Electric Motors

An electric motor is a device that converts electrical energy into mechanical energy. For an electric motor, electric power from a battery or grid is input into the motor, and mechanical energy is output in the form of a rotating shaft.

Once merely a scientific toy, electric motors are found today inside everything from power tools to elevators to toothbrushes to once again toys. Even a gasoline-engine automobile will have electric motors to move its windows, ventilation fans, and wipers.

Modern civilization would literally grind to a stop without electric motors. The future promises roads dominated by electric vehicles and factories staffed by robots whose movements are impelled by electric motors. A basic understanding of electric motors is essential for their proper application.

While all electric motors provide the same basic function of converting electrical energy to mechanical energy, the method by which they convert the energy can differ greatly. In terms of conversion methods, there are four main types of electric motors: servo motors, synchronous motors, induction motors and electrostatic motors, which are also referred to as capacitor motors.

Quick links to Electric Motors Information

The History of Electric Motors

In 1821, Michael Faraday used electrical power from a battery to cause a wire to circle around a magnet in a pool of mercury. A similar experiment was conducted in 1822 by Peter Barlow, using a star-shaped wheel called a Barlow Wheel, which dipped its tips into mercury as it rotated.

In 1827, a Hungarian scientist and priest named Ányos Jedlik invented what he called an 'electromagnetic self-rotor,' which was the first designed-and-built electric motor that contained the same components of stator and rotor that are recognizable in motors today.

In 1837, Thomas Davenport acquired the first patent for an electric motor intended for commercial use. Davenport was a man ahead of his time, and while his design was sound, it was only long after his patent expired that batteries and electrical grids were developed to economically power his motor.

By the late nineteenth century, effective electric power sources were available, and electric motors became a key part of the industrial revolution. The early inventors have been followed by countless other inventors and innovators, improving the efficiency and effectiveness of electric motors.

Principles of Electricity

To understand how to best use electric motors, it is useful to understand the underlying principles of electricity.

Electricity is the movement of electrons from atom to atom within a conducting medium such as a wire. Early experimenters thought of electricity as a 'fluid' with attributes corresponding to a liquid flowing through pipes. Modern technicians, electricians, and engineers still find this analogy useful.

In this fluid analogy, electrical charge is a measure of the quantity of electrical 'fluid,' voltage is a measure of electrical pressure and current is a measure of electrical flow rate. Since like charges repel each other, electric current flows from places of positive charge to those of negative charge.

Hans Christian Ørsted discovered in 1820 that an electric current generates a magnetic field. Expanding on this work, André-Marie Ampère discovered what has become known as Ampere's Law, that when two wires are placed in parallel and an electrical current is run through one wire, an electrical current will be induced in the other wire.

As a memory aid, John Ambrose Fleming developed the left-hand rule, in which the left hand is used with the thumb pointing up to indicate the direction of motion for the motor, the forefinger pointing ahead to indicate the direction of current, and the middle finger pointing sideways to indicate the direction of the magnetic field.

This push-me/pull-you relationship between electricity and magnetism makes it possible for an electric current to physically move a magnet, and vice versa.

Electric Motor Design

From the early experimental motors that were fundamentally magnets spinning inside wire loops, countless innovations and variations have blossomed. Perhaps the most important difference between types of electric motors is if they are manufactured to run on direct current (DC) or alternating current (AC).

A phase converter can be used in the motor circuit to convert AC power into DC power before it reaches the DC motor, and then the DC motor can run -- indirectly -- with an AC power source. Likewise, there are phase converters that convert DC power into AC power to run AC motors.

Motors also vary in size, number of stator and rotor magnetic poles, rotational speed, and voltage and current ratings. Motors which have a mechanical power output rating of less than one horsepower -- that is, 746 watts -- are called fractional horsepower motors or FHP motors. Motors capable of having their RPM rate adjusted are variable speed motors.

Lastly, electrostatic motors are very different from the others, and instead operate based on the principle of the attraction and repulsion of an electric charge. Electrostatic motors are often used in very small-scale applications such as in micro-mechanical systems (MEMS).

This list of all possible motors is hardly complete and is intended only to give a sense of how much variety is offered by electric motor manufacturers.

