pattern that will melt away, leaving a hardened shell that can be filled with molten metal.

The creation of investment cast parts starts with the wax model, which, after it is created, is attached to a channel called a sprue. Several hundred waxes may be affixed to the same sprue forming an assembly called a tree. After the tree is dipped into the slurry multiple times it is sprinkled with coarse material such as sand. Once the investment is thick enough around the wax, it is inserted into an oven where temperatures can reach upwards of 1000°F.

The wax melts and drips out while the investment maintains its size and shape. Manufacturers heat a metal until it melts. Then they pour the molten metal into the hollow shell, where it travels along the lines left by the sprue and fills the impressions left by the wax. When the molten metal is no longer glowing red hot, manufacturers remove the shell and cut the investment cast metal parts off from the sprue. After this, the now solid parts may receive additional machining and finishing. However, they do require less than other methods of casting.

As manufacturers mix the investment, fans and blowers remove the dust which contains silica, a potentially harmful dust that should not be inhaled. They often use vacuums to remove air bubbles from the investment to ensure that all the patterns on the tree are encased in the ceramic slurry free of air pockets. Automated ovens and furnacescontrol the temperature for a precise burnout while other heating equipment can melt the alloys to the appropriate temperature.

Extensive knowledge regarding the chemical formulas and molecular composition of the materials makes it possible for manufacturers to choose specific attributes for the investment cast part, such as durability, magnetism or weight load while avoiding negative characteristics. Science and engineering have helped make the traditional process of investment casting even more successful in the modern age.

Investment cast parts and investment cast products are unique because their success has spanned thousands of years. Investment casting stands the test of time. In addition, investment cast parts are less expensive to make and less taxing on the environment.

