Hydraulic Motors

Hydraulic motors (sometimes incorrectly spelled as “hydrolic” motors) convert hydraulic pressure into force that is able to generate great power. They are a type of actuator that converts the pressure of the moving hydraulic fluid into torque and rotational energy.

Hydraulic motors are an important component overall in the field of hydraulics, a specialized form of power transmission that harnesses the energy transmitted by moving liquids under pressure and converts it into mechanical energy. Power transmission is a general term denoting the field of translating energy into usable, everyday forms. The three main branches of power transmission are electrical power, mechanical power, and fluid power. Fluid power can further be divided into the field of hydraulics and the field of pneumatics (translating the energy in compressed gas into mechanical energy).

Quick links to Hydraulic Motors Information

History of Hydraulic Motors

Arguably, hydraulic power traces back to the beginnings of human civilization. For thousands of years, humans have harnessed the power of moving water for energy. (The most basic “hydraulic” application is harnessing moving water to turn wheels.) For a brief survey of hydraulic history, please refer to our article on Hydraulic Cylinders.

In terms of hydraulic motor development, the middle of the Industrial Revolution proved to be a notable turning point. During that year, English industrialist William Armstrong started developing more efficient applications of hydraulic power after observing inefficiencies in water wheel usage on a fishing trip. One of his first inventions was a rotary, water-powered engine. Unfortunately, this invention failed to attract much attention, but it provided an early model for a rotary actuator based on hydraulic power.

Advantages of Hydraulic Systems and Motors

The use of hydraulic systems in general offer several advantages within the overall field of power transmission. Some of those advantages include efficiency, simplicity, versatility, relative safety, etc. These and other advantages are further elaborated on in our article on Hydraulic Pumps.

Hydraulic motors, in particular, have two distinct advantages:

Hydraulic Power

Hydraulic motors are able to produce much more power than other motors of the same size and for this reason are used for larger loads than electric motors.

Hydraulic Motor Compactness

When space constrictions are an issue, small hydraulic motors are used. Small hydraulic motors have small stroke lengths; they may be less than an inch.

A major disadvantage of using hydraulic motors is inefficient usage of the actual energy source. Power systems with hydraulic motors can consume large amounts of hydraulic fluid. For example, it is not uncommon for hydraulically-driven machines on construction sites to require 100 or more gallons of hydraulic oil to operate.

Differences Between Hydraulic Motors and Hydraulic Power Units

Since they are often confused in everyday language, it is important to distinguish between hydraulic motors and hydraulic power packs or hydraulic power units. Technically speaking, an enclosed mechanical system that uses liquid to produce hydraulic power is known as a hydraulic power pack or a hydraulic power unit. These packs, or units, generally include a reservoir, a pump, a piping/tubing system, valves, and actuators (including both cylinders and motors). It is not uncommon, however, to hear a hydraulic motor described as consisting of these components – a reservoir, a pump, etc. However, it is more accurate to describe a hydraulic motor as a part of an overall hydraulic power system that works in sync with these other components. Hydraulic motors are a type of actuating component within an overall hydraulic power system – a component responsible for actually translating hydraulic energy into mechanical energy.

How Hydraulic Power Works

Liquids represent a “median” state between gases and solids on the matter spectrum. Despite this, liquids represent solids far more than gases in an important aspect: they are virtually incompressible. One consequence of this is that force applied to one point in a confined liquid can be transmitted quite efficiently to another point in that same liquid. This reality forms the basis of the mechanical energy that hydraulic systems are able to produce. For a fuller explanation of how hydraulic power works, please refer to our article on Hydraulic Pumps.

