EMI Shielding

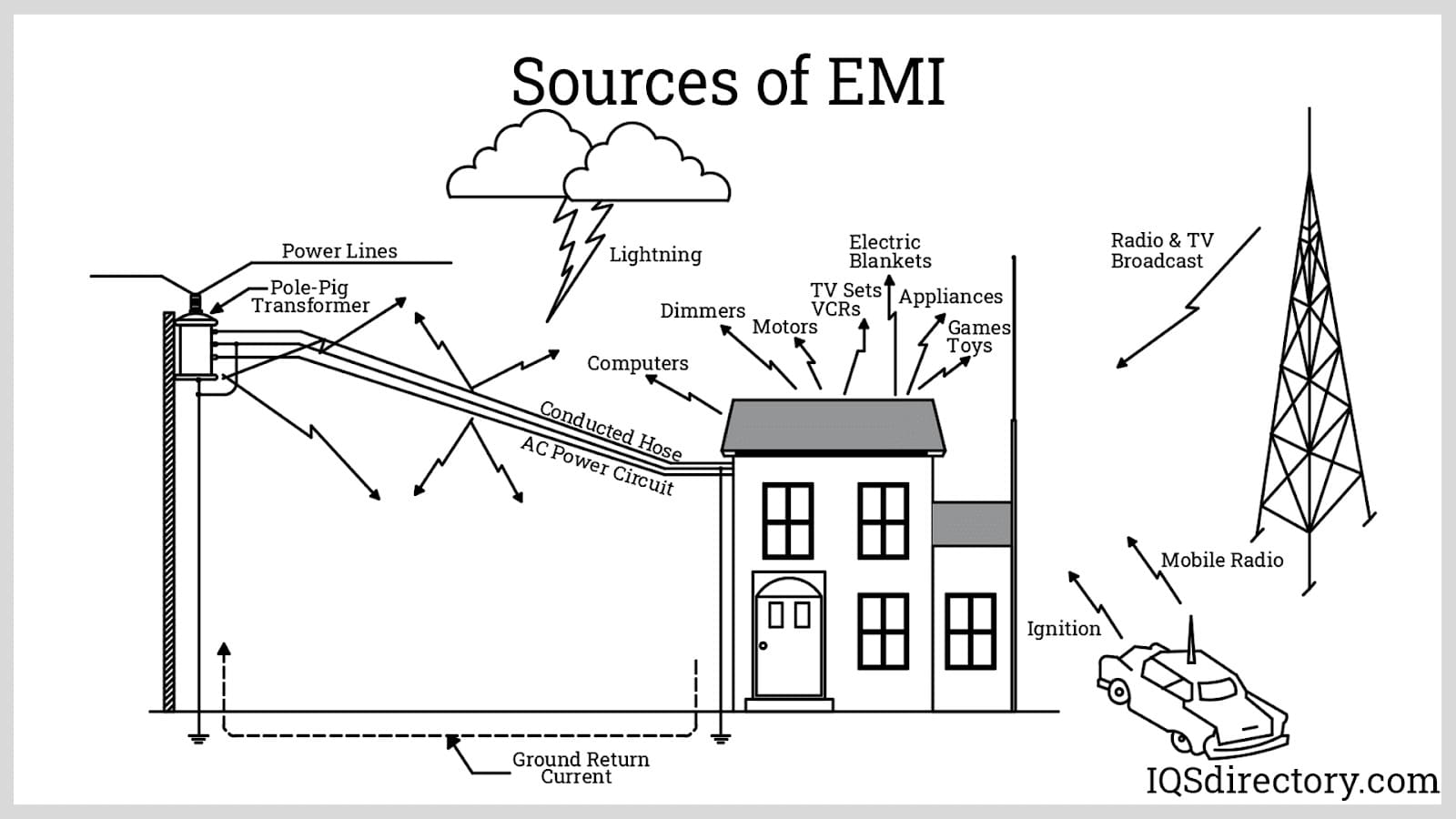

Electromagnetic interference shielding (EMI shielding) is a service many companies offer or routinely include, depending on their products. Using a variety of techniques, they offer EMI shielding in order to shield products from EMI. EMI is the magnetic field created by electrical currents, or electromagnetic radiation; This field can travel along wires, electrical circuits, conductors and free space. Similarly, radio frequency interference (RFI) is radiated electromagnetic field "noise," which travels through the air as radio waves. It’s true that some products need EMI to work; most, however, have electromagnetic compatibility, or the ability to work without it. For those that don’t need it, both EMI and RFI cause the same effect, which is a sort of disruption, or interference with the work of the device.

Electromagnetic Manufacturers guard devices from EMI and RFI using magnetic shield technology such as: EMI enclosures, RF absorbers, EMI coating, EMI gaskets and EMI filters.

Quick Links to EMI Shielding Information

The History of EMI Shielding

The oldest type of EMI shielding is the Faraday cage, which was invented in 1836 by the English scientist, Michael Faraday. He built his cage coated with metal foil in order to demonstrate that it blocked an electric charge from reaching its interior. This built off Benjamin Franklin’s recorded discovery of the effect in 1755. Faraday cages are still used today.

Interested parties first attempted to find a solution for the problem of EMI and RF/RFI in 1933, during a meeting of the International Electrochemical Commission (IEC) in Paris. At that time, they recommended the formation of a committee to address the problem. From this was born the International Special Committee on Radio Interference (CISPR), which developed what evolved into most of today’s EMC regulations. The USA officially started imposing regulations on EMI in 1979, and the European Union soon followed in the mid 1980s.

