Power Supplies

Power supplies, or power supply units (PSU), are devices that produce electrical power and provide reliable electrical currents that power electronics, machinery and devices for both industrial and commercial use.

Quick links to Power Supplies Information

The History of Power Supplies

The power supply industry is relatively young; it began in the 1920s. The first power supply units were used to power commercial radios, as well as radios used in the home. In 1929, engineers figured out how to make radios with integrated power supply units. Between the 1930s and 1940s, manufacturers regulated power with vacuum tube linear regulators. They controlled the stable power channeled through these using knobs. While these worked, they were somewhat dangerous, as they became incredibly hot. Made from glass, the tubes could even turn red or melt.

In the ‘50s, engineers came up with superconductors, including the transistor, which was originally perfected in 1947 at Bell Labs. Early transistors were smaller and much more efficient and reliable than vacuum tubes, which they quickly replaced. They were also safer than vacuum tubes. Unfortunately, they also presented new problems, namely their ability to only work with low to medium voltage systems. This changed in the early 1960s, when manufacturers began producing magnetic amplifiers (mag-amps). These worked by amplifying small signals and making them much stronger. These were quite durable and were used into the 1980s and 1990s.

In the 1960s, Dr. Kenneth Kupferberg patented the first designs for remotely controlled power supply systems. During this decade, when the world was slowing switching from analog to digital, scientists and engineers came up with all kinds of power supplying methods, including: linear series pass power supplies, high power operational amplifiers, bipolar source and sink units, ferroresonance, and control of input voltage and feedback control elements.

In the 1970s, researchers paired high speed silicon transistors with low loss ferrite, a transformer core material. As a result, they were able to develop products that could work at high, inaudible frequencies upwards of 20KHz. In 1972, Hewlett Packard came out with a pocket calculator that they fueled with a switching power supply. Later in the ‘70s, engineers figured out how to get linear power supplies to act based on the commands of a computer. This led to the further development of digital controls. First of the digital controls was BCD (Binary Coded Decimal) digital control. Next was digital to analog power conversion (DAC), then the instrumentation bus standard. Hewlett Packard originally marketed it to the power supply industry as HPIB. Later, it was renamed RS232. This interface allowed for much faster and broader communications between power supplies and their controllers.

During the 1980s, as computers were being developed and digital products became more prominent, power supplies became that much more important. In response to demand, many new power supply companies cropped up all over the world. They helped power supplies to get even more powerful and easy to control.

The early ‘90s saw power supplies manufacturers come out with smaller and smaller products. Because they were finding and creating stronger components, power supplies in the ‘90s were more dense and far more efficient than anything made before. Today, power supplies are an integral part of our lives. In our digital world, we couldn’t do without them.

Power Supply Design

Power supply manufacturers offer many different designs and configurations of power supply units, which range depending on their application, type of current, frequency, power supply wattage and voltage level. When designing a custom power supply unit for you, or helping you pick a standard one, they consider specifications such as: the number of outputs, DC output voltage, DC output power, AC output voltage, AC output frequency, operating temperature and apparent power.

They make some unit designs and styles that are external, meaning they are separate components to the electronic device. These include board, cabinet, desktop, module, open frame, enclosed, rack mount and wall mount. They also make interior unit designs and styles. Generally, if their operating temperature is low enough, manufacturers will place many power supply units inside of the device. Manufacturers offer a variety of display choices in order to best provide you with information about the voltage and current that are the result of measuring and monitoring. Typical options include: digital numerical displays, analog visual indicators and graphic or video displays.

Learn about what custom options a specific supplier offers by checking out their website or talking to them directly.

How Power Supplies Work

PSUs

PSUs work like this:

- They receive power, aka the input power, from a source such as a battery or wall socket.

- They invert, convert or adapt the power.

- They provide the converted power as an output power to an electronic device.

There are two main types of electrical current that are regulated, controlled and altered by power supplies—alternating current and direct current. Both are used to power different kinds of electrical products, but the input into a power supply from a battery or other power source is almost always AC.

