Automation Equipment

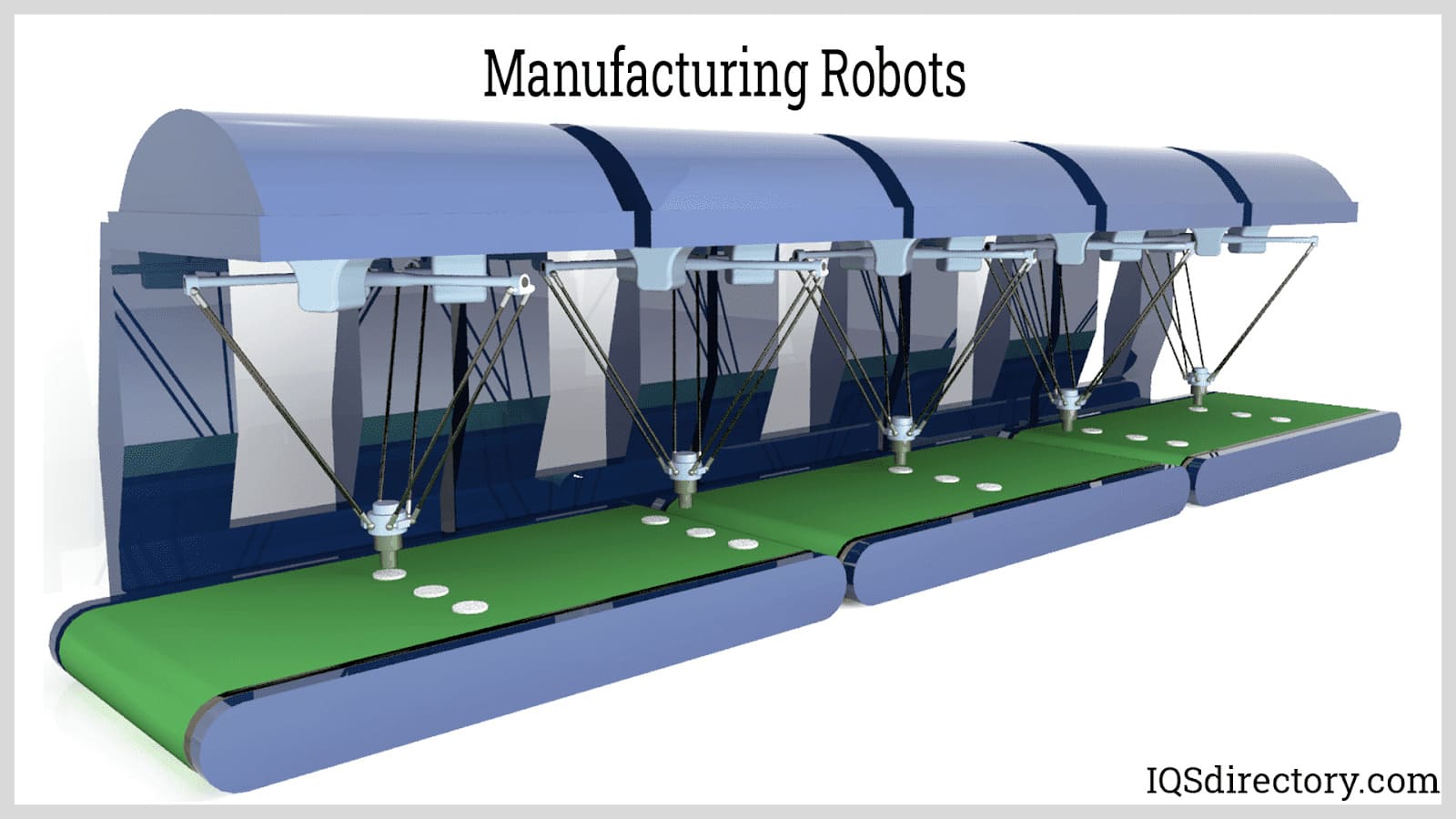

Many manufacturing functions such as material handling, product forming, welding, milling, grinding, cleaning, assembly, and packaging are accomplished through the use of computer controlled, automated, and robotic machinery. Automated systems sort mail, packaged goods, and food products.

These systems may be partially manned, supervised by a production manager, or totally automated, operating without any human guidance or intervention beyond the initial programming and necessary maintenance.

Quick links to Automation Equipment Information

The History of Automation

- The History of West and Automation

- Since the dawn of the Industrial Age and the advent of Henry Ford's assembly line, great strides have been taken toward product automation. New technology has made the unmanned assembly line a reality that Mr. Ford probably could not even imagine.

- Henry Ford is known as the Father of the Assembly Line, but Ransom Olds actually received the first patent for it, in 1901. Olds' line required workers to manually move the vehicles from station to station, but productivity was still increased by 500 percent over previous assembly methods.

- The first successful automated bottle blowing machine was introduced in 1905. A total of four men were able to produce 17,280 bottles in twenty four hours - versus - six men producing 2,880 bottles in a twelve hour shift. The cost plummeted from $1.80 per gross to about 11 cents per gross.