Today, EMI Coating and Shielding are more important than ever. With the advancement of technology, devices are getting smaller and their electronic components are more intricate and sensitive. This is contributing to the rise in device failures due to EMI or "noise." Managing this noise has become an even bigger challenge due to the small size of the mechanical parts and faster operating speeds of these components. Engineers, however, continue to innovate and adapt to meet this particular challenge of our ever-changing world.

EMI Shielding Benefits

- Improved Performance

- The primary benefit and aim of EMI/RF shielding is the reduction of electromagnetic interference, which in turn prevents interruption, obstruction, performance degradation or even malfunctioning of electronic devices and appliances. The efficiency of an electronic device can be greatly improved with a high quality and reliable EMI or RFI shield.

- Recyclability

- Unlike conductive coatings, EMI/RF shielding compounds are highly recyclable. This is a huge plus in the sustainability category.

- Permanence

- Shield permanence is an integral property in EMI shielding compounds. This contrasts sharply with conductive coatings, which are scratch prone, and may cause a magnetic shield to fail, delamination during thermal cycling, or any other host of adhesion issues.

- Protection of Human Health

- EMI shielding helps protect humans from all the potential health problems caused by exposure to EMI/RFI. These potential problems include: immediate burns from acute exposure to EMR, eye damage from millimeter (mm) waves (mm waves are used in airport security scanners), and human tissue heating from shortwave radio frequencies. Even extremely low radio frequencies have been known to induce perceivable effects in the human body, such as an irritating tingling sensation.

EMI Materials Process

EMI Enclosure Suppliers offer EMI shields are also called magnetic shields, and may be made from metals with high magnetic permeability, which is the ability to absorb magnetic energy. Metals such as nickel, copper, steel and aluminum are commonly used, although the industry standard magnetic shield material is Mu-Metal®.

- Nickel

- While nickel, a naturally occurring element, can be used alone as a shield, it is often an alloy ingredient. It offers hardness and durability, electrical conductivity, and magnetism.

- Copper

- Copper is one of, if not the, most reliable sources of magnetic shield material. It is easy to form, and it is highly effective at blocking and reducing magnetic and electrical waves. It is, however, more expensive than many other shield materials.

- Steel

- Steel, particularly carbon steel or stainless steel, works well as an EMI shield material because of its permeability value, which allows it to block low-frequency magnetic interference.

- Aluminum

- Aluminum is chosen for shield applications because it is non-ferrous, highly conductive, and lightweight.

- Mu-Metal®

- This metal is an alloy of nickel, iron, copper and molybdenum. It is recognized as the industry standard shield metal, and offers very high magnetic permeability and the highest level of EMI/RF reduction.

EMI Shielding Design

Manufacturers design enclosures and shields in such a way that, usually, they do not need to be solid. Rather, manufacturers prefer to use perforated metal suppliers to provide the material. They are able to do so as long as the shield surface holes are smaller and closer together than the electromagnetic waves to be blocked. Microwave doors are a good example of this.

Also, when manufacturers need more flexibility, they opt for a coating over a shield. EMI coating allows for more flexible applications, as it may be spray-coated to the inside of plastic housings or the outsides of wires and regular enclosures.

When designing EMI shield products, manufacturers also take into account the specific application requirements of their individual clients. For example, while shields are generally available in one piece, they can also be designed with: peel-off tops or as a “fence and cover” (a combination of two-piece shields). Also, manufacturers can produce custom shields.

EMI Shielding Images, Diagrams and Visual Concepts

EMI shielding, a technique of creating a barrier that prevents the leakage of strong electromagnetic fields which interfere with sensitive devices and signals.

EMI shielding, a technique of creating a barrier that prevents the leakage of strong electromagnetic fields which interfere with sensitive devices and signals.

EMI are classified according to the duration of the interference, which the types of interference are continuous which emits a continuous unwanted signal and a pulse which only occurs for a short duration.

EMI are classified according to the duration of the interference, which the types of interference are continuous which emits a continuous unwanted signal and a pulse which only occurs for a short duration.