How Hydraulic Motors Work

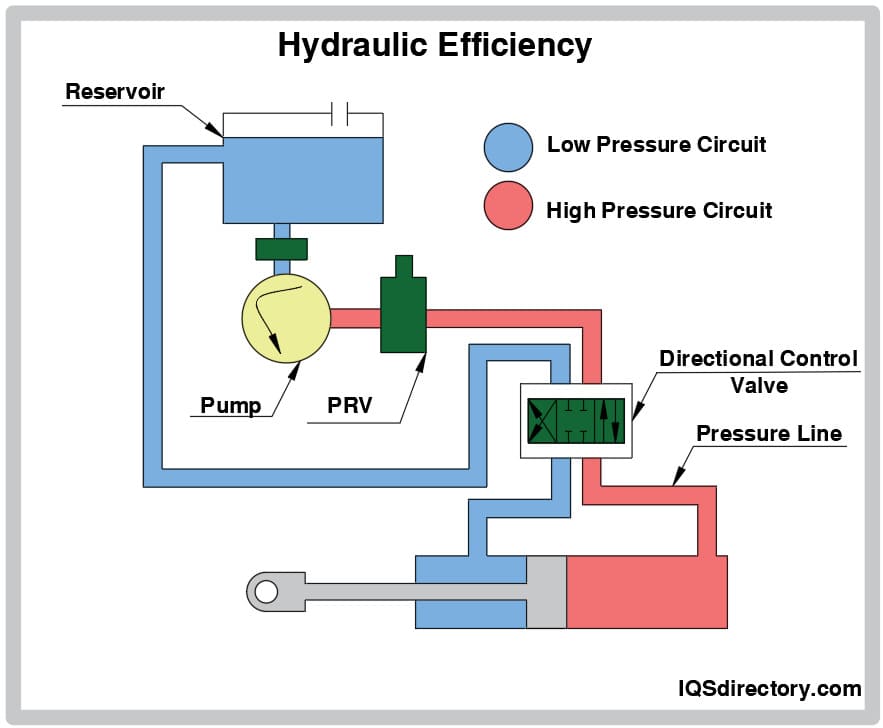

It has previously been noted that “Pascal’s Law” applies to confined liquids. Thus, for liquids to act in a hydraulic fashion, it must function with some type of enclosed system. As noticed in the introduction, these “systems” are known as hydraulic power packs and share three main parts—a reservoir, a pump and an actuator—that work together to convert hydraulic energy into mechanical energy.

Hydraulic motors are an integral part of machines that rely on hydraulic power for operation because they actuate and “complete” the process of converting hydraulic energy into mechanical energy. Since hydraulic motors are fairly simple machines that are composed of rotating machinery, they specifically translate hydraulic energy into rotational mechanical energy. The main enclosure and interior components of the motor are made from metal such as steel or iron so they can withstand high pressures and operating speeds. In a sense, motors can be thought of as hydraulic pumps working “backward” or in reverse.

Overall, a hydraulic power unit pumps fluid (usually a type of oil) via a small pneumatic engine from a reservoir and sends it to the motor while regulating fluid temperature. Oil is pumped from the reservoir through an inlet valve to an outlet valve through a series of gears, turning vanes or cylinders, depending on what specific type of hydraulic motor it is. Pressurized fluid creates mechanical energy and motion by physically pushing the motor, causing the rotating components to turn very quickly, and transferring energy to the machinery that the motor is linked to. Typically, not every rotational component is directly connected to producing mechanical energy; for example, in a typical gear motor, only one of the two gears is connected to and responsible for turning the motor shaft. This type of operation directly contrasts with electric engines, in which electromagnetic forces produced by flowing electric current are the response for rotating the motor shaft.

Hydraulic Motor Images, Diagrams and Visual Concepts

Hydraulic motors, rotary or mechanical actuators which is operated by the conversion of hydraulic pressure or fluid energy to torque and angular displacement.

Hydraulic motors, rotary or mechanical actuators which is operated by the conversion of hydraulic pressure or fluid energy to torque and angular displacement.

Mechanical efficiency, measures the effectiveness in a machine or mechanical system.

Mechanical efficiency, measures the effectiveness in a machine or mechanical system.

