Fractional Horsepower Motors

A fractional horsepower motor (FHP motor) is a small electric motor. Its power output is measured as a fraction of one horsepower. Typically, fractional horsepower motors are mounted on frames. Though no formal standard specifies a minimum size, most fractional horsepower motors are too large to fit into a pocket. Almost all have a power rating below that measures below one horsepower; larger motors are referred to as integral horsepower motors, and their power ratings are specified by integer multiples of one horsepower. Notably, motors on frame sizes 42, 48, and 56 are considered fractional horsepower motors even if the motor's power exceeds one horsepower.

Fractional horsepower motors are very common in residential, commercial, and industrial settings. There are two major types of fractional horsepower motors. Standard fractional horsepower motors are those larger than 1/20 horsepower. They are distributed among kitchen appliances, grocery store conveyor belts, and vacuum cleaners. Very small motors, those of 1/20 horsepower or less, are referred to as sub-fractional horsepower motors or micro motors. They are often found powering small consumer devices such as electric toothbrushes and toys.

Some even refer to small internal combustion engines as fractional horsepower motors.

Quick Links to Fractional Horsepower Motors Information

The History of Fractional Horsepower Motors

The earliest record of fractional horsepower motors of commercial importance was Nicola Tesla's 1888 U.S. patent on the induction motor. They remained uncommon until 1915, when major urban centers started receiving electrical utility services. With broadening electrification, the nascent fractional horsepower industry began to grow to meet the demand for consumer appliances such as washing machines. By 1920, over half a million fractional horsepower motors were in use in the U.S.

As fractional horsepower motors became more common, powered woodworking machines such as band saws, circular saws, and drill presses grew smaller, less expensive, and more portable. Furniture and wooden structures became much less expensive and labor-intensive to produce. Powered machine tools accelerated the industrial revolution, already well in motion since the early 1800s. Assembly lines started producing faster and required less labor, and machines both large and small, increased in supply and dropped in cost, as quality increased.

After World War II, demand for fractional horsepower motors surged as Americans used more and more electrically powered devices. Since that time, demand has continued to increase. They have become ubiquitous in automobiles, household appliances, and small machinery. In 2017 the European fractional horsepower market was estimated at around 300 million motors worth $4.5 billion USD.

Fractional Horsepower Motors Images, Diagrams and Visual Concepts

A fractional horsepower motor is an AC or DC current motor that produces less than one horsepower at an output rating of 746 watts or less.

A fractional horsepower motor is an AC or DC current motor that produces less than one horsepower at an output rating of 746 watts or less.

Fractional horsepower motors have an output power of 746 watts or less with a size of less than 104 mm2.

Fractional horsepower motors have an output power of 746 watts or less with a size of less than 104 mm2.