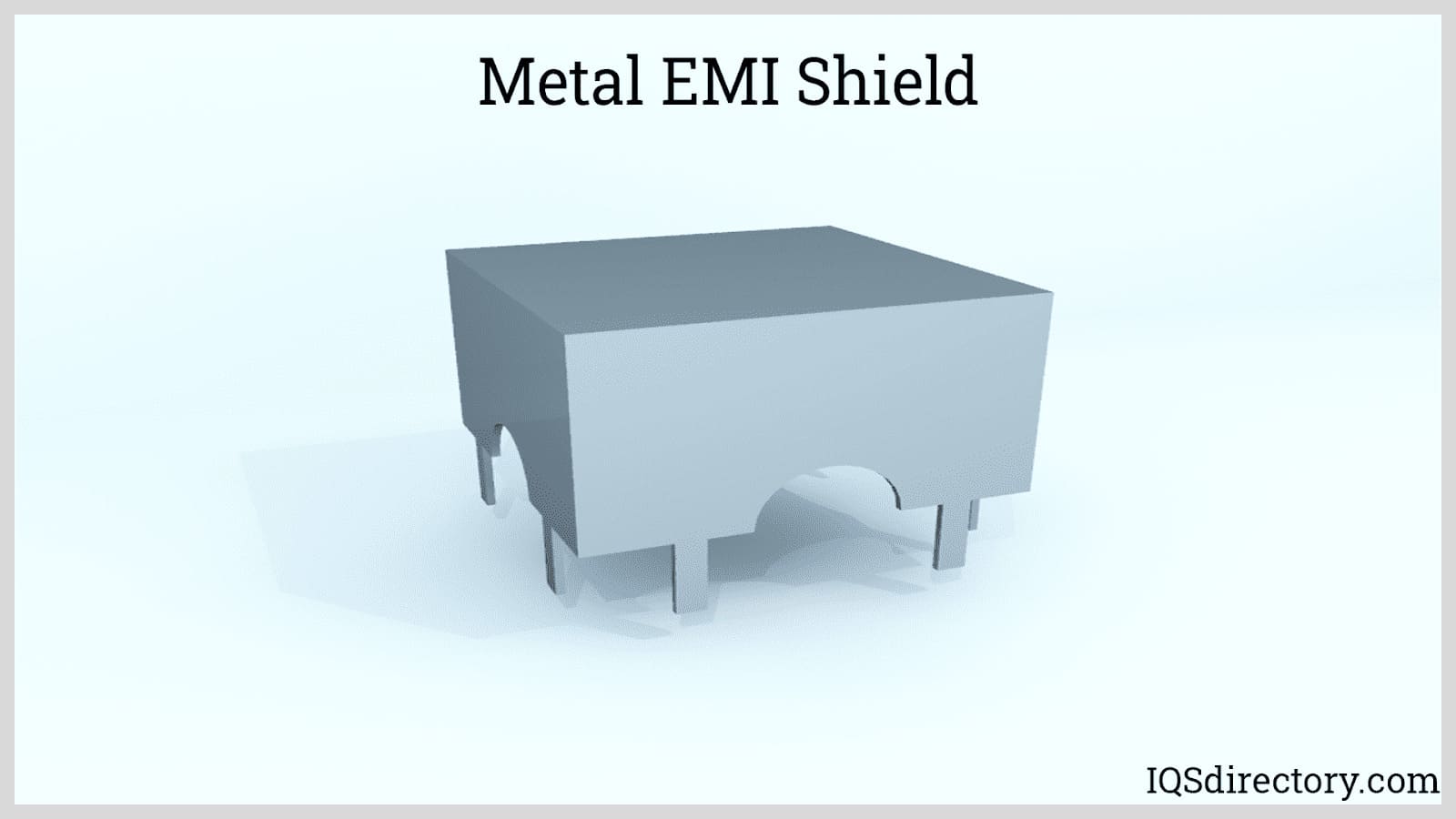

Metallic properties such as electrical conductivity, magnetic permeability, strength, and ductility are suitable for shielding structural materials.

Metallic properties such as electrical conductivity, magnetic permeability, strength, and ductility are suitable for shielding structural materials.

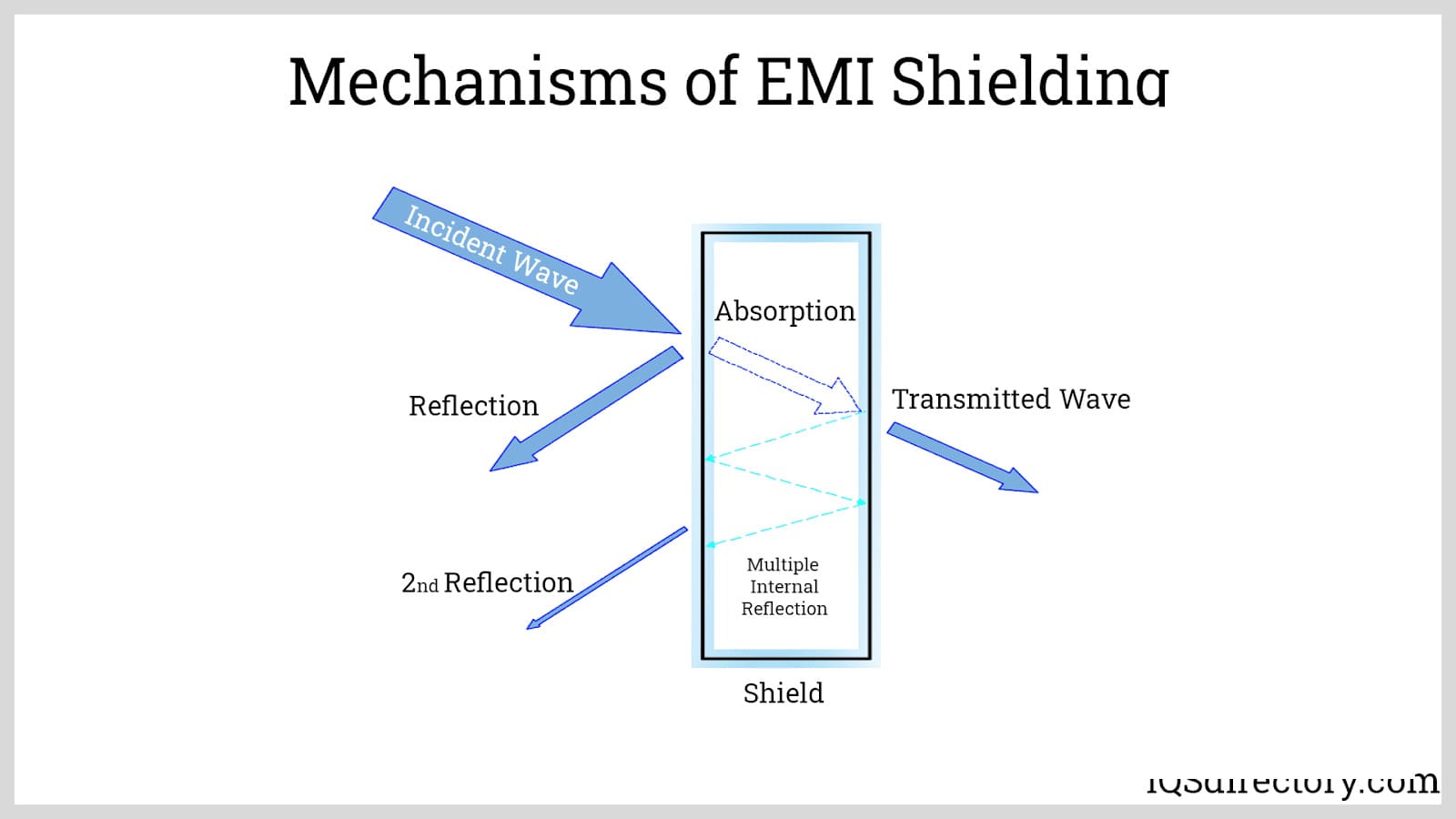

The mechanisms of EMI shielding includes reflecting the incident wave or absorbing the wave.