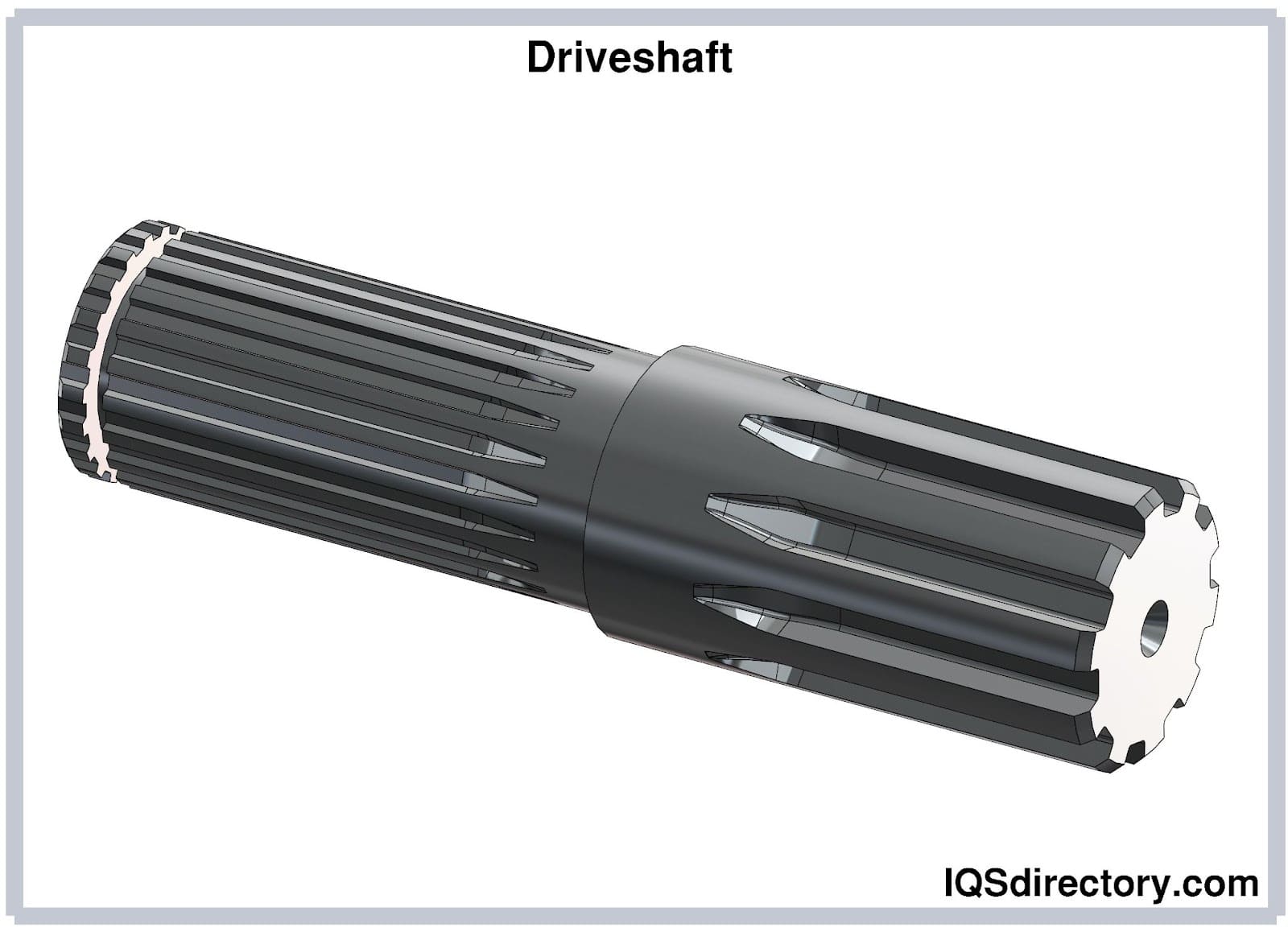

Driveshaft, a part of the hydraulic motor that delivers or transfers the torque created inside the motor to the outside environment where it is used for lifting loads and other applications.

Driveshaft, a part of the hydraulic motor that delivers or transfers the torque created inside the motor to the outside environment where it is used for lifting loads and other applications.