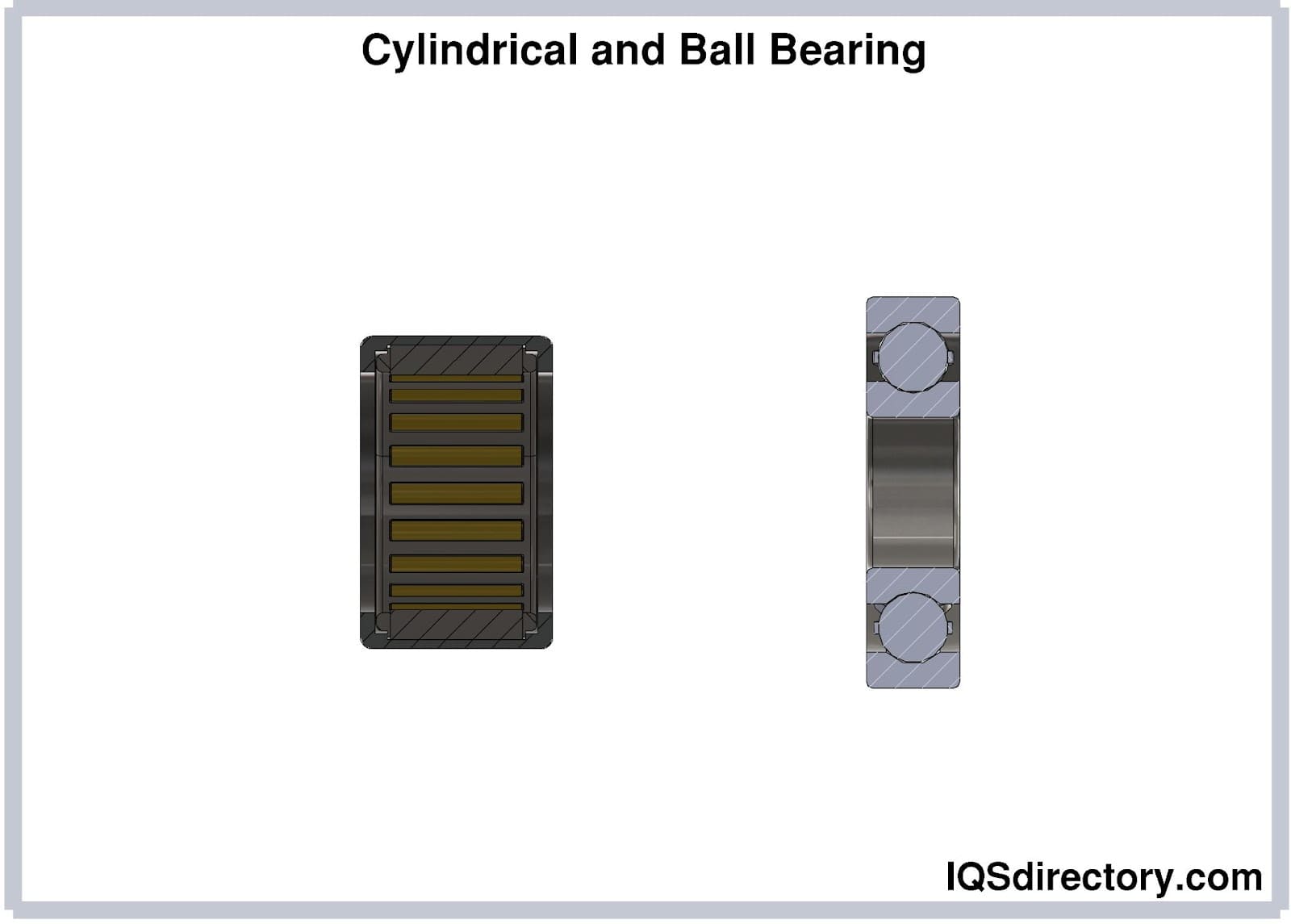

Bearings are an essential part of electric motors for reducing friction and wear.

Bearings are an essential part of electric motors for reducing friction and wear.

The power supply for fractional horsepower motors can be AC or DC, with AC being single or three phase.

The power supply for fractional horsepower motors can be AC or DC, with AC being single or three phase.

Types of Fractional Horsepower Motors

There are several types of fractional horsepower motors, but all electric motors have the same basic components: a rotor, coil, field magnet, axle, and enclosure. They usually contain a stator, which may be part of the enclosure. If you are confused, remember: the rotor rotates while the stator remains stationary. Some motors contain internal brushes, which help conduct precisely-timed electrical currents to parts of the device when they need power. Brushless DC motors demand higher prices than regular DC motors since they require a power supply, usually located externally.

All types of electric motors use field magnets to generate power. Some motors incorporate permanent magnets; others, referred to as induction motors, contain only electromagnets. The magnets are repulsed or attracted when electrical current flows through the coil, generating a rotational force on the rotor that transfers to the axle.

- ½ HP Motor

- Fractional horsepower motors with a power output of ½ HP, which is roughly equivalent to 373 Watts.

- ¼ HP Motors

- Fractional horsepower motors because they output power that is less than one HP, or 746 watts when referring to electric motors.

- AC Motors (Altertnating Current)

- Either induction or synchronous. They have a current that flows in either direction, usually with electric power.

- DC Motors (Direct Current)

- Have variable speed operation capabilities with current, which flows in one direction. Often use electric power.

- Electric Motors

- Motors that convert electric energy into motion using magnetism.

- FHP Motors

- Abbreviation for fractional horsepower motors, which are motors that are built in a frame, traditionally with a power output of smaller than one horsepower.

- Gearmotors

- A combination of a motor and gearhead that reduce motor speed to desired RPM’s.

- Induction Motor

- An induction motor operates by modulating the electrical current in the coil which is wrapped around the stator. The modulation induces a rotating magnetic field, exerting a force on the rotor. The magnetic field revolves slower than synchronous speed would dictate. Three-phase induction motors are used extensively in industry, but single-phase fractional horsepower induction motors are also extremely common. They are cheap, dependable, and robust.

- Integral-Horsepower Shunt Motors

- Used when minimum speed variation requirements are necessary at constant potential with full to no load and/or constant horsepower.

- Miniature Motors

- Also referred to as micro motors or small motors, are fractional horsepower motors that must not only fit the frame size and/or less than one horsepower requirements, but also size dimensions of a couple inches or less.

- Multi-Speed Motors

- Come in two, three or four speeds. They have varying connections that can alter the speed at the starter, because of the way they are wound.

- NEMA Motors

- Electric motors that fit the standards set by NEMA, which stands for the National Electrical Manufacturers Association.

- Permanent Magnet Motors

- Have magnets in their rotor assemblies. These allow the rotor assembly to arrange itself in a line with the rotating magnetic field of the stator, which results in no slip and higher torque efficiency.