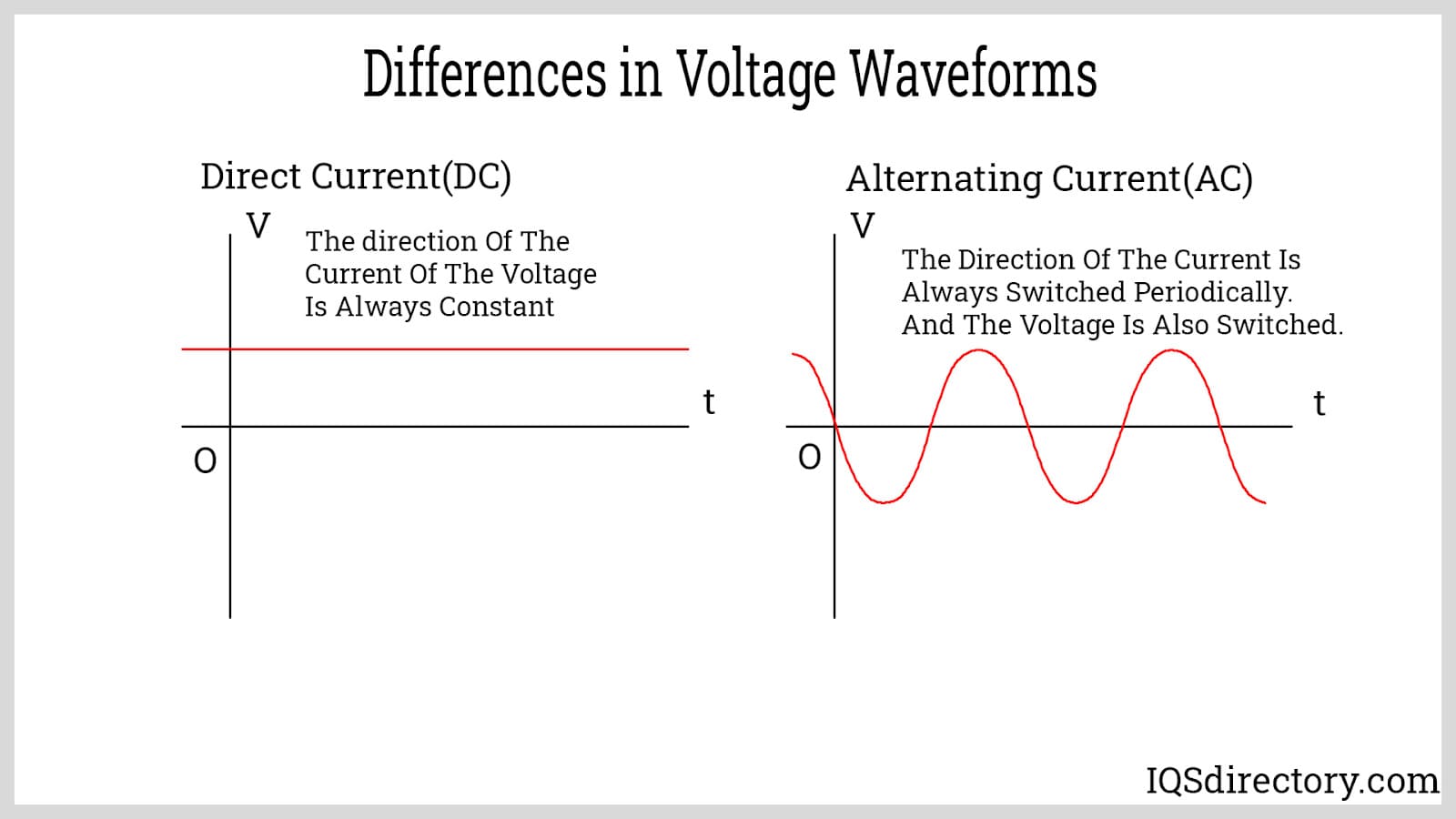

Alternating Current

Alternating current exhibits electrical charge that consistently and periodically reverses direction. It moves forward then backwards over and over. This form of current is used in commercial businesses and residential buildings. The alteration of the current’s direction is measured in Hertz. For example, 60 Hertz refers to the number of alternative directions the current takes in a second.

Direct Current

Direct current, on the other hand, refers to electric charge flow that runs in a single, linear direction. It flows in metal conductors like wires, semiconductors, insulators or even a vacuum. Cell phones and laptop computers use DC, as well as medical equipment, video technology and process control systems. Direct current units are usually external from the electronic device and held within a protective casing.