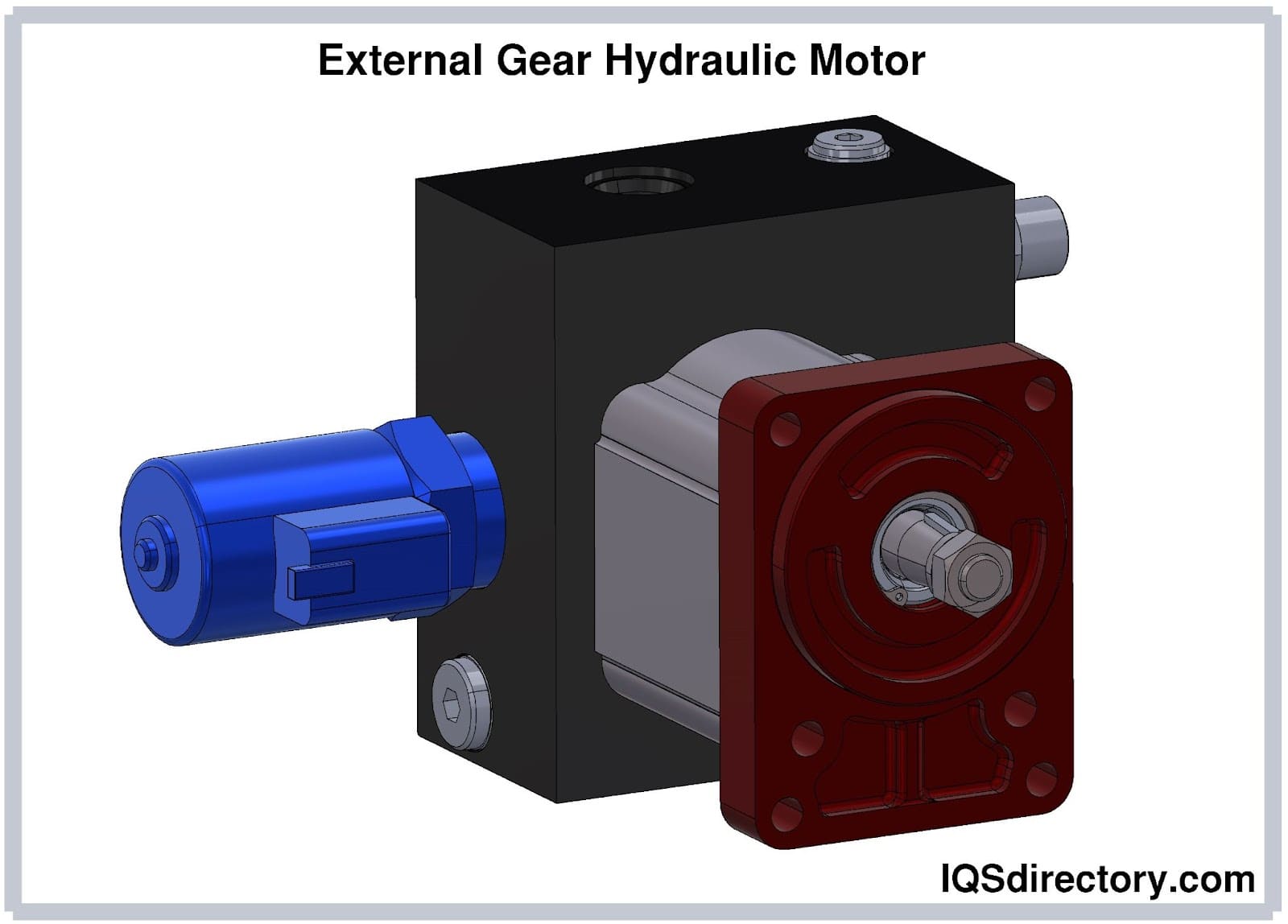

External gear hydraulic motors, operates under high pressure and for longer periods of time.

External gear hydraulic motors, operates under high pressure and for longer periods of time.