Investment Castings Images, Diagrams and Visual Concepts

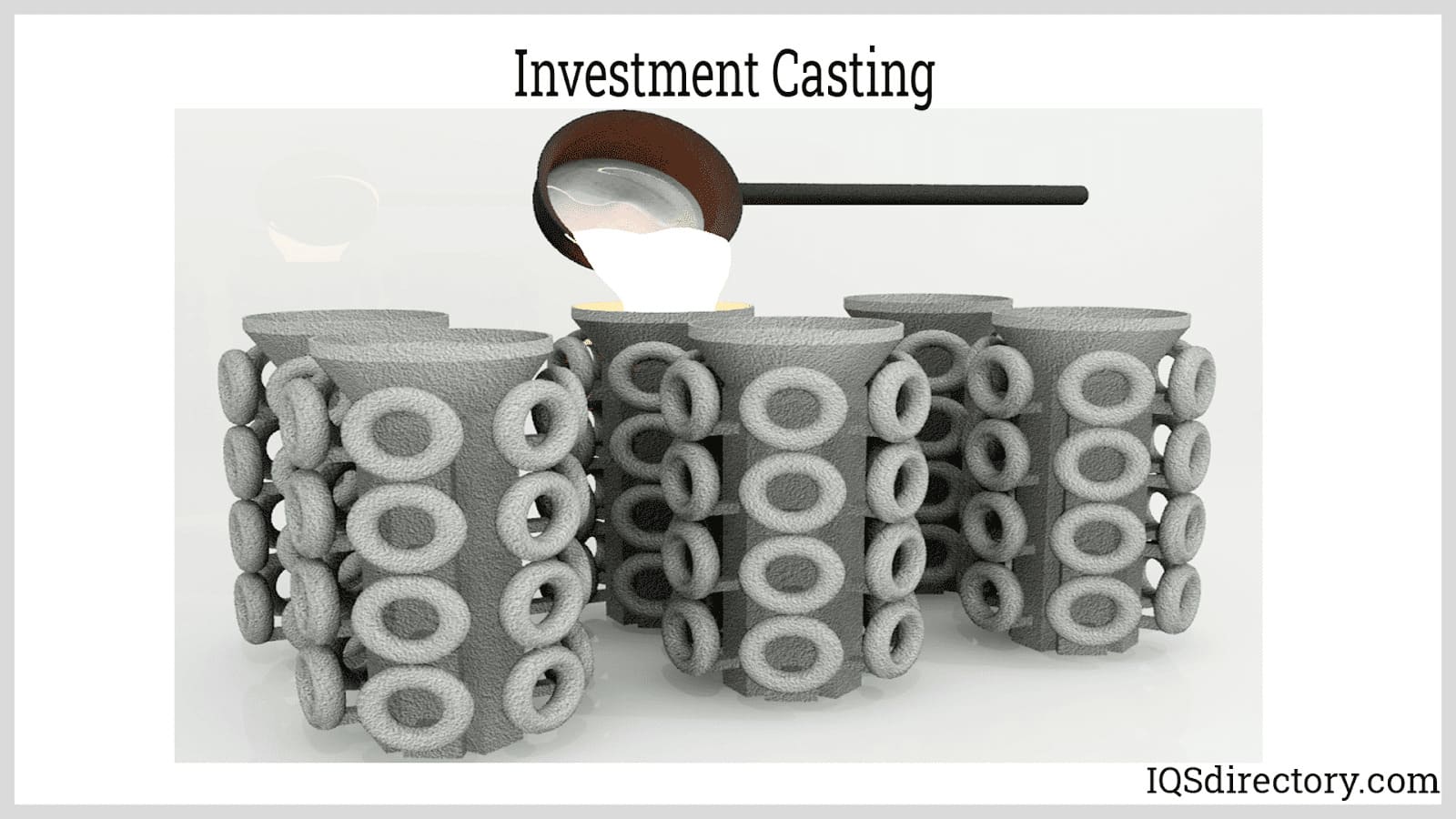

Using a ceramic shell built over a wax pattern which can produce parts with uniformity and even surfaces.

Using a ceramic shell built over a wax pattern which can produce parts with uniformity and even surfaces.

