Gaskets

In industrial terms, a gasket, or an industrial gasket, is a mechanical seal used to bridge the gap between two surfaces. Gaskets work very simply. Resting in a space between two parts, gaskets create a pressure-tight seal that does not allow any leakage into or out of the component they are sealing. They put an end to the potential for leaks from or into products or areas. They ensure the smooth and proper functioning of many of the gadgets and equipment we use in our everyday lives.

Quick links to Gaskets Information

Applications of Gaskets

The purpose of gaskets is to create seals at the point of connection between two pieces of equipment or two separate stationary components. Gaskets are used where tight pressure is required. They ensure that the environment inside the housing does not come into contact with air, liquid, contaminants, or anything else from the outside environment. In applications in which liquids or gasses are transmitted through pipes, hoses, or tubing, gaskets prevent leaking and loss of pressure at connection points.

Gaskets of all shapes, sizes, and compositions are used for sealing applications. Some of the industries that make use of gasket manufacturing include the aerospace, automotive, appliance, aviation, consumer goods, electronics, food and beverage, military, and transportation industries.

In commercial aircraft, for example, gaskets throughout the aircraft keep the cabin from depressurizing. In addition, gaskets are used to make pressure cookers work. Finally, airframes, appliances, business machines, compressors, elevators, escalators, medical equipment, meters, turbines, pumps, valves, engines, plumbing systems, and a host of other varieties of equipment require the use of gaskets in order to function safely and effectively.

History of Gaskets

Gaskets have historically played an important role in the safe operation of equipment. Gasket failure can have catastrophic consequences, as was the case in the explosion of the Challenger space shuttle in 1986. The failure of an O-ring seal used in the shuttle's fuel system was attributed to low-temperature exposure, which made it become brittle.

The first gaskets of sorts were made in 1820; at that time, manufacturers made solid iron sulphate seals from a combination of water, pack iron filings, and Sulphur powder. Prior to the 1840s, people also made gaskets by picking apart rope and packing it into seams with lubricant or tar, depending on the application. They also used leather gaskets for water pumps, which would eventually degrade and tear apart.

Manufacturers used to make extensive use of asbestos as well. The first asbestos gasket was developed in 1899. For years, asbestos gaskets were used on locomotives, on Navy ships, and with mechanical systems that transported materials like grease, hot oil, and gases. Asbestos gasket use was popular until the 1980s, when scientists discovered its links to cancers. Since the 2000s, asbestos has been highly regulated, and its use is discouraged.

Gaskets didn’t really advance until after the discovery of vulcanization in 1850. With this discovery, scientists and engineers were able to begin experimenting with rubber. Of particular importance to the gasket manufacturing industry have been advancements in the field of synthetic rubber development. Synthetic rubber materials have allowed researchers to develop heat resistant gaskets, chemical resistant gaskets, and gaskets with a host of other useful qualities. Today, while gaskets can also be made from plastic polymers, metals, fibers, and more, they are most often made from synthetic rubbers, including custom rubbers like custom neoprene.

Gasket Design and Customization

Most rubber gaskets are die cut or punched from flat rubber or metal sheets. (A gasket with shapes punched from a sheet is known as a sheet gasket; a gasket with die cut shapes is known as a die cut gasket.) Die cutting allows a gasket manufacturer significant design flexibility. A die cut gasket can be cut into a shape as simple as a basic ring or as complex as an automotive engine block. Some applications require simple gaskets with thick, strong construction. It does not make sense to make gaskets such as these with die cutting. For these, manufacturers can choose rubber molding, compression molding, or liquid injection molding as die cutting alternatives. Also, some gaskets can be laser cut or water jet cut. Laser cutting and waterjet cutting both offer precision and minimum wasted material. Finally, some gaskets are formed when manufacturers place a rubber sealing ring in the center of a washer; in this case, the sealing ring is molded to fit over a bolt.