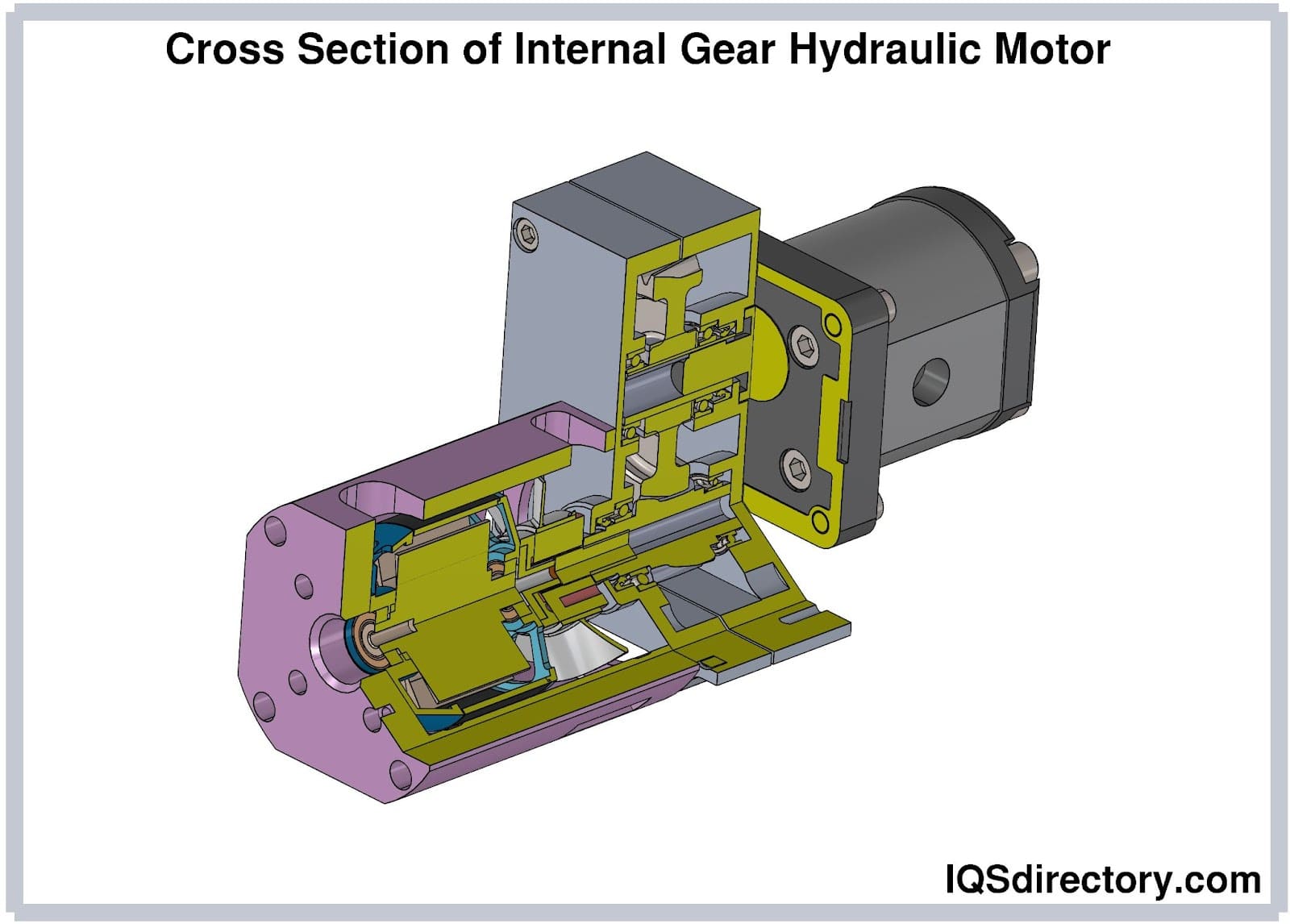

Internal gear motors, low weight and light size allows for smooth operation of the gears.

Internal gear motors, low weight and light size allows for smooth operation of the gears.