The mechanisms of EMI shielding includes reflecting the incident wave or absorbing the wave.

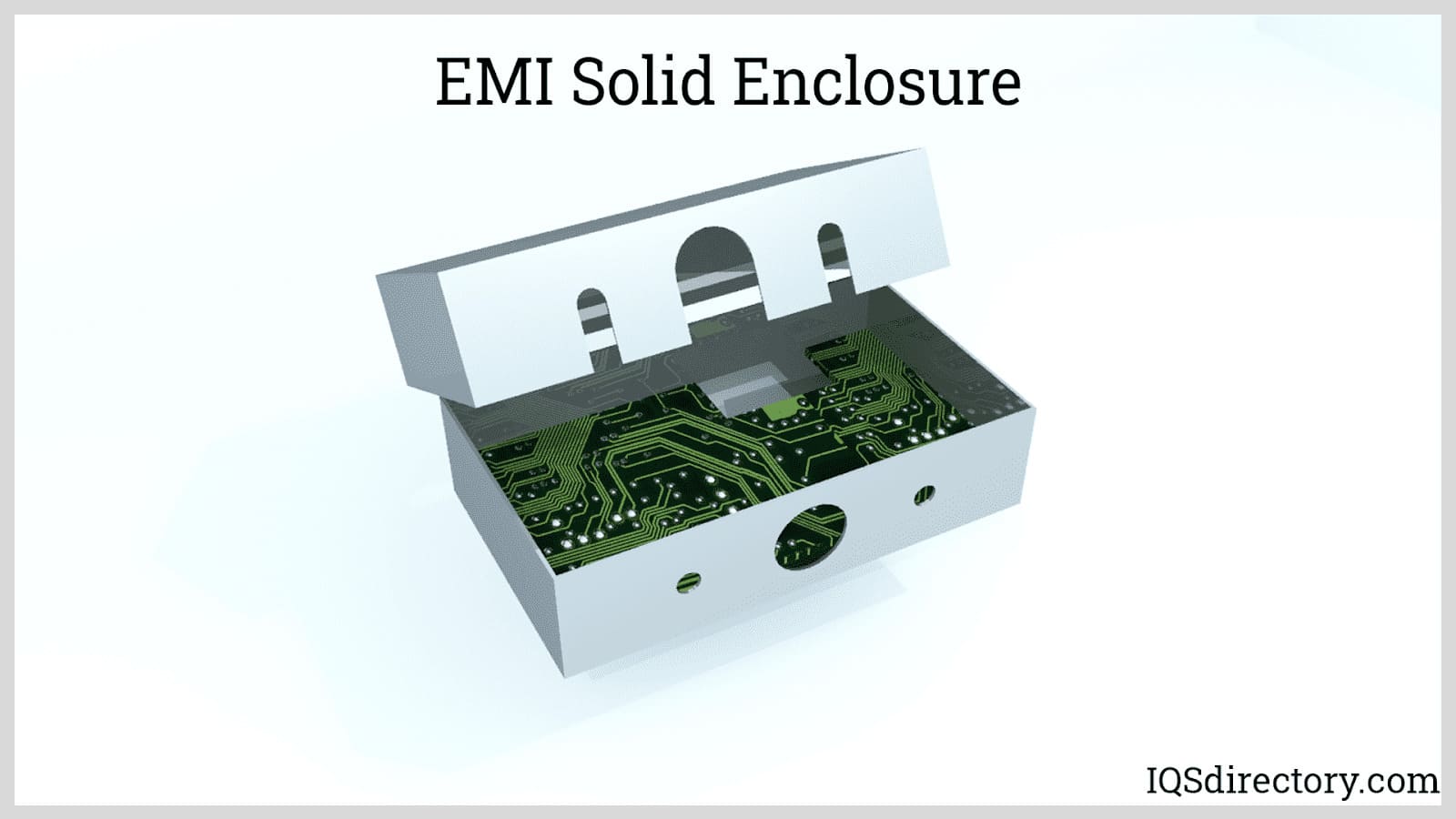

Solid Enclosures prevents electromagnetic waves from getting into or out of the system, the enclosure is grounded so that any stray current is diverted to ground, which minimizes the risk of electric shock.

Solid Enclosures prevents electromagnetic waves from getting into or out of the system, the enclosure is grounded so that any stray current is diverted to ground, which minimizes the risk of electric shock.