Common elastomeric materials used to make gaskets include silicone, neoprene, nitrile (nitrile rubber), EPDM, Viton, and custom rubber. Rubber is the most effective material for gaskets, but gaskets are also made from a wide range of metals, semi-metals, foams, fibers, and other composite material types. Plastics commonly used to make either gasket material or for jacketing include Teflon, nylon, polyethylene (PE), polyurethane, and Mylar. Sponge rubber, like open or closed cell silicone, is used for applications requiring a flexible rubber seal. Gaskets are also made out of non-asbestos sheets such as carbon filament, flexible graphite, fiberglass, ceramics, or Kevlar. A gasket made from any one of these materials may be called a non-asbestos gasket.

Gaskets are unique because they allow less than perfectly matched mating surfaces. They allow because they fill in the gaps between them, no matter their shape. As such, gaskets can be customized in all sorts of ways; they range in their design from very simple to very complex, come in all shapes and sizes, and are used for a broad range of sealing applications. You can customize even the simplest type of gasket, the o-ring, or you can get a more complex custom gasket. If you want, for example, you can have your gasket textured to fit into a connection point more effectively. Typical textures include tapered, ridged, and grooved. However, in order to create a tight seal between two objects, you can ask for virtually any die cut or molded shape.

Advantages of Gaskets

- Control Over Connections

- In addition to the increasing availability of new gasketing materials, innovative gasket configurations have given professionals control over the most demanding and irregular connections.

- Efficiency

- The soft, malleable material of gaskets conveniently and efficiently works between the parts where it is placed.

- Effectiveness

- Gaskets work incredibly well. Pressure-tight closures enforced by gaskets can strongly resist the impact of pressure, temperature, and several other factors, such as an electromagnetic field.

- Improved Safety

- Innovations in gasket design and gasket manufacturing have contributed significantly to improved safety and efficiency of all kinds of industrial products: vehicles, pumping equipment and pipelines are just a few examples. Furthermore, gaskets play a very important role in any system that uses them, especially when toxic chemicals or liquids are involved and a spill could place harm on surrounding people and the environment.

Gasket Installation

When installing gaskets, the first thing you need to do is clean your mating surfaces. They need to be clear of dirt, oil, water, and anything else that could get in the way of a high-quality seal. After that, lay your mating surface flat and, if necessary, apply a thin layer of adhesive. The best adhesive for this is a pressure sensitive adhesive. Place it in position, add the gasket, and, if you’re using adhesive, continue to apply it in order to seal it. If not, skip this step and go on to connecting the gasket to the other mating surface. After this, if applicable, let your adhesive sit. If not applicable, another great way to get a better seal is to tighten your gasket with a wrench. This will compress your gasket uniformly.

Note: Because there are so many different ways that you can use gaskets, gasket installation can vary. For advice on gasket installation for your application, talk to your supplier.

Proper Care of Gaskets

In order to stay up to snuff, gaskets need occasional cleaning. Depending on where they’re being used, that cleaning can manifest itself in different ways. For example, refrigerator gaskets are best cleaned with warm water, baking soda, and a scrub brush. This non-toxic cleaning method also neutralizes odors. Gaskets that can be submerged in water, such as pressure cooker gaskets, should simply be washed in warm, soapy water. Make sure to let them air dry. Gaskets used for other applications, such as vehicles, can also be washed with soap and water. Just make sure to use a gentle cloth so that you don’t scratch them.

No matter how well you keep up your gaskets, they will most likely need to be replaced at some point. Quick tip: if they’re cracked or leaking, it’s time to replace them. When you do so, make sure to scrape off all of the residue from the old gasket first. You always want to start with a clean, flat surface.

To help prolong the life of your gaskets, also consider investing in a wax solvent or a rubber protectant. Products like these can shield your gaskets from the detrimental effects of UV light, heat, and moisture.

Gasket Standards and Compliance

The standards to which gaskets must adhere depend largely on the application or industry for which they are intended. For example, sanitary gaskets or gaskets intended for pharmaceutical purposes must be up to FDA and USP Class VI standards. Your gaskets will likely also need to fit the standards of the region or country they’ll be working in. The most common standards are BS10 (British/Australian), PN/DIN (European), ASA/ANSI (USA), and JIS/KS (Japanese/Korean).

It’s also a good idea to get gaskets that adhere to ASME and/or ISO standards.