- Henry Ford's famed assembly line began in 1913. His cars were placed on a conveyor rail, bringing the project to the workers, instead of the workers going to the project or dragging it to its next destination. He was able to boost production from one car every twelve hours to a car every hour and a half.

- Expansion to the West caused a demand for printed media, which created the need for quality paper manufacturing on a huge scale. As paper dries, the drying rate must be slowed to keep the paper from wrinkling. A sectional electric drive control was first developed in 1919 to facilitate the progressively slower drying times, providing consistently smooth paper.

- History of Automation in the East

- In Japan, in 1930, an accurate electrical timer with micro-switches and protective relays was invented. This development was the basis of synchronized automation as it allowed machines to interact without human intervention.

- Following World War II, the rebuilding of occupied Japan gave rise to new factories with cutting edge technology and allied support. The finest state-of-the-art equipment was installed, and by 1952, Japan was the world leader in automated manufacturing, particularly production of automobiles.

- The 1960s ushered in the use of robotic arms that could perform simple tasks such as lifting, clamping, and turning.

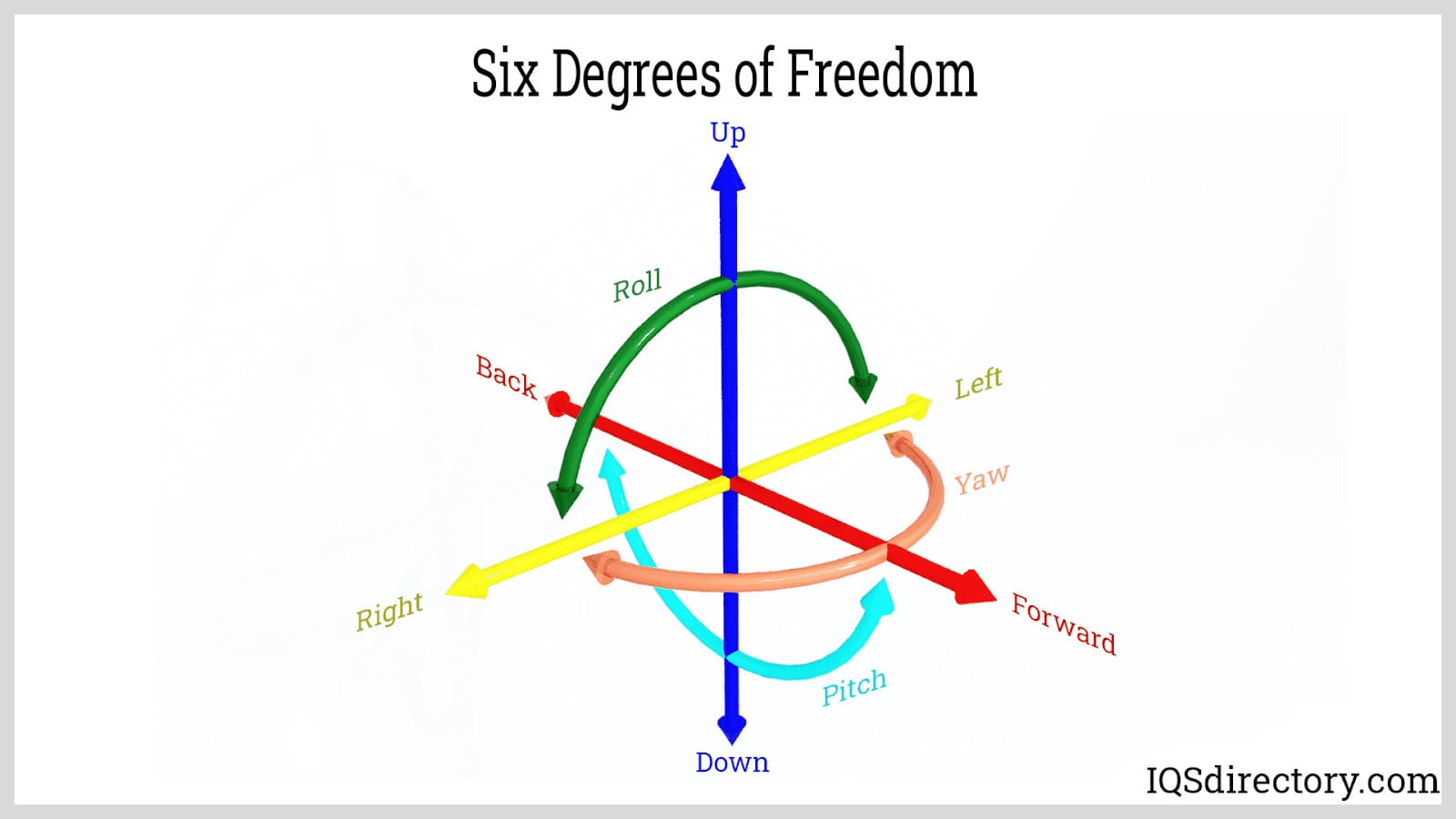

- In 1969, Victor Scheinman introduced a 6 axis robotic arm, known as the Stanford Arm, which could move and assemble parts repeatedly and continuously, allowing multiple functions to be performed by a single unit. Prior to this, each function had to be performed by a single unit at a separate station.