Power Supplies Images, Diagrams and Visual Concepts

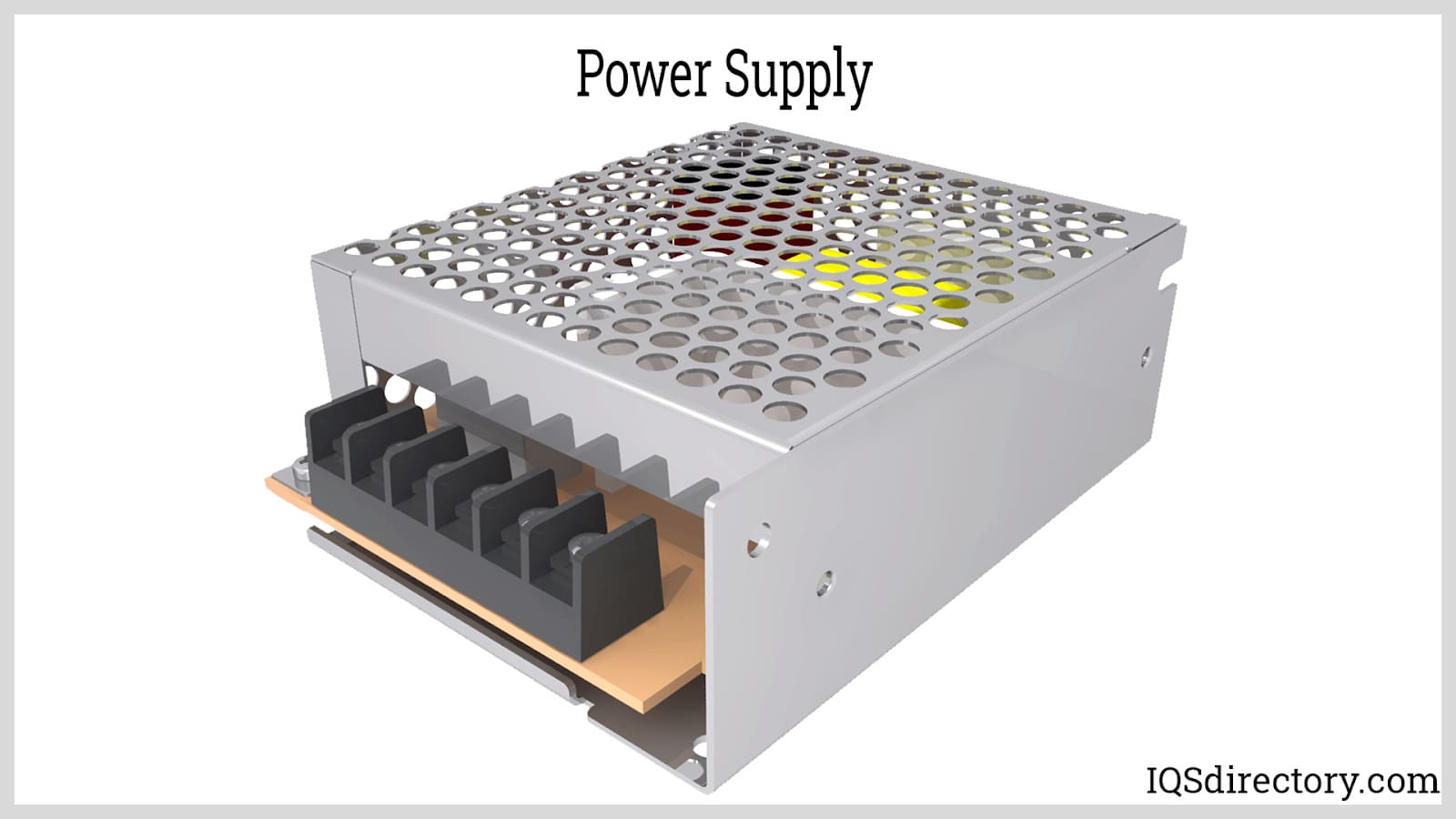

Power supplies are electrical circuits and devices designed to convert mains power or electricity from any electric source to specific values of voltage and current for the target device.

Power supplies are electrical circuits and devices designed to convert mains power or electricity from any electric source to specific values of voltage and current for the target device.

An example of an alternating current (AC) power supply.

An example of an alternating current (AC) power supply.

An example of an direct current (DC) power supply.

An example of an direct current (DC) power supply.

High voltage power supplies are designed to produce a high electrical load.

High voltage power supplies are designed to produce a high electrical load.