Electric Motors Images, Diagrams and Visual Concepts

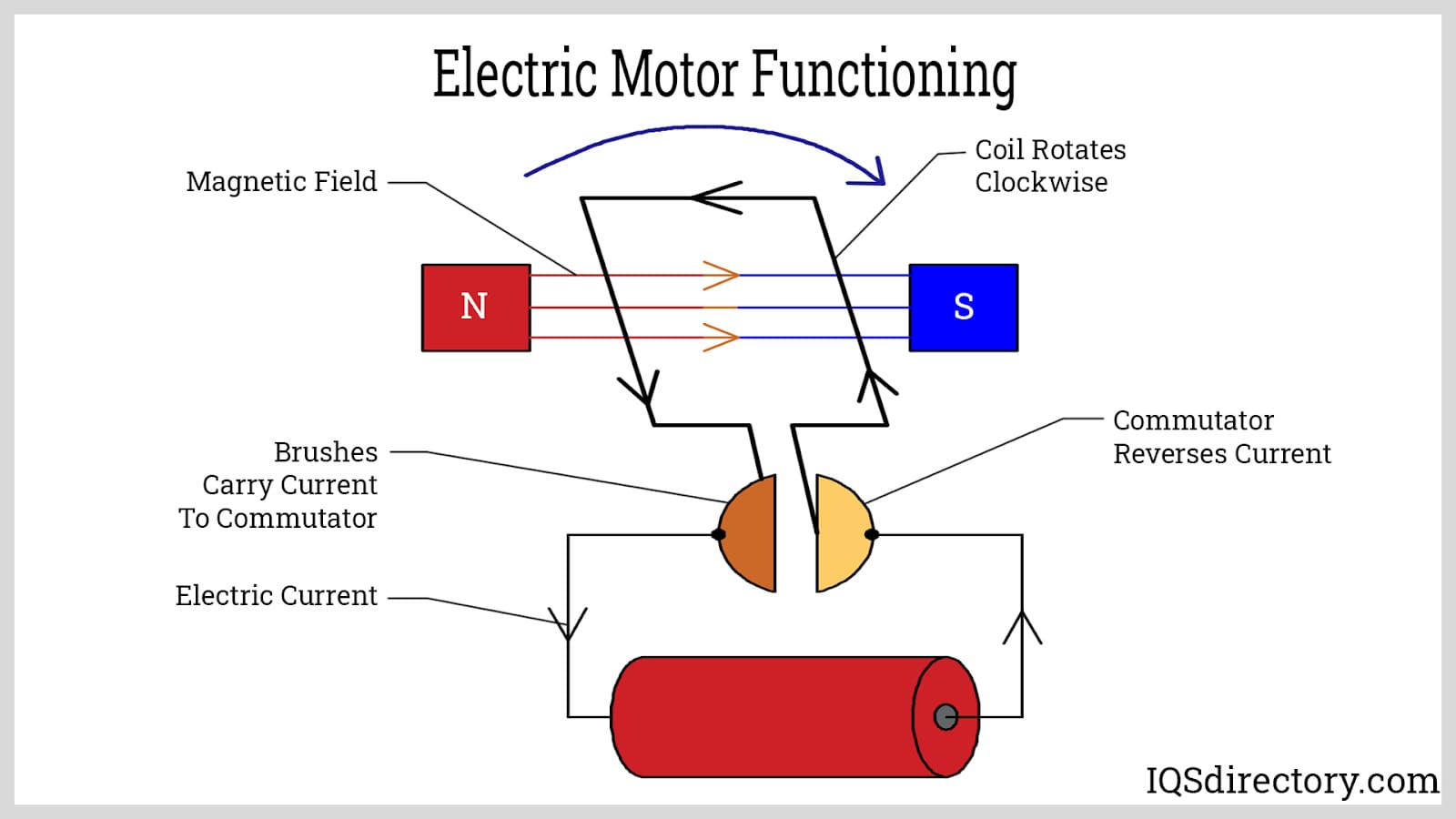

Electric motors function by changing electrical power to mechanical power.

Electric motors function by changing electrical power to mechanical power.

The conversion of electrical power to mechanical power creates force within the motor from the interaction between the electric current and the magnetic field.

The conversion of electrical power to mechanical power creates force within the motor from the interaction between the electric current and the magnetic field.

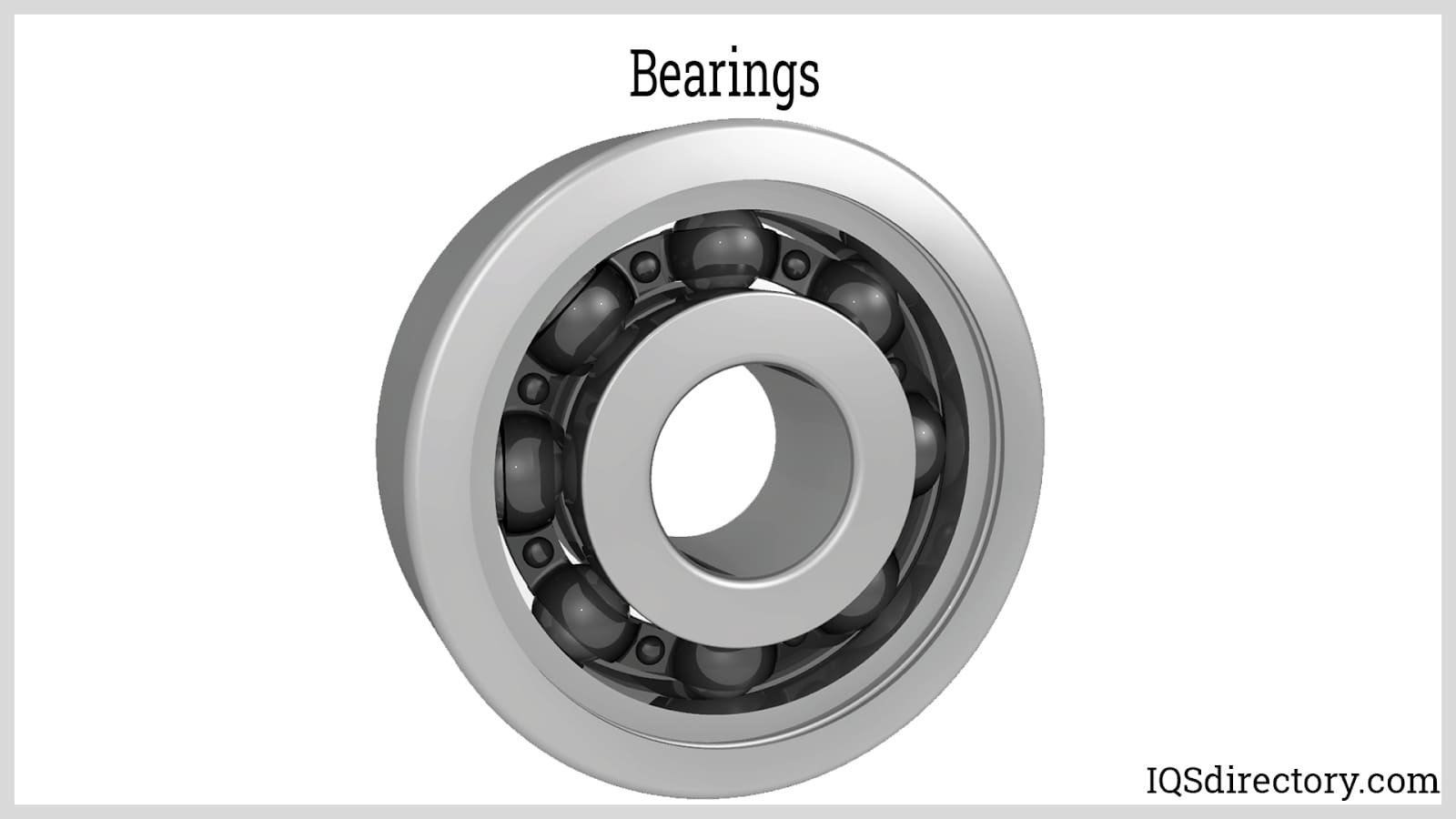

Bearings supports the rotor and allow the rotor to spin on its axis.