- The 1980s saw the dawn of the Computer Age. Computer Integrated Manufacturing (CIM) and Computer Numerical Control (CNC) manufacturing became indispensable to the industrial design of every faction.

- By Y2K, everything, from the tiniest pill to missions to Mars, were being calculated to present the best product in the most efficient manner. Automated assembly machinery had to be designed to faithfully reproduce these designs in the same efficient manner.

- The 2010s ushered in 3-D printing or additive manufacturing (AM) which used computer controlled designs from an AM file to create three dimensional objects. The "printers" deposited sequential layers of binder materials onto a bed of powder in pre-programmed patterns, via inkjets.

Industrial Automation Design and Uses

Automated equipment systems are purpose designed and built to perform a specific series of tasks. These machines use systems of servos and pneumatics to operate synchronized processes on a production line or rotation. Computer control of the system assures impeccably timed delivery of materials to each station in the manufacturing process.

The item being made is conveyed through the steps as progressive operations work toward creating a finished product. Conveyor systems may consist of beltways, bucket lifts, rolling conveyors, hanging clips or hooks, or pneumatically driven tubes.

Steps along the assembly line can include extrusion, forming, welding, brazing, soldering, cutting, perforating, punching, bolting, screwing, gluing, or coating.

In a food processing plant, farm fresh products are cleaned, sorted, and separated for packaging or further processing. Ingredients are prepared, measured, mixed, portioned, cooked, and packaged by machines to provide consistent food products for distribution.

Glass and plastic components can be mixed, melted, blown, injection molded, hardened, cooled, cleaned, and packaged in a synchronous factory automation process. Massive industrial mining and forging operations rely on automated systems to move tonnage, handle material, and process molten metals into parts and components for structural, mechanical, and household items.