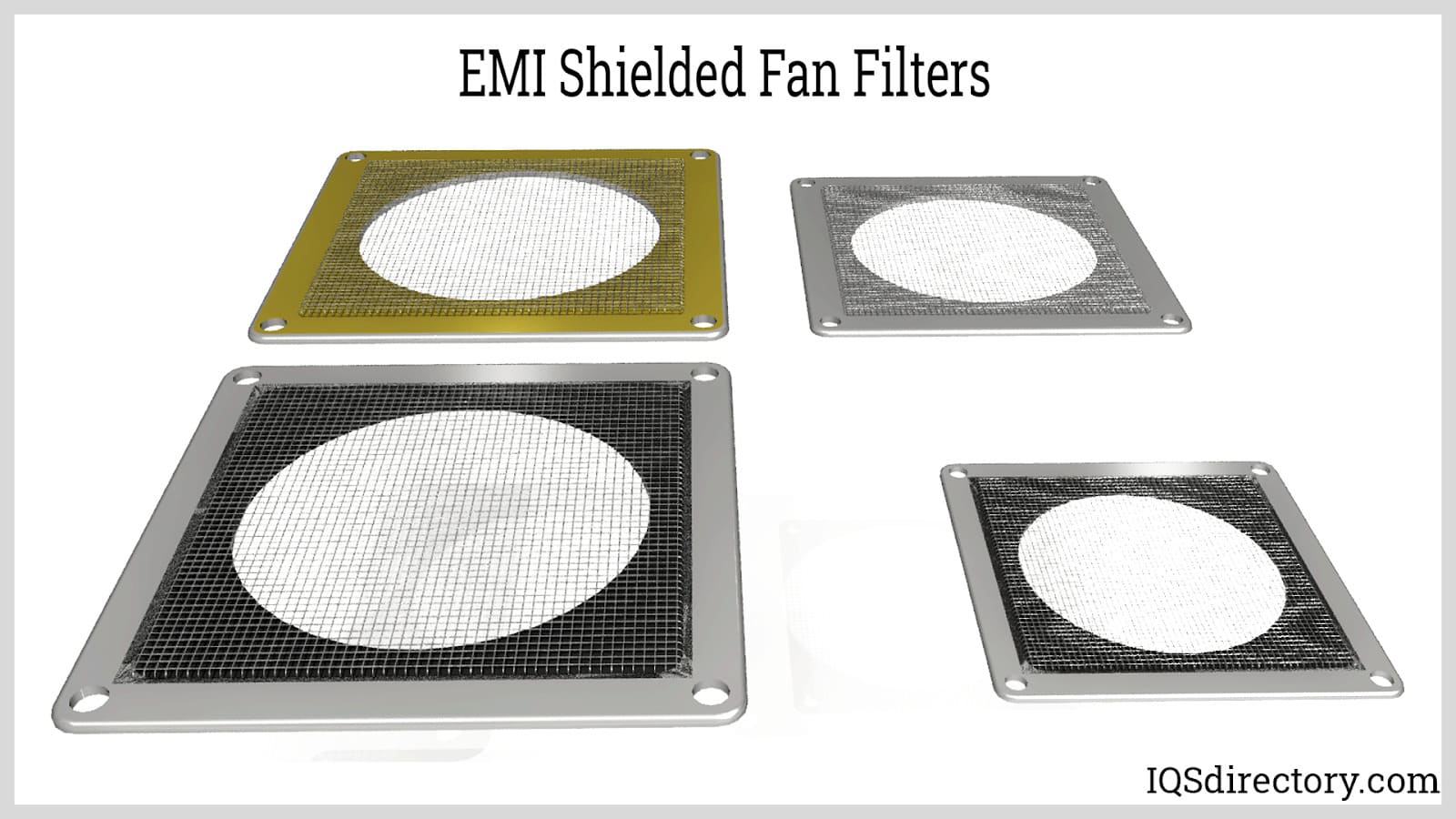

Shielding materials with penetrations or discontinuities less than the expected wavelength of the EMI while allowing ventilation to the system.

Shielding materials with penetrations or discontinuities less than the expected wavelength of the EMI while allowing ventilation to the system.