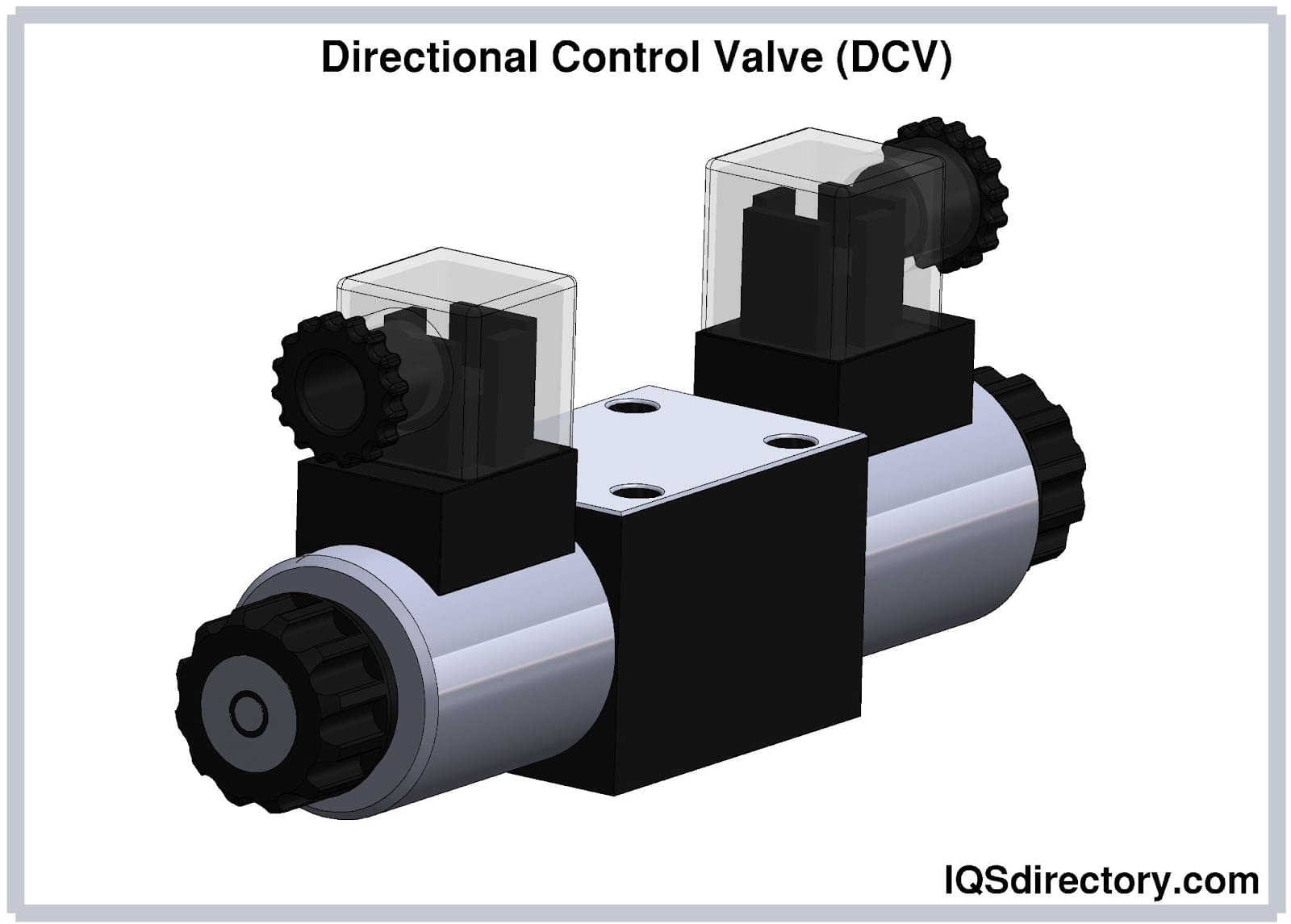

Directional control valves are designed to control fluid flow inside the motor.

Directional control valves are designed to control fluid flow inside the motor.