What Automation Means For Industry

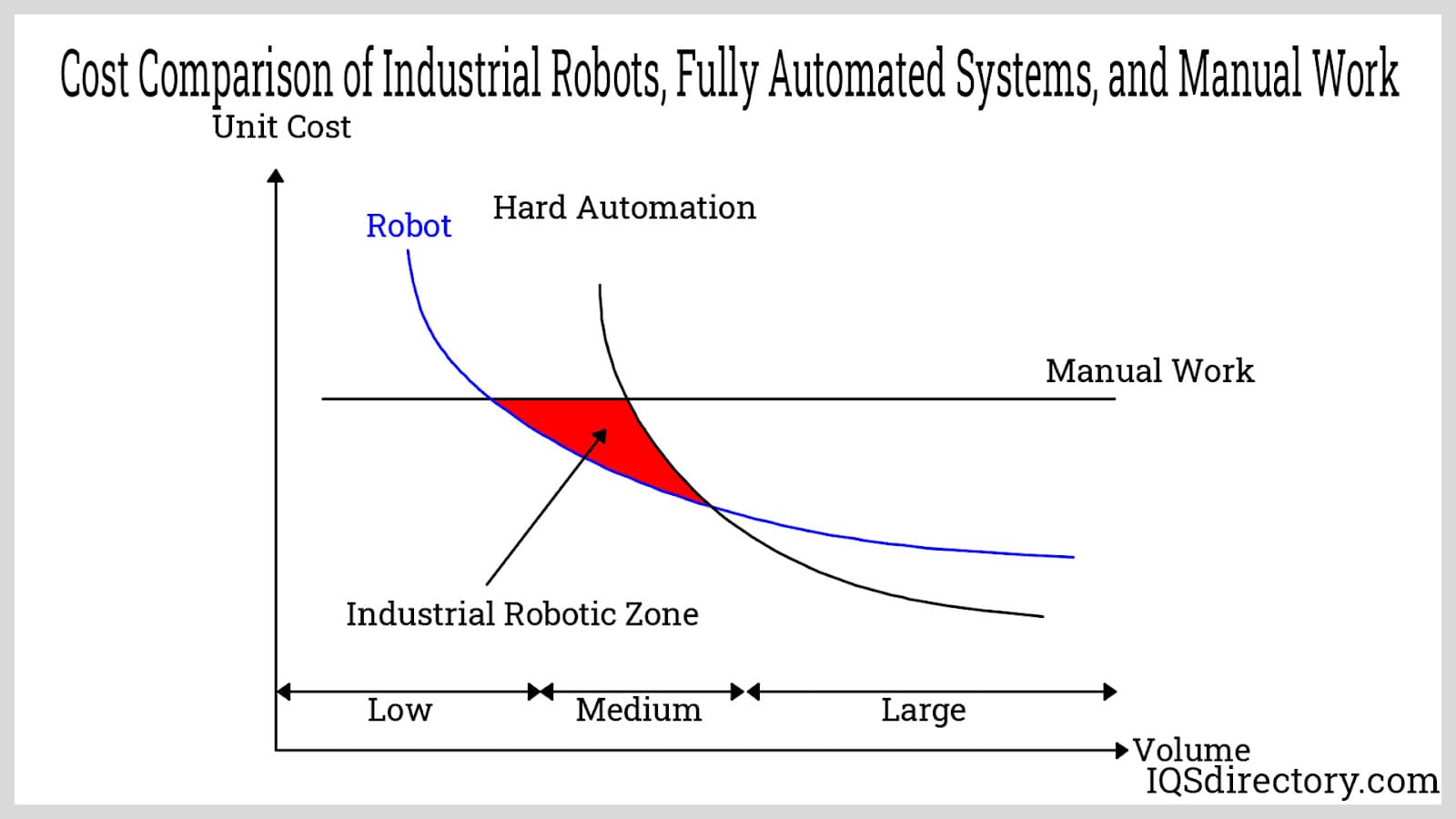

The goals of factory automation are safety, cost effectiveness, production quality, speed, consistency, and convenience. By removing the human element, these goals are more likely to be achieved.

Manufacturing facilities can be dangerous to humans. Heat, cold, toxic fumes, corrosive liquids, caustic materials, and sharp or abrasive items, can cause injuries to workers on a production line. Repetitive motion injuries, lifting injuries, slips, trips, and falls also put workers at risk, raise insurance rates, and lower productivity.

Replacing human workers with automated systems greatly reduces accidents and injury in the workplace, as well as eliminating the direct impact of paying wages. Machines can work continually, eliminating downtime for employee breaks and shift changes. Automated equipment is fast, providing consistent quantity and quality of work, at rates faster than humans can perform.

Less overhead, fewer errors, and faster manufacturing with minimal waste equate to cost effective production.

Consideration must be given to the possibility of machine malfunction, which could result in catastrophic repetition. In a dark system, one which is completely automated with no supervisor on hand, a single glitch in the system, such as a defective part, breakdown of equipment, or power disruption, can create a domino effect that topples the entire line.

Safety has been designed into these systems with the use of electronic monitoring devices that detect malfunctions, whether they are mechanical or environmental, and react accordingly. Remote visual monitors allow video surveillance of the equipment to reassure management of proper function of the operation, keeping man hours to a minimum and production at its maximum.

Automation Industry Images, Diagrams and Visual Concepts

Automation systems are an integration of sensors, controls, and actuators designed to perform functions with minimal or no human intervention.

Automation systems are an integration of sensors, controls, and actuators designed to perform functions with minimal or no human intervention.

Robots do not experience fatigue and there processing speed is much faster than humans with continuous operation.

Robots do not experience fatigue and there processing speed is much faster than humans with continuous operation.

Wastes less raw material and fewer human resource costs once the robotic system is online, an increase product quality, and an increase in production rate.

Wastes less raw material and fewer human resource costs once the robotic system is online, an increase product quality, and an increase in production rate.