- Permanent magnet motors are more energy efficient than induction motors. Also, permanent magnet motors are more powerful than similar sized induction motors. A permanent magnet motor can have high torque over its entire speed range, even at low speeds. One major drawback of permanent magnet motors is their cost; their construction often requires expensive rare earth magnets. Permanent magnet motors run at synchronous speed, rotating in-step with the frequency of their power sources.

- Reversible Motors

- Can be AC or DC. A typical DC motor is almost always reversible by changing the polarity of the field; an AC motor is reversed in a three-phase power motor by reversing connections of one leg and in a single phase by reversing the leads.

- Small Electric Motors

- Have less than one horsepower of power.

- Small Motors

- Use a fraction of a horsepower, or 745.7 watts, of power to run.

- Synchronous Motors

- Operate up to full load at a constant speed and are often used to maintain an exact speed. The rotor speed and the rotating magnetic field speed are equal.

- Universal Electric Motors

- Can run on either AC or DC power.

- Universal Motors

- Capable of operating on both direct current and alternating current.

- Variable Speed Motors

- Direct the rotational speed of an AC motor and can be found in many heating and cooling systems.

- Variable Torque Motors

- Essentially multi-speed motors whose loads have varying torque requirements along with varying speed requirements. Found in pumps and blowers.

Uses of Fractional Horsepower Motors

Fractional horsepower motors are used both in industry and in consumer devices. Fractional horsepower motors are utilized in an extremely broad and diverse array of sectors, from agriculture to heating & cooling. They have thousands of applications, from powering cooling fans and electric drills to driving meat slicers and electric shavers.

The global automotive industry consumes more than a third of fractional horsepower motors sold worldwide. Most find uses in secondary applications such as starters, door openers, air conditioning, and powered seats.

More than 10% of fractional horsepower motors power domestic appliances, finding use in microwave turntables, blenders, mixers, refrigerators, washers and dryers, and garage door openers.

Large quantities of fractional horsepower motors are used in electric tools, office equipment, medical devices, and heating & cooling. Diverse industries use them for material handling and processing.

Choosing a Fractional Horsepower Motor

With few exceptions, fractional horsepower motors with equal specifications may be interchanged. If a motor made by one manufacturer is removed, a similar motor made by another manufacturer can typically be swapped into place with no change in operating characteristics.

- Replacing a Motor

- Of course, when replacing a fractional horsepower motor, the replacement motor must meet the correct specifications. The easiest way to match motor specifications is to copy the nameplate information from the broken, worn or defunct motor.

- When replacing motors that failed for unknown reasons, it is a good idea to consider whether the motor specifications are appropriate for the application. If the motor was too small or not rugged enough, a different type of motor should replace it.

- It is worth noting that sometimes a motor will be conspicuously marked as a special or custom motor; special motors should ordinarily be replaced by exact duplicates.

- A wide range of fractional horsepower motors exist, but nearly all general-purpose motors can be seen as variations along the following dimensions: power supply, motor type, power characteristics, enclosure, bearings, the direction of rotation, mount, and thermal protection. Each of these dimensions should be examined in detail before buying a fractional horsepower motor.

- Power Supply

- Fractional horsepower motors can be alternating current (AC) motors or direct current (DC) motors. AC motors can be either single-phase motors or three-phase motors. Most AC fractional horsepower motors are single phase, but a three-phase motor cannot be placed on a single-phase power supply. Some AC motors, typically those for American markets, need a 60 Hz power supply. Motors for the European and Asian markets typically demand a 50 Hz power supply. Voltage is an important consideration for both AC and DC motors; the power supply voltage must match the motor specifications.

- Continuously variable speed motors depend on a controller that regulates electrical current supplied to the motor. The controller must be matched with the motor type and available power sources. The controllers may operate by applying power at intervals to selected poles of the motor, by varying electrical power levels or by modulating the AC wavelength.

- Stepper and servo motors have their own power supply and timing requirements. These must be matched to meet specifications.

- Power Characteristics

- Motors have three major power characteristics. Horsepower is the capability to do a certain amount of work in a certain amount of time. Torque is the degree of angular force that a motor can exert. Speed is the rate at which the motor turns. These three factors conform to a simple relation. Speed multiplied by torque is directly proportional to horsepower; gear mechanisms can trade speed for torque or vice versa. There is no advantage to purchasing a motor with excessive horsepower, but the horsepower must be sufficient to meet the motor's maximum workload. In applications where extremely high torque or extremely low speed is required, gearmotors may be appropriate.

- Motor Class

- The precise details of the inner construction of fractional horsepower motors vary. Some have brushes; some are brushless. Some require a large capacitor to provide starting current. Some have large amounts of speed and torque to start, and some gradually build up torque as they build up speed. Some are reversible, some are variable speed. Some have two or more windings; some have only one. It is almost always possible to choose an appropriate motor type by looking at maximum starting current and starting torque.; choose the motor type based on the power supply and startup requirements of the motor.