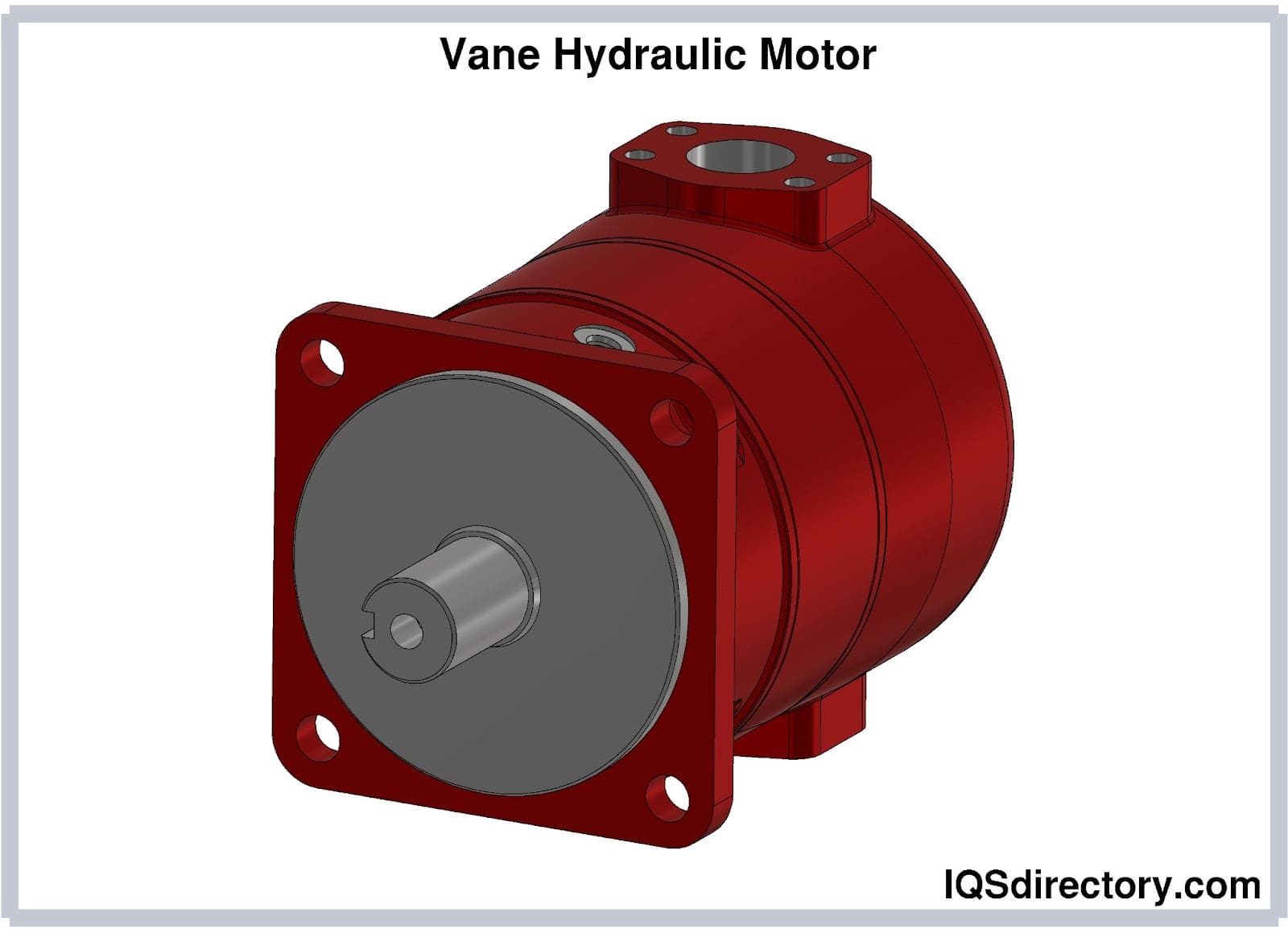

Vane hydraulic motors have a hydraulic balance that prevents the rotor from sideloading the shaft, with the pressure difference develops the torque as the oil from the pump is forced through the motor.

Vane hydraulic motors have a hydraulic balance that prevents the rotor from sideloading the shaft, with the pressure difference develops the torque as the oil from the pump is forced through the motor.

Types of Hydraulic Motors

There are three basic kinds of hydraulics motors: gear, vane and piston type. Each is identified by the design of the rotating component inside. Collectively, the various types of hydraulic motors are optimal for a wide range of specific applications, conditions or usages.

- Hydraulic Gear Motor

- Fluid is pumped into the gear box at high pressures which rotates the gears, generating energy.

- Piston Type Motors

- Another common type of hydraulic motor. Radial piston hydraulic motors have pistons mounted around a center shaft that is eccentrically balanced. Fluid causes the pistons to move outward, causing rotation. Axial piston hydraulic motors derive their name from the fact they use axial instead of radial motion, despite their similar design to radial piston motors.

- Hydraulic Vane Motors

- Take their name from the vanes (rectangular blades) that slide in and out of slotted rotors as fluid is forced into the motor through an inlet port.

- Hydraulic Wheel Motors

- Built into wheel hubs to supply the power needed to rotate the wheels and move the vehicle. A hydraulic wheel motor can operate a single wheel or multiple wheels, depending on the power of the motor and the size of the machine.

- Speed and Torque Motors

- Other motors focus on the rotational speed and torque. High speed hydraulic motors convert hydraulic pressure into force at elevated rotations per minute thereby generating large amounts of power. High torque hydraulic motors run at low speeds while operating with increased torque, thus earning the name low speed-high torque (LSHT) motors.

- Hybrid Hydraulics

- Advances are still being made to hydraulic motors and their various applications. One example is the development of hybrid hydraulic automobiles, which are being developed as an alternative to gas/electric hybrid cars. Hybrid hydraulic vehicles are particularly efficient at reclaiming energy when braking or slowing down.

- Hydraulic Drive Motors

- Used in systems with cylinders, pumps, valves and other components.

- Hydraulic Drum Motors

- An advanced and highly efficient conveyor drive system in which the motor, transmission and bearings are totally enclosed within the drum shell.

- Hydraulic Pump Motors

- Used in systems with cylinders, pumps, valves and other components.

- Roller Hydraulic Motors

- A type of orbital hydraulic motor, have rollers that are hydro-dynamically supported to minimize friction, ensuring maximum durability and high output at high pressure.

- Rotor Hydraulic Motors

- A type of orbital hydraulic motor, are particularly suited for long working cycles at average pressure. Rotor motors are operated by lobes that are fixed and set directly on the stator.

Applications of Hydraulic Motors

Hydraulic systems and their use are abundant in a wide variety of fields including construction fields, agricultural fields, industrial fields, transportation fields (e.g. automotive, aerospace), various marine work environments, etc. Hydraulic motors are commonly used in machinery that requires strong pressurized actions such as aircraft for raising the wing flaps, heavy duty construction vehicles such as backhoes or crane industrial lifting or for powering automated manufacturing systems. Hydraulics motors are also used in trenchers, automobiles, construction equipment, drives for marine winches, waste management and recycling processes, wheel motors for military vehicles, self-driven cranes, excavators, forestry, agriculture, conveyor and auger systems, dredging and industrial processing.