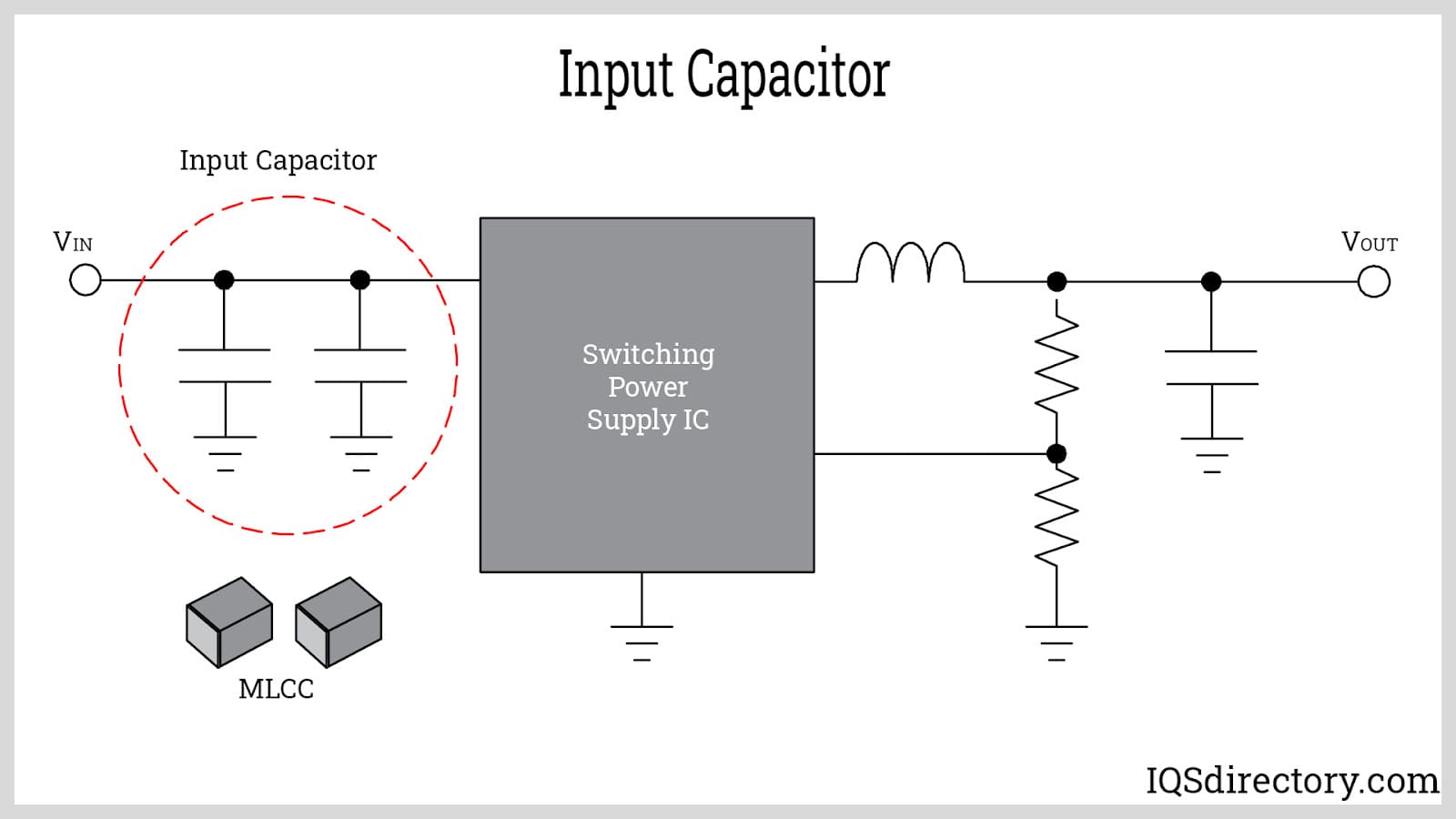

The input capacitor acts as the power supply ripple elimination capacitor for the IC for step down DC DC power supplies.

The input capacitor acts as the power supply ripple elimination capacitor for the IC for step down DC DC power supplies.

THe difference of the waveforms of both DC and AC current.

THe difference of the waveforms of both DC and AC current.