Points to Consider When Selecting a Gasket

When you’re searching for the perfect product for your gasket and seal application, keep these things in mind:

- Heat Resistance

- Make sure to check with your supplier regarding temperature resistance in relation to gasket material. The gasket that you select should be able to bear the temperature that your process employs. Different gasket materials support different degrees. For example, a neoprene gasket can support any temperature between -35° and 225°, and a Garlock Gylon PTFE gasket can work efficiently between -450° and 500°.

- Environmental Resistance

- Ask whether the gaskets you select will support environmental (e.g., gas, liquid, air, and pressure) health as it relates to your application. EPDM, or ethylene propylene diene monomer, is an exceptionally resilient synthetic rubber that is safe and good for almost all environments. See if the EPDM gasket is right for your application by talking to your internal engineers or external gasket suppliers.

- Pressure Resistance

- You also need to understand how much pressure the gasket material you are evaluating can withstand. The gasket should be hard enough to bear the load applied by the mating surfaces. Also ask for compression and pressure tests performed by a trusted lab.

- Have the Measurements On-Hand

- Often, gaskets fail to create a perfect seal just because they are the wrong size. Without the perfect seal, they won’t function properly. To make sure you don’t make this common mistake, prepare your measurements ahead of time and have them on hand while shopping. For the best results when preparing measurements and selecting gaskets, seek size suggestions from your process engineers.

- Consider the Material Properties

- As we mentioned earlier, gaskets are available in an array of materials, from thermoplastic rubber, to fiber. Note that all gasket materials are suitable for all industrial applications. Some processes employ extreme temperatures, while some appliances need shock-resistance, and many need rock-solid joints. Different materials render varying benefits; therefore, during selection, you should carefully consider the material of the gasket.