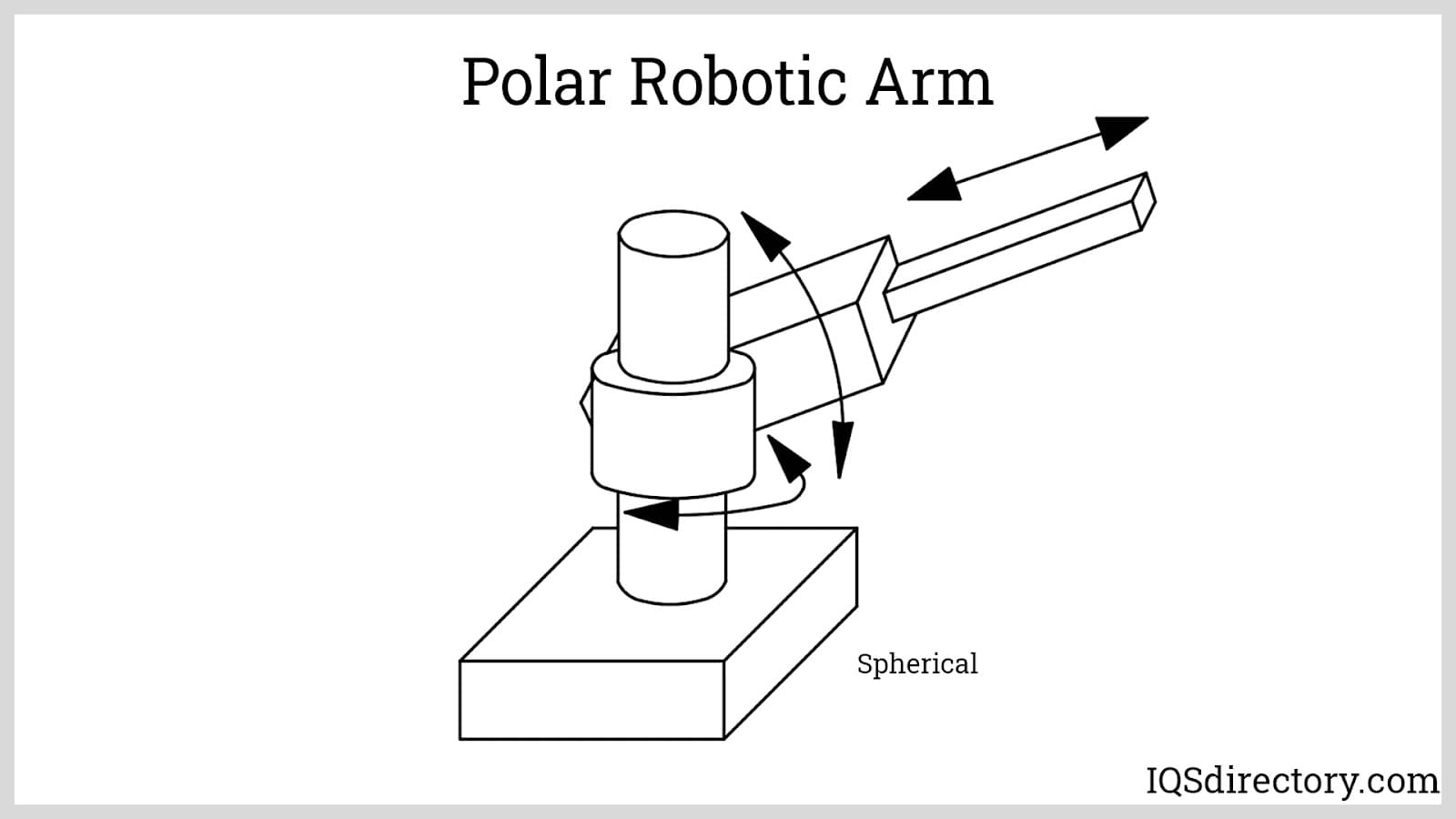

The number of axes and degrees of freedom define a robot's movability.

The number of axes and degrees of freedom define a robot's movability.

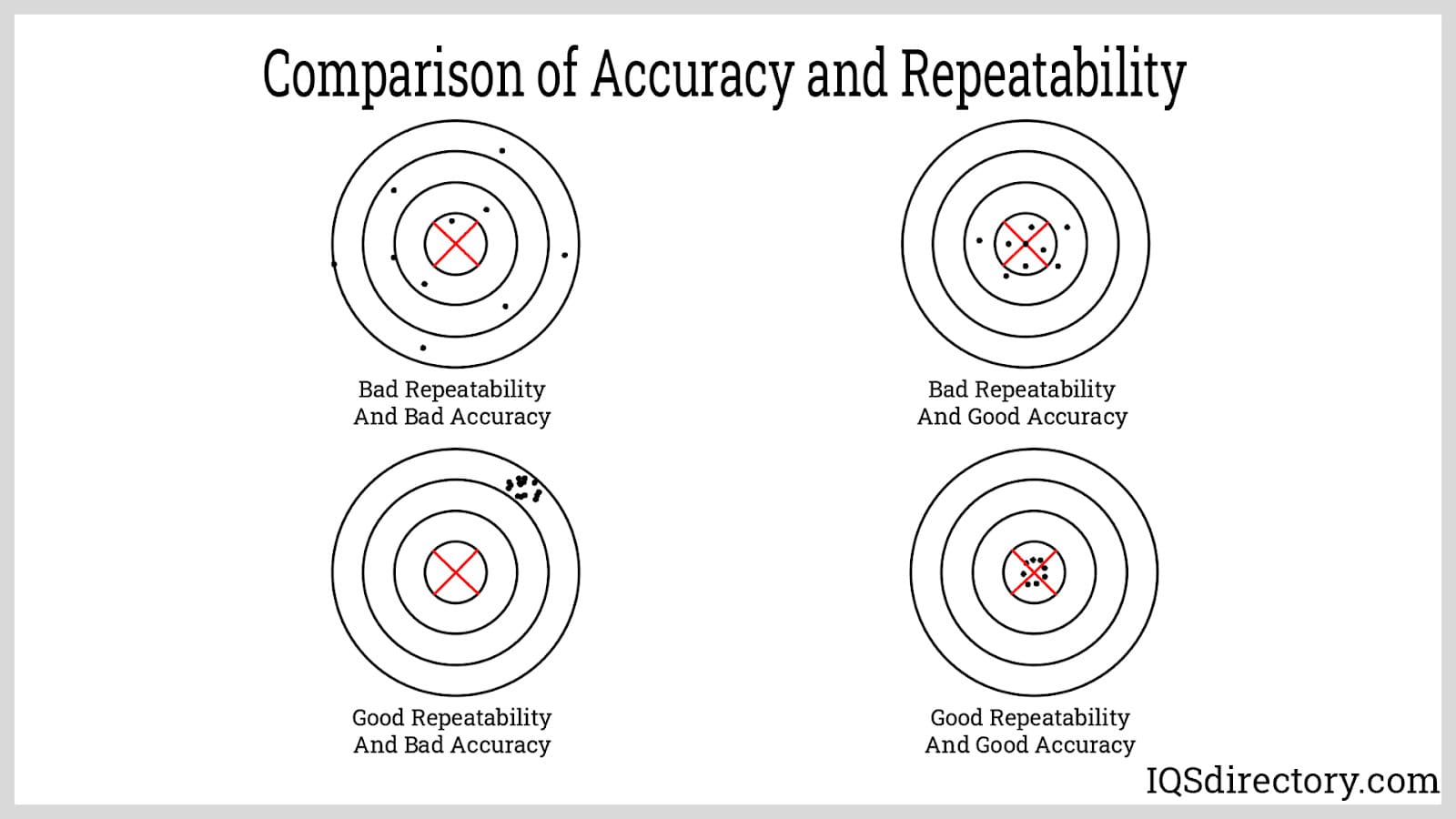

Accuracy and repeatability are the two main characteristics to determine the effectiveness of a robot in task performance.