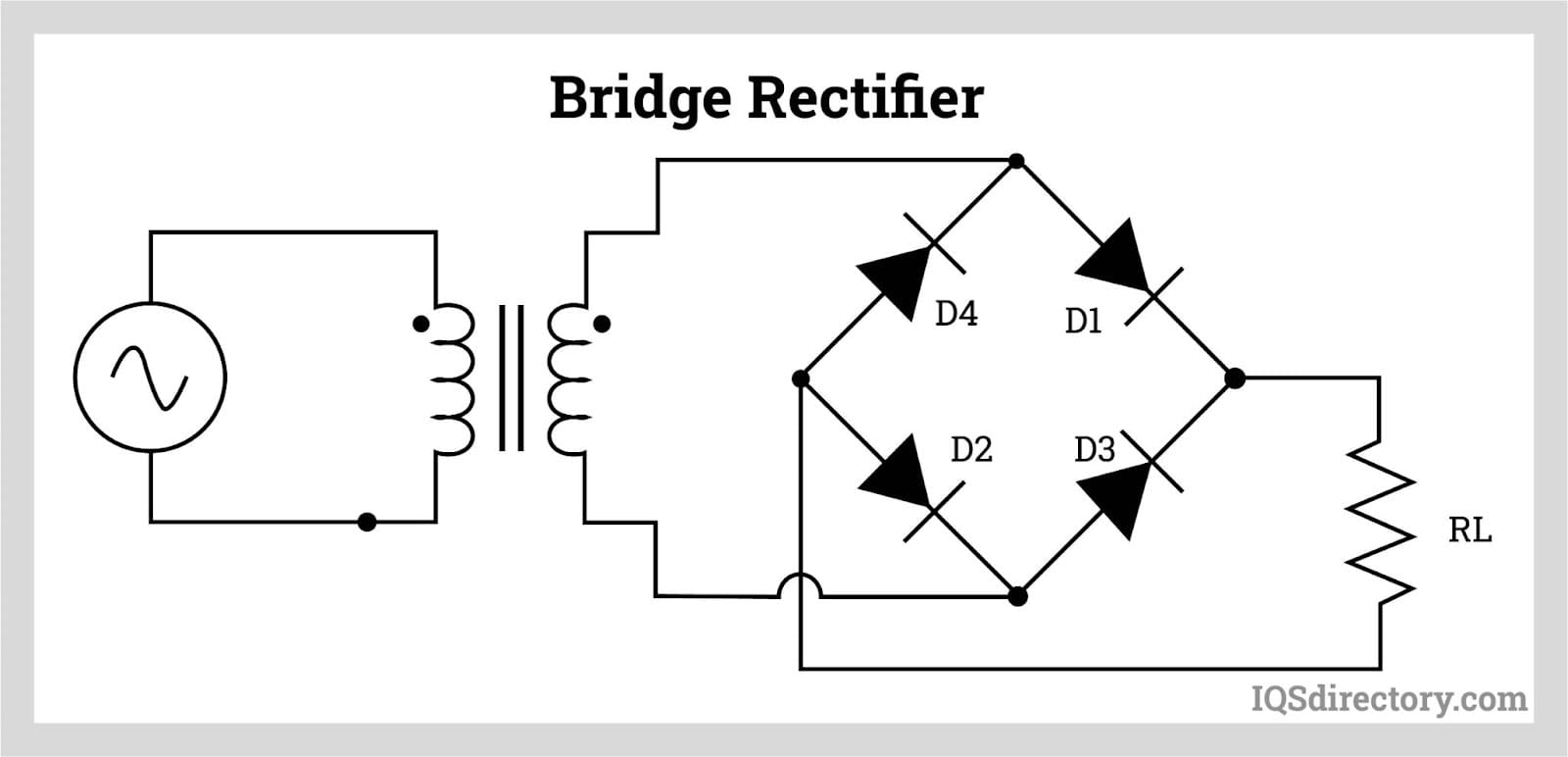

A rectifier, a device that changes the AC power into a pulsating DC.

A rectifier, a device that changes the AC power into a pulsating DC.

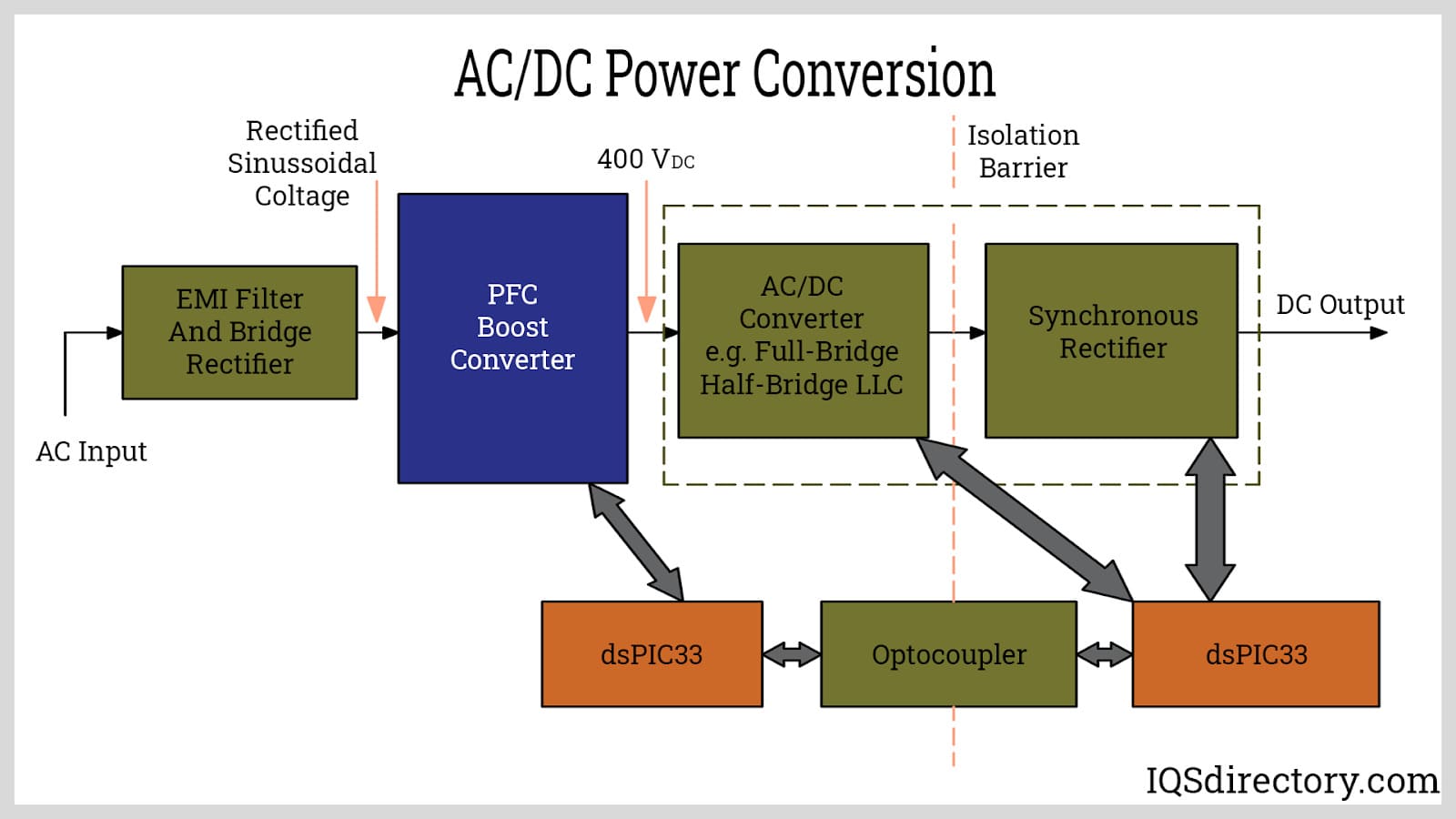

The process in converting AC current input into a DC current output.