Bearings supports the rotor and allow the rotor to spin on its axis.

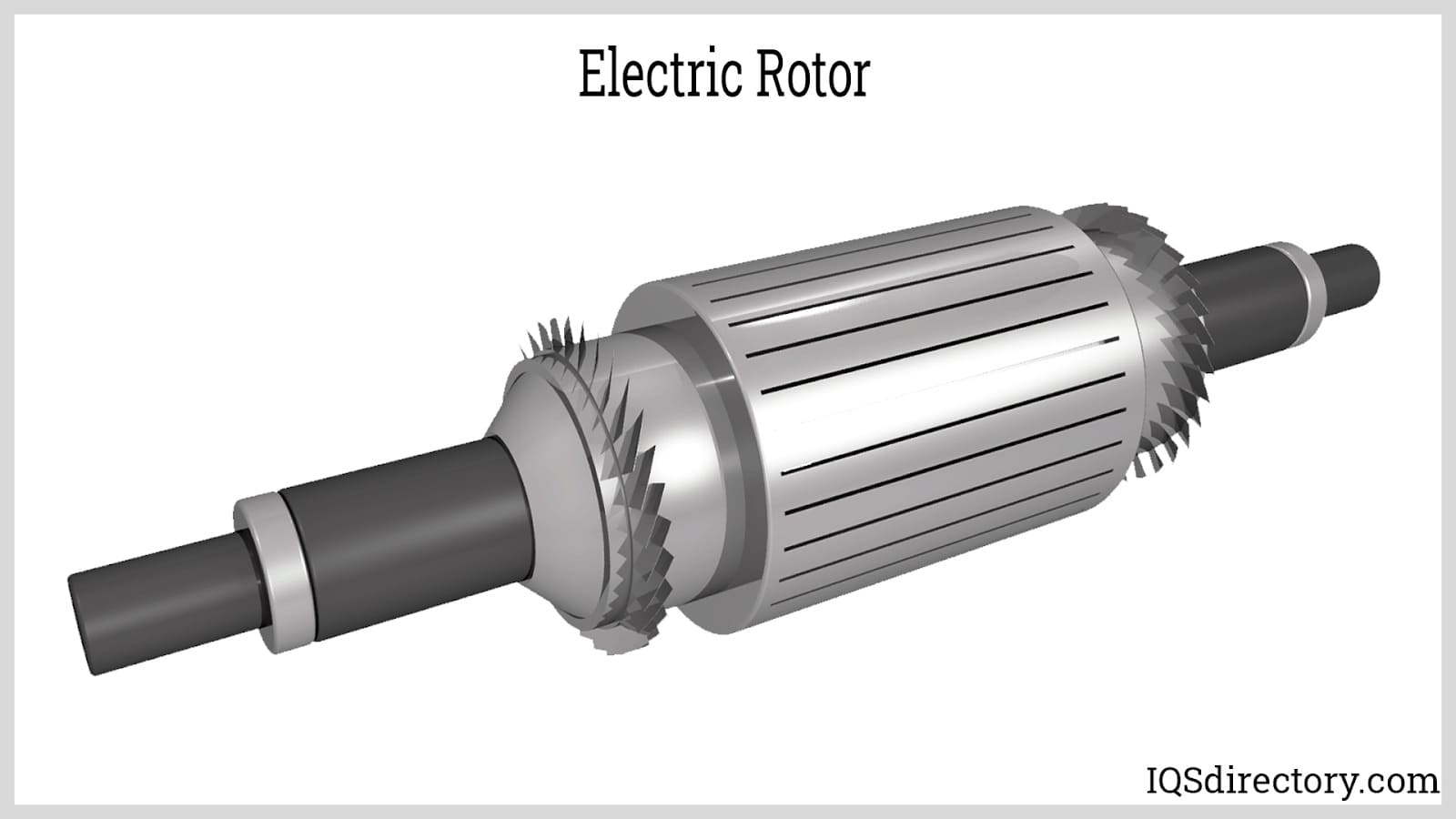

The rotor is the mobile part which supplies the mechanical power and generally holds the conductors that carries current and stator magnetic field which applies force to spin the shaft.

The rotor is the mobile part which supplies the mechanical power and generally holds the conductors that carries current and stator magnetic field which applies force to spin the shaft.