Accuracy and repeatability are the two main characteristics to determine the effectiveness of a robot in task performance.

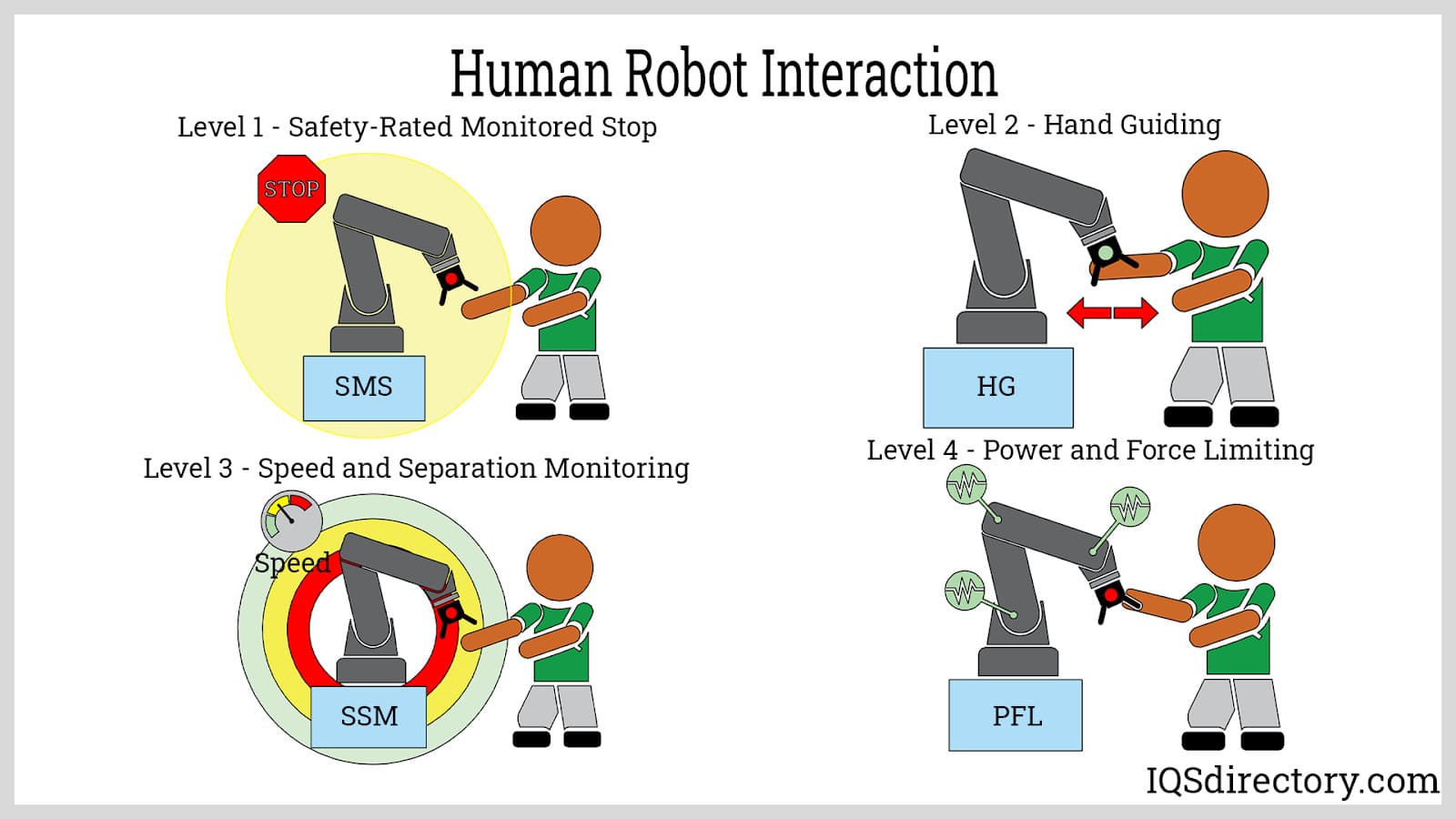

Collaborative robots allow to work safely and include safety features power limiting, safety monitored stop, hand guiding, speed and separation

Collaborative robots allow to work safely and include safety features power limiting, safety monitored stop, hand guiding, speed and separation

A type of arm configuration which allows for a fixed range of motion depending on the joints.

A type of arm configuration which allows for a fixed range of motion depending on the joints.