- Determine Chemical Resistance

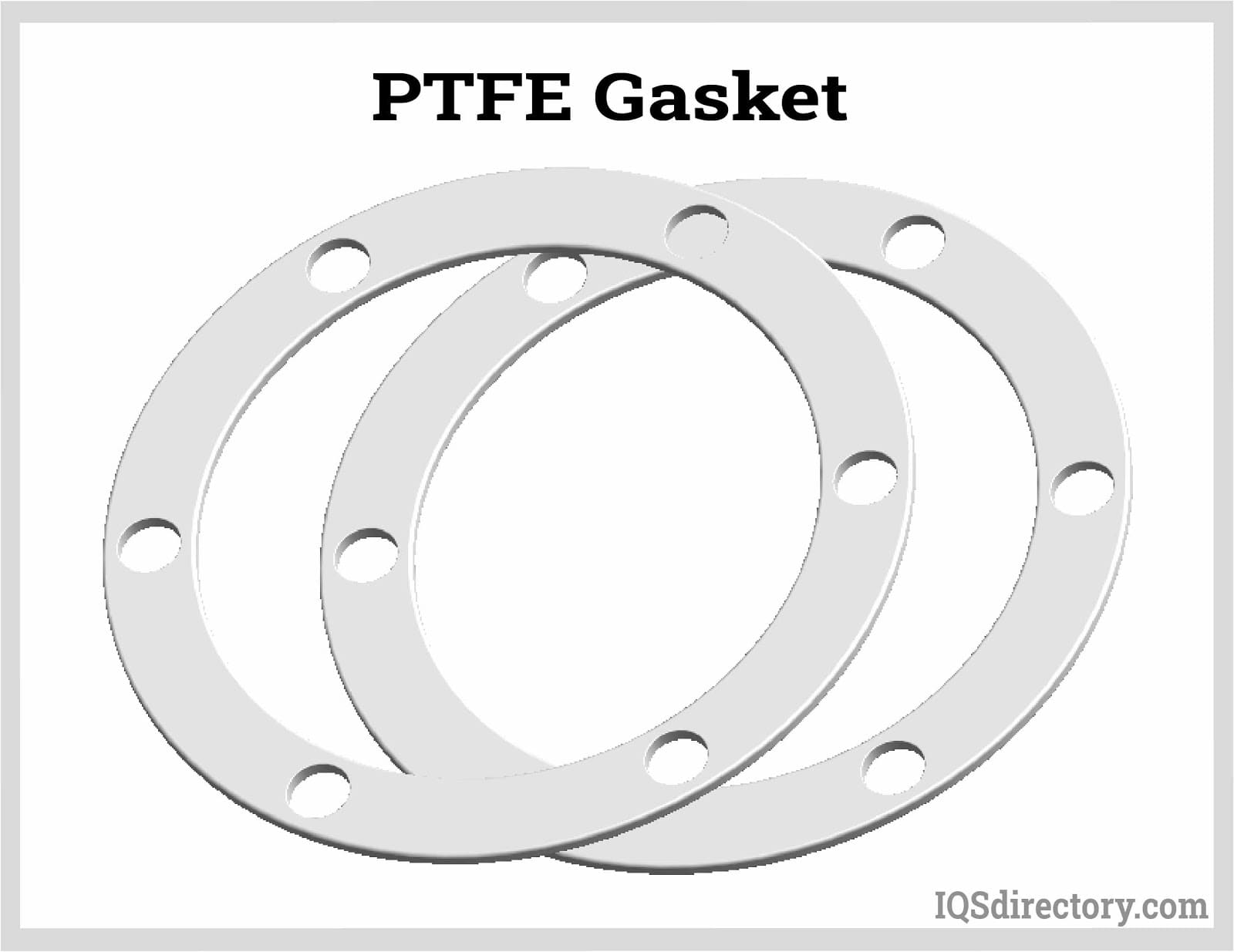

- Metal and metallic gaskets are useful for heavy-duty applications. While gaskets made of these materials can provide superior sealing for tough and weighty industrial procedures, they may not be suitable for processes that involve acidic or alkaline solutions. It is important to test the chemical resistance of the material in question. Match the chemical resistance of your gasket's material with the severity of chemicals in your process fluid. Polytetrafluoroethylene (PTFE) is one such material that has a strong resistance against fluids of 0 to 14 pH levels. However, this material may not be ideal for certain heavy applications.

- Conduct or Request Performance Tests

- Another important task in evaluating gaskets is to test the performance of each industrial gasket. This step is crucial to ensure the gasket that you have chosen for your application is most suitable. Some of the tests that should be performed include hot and cold compression, and a creep relaxation test. These tests can help you determine the temperature, pressure and negative force resistance of the gasket.

- Here are two ways to select a reliable gasket manufacturer:

- The Google Method

- Enter your desired keyword. For example: gasket manufacturers/suppliers in (your city).

- You will find the sites of different vendors who deliver gaskets in your city/state.

- Check out their site and offerings, then request a quote from a handful of suppliers.

- Partner with the one that matches your requirements.

- Through Directory

- Search for the business directory of your city/state/country. IQSdirectory.com is one such business directory. Locate the search box at the top of every page and enter your search term.

- Browse through the list of manufacturers and suppliers, then contact them.

- Evaluate their price quote and sign the contract.

- No matter how you choose to find your manufacturer, before deciding to do business, you need to make sure that they’re the right one for you. How do you know this? Simple: the right manufacturer will treat you with deference, respect, and care. They’ll work within your timeline, budget, and custom gasket requirements. Remember: customer service is key.

Gasket Images, Diagrams and Visual Concepts

Gaskets are mechanical seals that prevent leakage by filling the gaps between static mating surfaces.

Gaskets are mechanical seals that prevent leakage by filling the gaps between static mating surfaces.