- Motor Enclosure

- The motor enclosure must be the right size to inter-operate with the machinery that it powers. The enclosure should also protect the motor from the environment. Motors used in marine environments or highly corrosive environments such as chemical plants may need to be sealed in a full enclosure. Motors which power devices outdoors may need drip-proof enclosures.

- Bearings of a Motors

- Motors should have suitable bearings for their expected use. Sleeve bearings are often appropriate, but ball bearings may be required to support a heavy axial load. Needle bearings may be appropriate for high-speed applications. Also, if a motor is mounted vertically, the bearing must be suitable for a vertical orientation.

- Motor Rotation

- It may seem obvious, but the motor must rotate in the correct direction. Some motors can be reversed by reversing the poles of the power supply; some cannot. Typically, the direction a motor rotates is specified on the end opposite the shaft. On most motors, a notation of CW indicates that they rotate clockwise and a notation of CCW indicates that they rotate counterclockwise. Note that on pump motors, this notation is reversed.

- Motor Mount

- The motor must have mounts that match the machinery or supports to which it will be attached.

- Thermal Protection

- To protect the motor from overheating, many motors shut off when they reach a specified operating temperature. This capability is called thermal protection. There are two major types of thermal protection switches. Automatic Reset switches are reset automatically when the temperature drops. Manual Reset switches require the operator to push a button or throw a switch to power up the motor again. An automatic reset switch might be appropriate on a fan but would be a serious hazard on a circular saw. Wherever the automatic restart of a motor could create a safety hazard, manual reset should be considered mandatory.

Standards and Specifications for Fractional Horsepower Motors

There exist a number of standards that apply to fractional horsepower motors. In the United States, fractional horsepower motors use frame sizes outlined by NEMA, the National Electrical Manufacturers Association. Fractional horsepower motors are ordinarily exempt from energy requirements of larger motors, including the US Energy Policy Act of 2005 and the EN 60043-30:2009 ruling of the European Commission. In many environments, they may be subject to radio interference standards, meaning that they must tolerate radio interference and cannot generate excessive interference.

Choosing a Fractional Horsepower Motor Manufacturer

Several factors should be considered when choosing a manufacturer to meet your fractional horsepower motor needs. A good manufacturer will provide a quality product that will last for a minimum of five years of use. The right manufacturer will provide support and replacements not only a few weeks down the line but decades into the future.

Fractional Horsepower Motors Terms

- Actuator

- A device that creates mechanical motion by converting various forms of energy to rotational or linear mechanical energy.

- Coil (Stator or Armature)

- Electrical conductors in the core slot, insulated from the iron core. They produce and transmit the magnetic field as current passes through.

- Commutator

- A mounted cylindrical device, to which the motor brushes are attached, on the armature shaft made of copper segments set around the shaft.

- Constant H.P.

- Name used for motors with variable speeds whose loads need the same amount of horsepower despite their speed.

- Core

- The segment of the stator and rotor, usually iron; made up of cylindrical laminated electric steel.

- Cycles Per Second (HERTZ)

- A complete reverse flow of alternating current during a rate of time.

- Duty Cycle

- The comparison of operating and rest times due to normal operating temperature.

- Efficiency

- The ratio of electrical input to mechanical output. It measures the motor's effectiveness when converting electrical energy into mechanical energy.

- Enclosures

- Either open or closed, the frame or housing of the motor.

- Endshield

- The part of the motor housing that supports the bearing and acts as a protective guard to the electrical and rotating parts inside the motor. An endshield is often referred to as an "end bracket" or "end bell."

- Horsepower (HP)

- Work done per unit of time: 1 horsepower equals 33,000 foot-pounds of work per minute or approximately 746 watts. Motors for pumps are an example of a motor that is rated in horsepower.

- Jackscrew

- A device used for the positioning of a motor. These are adjustable screws fitted on the base or motor frame.

- Load

- The burden of the motor by its application. The required power to overcome the resistance of the machine it powers.

- Motor

- A device that turns a shaft by taking electrical energy and converting it into mechanical energy.

- Rotor

- Made of stacked laminations, the rotating component of an induction motor.

- Shaft

- The rotating part of the motor that protrudes past the bearings for attachment to the driven equipment.

- Skew

- The laminations arranged on a rotor or armature. These help abolish low-speed cogging effects in an armature and reduce induced vibration in a rotor.

- Stator

- In an AC induction motor, it is made of laminations with a large hole in the center for the rotor to turn and slots in the stator for the windings to be inserted.

- Thermocouple

- A device to detect temperature that contains two dissimilar metals which generate voltage as a function of temperature.