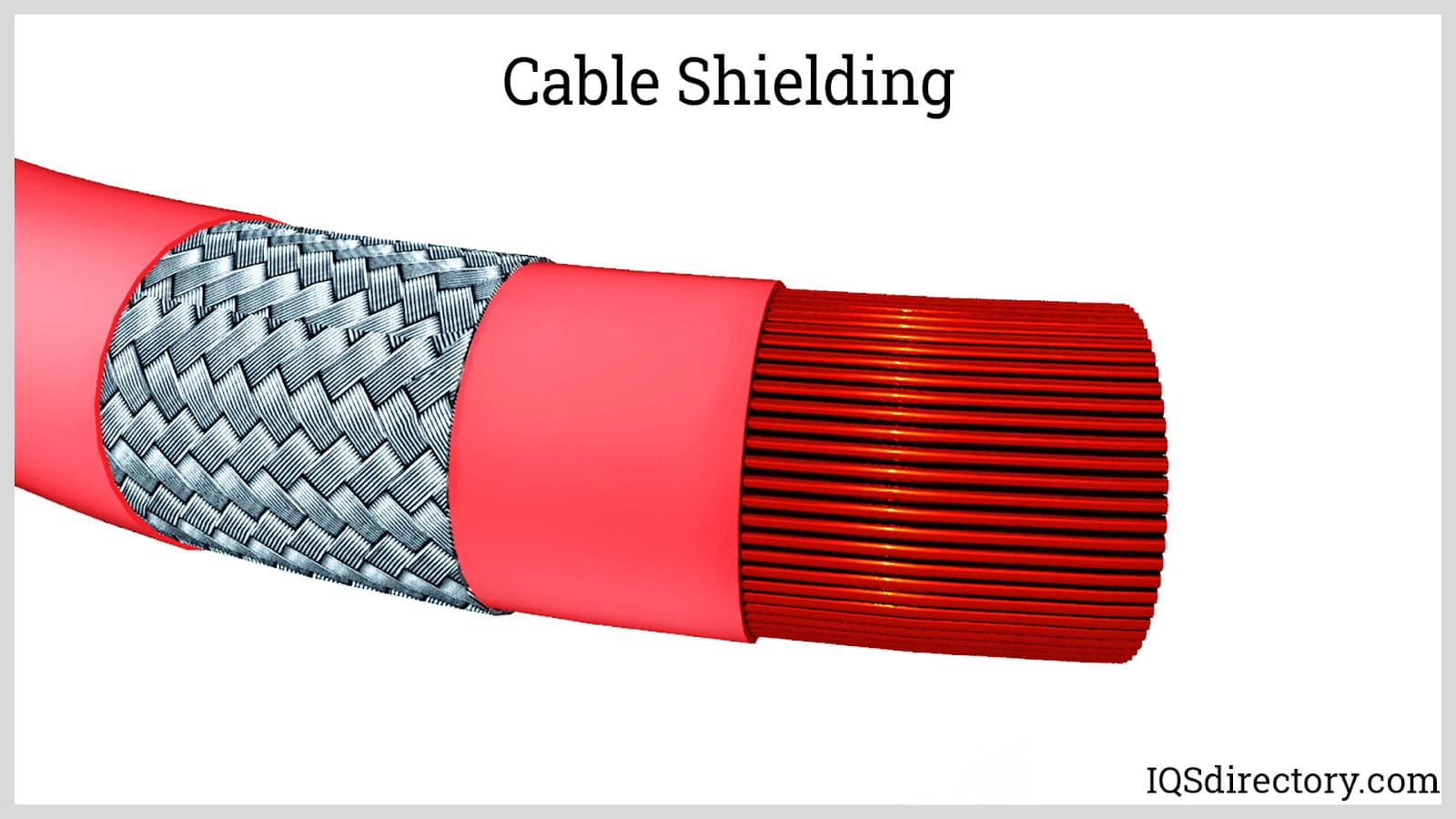

Tapes or wire braids that cover the insulated conductor of a power or instrument cable.

Tapes or wire braids that cover the insulated conductor of a power or instrument cable.

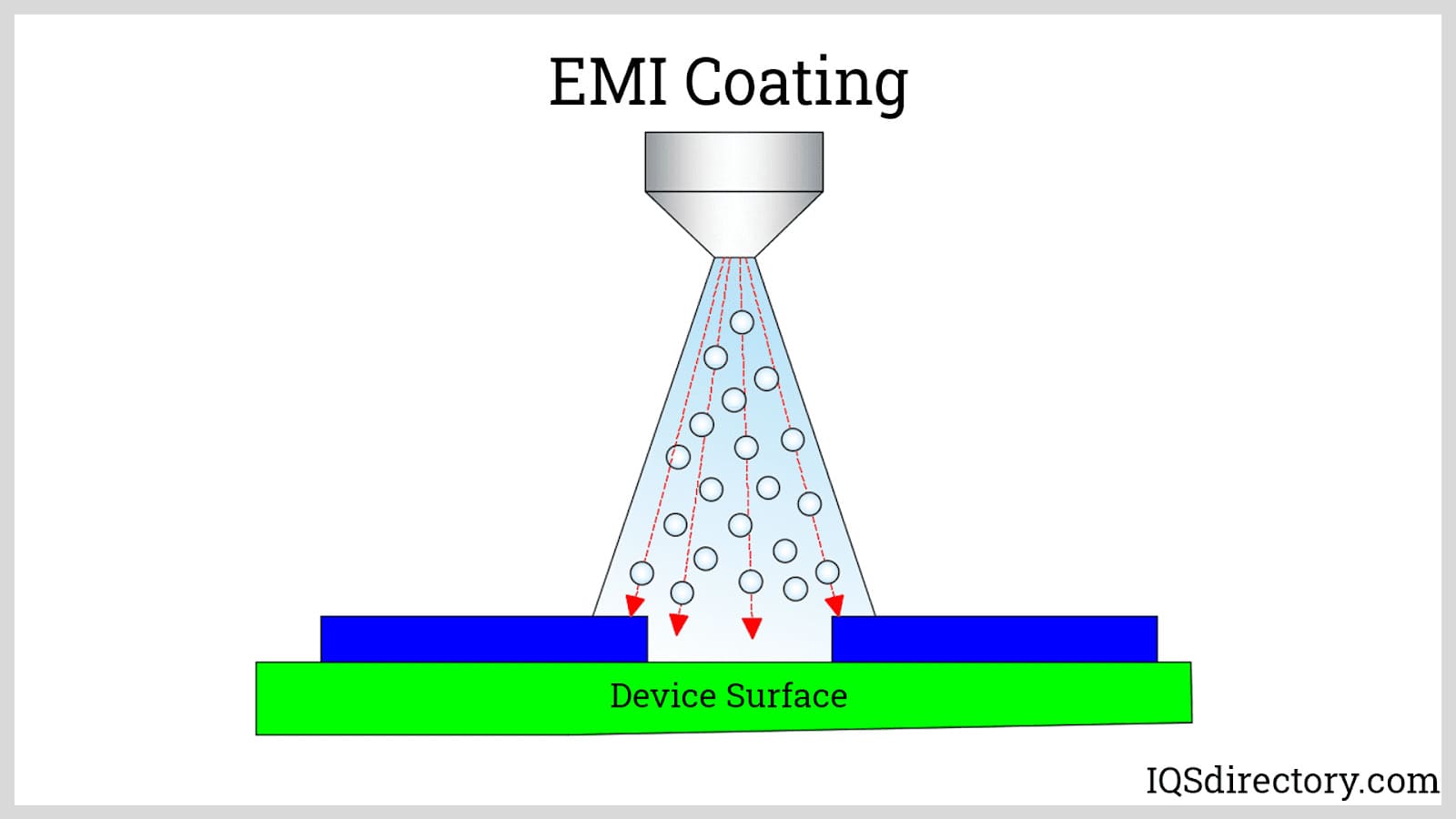

EMI shielding materials can be coated through painting, spraying, dispensing, and electroplating when metallic shielding would be impractical.