The process in converting AC current input into a DC current output.

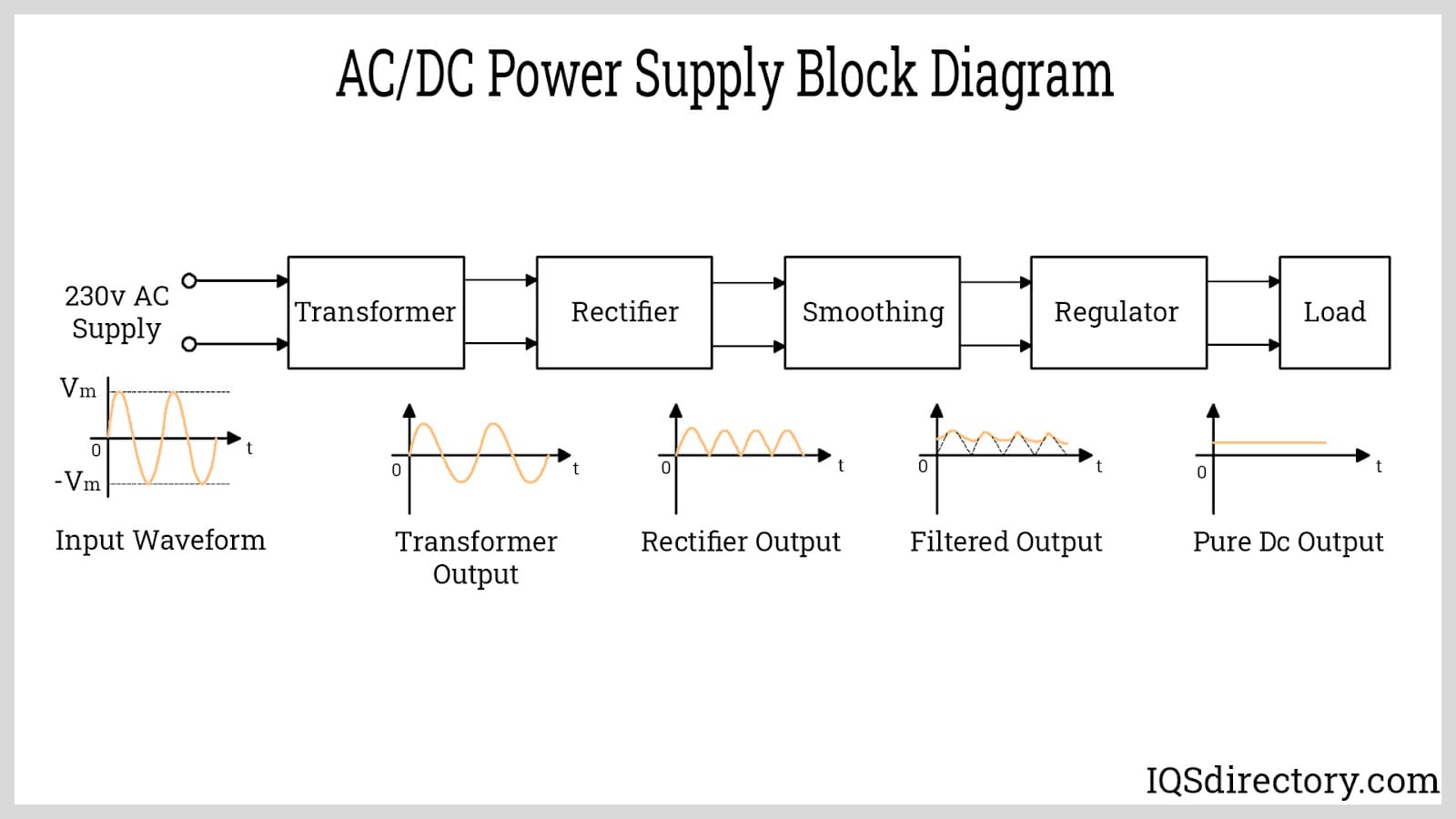

The use of a transformer is employed for the reduction of AC voltage into a smaller, the reduced voltage is then rectified into a DC voltage that is filtered to eliminate the ripples.

The use of a transformer is employed for the reduction of AC voltage into a smaller, the reduced voltage is then rectified into a DC voltage that is filtered to eliminate the ripples.

Types of Power Supplies

There are many ways to group power supplies. First, there are variable power supplies and uninterruptible power supplies.

Variable Power Supplies

Variable power supplies are able to adjust the output voltage to specific requirements for product testing and design. They are not super popular, though, because most electronic products today require regulated power supply.

Uninterrupted Power Supplies

Uninterrupted power supplies (UPS) are backup power supply units that continue to provide power during the loss of AC input power. In other words, they provide stable and constant output at a certain, unwavering voltage regardless of power outages, brownouts or surges. These batteries work with the assistance of a DC/AC inverter or DC/DC converter. They can work as external units or internal units. External power units are called stand alone UPS units, while UPS units implanted in the equipment are called battery backup UPS units.