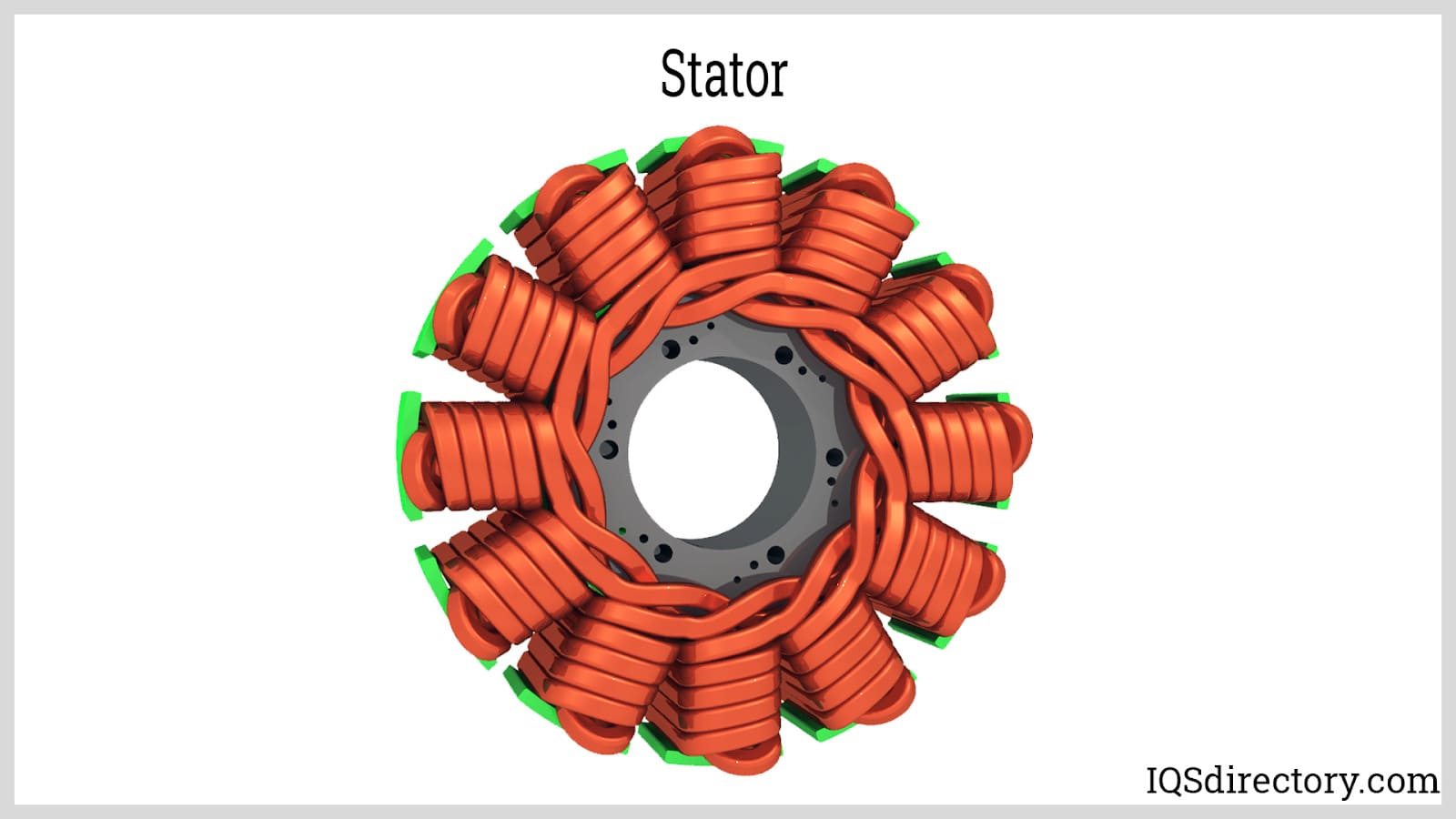

A stator surrounds the rotor, and generally holds the field magnets which produces the magnetic field when passing through the rotor winding.

A stator surrounds the rotor, and generally holds the field magnets which produces the magnetic field when passing through the rotor winding.

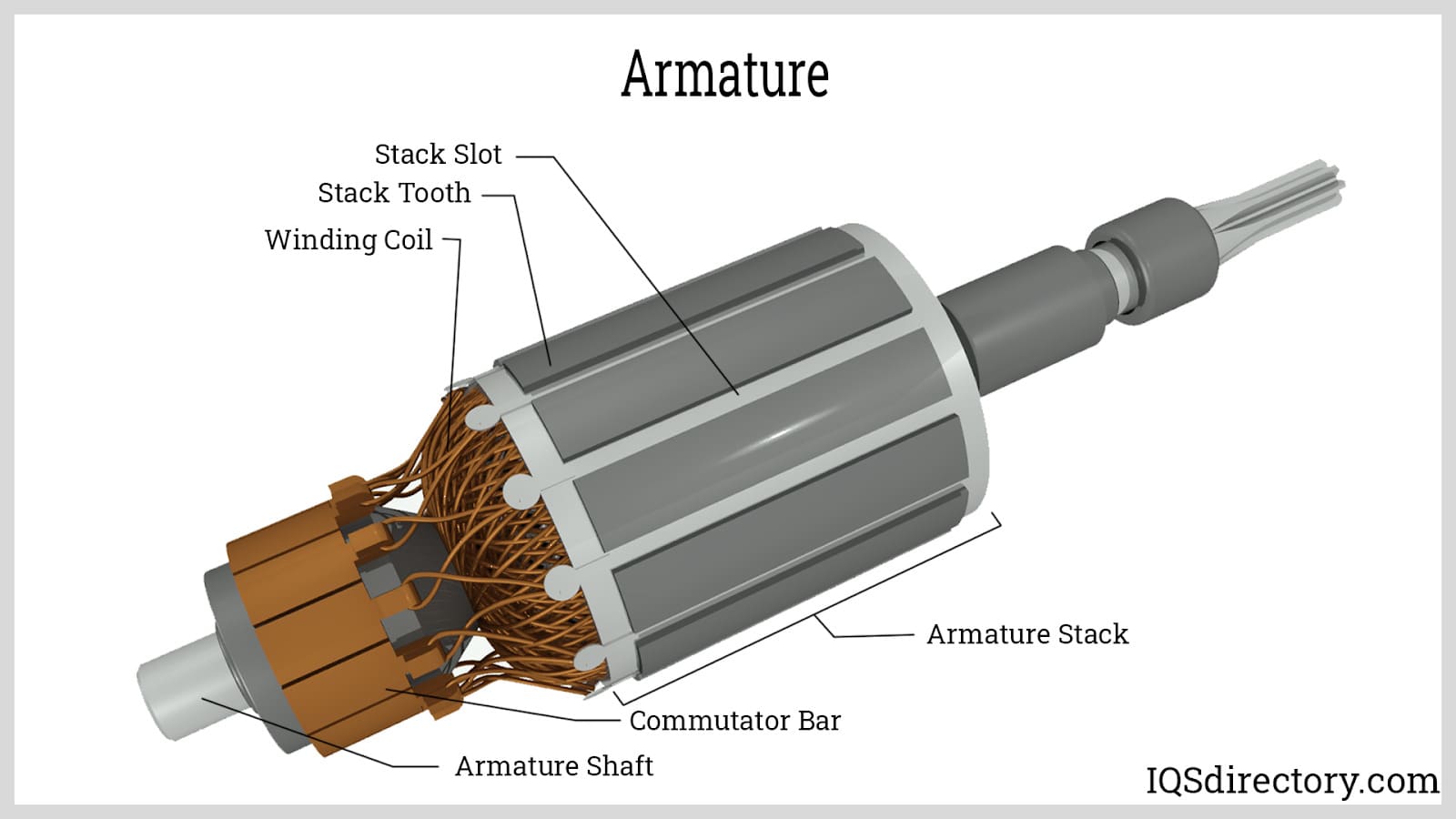

The armature has the electrical current passes through which generates torque.