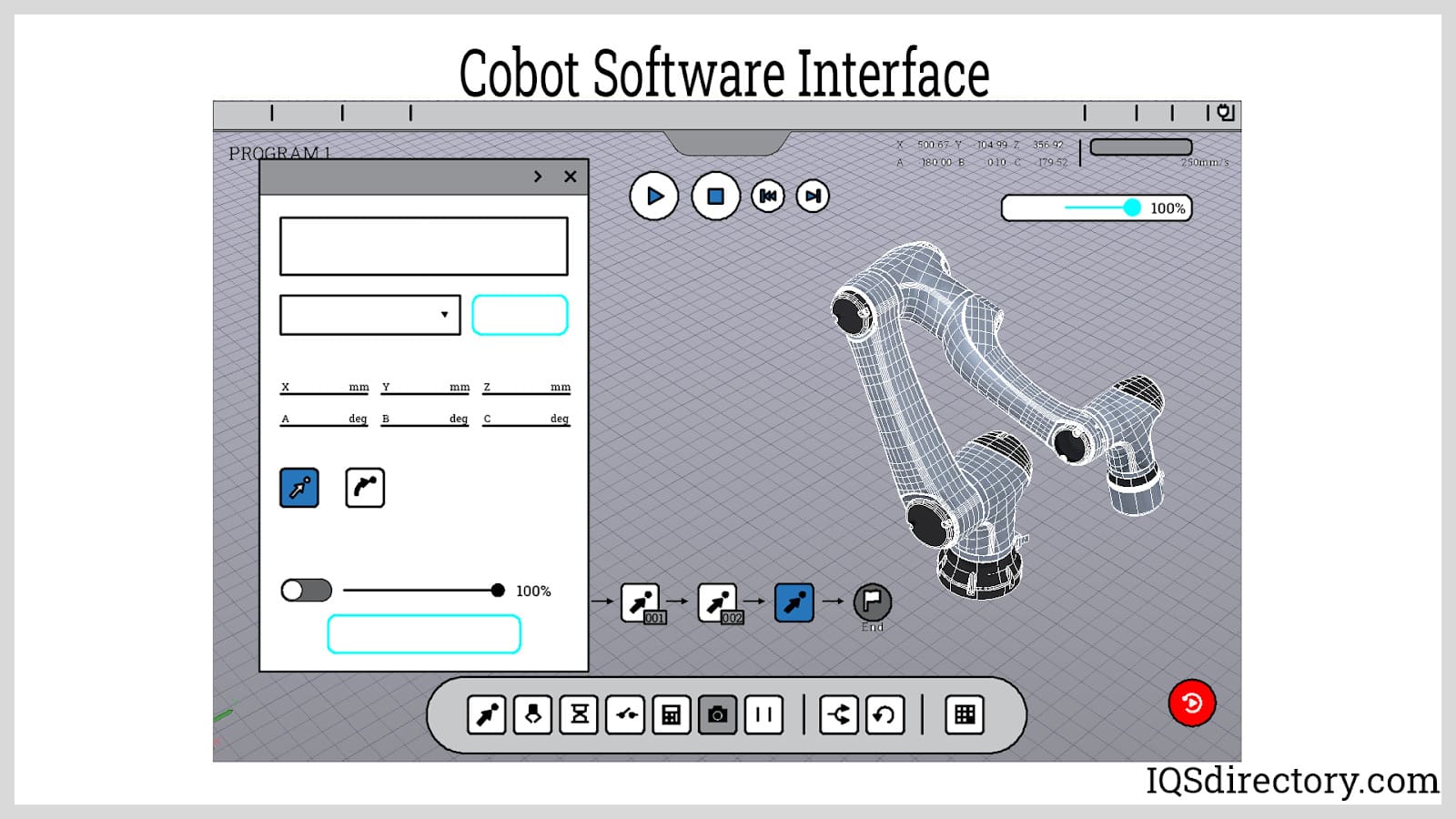

Applications are available for designing and programming collaborative robot applications which have an instinctive and user-friendly.

Applications are available for designing and programming collaborative robot applications which have an instinctive and user-friendly.

Types of Automation in Industry

- Computer Aided Design (CAD)

- The programmed design of equipment, through the use of computers, to create a design on paper that can then be replicated in a three dimensional fashion. These designs include plans for production procedures and processes to be performed by machines, rather than humans.

- Computer Aided Manufacturing (CAM) Method

- The method of using computer controlled mechanisms to perform some or all of the steps on an assembly line, with human supervision or intervention.

- Computer Integrated Manufacturing (CIM) Method

- A manufacturing method where the machinery is entirely computer controlled, operated, and monitored.

- Computer Numerical Control (CNC) Programming

- Or simply numerical control, is the method of programming automated equipment to function according to encoded commands without being manned by workers to flip switches, turn knobs, or place parts.

- Additive Manufacturing (AM)

- Also known as 3-D or lenticular printing. The additive material is deposited by inkjets onto a bed of powder in layers. The positioning of the deposits is computer controlled to replicate a three dimensional object from a 3-D model or electronic data file. The deposits can be joined together and solidified in any shape or geometry. This is ideal for rapid prototyping of parts to be manufactured on an assembly line.