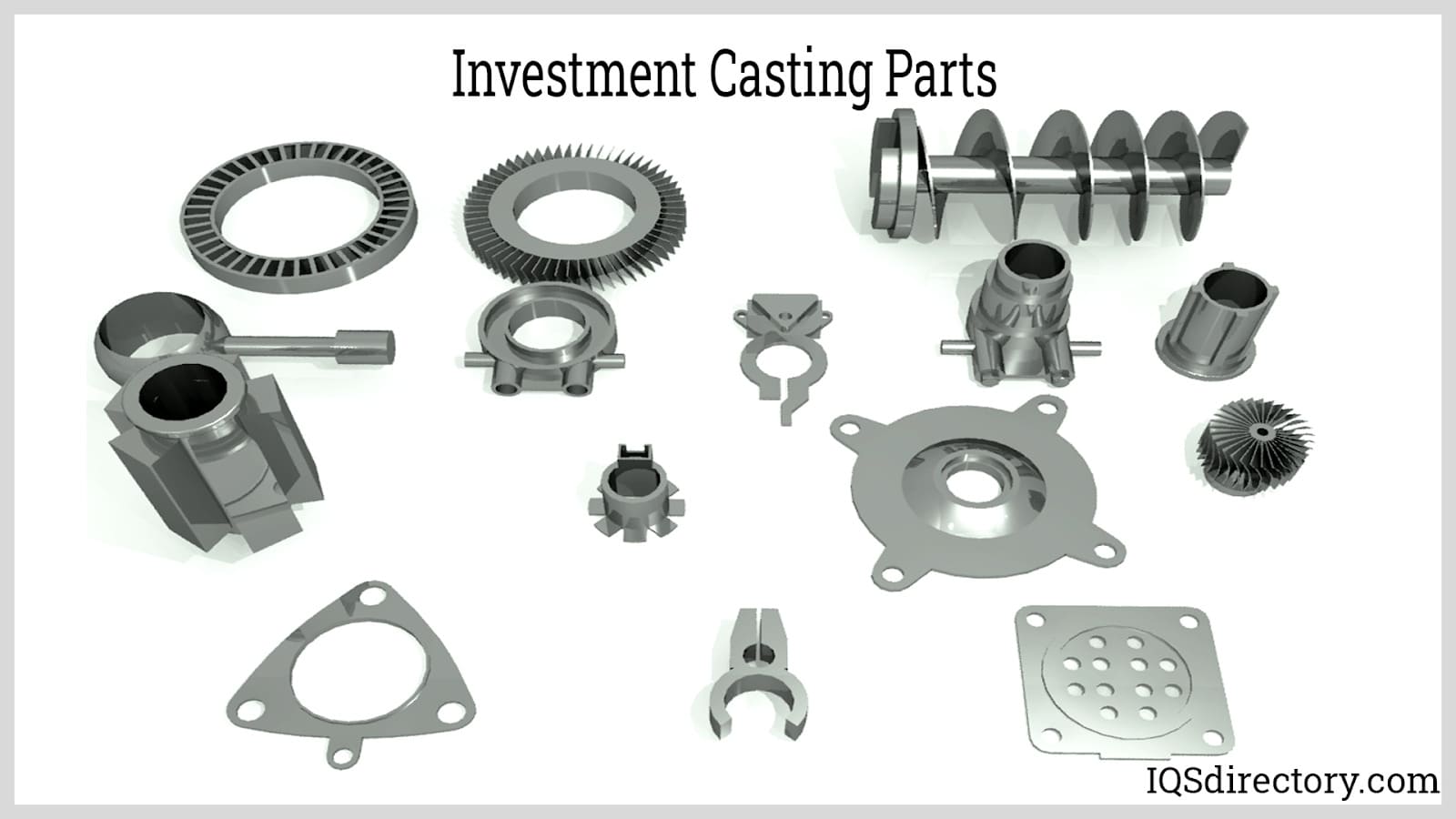

Examples of parts made with investment casting.

Examples of parts made with investment casting.

The common metals used in the casting process.

The common metals used in the casting process.

The equipment is placed vertically and spun at a vertical axis, the molten material is poured into at the top of the casting equipment.

The equipment is placed vertically and spun at a vertical axis, the molten material is poured into at the top of the casting equipment.

The equipment is set horizontal and spun at a horizontal axis while end is sealed, with a pour basin at the opposite end.

The equipment is set horizontal and spun at a horizontal axis while end is sealed, with a pour basin at the opposite end.