The armature has the electrical current passes through which generates torque.

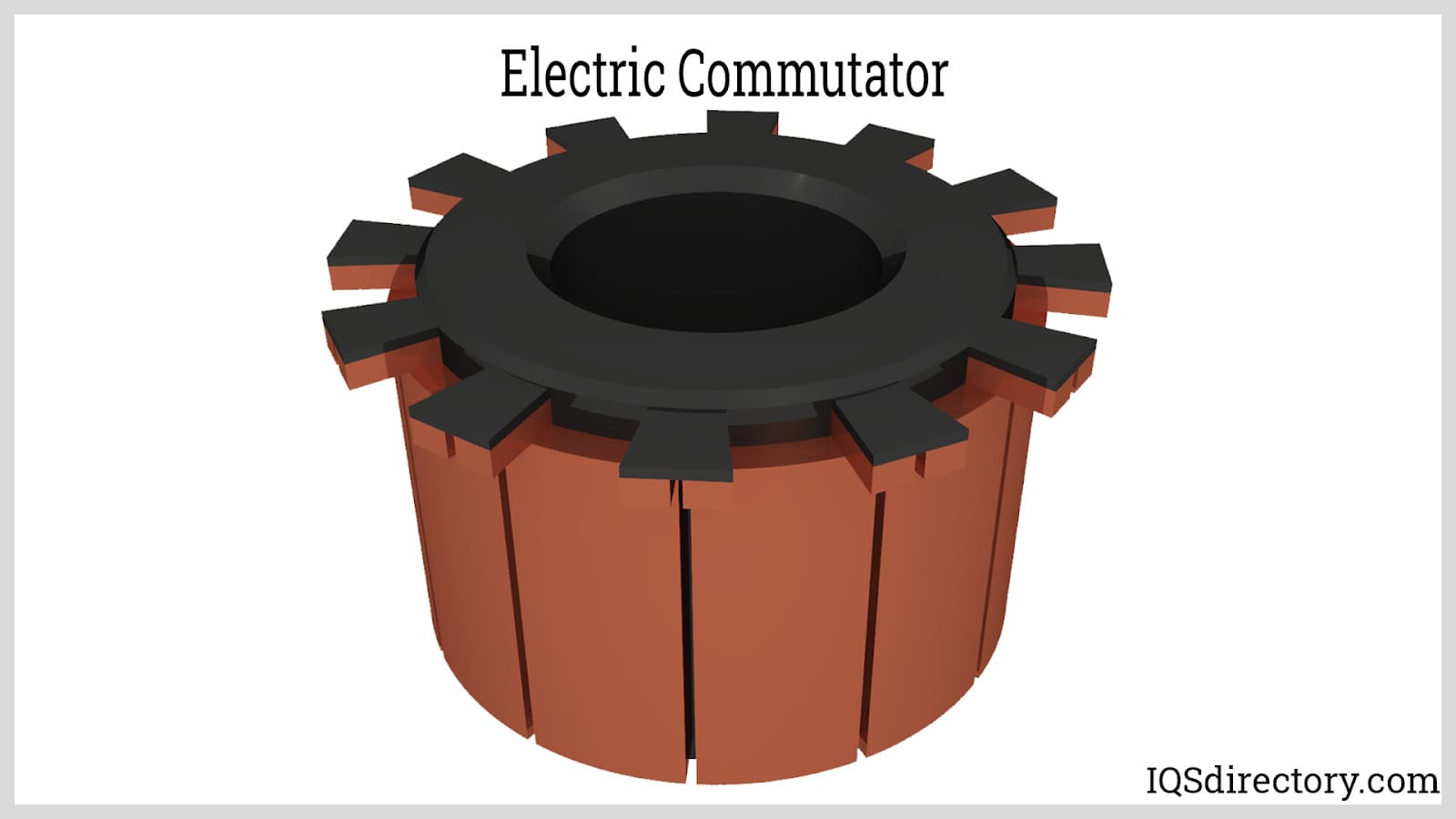

A commutator, a rotary electric switch which supplies alternating current or direct current to the rotor.

A commutator, a rotary electric switch which supplies alternating current or direct current to the rotor.