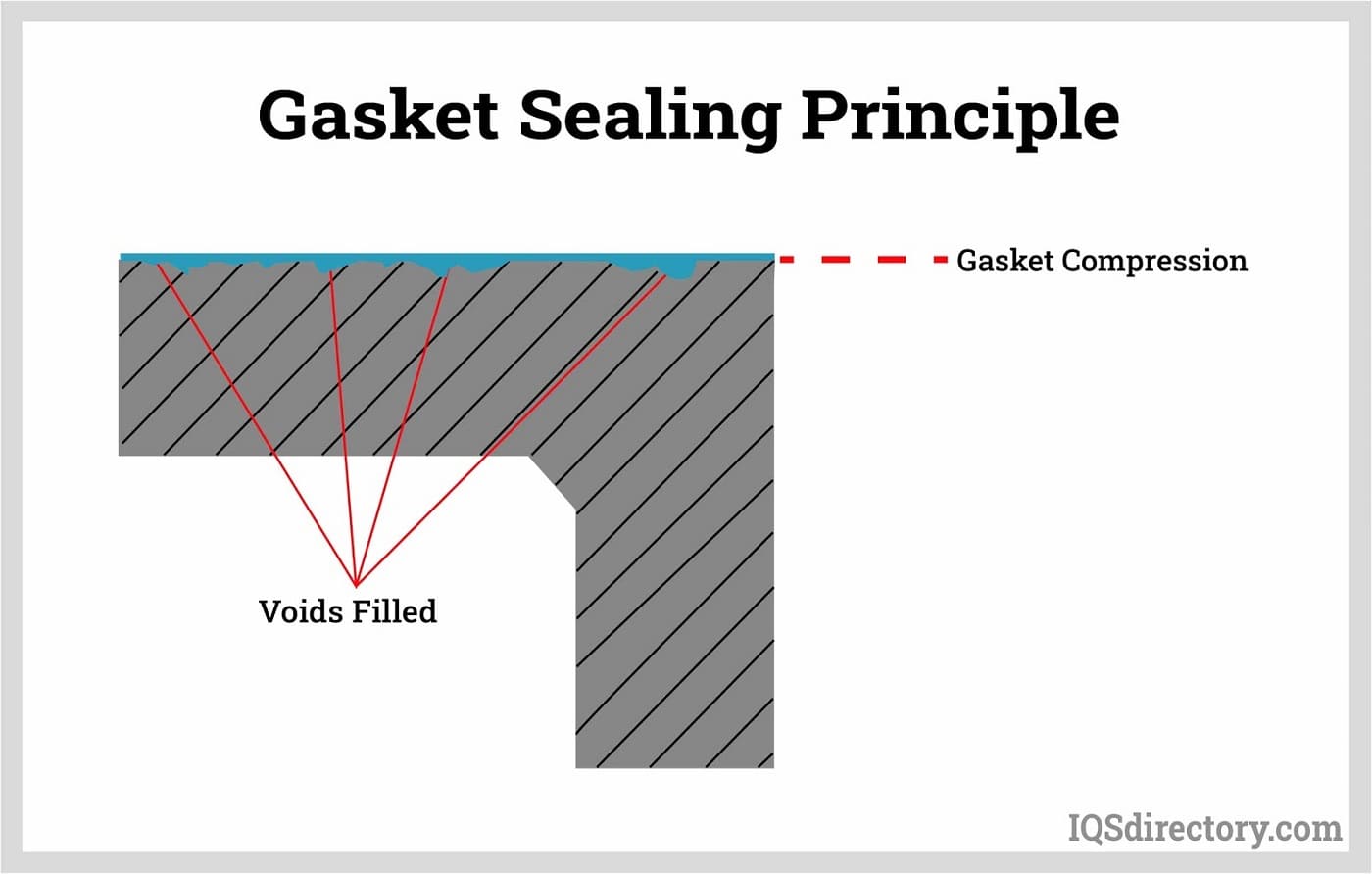

The compressive force deforms the gasket and conforms to the surface profile and fills the gaps between its peaks and troughs.

The compressive force deforms the gasket and conforms to the surface profile and fills the gaps between its peaks and troughs.

Rubber gaskets are elastic components for sealing the microscopic gap between two mating surfaces or joints.

Rubber gaskets are elastic components for sealing the microscopic gap between two mating surfaces or joints.

Head gaskets, a motor engine component that seals the combustion part of the engine so that oil and the motor coolant circulate.

Head gaskets, a motor engine component that seals the combustion part of the engine so that oil and the motor coolant circulate.

PTFE, a strong material, various materials are added as fillers to reinforce its natural mechanical properties and strength.

PTFE, a strong material, various materials are added as fillers to reinforce its natural mechanical properties and strength.