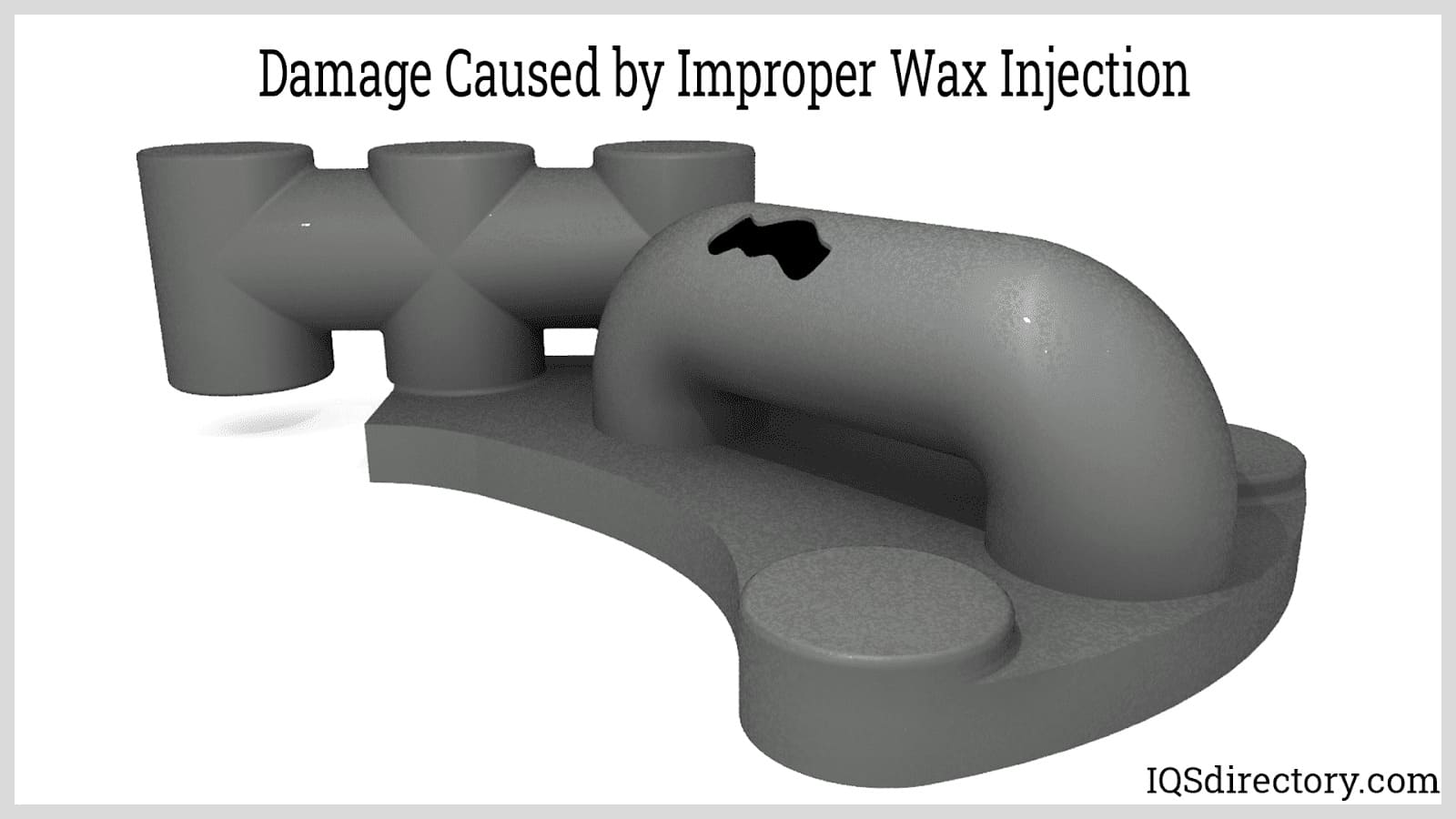

Improperly using the the wax mold could result in damage to the product being molded.

Improperly using the the wax mold could result in damage to the product being molded.

Investment Castings Types

- Aluminum Investment Casting

- The process that produces industrial parts through the metallic replication of wax models. Molten aluminum is used to create parts that have a very smooth surface finish, high dimensional accuracy and acute detail without flash or parting lines. Aluminum and aluminum alloys are among the most commonly used metals for investment casting.

- Brass Investment Casting

- The manufacturing process that creates parts through the metallic replication of wax models. Investment casting using molten brass results in a final product that is very smooth and detailed without flash or parting lines. This technique creates parts that are precise and lightweight.

- Centrifugal Casting

- A manufacturing process that is used to produce parts with thin walls. This technique is generally used for cylinders or for stock parts in standard sizes that are not finalized products.

- Copper Investment Casting

- The process where parts are manufactured through the metallic replication of wax models. The process of investment casting uses liquid copper to manufacture parts that have a very fine, smooth finish and are intricately detailed. Copper investment castings are lightweight and strong. As such, these investment cast products have diverse applications, including pipe fittings, machine tools, mixing equipment, lock parts and jewelry.

- Ferrous Investment Castings

- Cast out of metals that contain iron, including 300- and 400-series stainless steels, carbon and alloy steels and cobalt and tool steels.

- Investment Casting Process

- The method through which industrial parts are produced through the metallic replication of wax models.

- Investment Casting Products

- Parts produced through the metallic replication of wax models. The parts may be made of almost any castable metal including carbon, stainless steel, aluminum, copper, titanium and brass. Because the parts are made from a wax model made to the exact specifications of the intended design, there is a high degree of dimensional accuracy.

- Lost Wax Casting

- Consisted of creating and plastering a wax model, replacing the wax with molten metal and removing the plaster after the metal cooled.

- Non-Ferrous Investment Castings

- Formed from metals that do not contain iron, including aluminum and copper-based alloys.

- Precision Investment Casting

- Refers to the highly precise and reliable method of metal casting also known as investment casting. Investment casting is used to produce complex metal parts in an assortment of sizes, shapes, and weights. Many manufacturers depend on the investment casting process to produce accurate dimensional, precision investment casting parts.

- Stainless Steel Investment Casting

- The process through which parts are manufactured by the metallic replication of wax models. Parts created by investment casting have very fine finishes that require little additional machining. There are no flash or parting lines because the part is made as one whole piece from molten stainless steel. High levels of accuracy and precision are attainable; investment casting can produce parts that are too complex for other methods. Because steel is stronger than cast iron, wrought iron, and malleable iron, steel investment cast products are typically used in the manufacturing of parts that must endure shocks, wear or heavy loads. Also, stainless steel castings are used frequently around hazardous substances or in sanitary environments because stainless steel is easy to clean and resists corrosion.