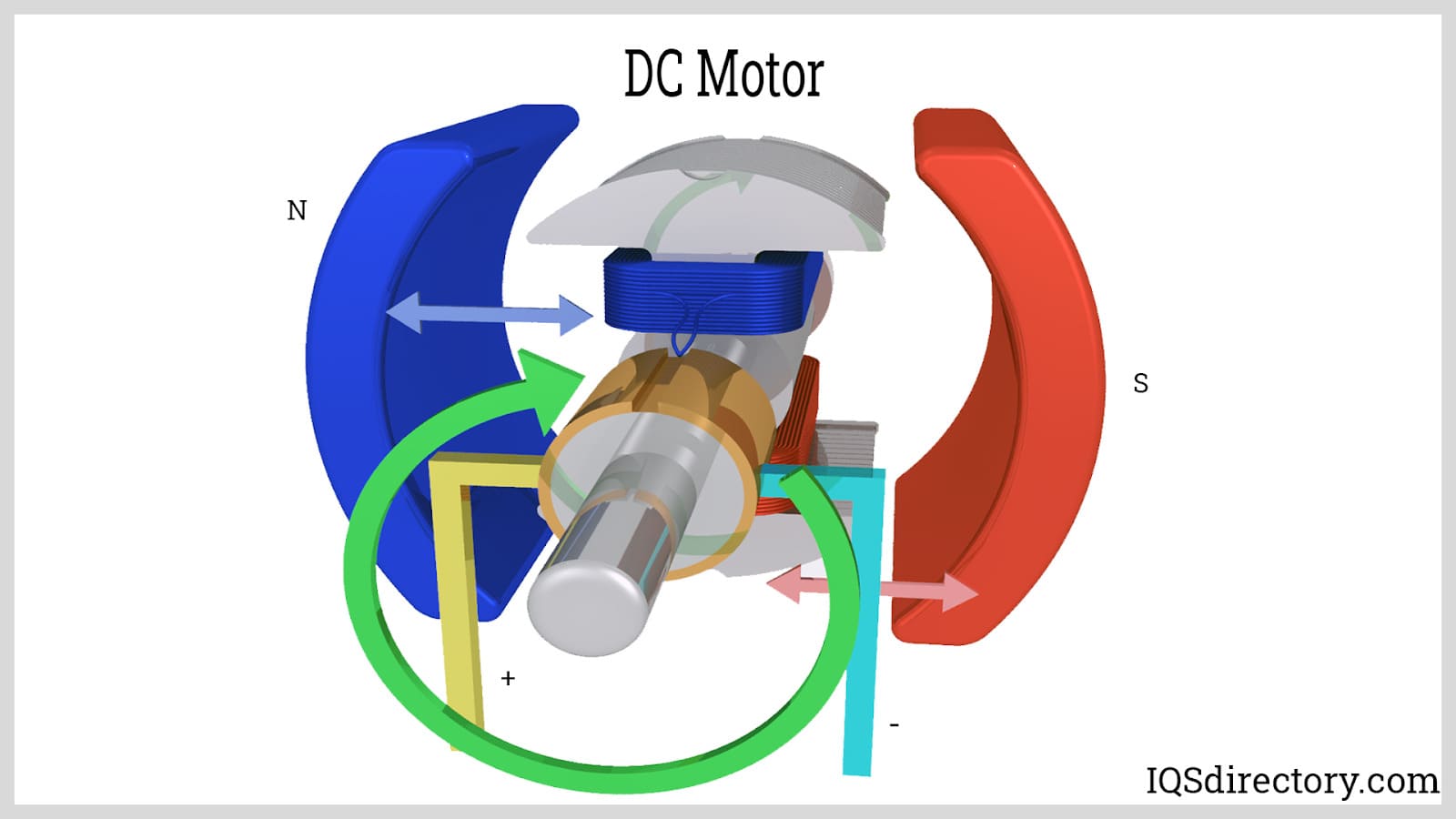

DC motor is a type of rotary electrical motor which converts electrical energy from direct current into mechanical energy.

DC motor is a type of rotary electrical motor which converts electrical energy from direct current into mechanical energy.

An AC motor is an electric motor that consists of a stator with a coil that is supplied with a current to convert an alternating current into mechanical power.

An AC motor is an electric motor that consists of a stator with a coil that is supplied with a current to convert an alternating current into mechanical power.

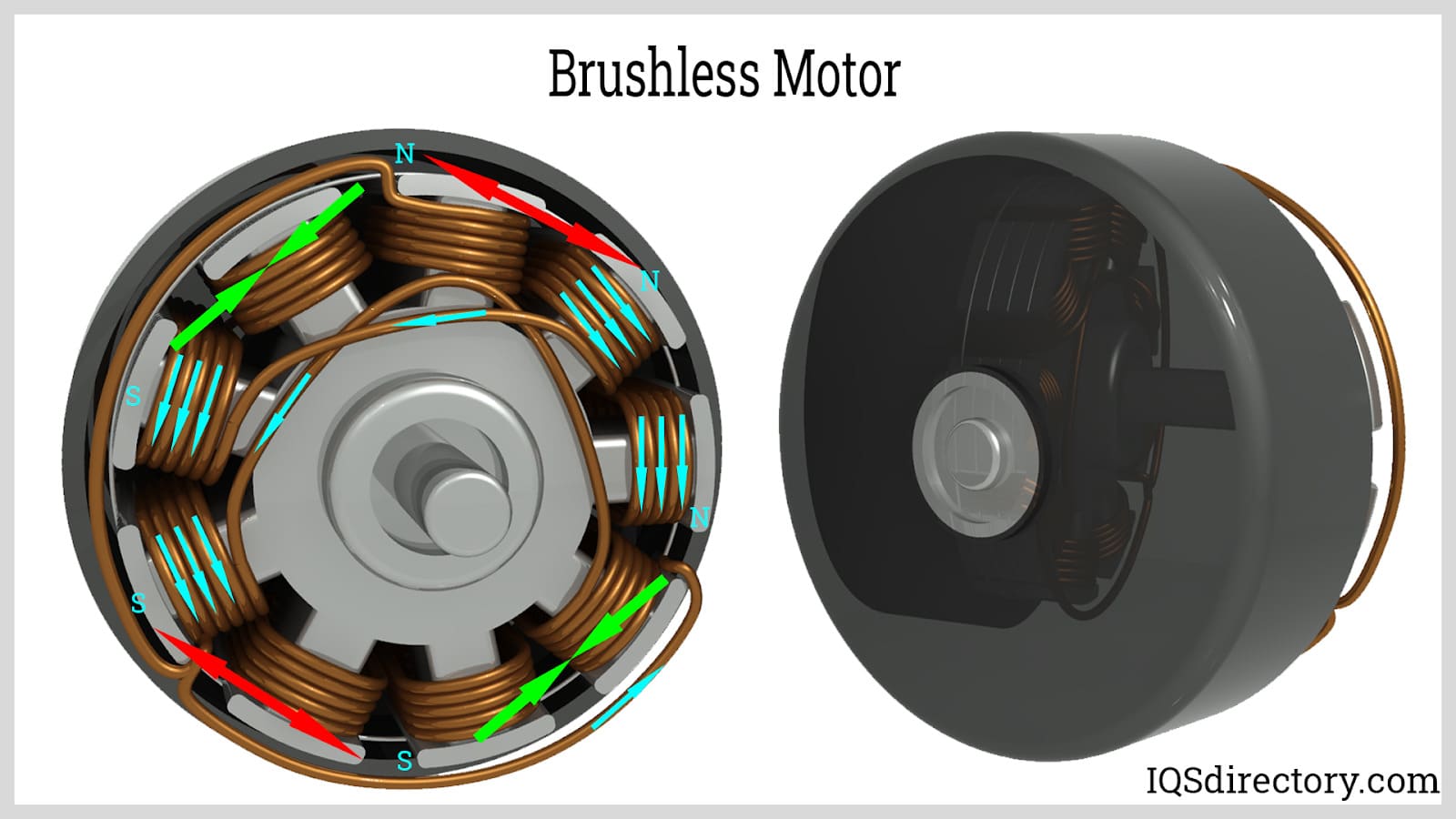

A brushless motor, a type of DC motor utilizing an electronic controller to turn DC currents to the windings creating a magnetic field.