There are three types of uninterruptible power supplies (UPS): offline UPS, line interactive UPS and online UPS.

Offline UPS Units

Offline UPS units are basically standby systems that provide battery power to equipment when the main power supplies fall below a set limit. These power supplies do not cost much and are recommended for home office use.

Line Interactive UPS Units

Line interactive UPS units are similar to offline UPS units, in that they switch to battery mode during a blackout. However, these UPS units actually boost the main power supply when they fall, using a regulator. These power supplies are ideal for business applications.

Online UPS Units

Online UPS units provide the highest level of protection for an electrical device. They supply critical power loads by converting AC to DC and then back to AC. These UPS units, often referred to as double conversions, contain an automatic bypass to ensure continuous power supplies during a short-term overload or UPS failure. Online UPS systems are perfect for critical loads and sensitive equipment, such as medical technology.

AC to DC Converters

AC to DC converters convert power from an AC input, such as a wall outlet, into DC current. AC-DC power supplies are units that provide power to an electronic device by converting AC current, such as that which comes from a wall outlet, to DC current at the proper voltage.

Constant Current Power Supplies

Constant current power supplies control the output current for alterations in load, line and ambient temperature and time within particular limits.

Constant Voltage Power Supplies

Constant voltage power supplies control the output voltage in load, line, ambient temperature and drift resulting from changes over time.

DC/DC Converters

DC/DC converters are used to increase or decrease the voltage level of DC electrical power, because, unlike AC, DC cannot be changed using a transformer.

DC Power Supplies

DC power supplies, such as linear power supplies, switching power supplies, DC/DC power converters and high voltage power supplies, receive input power and output the required form of DC power.

Ferroresonant Power Supplies

Ferroresonant power supplies are utilized at higher levels in static applications, due to their weight. Ferroresonant power supplies are effective only when the line frequency is extremely stable, as they are sensitive to changes of input AC frequencies.

Frequency Converters

Frequency converters, a special type of transducer, are simply electrical currents that convert periodic signals into their digital or analog equivalents. The most common frequency converters are frequency-to-digital and frequency-to-DC converters.

Half Bridge Converters

Half bridge converters are power switching circuits consisting of two transistors and two capacitors. Half bridge converters function in similar fashion to full bridge converters.

High Voltage Power Supplies

High voltage power supplies are capable of providing hundreds or thousands of volts from one or more DC outputs, using linear technology. Some high voltage power supplies have adjustable local or computer interface outputs and are used in specialized applications, including telecommunications, video technology and medical equipment.

Power Inverters

Power inverters change DC current to AC current and may be mechanical (e.g. motor), ferroresonant and solid state.

Linear Power Supplies

Linear power supplies have a bulky steel or iron laminate transformer that acts as a safety barrier for the low voltage output from the AC input and reduces that input to a much lower voltage. The AC output is then rectified by two or four diodes, and electrical converters change the output into low voltage DC, which is regulated into the required output voltage by dropping the difference in voltage across the shunt regulator.

Modular Power Supplies

Modular power supplies are composed of a number of separate subsections, such as power, input and filter modules.

Off-Line Power Supplies

Off-line power supplies operate directly off the AC line. Off-line power supplies do not use a power transformer before the process of rectification and filtering.

Operational Power Supplies

Operational power supplies have a high open loop gain regulator, for which passive components can be used to program. The regulator acts like an operational amplifier.

Ractifiers

Rectifiers are electrical components containing sets of diodes that change AC into DC. They alter and regulate electrical current.

Switch Mode Power Supplies

Switch mode power supplies rectify and smooth AC voltage using diodes and capacitors, resulting in a high voltage DC, which in turn is converted by a small ferrite transformer and FETs or transistors into a safe, low voltage, high frequency voltage. Another set of diodes, capacitors and inductors convert that DC voltage into the required voltage, the corrections of which are done by adjusting the pulse width of the high frequency waveform.

Power Supply Applications

Power supplies can be integrated into a device or externally attached, portable modules, depending on their operating temperature and risk of overheating. PSUs are necessary to the operation of just about every electrical device, including: desktop computers (pc power control), laptop computers, cell phones, lasers, ac power cords, supply cords, telecommunications like radio, phone lines and the internet, medical equipment, lamps, appliances and industrial machinery.

They provide either AC power supply, which is an alternating current, or DC power supplies, which offer a direct current. Today, most electronic devices in the home and office are powered by 12v power supply, while industrial applications employ high voltage power supply (high volt power supplies).

Equipment Components of Power Supplies

The equipment components of any given power supply unit depends entirely on its configuration and its application. In general, power supplies contain a power inverter, power converter or power adapter.

From there, they may have any number of components. Examples of various common power supply features include: adjustable voltage (which can be increased or decreased by a dial or knob), adjustable frequency, computer interface, fan cooling systems, as well as integral heatsink and overcurrent protection.