- Steel Investment Castings

- A type of ferrous investment casting in which casts are made out of stainless and carbon alloy steels. During steel investment casting, free-flowing liquid steel is shaped through the use of molds. Steel investment casting produces small, complex, or hard-to-machine shapes, eliminating the need for assembly, welding, and other finishing work.

- Titanium Investment Casting

- The manufacturing process that produces parts through the metallic replication of wax models. The resulting titanium parts have a very smooth finish that requires little finishing after the process. Investment casting is effective at producing complex and detailed parts that other methods cannot. There are no joints or flash lines because the part is made as one whole piece. Titanium castings are very strong and lightweight and are used for turbocharger components, industrial tools and instruments and other applications in the defense, aerospace, transportation, power generation, marine and medical industries.

- Wax Casting

- A process that uses a wax pattern to create metal parts. Due to the smooth surface of the wax pattern that is used to create a ceramic mold, the resulting parts have a very fine finish that requires little machining. Wax casting is effective at producing complex and detailed parts that other manufacturing methods cannot.

Standards and Specifications of Investment Castings

The standards to which you’ll want your manufacturer to adhere when making your investment cast parts depend upon your application, industry, and region. For example, if you’ve requested a part for a military application, you’ll want it to meet Mil-Specs. Likewise, your investment cast part may need to meet FDA, ADA, OSHA, EPA or any other host of standards. Make sure you know what those are by discussing your industry and your specs with your supplier. For the best and most reliable investment cast parts, you’ll also want your manufacturer to follow the manufacturing standards of ISO (International Standards Organization).

Things to Consider When Choosing Investment Casting

- Questions to Consider With Investment Casting

- Investment casting is a great method that has been proven to work well over thousands of years. If you’re not sure if it’s right for you, though, ask yourself the following questions:

- Does your part require great precision or detail? If yes, consider investment casting!

- Do you need to create parts with close dimensional accuracy? If yes, consider investment casting!

- Are you looking for a machining alternative with high quality and low tooling costs? If yes, consider investment casting!

- What is your application’s weight requirement? Please note that investment casting can only work with applications up to around 695 pounds.

- If your intended application exceeds this limit, do not fear! Consider its cousin, sand casting, which can be used to create castings weighing up to 2204.62 pounds, or 1000 kilograms. In sand casting, manufacturers use a molten metal in place of wax, along with a mold composed by compressing a combination of sand and clay. These molds are created in two parts or pieces. To perform casting, manufacturers put both the halves together and fill them with molten metal. Once the metal cools down, they open the mold, take the new part out and remove the sand and clay from it.

- Considering Design Factors

- Once you’ve made the decision to go with investment casting, consider design factors like required flexibility, desired surface finish, required tensile strength, required weight, production volume, etc.

- Considering a Manufacturer

- The last thing to consider is your manufacturer. There are many talented manufacturers out there, so how do you choose? We recommend that you look for the manufacturer who is dedicated to you and the outcome of your investment (pun intended!) in them. In addition, look for a manufacturer that adheres to the standards of non-destructive testing (NDT). When manufacturers use NDT, they are able to "look into" a part and check it for discontinuities and other imperfections, without rendering the part unusable. Find the one for you by reaching out to and discussing your specifications with one or more of those excellent companies we have listed above.

Proper Care for Investment Castings

How to care for your investment cast product depends entirely upon what it is. So, while we can certainly offer generic recommendations, such as to store your investment cast parts in a dry place, and do not use your investment cast parts in ways that exceed their weight limit, we cannot offer much specific advice. For that reason, in that regard, it’s best to discuss care for your individual investment cast part with your manufacturer.

Casting Accessories

Today's manufacturers are aided by improved equipment that can produce identical investment cast parts again and again. These include 3D printers, mold frames, molding rubber, easy rings, measuring cylinders and bowls, crucible, tongs and more.

Investment Casting Terms

- Alloy

- A compound consisting of either more than one metal or a metal and a nonmetal blended together.

- "As Cast" Condition

- Casting that is not heat treated after being removed from the mold.