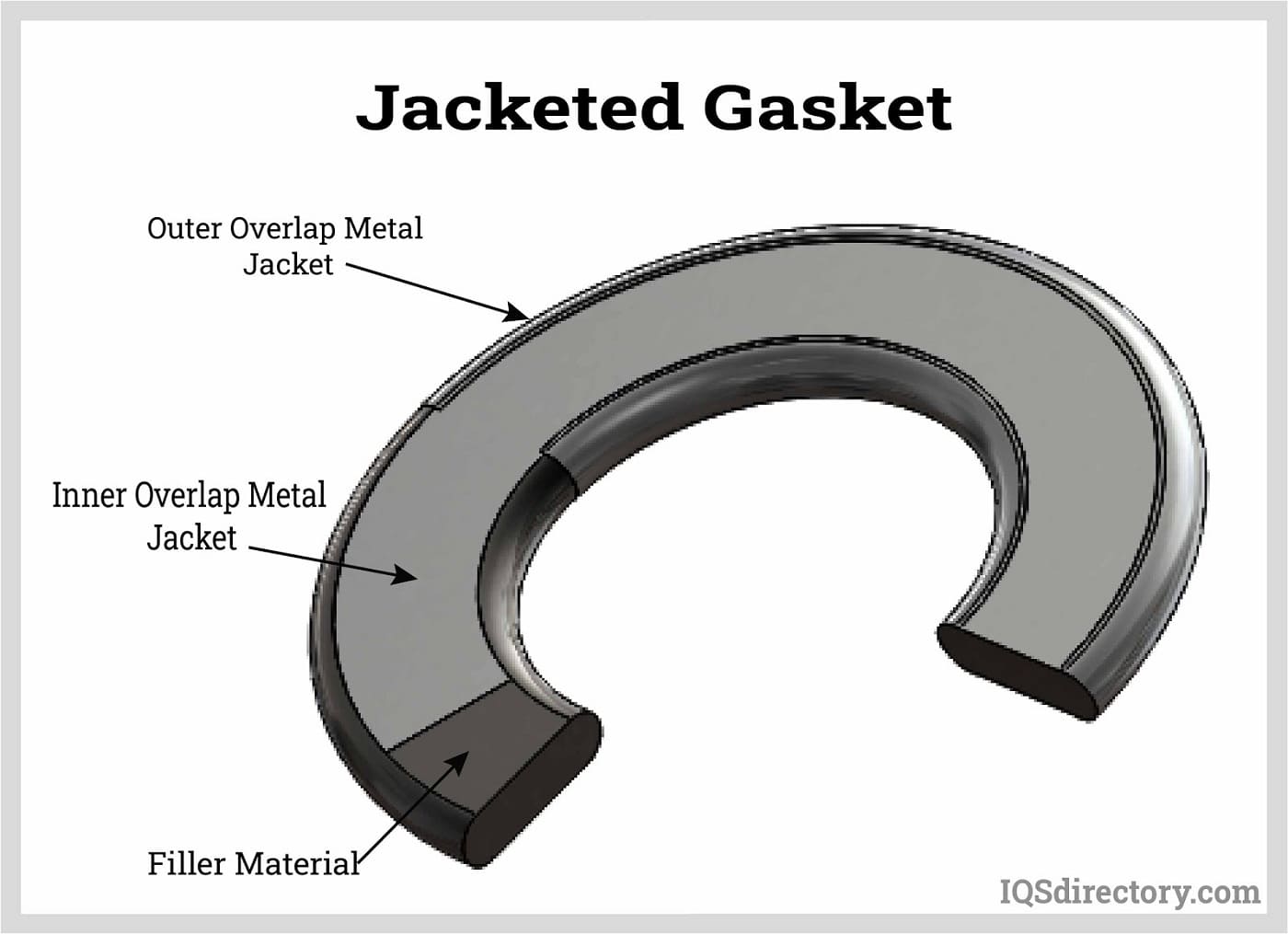

Jacketed gaskets filler material is partially or entirely enclosed in a metal jacket to create a compressive load.

Jacketed gaskets filler material is partially or entirely enclosed in a metal jacket to create a compressive load.