Things to Consider When Purchasing Hydraulic Motors

While hydraulic power transmission is extremely useful in a wide variety of professional applications, it is generally not recommended to use only one form of power transmission. Although it is somewhat counter-intuitive, the maximum benefit of each form of power transmission (electrical, mechanical, pneumatic, and hydraulic) occurs when each form is integrated into an overall power transmission strategy. As a result, it is worthwhile to put in an effort to find honest and skilled hydraulic manufacturers / suppliers who can assist you in developing and implementing an overall hydraulic strategy.

You should also make sure to discuss the pros and cons of different motors with your manufacturer in order to select the best one for your specific application. For example, vane motors generally cost less than piston type motors. However, they generally do not achieve the same efficiency as piston type motors, nor do they typically last as long. Properly identifying and weighing different factors such as these will enable you to choose the right motor for the right application.

Proper Care for Hydraulic Motors

Despite the apparent simplicity of hydraulic systems, engineers and manufacturers must take into account certain variables in order to build an efficient and safe device. The fluid used in the motor or system must be a good lubricant, first and foremost. It should also be chemically stable and compatible with the metals inside the motor. The pump, fluid reservoir and relief valves should be of appropriate power, capacity or strength to allow the motor to perform at optimum levels.

Problems with Hydraulic Motors

Problems with hydraulic motors can often be traced to poor maintenance, the use of improper fluid within the motor, or improper usage of the motor itself. Some not uncommon causes of motor failure are:

- Internal Leakage (from lines that feed the motor, etc.)

- Bad Motor Alignment (e.g. misalignment of the motor shaft during an installation)

- The Use of Dirty Hydraulic Fluid

You should never delay diagnosing and correcting the root cause of motor failure whenever it occurs.

Motor Limits

It is important to keep in mind that hydraulic motors are designed to function within certain limits which should not be exceeded. Those limits mainly include torque, pressure, speed, temperature, and load. To give one example, operating a hydraulic motor at excessive temperatures thins hydraulic fluid, negatively affects internal lubrication, and decreases overall the efficiency of the motor. Staying within a motor’s operational limits will preempt unnecessary and needless malfunctions.

Hydraulic System Safety

In terms of safety, the relative simplicity of hydraulic systems and components (when compared to electrical or mechanical counterparts) does not mean they should not be handled with care. A fundamental safety precaution when interacting with hydraulic systems is to avoid physical contact if possible. Active fluid pressure within a hydraulic system can pose a hazard even if a hydraulic machine is not actively operating.

Hydraulic Motor Terms

- Aeration

- Air in hydraulic fluid.

- Accumulator

- A container that stores fluid under pressure. Accumulators, the common types of which are piston, bladder and diaphragm, are used as an energy source or to absorb hydraulic shock.

- Cylinder

- A device that converts hydraulic energy into linear mechanical motion and force.

- Displacement

- The amount of fluid that passes through a pump, motor or cylinder in a period of time or during a single actuation event, such as a revolution or stroke.

- Dry Friction Coefficient

- The degree of friction that results from the contact between the moving surfaces of a motor shaft.

- Filter

- A device within a hydraulic system that is used to remove contaminants from the oil.

- Fluid Power System

- A system that utilizes fluid pressure to transmit and control power.

- Gear

- A toothed wheel used to transfer mechanical energy.

- Hydraulics

- The science dealing with the transmission of force through the medium of a contained fluid.

- Hydraulic Tester

- A device that is used to troubleshoot and check hydraulic-powered system components.

- Line

- A tube, pipe or hose that acts as a conductor of hydraulic fluid.

- Oil

- A slippery and viscous liquid that is not miscible with water. Oil is often used in hydraulic systems because it cannot be compressed.

- Piston

- A cylindrical piece of metal that moves up and down inside the cylinder of a hydraulic motor.

- Pressure Plate

- A plate on the side of a gear or vane pump or motor cartridge that is used to keep clearance and slippage to a minimum.

- Pump

- A mechanical device that transports liquids and gases by suction or pressure.

- Resistance

- In hydraulics, the condition engendered by an obstruction or restriction in the flow path.

- Shaft

- A device that is mechanically attached to the work load and provides rotary motion in motors.

- Stroke

- The movement of an element of a valve spool, cylinder rod or pump or motor displacement in a straight line that sets the limits of motion.

- Throttle

- A restriction to the normal flow of fluid.

- Torque

- The measure of the force applied to produce rotational motion, usually measured in foot-pounds.

- Valve

- A device that controls fluid flow rate, direction or pressure.

- Vane

- In a hydraulic motor, a flat surface that rotates and pushes against the fluid.