A brushless motor, a type of DC motor utilizing an electronic controller to turn DC currents to the windings creating a magnetic field.

Electric Motors Types

- 12V Motors

- A type of electric motor that operate based on 12 voltages, which are a unit of electrical force, of energy which they convert into mechanical energy to be utilized in the powering of various machinery or equipment.

- 3 Phase Motors

- A type of electric motor that operates based upon a three-phase electrical load, which is a common form of electric power transmission.

- AC Motors

- Alternating current motors generate their magnetic field by an electromagnet powered by the same AC voltage as the motor coil. It is dispersed in single or three-phase forms with the ability for direction changes of its current cycles. An AC motor can be a single or three phase motor, so that there are four basic types of AC motors: single phase induction motor, three phase induction motor, single phase synchronous motor, and three phase synchronous motor. DC motors are always single phase.

- Brushed Motors

- Have built mechanical brushes that automatically commutate coils on the rotor as the motor rotates. Brush-type motors are more cost effective than brushless.

- Brushless Motors

- Allow commutation of the coils on the stator by using an outside power drive without brushes.

- DC Motors

- Or direct current motors have adjustable speed and torque applications. In a DC electric motor, there would be adjustable speed and torque along with a rotor and a permanent magnetic field stator.

- Electrical Motors

- Motors that convert electric energy into motion using magnetism. Electric motors contrast engines because engines use fuel and electric motors do not.

- Gear Motors

- Consist of a gear head and motor. Together they can reduce the speed of the motor to the preferred RPM's.

- Induction Motors

- Use electric current to generate rotation in the coils instead of delivering the rotation directly. They acquire their torque from currents produced in loops by a changing magnetic field in the field coils.

- Linear Motors

- A type of electric motor in which the converted mechanical energy provides motion to the equipment or machinery solely upon a single linear-axis.

- Permanent Magnet Motors

- Motor magnets embedded into the rotor assembly. This design allows them to align with the rotating magnetic field of the stator.

- Servo Motors

- Have shafts that do not rotate freely; the shafts move to a definite angular location. They are often used for motion control in robots, hard disc drives, etc. Servo motors, used in hobby aircraft and robotic actuators, have built-in microcontrollers so that they can be turned to a precise number of degrees on command. Stepper motors, used in robots and 3D printers, are even more precise, and also much more expensive and complicated to control. Servo electric motors operate based on a servomechanism (often shortened simply to servo) that utilizes error-sensing feedback to function and make corrections. Servo motors are extremely small electric motors and are often utilized in robotics, such as remote-controlled cars.

- Single Phase

- A type of electric motor that operate on single phase electrical power, which is a power source in which all of the voltages of the power supply in unison as a single unit, functioning to distribute alternating current (AC) power.

- Stepper Motors

- Essentially electric motors without commutators. All of the commutation handled externally by the motor controller can be stepped at audio frequencies, allowing them to spin quite quickly and be started and stopped precisely at controlled orientations.

- Synchronous Motors

- Can operate at a constant speed up to full load. They have a series of three windings in the stator section with a rotating area; there is no slip. Nikola Tesla is credited with creating the first AC motor in 1887. An AC motor runs on AC current and uses the changing magnetic field produced by the alternating current to move the rotor, so that a commutator is not required. AC motors can be induction or synchronous. Synchronous electric motors are a type of AC motor that operate based on a rotating magnetic field that is the result of the motor’s rotor and current passing at the same rate. Much like synchronous motors are induction motors, which are fairly identical except that induction motors are asynchronous, even at times being referred to as asynchronous motors instead of induction motors. Induction motors operate based on the principle of electromagnetic induction in which a voltage is produced across a conductor, being the rotor, as it is moving through a magnetic field. Induction motors are less expensive while synchronous motors can provide constant speed with changes in torque.

Electric Motor Operation

The basic operation of an electric motor can be understood by visualizing a very simple design which consists of only a rotor and stator. As the names imply, the rotor rotates and the stator is static or stationary.

The rotor is a rod that rotates on its long axis. An arm extends out from the rod, and at the tip of the arm is a permanent magnet. The stator is a rod positioned parallel to the rotor and outside the radius of swing for the rotor arm.

The stator rod is wrapped with wire. When electric power is connected, current flows through the wire and generates a magnetic field around the stator. The magnetic fields of the coils combine to transform the stator into an electromagnet. The electromagnet magnetic field then attracts the permanent magnet on the rotor, causing the rotor to swing.

A switching system involving wire brushes on the stator and metal strips on the rotor completes the circuit and alternately energizes and de-energizes the electromagnet, depending whether the rotor magnet needs to be attracted or not.

To produce mechanical power, a shaft can be attached to the rotor. As the rotor rotates, the shaft will rotate too, and so will the wheel, drill, pump or fan blades, or whatever else is attached to the shaft.

This imaginary motor is very inefficient and flawed; for example, the rotor would be better balanced with two arms rather than one. And for greater efficiency, in all but the most primitive motors the electromagnet magnetic poles are cyclically switched with the more complex brush-and-contact system of a commutator, so that the rotor magnet is attracted when it is turning toward the stator and repelled when it is turning away.

Despite these deficiencies, the design does demonstrate the basic principle of how virtually all electric motors work with stators and rotors to convert electric power into magnetism and magnetism into mechanical power.

When categorizing based upon the construction of the electric motor, there are two main categories: brushed motors and brushless motors. Brushed electric motors can be easily determined based upon the design of the motor. A brushed motor is typically a type of DC motor, and operates based upon the actions of a wound rotor (also known as an armature), a commutator, and a permanent or wound magnet stator. The motor gets its name from the commutator, which is equipped with numerous brushes. These brushes operate by allowing the current to flow through them and thus arrive at the wound rotor. There are five main types of brushed motors: DC shunt wound motors, DC series wound motors, DC compound motors, permanent magnet DC motors and separately-excited motors. Capable of operation without the use of brushes to transfer the electrical current, brushless electric motors are also most often a type of DC motor. Whereas brushed motors can run into some problems due to their more complicated design, brushless motors eliminate many of those issues. Brushless motors consist of a permanent magnet external rotor, a three-phase coil, a type of sensor and drive electronics. Instead of brushes, brushless motors transfer the current by means of the sensors, called Hall effect sensors.