EMI shielding materials can be coated through painting, spraying, dispensing, and electroplating when metallic shielding would be impractical.

EMI Shielding Types

- Electromagnetic Shielding

- A barrier which protects electronic equipment from ambient electromagnetic interference.

- EMF Protection

- Requires the use of magnetic shielding materials or products to absorb or redirect electromagnetic fields (EMF) from interfering with sensitive devices as well as contact with people.

- EMI Coating

- Sprayed on the interior of electronic device housings in order to protect sensitive electronic equipment from electromagnetic interference. In a majority of scenarios, EMI/RFI shielding is created using a type of spray, often made from acrylic-based materials. This type of shielding is used in plastic electronics housings. "Metal inks" containing copper, nickel or chromium alloys may be sprayed on to virtually any housing or material to create the effect of EMI shielding. Field shielding agents can be bought in the forms of paints and brush on coatings too.

- EMI Enclosures

- Or "faraday cages", protect sensitive electronic equipment from electromagnetic interference. EMI enclosures surround the equipment which needs to be shielded, absorbing harmful EMI and RF/RFI.

- EMI Filters

- Passive electronic devices which block conducted electromagnetic interference generated by surrounding electronics. An alternative to electromagnetic field enclosures, coatings and gaskets is the EMI filter, a passive electronic device which suppresses the electromagnetic interference generated by surrounding electronics. EMI filters are used to block electromagnetic interference conducted through power lines and signals (not RFI). Usually attached or integrated into the power source or switch which is to be shielded, EMI filters shunt high EMI frequencies, allowing normal low frequencies to pass; as with all types of EMI shielding, EMI filters work to both block incoming EMI and outgoing EMI. EMI filters can be an effective way to manage the EMI created on a specific power source or power line, although EMI shielding such as coating, enclosures and gaskets are still necessary to provide full protection from RF/RFI.

- EMI Gaskets

- Create more robust EMI and RFI protection by preventing the leakage of EMI in or out of an enclosure through seams or gaps. EMI gaskets create more robust EMF protection by preventing the leakage of EMI in or out of an enclosure through seams or gaps. Gaskets are made from electrically conductive rubber materials and are often combined with EMI shielding metals. As electronic equipment advances and electromagnetic and radio frequencies become higher and stronger, EMI gaskets are used for more robust protection.

- EMI Shields

- Materials or products used to redirect or absorb electromagnetic interference in order to protect sensitive electrical devices.

- Magnetic Shielding

- Also called electromagnetic (EMI) shielding, is the process of protecting electronic equipment from ambient electromagnetic interference.

- Magnetic Shields

- Materials or products that protect electronic devices from interference from magnetic fields or electromagnetic fields (EMF).

- Mu Metal®

- A nickel-iron alloy that is used to protect sensitive devices from magnetic fields that would cause magnetic interference.

- RF Absorbers

- Also referred to as radar absorbers or microwave absorbers, protect equipment from radio frequency interference (RFI) by absorbing the magnetic energy before it can reach the equipment. RF absorbers, sometimes called microwave absorbers or radar absorbers, protect equipment from RFI by absorbing the magnetic energy before it can reach the equipment.

- RFI Shielding

- The protection of equipment from radiated electromagnetic "noise" which travels through the air as radio waves.

- Cable Shielding

- Runs beneath the plastic jacket of a cable and encapsulates the wire or series of wires inside. This shielding can be made from braided strands of copper, other metals like aluminum, a spiral of copper tape or a layer of conductive polymer. The purpose of cable shielding is to reduce the noise affecting the cable’s signal and to dampen any electromagnetic radiation that might interfere with other devices. In order to work, the shield must cover all splices in the cable.

- Radiation Shielding

- Reduces the amount of radio frequency that interferes with an electronic device. A radiation shield is usually used in mobile phones because they operate through wireless communications in a microwave band frequency.

EMI Shielding Applications

In today's world where gadgets have almost overcome our lives, there are millions, probably billions of magnetic field waves scattering around at any given point of time. These signals can cause unending EMI, RF and RFI Shielding problems; magnetic field waves and radio frequency signals hamper other similar electronic devices from working. Here’s a simple example: When the radio is switched on and there is a call on a nearby cell phone, you can hear noise coming out of the radio. This happens because the receiver in the radio also captures some of the cell phone signal. While this specific interference is not a huge problem, similar interactions in other equipment can lead to the appliance or device malfunctioning.

In addition, many of those common household electronic devices and appliances that produce EMR can pose a risk to human health. To avoid exposure to the radiation field and reduce this risk, manufacturers rely on EMI shielding and other magnetic shielding techniques, such as EMI shielding and RF/RFI shielding.

A wide variety of consumer markets and industrial industries rely on shielding products. These include: healthcare, telecommunications, stage production, sound production, radio, marine, medical device, electronics, computer technology, process control and appliance.

Service Details for EMI Shielding

Manufacturers can successfully shield equipment from EMI by enclosing it in a conductive EMI absorbing material (an electromagnetic shield), or by blanketing the equipment enclosures with an EMI coating.

The process employs several methods, including foils and conductive fabric, metallic inner shields, and plastics with a conductive coating. There are also conductive paints, which is a common technique of creating a conductive surface coating in plastics.