Notable Types of Gaskets

Different types of seals are utilized to make a joint or compartment leak-proof. Some of the most common types include O-rings, head gaskets, spiral wound gaskets, flange gaskets, and shims. Other gaskets are specialized for specific applications. For example, an exhaust gasket is used only for exhaust management purposes. Likewise, high temperature gaskets are designed to be able to work with extremely high temperatures. Still others are categorized by the material with which they’re made. Examples of these include rubber gaskets, plastic gaskets, metal gaskets, solid gaskets, jacketed gaskets, and silicone gaskets.

- Composite Gaskets

- Custom-fit to individual applications and typically applied with a gasket dressing or adhesive in assembly and sealing. Composite gaskets are made from any combination of the following materials: cork, rubber, paper, and felt.

- Corrugated Gaskets

- Metal gaskets which may be surface-treated with ceramic, non-asbestos or flexible graphite. Corrugated gaskets, which may be used with Teflon envelopes, provide a seal at low seating stress.

- Die Cut Gaskets

- Made of materials that can be cut before assembly.

- ElastaGraph Gaskets

- Corrugated gaskets that are suitable for high temperature, high pressure applications, and consist of a metallic core over which a seamless flexible graphite is applied. ElastaGraph gaskets have a high density inner ring to increase sealability and provide low minimum seating stress.

- Encapsulated Gaskets

- Consist of a gasket of one material and a continuous layer of another material, typically Teflon, which completely encloses the gasket.

- Envelope Gaskets

- Consist of a gasket of one material and an envelope of another material, typically Teflon, which covers the gasket.

- EPDM Gaskets

- Made of a synthetic rubber that serves as a seal between two mating surfaces in machine parts.

- Exhaust Gaskets

- Provide a seal on exhaust parts in vehicles to guarantee that when gases leave the engine, they stay in the exhaust system until they are expelled into the atmosphere.

- Fibre Seal Rings

- Die cut, water-jet cut, or formed gaskets or rings that provide a seal between two surfaces.

- Flange Gaskets

- Named after their flange shape; a flange is an external or external ridge, rim, or lip, and flange gaskets have protruding rims or lips that aid in the attaching process.

- Foam Gaskets

- Made out of strips of plastic, foam, or rubber.

- Gasket Materials

- Various materials with sealant qualities that are used in gasketing applications.

- Head Gaskets (Cylinder Head Gasket)

- Among the most complicated gasket varieties. They are used to create a seal between combustion engine blocks and cylinder heads. By combining the features of strength, heat resistance, and chemical resistance, they are able to weather the exposure to the chemicals and heat associated with fossil-fuel combustion engines.

- High Temperature Gaskets

- Help prevent leakage of fluids and gas by providing an airtight seal between gaps in machine parts whose temperatures may exceed 500° F.

- Hollow Tube Gaskets

- Tubular cross section that is typically made out of rubber or plastic.

- Jacketed Gaskets

- Come with attractive advantages of strength, flexibility, and robustness. They are made from rubber or plastic, and have an external metallic coating. Jacketed gaskets are also available in two types-single-jacket and double-jacket. The single-jacket gasket has only one side coated, and the double-jackets are completely coated. The double-jacket has an improved resistance to high temperatures, decay, and pressure. French-style gaskets come with jacketing on both the inside and outside of the gaskets.

- Laminated Gaskets

- Consist of two or more layered materials and are often enclosed in an envelope.

- Metal Gaskets

- Manufactured of metal and metal alloys, metal gaskets are considered ideal for processes within high pressure or high temperature zones. Some of the most common metals and ores used for gaskets are aluminum, stainless steel, brass, copper, and nickel. These are some of the strongest materials available, and they offer superior resistance against heat, pressure, and corrosion. In addition, they offer outstanding durability and flexibility, making them a suitable choice for the formation of mechanical seals.

- Neoprene Gaskets

- Made of synthetic rubber, these create a long-lasting seal for gaps on machine parts in several industries.

- O-Ring

- Thin, O-shaped rings. They are incredibly simple, inexpensive, easy to make, and common. They work for both static and dynamic applications (e.g., rotating pump and shafts and hydraulic cylinder pistons).

- Plastic Gaskets

- Gaskets made from a combination of plastic and rubber. These include thermoplastic elastomer, thermoplastic rubber, and various similar materials. Rubber and plastic are the two most popular materials for gaskets. These materials are also a favorite choice of gasket manufacturers. Plastic by itself is also used for gasket fabrication. Seals made of these compounds are strong and display the properties of rubber as well as plastic. However, due to their low melting point, they are not used for applications that include high temperatures.