A good example of a piece of power supply equipment with some of these features is the power supply unit that provides electrical power for computers. This vital component is a smaller, black metal box typically located on the back of the computer in a corner of the case. It contains a power-cord receptacle and a cooling fan that is usually visible from the back of the system in which it is installed.

Many power supply units also work in conjunction with a backup battery that is employed in case of a power outage. Other features include: overvoltage protection, power factor correction, pure sine output, remote on and off switch, short circuit protection and water cooling.

Standards and Specifications for Power Supplies

Power supplies are beholden to a wide range of safety and compliance standards. These vary based on your industry, application and location. Some of the major standards agencies around the world include: IEC (International Electrotechnical Commission), ISO (International Standards Organization), CSA (Canadian Standards Association) and UL (Underwriters Laboratories). Some offer guidance or requirements based on energy efficiency, while others discuss things like: insulation, voltage types, safety for medical use, safety in the lab, proper handling, etc. Find out what standard requirement certifications your power supplies should have by talking to your industry leaders.

Finding a Power Supply Manufacturer

For the most efficient, highest quality and best-matched power supplies, you need to work with an experienced power supply provider. To find such a provider, check out the list we’ve provided on this page. All of those power supplies providers with whom we work have proven their worth to their customers time and time again. To find the right one for you, start by writing out a list of your specifications. Don’t forget to include your budget, required lead times, delivery preferences, installation support preferences and post-installation support preferences.

Power Supply Terms

- Autoranging Input

- A sensing circuit for the input voltage located within the power supply that automatically switches to the necessary voltage range.

- Breakdown Voltage

- The highest AC or DC voltage that may be applied from the input, output and/or chassis of a power supply.

- Burn-in

- Operating a newly manufactured power supply, usually at rated load, for a period of time in order to force early failures or other latent defects of the component before the unit is delivered to a customer.

- Common-mode Noise

- Noise that is typical of DC output and return lines with respect to input ground.

- Compliance Voltage

- The voltage output from a constant current power supply.

- Cooling

- The removal of heat in a power supply by convection, forced air, radiation or liquid. Heat comes from regulation, transformation, filtering and rectification.

- Cross Regulation

- The percent of voltage change at one output of a multiple output power supply resulting from the load change on another output.

- Current Limiting Circuit

- An overload protection circuit, which controls the highest output current of a power supply to safeguard the power supply or the load.

- Design Life

- The projected lifetime of a power supply during which it will run at its stated specifications.

- Differential Mode Noise

- Also referred to as "ripples," it is the noise measured between the DC output and the output return.

- Drift

- With operating parameters including line, load and ambient temperature held constant, it is the change in output voltage, following a warm-up period, over a certain period of time.

- Efficiency

- The ratio of power in terms of the input power against the output power. Efficiency is measured at full load and nominal line conditions.

- Electromagnetic Interference (EMI)

- Also known as "radio-frequency interference (RFI)," it is unwanted high frequency energy conducted through the input or output lines of switching power supplies or radiated through space. EMI is caused by the switching transistors, output rectifiers and zener diodes.

- Foldback Current Limiting Circuit

- A current limiting circuit that, when under overload conditions, will gradually decrease the output current to a specified minimum current level under a direct short circuit.

- Ground

- An electrical connection to earth that has a zero voltage or another conductor connected to earth.

- Inhibit

- The capability of remotely switching off the output power of a power supply.

- Input Line Filter

- A low-pass or band-reject filter used to decrease the noise fed to the supply. Input line filters are located at the input of a power supply and may be external.

- Isolation Voltage

- The highest AC or DC voltage that can be continuously run from a power supply chassis or from input to output.

- Margining

- Altering a power supply output voltage, either higher or lower from its minimal setting, in order to confirm the system performance margin in respect to the supply voltage. Margining is typically done electrically via a system generated control signal.

- Minimum Load

- The least amount of load current or power that needs to be drawn from the power supply in order for the supply to meet its performance specifications.

- Non-Shutdown Over Voltage Protection

- A feature of a converter such that it continues to provide voltage to a load at a set upper limit without turning off and without necessitating a reset when the overvoltage event ceases.

- Overvoltage Protection

- A circuit that either shuts down the power supply or shorts the power supply to ground if an overvoltage condition occurs.

- Parallel Operation

- The connection of the outputs of multiple power supplies with the same output voltage that are designed to share a load. The parallel operation generates a higher output current than would be available from a single supply.

- Peak Power

- The absolute highest output power that a power supply can create without immediate damage. Typically, peak power is much higher than the continuous reliable output capacity and ought to be utilized rarely.

- Power Fail

- A signal from the power supply interface that relays a warning that the input voltage is not sustaining full power regulated output.

- Reverse Voltage Protection

- A protection circuit that prevents damage to the power supply if a reverse voltage is applied at either the output or input terminals.

- Safety Ground

- A conductive path to earth intended to safeguard people from electrical shock by shunting away any dangerous currents that could happen from accident or malfunction.

- Turn-on Time

- Also known as "warm up time," it is the time a converter needs to start running within specification after proper power has been applied.