No matter which method manufacturers choose, they do so with the intention of creating a barrier, or layer, surrounding electronics, cables with conductive/magnetic materials, and all other electrical components such as EMI Gaskets. This barrier protects them from absorbing outward magnetic interferences, or emitting their own electromagnetic frequencies (EMFs); that’s why it’s called an electromagnetic shield.

EMI Variations and Similar Processes

There are several alternative shield materials and methods competing for dominance. Materials include: foils (copper foil, etc.), plastics with a conductive layer, conductive particle-filled silicone, fabrics with conductive adhesive coating, and metallic inner shields. Methods include: vacuum metallization and Master Bond Coating.

- Vacuum Metallization

- Vacuum molding suppliers provide metallization as an up-and-coming EMI/RF shielding alternative. It involves heating a metal inside a vacuum until it reaches its boiling point, and then allowing the resulting condensation to drip onto a substrate. Once dry, the substrate is protected from EMI and RF.

- Master Bond MB600S

- Master Bond has created a new conductive coating system that offers EMI shielding, temperature resistance, and easy application. Master Bond MB600S is manufactured using one component–sodium silicate. The coating is silver and fully conductive, offering effective shielding and temperature resistance up to 700 degrees Fahrenheit. As a water-based coating, it is non-toxic and easy to handle.

- The coating is effective as a shield within a range of 95 to 105 dB, from 100 MHz to 2 GHz. For above 2 GHz, the shield effectiveness decreases to 60 to 80 dB. It is possible to apply the coating by brushing or spraying. Spraying the coating makes it more effective than brushing. Note: It takes about 48 hours for the coating to set and become an effective shield.

Things to Consider When Choosing EMI Shielding

Whether you’re looking to block mm waves or radio waves, EMI shielding is an important service. However, it can be a little hard to know what type of shield is best for you. For that reason, it is of the utmost importance that you connect with a service provider that is not only skilled and knowledgeable, but concerned with providing you with the best solution possible. You can find that service provider by browsing the companies listed above.

Once you have found the right manufacturer for you, discuss your application at length, as EMI/RF shield effectiveness is dependent on several factors. These include: materials used for the shielding, frequency of the EMI, the size of the application on which the shielding is being applied, etc. With the right service provider, your device will work better and your health will be more secure for years to come.

EMI Shielding Terms

- Anechoic Chamber

- A room in which no acoustical reflections or echoes exist. The floor, walls and ceilings of these rooms are lined with a metallic substance to prevent the passage of electromagnetic waves.

- Attenuation

- An electrical signal’s reduction in concentration as the signal passes through the media. Attenuation is measured in decibels.

- Canted Coil

- A round-wire spring with inclining (canted) elliptical coils that, when compressed, deflect independently. Whenever any part of the coil is deflected, the whole spring responds, allowing consistent loading at each point of contact.

- CE Marking

- A mandatory mark for about 70% of the products sold on the European Free Trade Association (EFTA) and European Union (EU) markets. CE Marking is sometimes called “CE Mark” and referred to as the “Trade Passport to Europe ” for non-EU products.

- Double Shielded Enclosure

- A shielded enclosure containing inner and outer walls isolated from one another, except at the point of filter penetration.

- Electromagnetic Compatibility (EMC)

- The ability of electronic equipment to be operated without EMI.

- Electrostatic Discharge (ESD)

- The release of electrical energy usually caused by the shift of electrons from one object to another as the objects come into contact with and separate from one another. ESD is also known as triboelectric charge.

- ESD Shielding

- Shielding that prevents the failure of electronic equipment from interference associated with electrostatic discharge.

- Emission

- The release from electronic equipment of electromagnetic waves that have the potential to create EMI.

- Filtering

- The removal of certain unwanted signal components through attenuation while allowing the passage of the remaining signal components.

- Impedance

- The complete opposition offered by a circuit to the flow of current at a certain frequency that is a combination of resistance (R) and reactance (X). Impedance is measured in ohms; the quality of the conductor is better the lower the ohmic value.

- Insertion Loss

- Measurement reflecting filtering ability. Insertion loss represents the difference in power reception prior to and after the use of a filter.

- Radiation

- The movement of electromagnetic energy in the form of particles, rays or waves.

- Radio Frequency

- Low frequencies of electromagnetic radiation used for communications.

- RFI (Radio Frequency Interference)

- Interference in a specific frequency range used for radio communication. Unlike EMI, RFI is not conducted through circuits or power lines, but through "free" air space as radio waves. EMI and RFI are often used interchangeably; the term EMI/RFI shielding covers all interference caused by electromagnetic radiation.

- Shielding Effectiveness

- The ability of a shield component to prevent the passage of electromagnetic radiation. Shielding effectiveness is expressed as a ratio of electromagnetic signals with and without the shield component.

- Skin Effect

- The propensity of high frequency current to travel close to the outside of an electric conductor rather than through its cross section. At high frequencies, the effective resistance of a wire is increased by skin effect.

- Slot Antenna

- A radiating element that is created by a slot in the conducting surface or in a waveguide’s wall.

- Vacuum Deposition

- In a vacuum, the condensation of thin material coatings on cool surfaces.

- Waveguide

- Media that controls the passage of electromagnetic energy and signals.

- Magnetic Shielding Foil

- Used in sensitive electronic equipment like industrial controls, circuit control boards and more. Because the foil is so thin, it can easily be cut and installed in tight spaces where there is not much room for heavy layers of protection.

- Wire Shielding

- A specific type of EMI shielding that protects wires and cables from damaging electromagnetic energy. It is also employed when a product is suspected of causing electromagnetic energy, therefore blocking the waves it creates from affecting outside equipment.