Things to Consider When Purchasing Electric Motors

For large motors, proper installation is critical for the safety of the motor, workplace, and personnel.

For safety, the motor should be located in a place where its rotating shaft cannot snag workers’ clothing and its power cords won't trip workers’ feet. Motor noise can cause hearing loss, which calls for measures such as a special padded housing or requiring workers to wear hearing protection.

If the mounting is insecure, the motor may vibrate excessively, causing internal damage that will not be seen until the motor breaks down. Unless they are specifically designed for such environments, motors should be protected from water, dust, vibration and impact, and extreme temperatures. If a motor has ventilation slits on its casing, these should not be placed against a wall or covered in any way lest the motor overheat.

Electric motors will generate electromagnetic interference that can disrupt electronic communications systems. A motor's magnets may also disrupt electronics.

Under normal circumstances, a motor simply needs to be securely connected to the proper power source and can then be operated with just a flip of a switch for years of trouble-free operation. However, some electric motors may have internal fuses to protect them from power line surges, while others require external circuit protection. Some electric motors may require scheduled inspection and maintenance by certified inspectors. Such requirements usually apply toward heavy-duty industrial motors, while in general smaller motors such as those in consumer appliances are no or very low maintenance.

Perhaps the first question in obtaining a motor is whether it can utilize the power available. An AC motor requires AC power or a power converter. A DC motor requires DC power or a power converter.

Electric motors are primarily distinguished by RPM (rotations per minute), power output (watts), and voltage/current ratings.

Some motors have a fixed rotation speed, while others are variable. Gear boxes can shift shaft rotation speed either up and down. In general, for a given motor, slower speed equals greater torque.

The motor power output (measured in watts or horsepower) is an important economic consideration. Too much power may have been money wasted, and too little power certainly is.

Too little voltage or current and the motor will not turn. Too much, and the motor may be damaged.

NEMA, the National Electrical Manufacturers Association, offers a chart of standardized sizes for motors available from electric motor manufacturers.

To easily find a list of industrial motor manufacturers, you can check out IQS Directory's company listings.

Repair for Electric Motors

Professional customer service professionals will tell you, the first question to ask if equipment doesn't turn on is, “Is it plugged in?” This is less of a dumb question when it comes to larger motors because the entire dedicated motor circuit should be checked to see that there are no gaps between power source and motor connections. Almost needless to say, the fuses and circuit breaker should be checked too.

Another reason a motor may not work at all is that the coils are damaged. The coil insulation may have failed, causing a short. In this case, the coil will have to be replaced.

In DC motors, commutator brushes may wear out. Replacing brushes is often relatively easy and inexpensive. The permanent magnets can be replaced or upgraded to rare earth magnets for better performance.

Motors that make loud or 'odd' noises likely have a bearing problem. The bearings could last years, or go out the next instant. To avoid damage to the motor and environment, it's best to shut the motor down and have it inspected.

Electric Motors Terms

- 1 Horsepower Electric Motor

- Usually used to power slow moving vehicles like tractors and other agricultural equipment, and high power tools and appliances, like table saws and pool pumps.

- 2 Horsepower Electric Motor

- Simply electric motors which have a power output of two horsepower.

- AC (Alternating Current)

- Current whose flow can be changed. Alternating current is commonly available in single and three forms.

- Air Gap

- The space between the rotor and stationary stator member in an electric motor.

- Amps

- The meter-kilogram-second unit of electric current that is equivalent to the steady current produced by one volt applied across a resistance of one ohm.

- Armature

- A part of the magnetic structure of a motor that rotates in a DC or universal motor.

- Back End

- The end that holds the coupling or driving pulley. Also referred to as the drive end.

- Brush

- Current conducting material that guides current from the power supply to the armature windings.

- Commutation

- Converting an electric current from direct current to alternating current. Can go both ways.

- Core

- The segment of the stator and rotor, usually iron, which is made up of cylindrical laminated electric steel.

- Cycles Per Second (Hertz)

- One complete reverse of flow of alternating current per rate of time.

- Duty Cycle

- The duration and relationship of operating and non-operating times or repeatable operation at different loads.

- Enclosures

- The housing or frame of a motor in which there are two wide classifications: open and totally closed.

- Endshield

- The part of the motor housing that supports the bearing and acts as a protective guard to the electrical and rotating parts inside the motor. Often referred to as an "end bracket" or "end bell."

- Fractional Horse-Power

- A motor usually built smaller than that having a continuous rating of one horsepower. The frame size can categorize the motor as fractional also.

- Front End

- The end opposite the coupling or driving pulley. Also referred to as the commutator end.

- Gearhead

- A gearmotor part that holds the gearing, which converts the basic motor speed to the rated output speed.

- Horsepower

- A function of torque and rpm.

- Jackscrew

- A device used for the positioning of a motor. These are adjustable screws fitted on the base or motor frame.

- Load

- The burden forced on a motor by the driven machine. Often stated as the torque required to overcome the resistance of the machine it drives.

- Motor

- A device that takes electrical energy and converts it into mechanical energy to turn a shaft.

- Relay

- A device that is effective by a variation in the conditions of one electric circuit to affect the operation of other devices in the same or another electric circuit.

- Rotor

- Made of stacked laminations, it is the rotating component of an induction motor.

- RPM

- Revolutions per minute. The number of times per minute the shaft of the motor rotates.

- Shaft

- The rotating part of the motor that protrudes past the bearings for attachment to the driven equipment.

- Stator

- In an AC induction motor the stator is made of laminations with a large hole in the center for the rotor to turn and slots in the stator for the windings to be inserted.

- Torque

- Force for turning provided by a motor or gear motor shaft. Often described in pounds.

- Volts

- The difference of possibility between two points in a conducting wire with a constant current of one ampere.