- Profiled and Serrated Gaskets

- Solid metal gaskets with surface grooves, which facilitate a good seal with low seating stress. To protect flange surfaces, profiled and serrated gaskets can be jacketed.

- Rubber Gaskets

- Made of rubber. Rubber is known for its impressive elastomeric characteristics; therefore, it can be adopted in applications that involve high pressure. Rubber gaskets can bear heavy loads applied by weighty, substantial machine parts. Rubber can also maintain a tight seal under high-pressure zones for a long duration of time. Also categorized as rubber gaskets are the nitrile rubber gasket, neoprene gasket, and EPDM gasket types.

- Rubber Window Gaskets

- Used for weatherproofing and weatherstripping purposes. They are used frequently, for example, around car windows, around house windows, and at the bottom and/or sides of screen doors.

- Silicone Gaskets

- Also known as silicone rubber gaskets, these are made to handle extreme temperatures. Silicone gaskets are a valuable utility, as they can perform their duties under a broad variation in temperature, from -140 degrees to 480 degrees Fahrenheit. Silicone gaskets can also provide shielding and resistance from ultraviolet light. Furthermore, these gaskets can be used with the gaskets of other materials to enhance the strength of pressure and temperature bearing.

- Solid Gaskets

- Usually formed from soft and elastic materials. However, they can also be made from hard, rock-solid metals, with properties like superior thermal and pressure resistance. Although forming metal pieces into a seal-like shape takes hard effort and strong pressure, solid gaskets are an affordable replacement for jacketed gaskets. They are best suited for use between two metal parts and/or in machines that create or work under/on an extreme pressure and temperature. The type of metal used for the creation of these gaskets has to be stronger and denser than the metal used in the application that houses them.

- Spiral Wound Gaskets

- Used in situations in which the point of a connection may be subject to stress, tension, or movement, as they can maintain a tight seal and provide the flexibility necessary to allow movement without breaking. These seals feature interwoven or combined metal and filler material to provide a combination of strength, flexibility, and effective sealing.

- Teflon Gaskets

- Designed to resist sticking to the adjoining materials.

- Viton Gaskets

- Made of a synthetic tube that is resistant to heat, oil, and various acids.

Gasket Terms

- Anti-Extrusion Rings

- Also referred to as “back-up rings,” these are rings designed to fit behind rubber o-ring seals in order to prevent extrusion into the gap between the metal pieces.

- Beryllium Copper

- A lightweight metal that resists corrosion and is used in aerospace materials, springs, and gaskets.

- Blowout Pressure

- The internal forces that exert pressure against a gasket, which may cause the unsealing of the gasketed joint.

- Bonded Seals

- Flat steel washers in the center of which a rubber sealing ring is molded to fit over a bolt, providing a seal.

- Die Cutting

- Cutting shapes out of material using a die. The die is a pre-formed stencil.

- Electromagnetic Interference

- An interruption produced by an electric current, which can be filtered out by some gaskets.

- Flange Load

- The total force that creates a seal through compression of the gasket.

- Hydrostatic End Force

- The internal forces working against the flanges holding the gasket in place.

- Mismatch

- The unevenness of a seal due to differences in the two adjoining surfaces.

- Nebar

- A specialized gasket material that is used in electrical transformers.

- Neoprene

- A rubber used in weather resistant products, adhesives, paints, rocket fuel, and gaskets.

- Parback

- A back-up ring that is used as an anti-extrusion ring for an o-ring. Parbacks are concave-shaped on one side.

- Rings

- Circular sealing devices.

- Seal Strips

- Strips made of multiple layers of metal welded together to allow gaskets to be used in extreme heat or pressure.

- Slip O-ring

- A type of ring that relieves friction by fitting over an o-ring.

- Shims

- Used as spacers between a gasket and the adjoining material.

- Static Seal

- A seal, created by a gasket, between two unmoving parts.

- Washers

- Flat, circular rings placed under the head of a bolt to serve as spacers, gaskets, or slip devices.