- Burnout

- The process whereby excess water and wax is removed from a molding.

- Casting

- Forming and shaping a material substance, such as an industrial piece of equipment, by pouring liquid into a mold and allowing it to harden.

- Cavity

- The empty space within the mold into which the molten metal will be poured.

- Centrifugal Casting

- The process of filling a permanent mold cavity with molten material while rotating the mold. Centrifugal casting is often used during the investment casting process to increase the amount of pressure exerted upon the metal in order to reproduce mold details, such as lettering and holes.

- Ceramic Mold Process

- The process by which an investment mold is created from a pattern in order to be cast. Ceramic molds consist of solid molds and ceramic shells.

- Ceramic Shell Process

- The method of creating a ceramic mold through the immersion of a pattern into a slurry of liquid and covering the coated pattern with sand. The pattern is usually immersed and coated nine to ten times before the shell is completed.

- Cocoon Process

- The method of applying protective plastic to metal.

- Cold Shut

- Lines on the surface of a casting that are the by-product of the incomplete fusion of metal streams.

- Concentricity

- The sharing of a common point or axis of two or more surfaces of shapes, such as cylinders, cones, spheres and hexagons.

- Core

- A form inserted into a mold to create internal mold features.

- Dirty Casting

- A surplus of nonmetal substances within a casting.

- Ferrous

- Pertaining to or containing iron.

- Forging

- The method of reshaping metal through the application of heat and compression.

- Gates

- The openings in the gating system that transfer the molten metal from the runners into the mold cavity.

- Gating System

- The structure that transfers the molten metal into the mold. Gating systems are designed to uniformly transfer the metal into the mold cavity to create an even mold.

- Inclusions

- Small pieces of refractory materials, sand, slag or deoxidation products that have been trapped within the casting while it was solidifying.

- Injection Molding

- The injection of a molten substance, usually metal, under substantial pressure into a mold.

- Lost Wax Process

- An ancient process related to investment casting that consisted of creating and plastering a wax model, replacing the wax with molten metal and removing the plaster after the metal cooled.

- Misrun

- An incomplete casting.

- Mold

- A hollow container from which liquid substances can be formed into solid shapes.

- Molten

- A solid that has been converted into a liquid through the application of heat.

- Non-Ferrous

- Not pertaining to or containing iron. Examples of non-ferrous metals include aluminum- and copper-based substances.

- Pattern

- A casting model created by injecting metal dye with wax. When the wax solidifies, it forms the pattern, which is then molded and cast.

- Pattern Oversize Factor

- A term that refers to the extent to which the pattern size must be increased to allow for metal shrinkage.

- Plaster Mold Casting

- The process in which a wax pattern is sprayed with plaster slurry to create a mold.

- Permanent Mold Casting

- The process of using metal, often iron, to create the mold. Permanent molds are cheaper than sand molds when a large quantity of parts is produced, as they can be used more than once.

- Pouring Cup

- The part of the gating system that pushes the molten metal into a mold.

- Riser

- An open space in a mold into which extra molten metal is trapped.

- Runners

- Horizontal mechanisms connected to the sprue that transfer the molten metal from the sprue to the mold.

- Sand Casting

- The process of pouring molten metal into a natural or an artificial sand mold to form large parts, often made of iron.

- Shell Casting

- The process in which sand and plastic are poured over a hot metal pattern, whose heat causes the sand and plastic to mold to the pattern. The mold is removed from the metal, filled with molten metal and broken once the metal hardens, forming a cast.

- Shrinkage

- The contraction of metal during the cooling process.

- Shrinkage Allowance

- The degree to which a pattern is enlarged to allow for the contraction of the metal during the cooling process.

- Slurry

- The thick, insoluble liquid made of substances like plaster and silica from which a mold is created by repeatedly covering the patterned wax with the liquid.

- Solid Mold Process

- The method in which a wax pattern is placed within a steel container called a flask. The flask is then filled with a liquid plaster, which hardens into a mold of the pattern.

- Sprue

- Vertical mechanism connected to the pouring cup that transfers the molten metal to the runners.

- Straightness

- A term that refers to the deviation of the cast axis from the true axis.

- Vents

- Small holes in the gating system through which air is pushed out of the mold as molten metal is poured into the mold.