- Automatic Assembly Lines

- Uses integrated equipment with precision timing. The bulk feeders must materially handle products along the line so that each step in the process is accurately aligned for work to be accomplished at the next station. These steps are controlled by actuators that translate control signals from a pre-programmed design and activate the machinery, which, in turn performs a precision task as per the controllers.

- Robotic Automation

- Allows for multi-axial functions to take place at one production station. The robotic arms load and turn screws and bolts to precision torque specifications, position and insert parts, provide pre-measured quantities of adhesives to precise locations, or perform other complex manufacturing tasks, such as sorting, folding, sealing, and crating.

- Metal Production for Manufacturing

- Facilitated through the use of huge bucket conveyors that carry raw materials that are dumped into crucibles that are conveyed through smelting furnaces into forming processes that may include molding, casting, or extrusion. Welding equipment can be integrated into automation production. Automated stations may spot weld metal or plastic parts together. Robotic arms may produce lengthy bead welds or perform varied cutting operations.

Automated Manufacturing Proper Care and Standards

Because every function of automated manufacturing is product specific, it is important to find a company that can design custom automation equipment that meets your needs. A good designer can help you create an automation system based on the size of your facility, the number and complexity of steps required to produce your product, and the quantity or range of production you need to achieve.

Your system should be integrated for maximum production levels, custom manufacturing capabilities, and systematic changes that may take place with growth and development of your business.

Scheduled maintenance of your automation system is imperative for continuous operation. Breakdowns in the system should be addressed before they happen, to minimize damages. Making sure your system is appropriately cleaned, lubricated, and all fasteners and electronic connections are firmly attached, on a regular basis, is key to successful operation. Checking controls and alignments will keep the assembly line moving forward.

Industrial safety and cleanliness standards for automated manufacturing are set forth by several governing entities and committees to ensure safe environments for workers, materials, and products.

Current Good Manufacturing Practices (CGMP) or Good Automated Manufacturing Practice (GAMP)is a set of processing guidelines, as well as a committee to ensure adherence to those guidelines, for the International Society for Pharmaceutical Engineering (ISPE). Their purpose is to regulate quality and consistency standards of pharmaceutical drug processing to assure proper, safe, and effective medications are being produced.

U.S. Department of Labor standards are outlined for operator safety, equipment safety, food safety, and consumer safety.

OSHA provides Federal Register notices, which are rules or proposed rules with regard to occupational safety, directives, official interpretations of standards, and national consensus standards (average national performance of tasks)for mandatory and non-mandatory compliance.

American National Standards Institute (ANSI) and American Society for Testing and Materials (ASTM) address machine and tool safety standards for manufacturing equipment and materials.

The Food and Drug Administration (FDA) maintains standards for food and drug processing to regulate the cleanliness, quality, and safety of food production equipment, products, packaging, and distribution.

Your equipment provider should be able to offer information and services that keep your operation in compliance with these guidelines.

Other Automation Equipment Types

Machine automation refers to the computer-operated machines used in an assembly line.

Manufacturing automation refers to the computer-operated equipment and machines found in a manufacturing setting.

Automation Equipment Terms

- Actuator

- A device in a closed-loop control system that translates the control signal of the final control element into action by the control device.

- Adjustable Speed

- The concept of varying the speed of a motor, either manually or automatically. The desired operating speed (set speed) is relatively constant regardless of load.

- Assembler

- A program that translates assembly language into machine instructions.

- Automation

- Automatic, as opposed to human, operation or control of a process, equipment or a system. Automation also refers to the techniques and equipment used to achieve this automatic control.

- Automated Storage & Retrieval System

- Consists of a variety of controlled systems for automatically placing and retrieving loads from storage locations.

- Axis

- Any movable part of a machine or system that requires controlled motion. Several axes of motion can be combined in a coordinated multi-axis system.

- Bill of Material

- A list of all the subassemblies, parts and raw materials of which a parent assembly consists.

- CAD (Computer Aided Design)

- Also called "CADD (computer aided design and drafting)," it is a system that can be integrated with a CAM system.

- CAM (Computer-Aided Manufacturing)

- The use of computer technology to generate data to control part or all of a manufacturing process.

- Calibration

- The process of determining the capacity or scale graduations of a measuring instrument.

- CIM (Computer-Integrated Manufacturing)

- The use of computers in all facets of manufacturing.

- Conveyor Belt

- A moving belt that transports objects along the assembly process.

- Dark Factory

- An entirely automated plant floor in which there is no labor.

- FMC (Flexible Machine Centre)

- Typically, an automated system comprised of CNC machines in which robots load and unload parts that are conveyed through the system.

- JIT (Just-in-Time)

- An approach to manufacturing in which each operation is closely synchronized with subsequent operations.

- Load Cell

- A transducer for the measurement of force or weight. Action is based on strain gages mounted within the cell on a force beam.

- Network

- Any system of computers and peripherals.

- Proximity Switch

- A device that senses the presence or absence of an object without physical contact and, in response, closes or opens circuit contacts.

- RP (Rapid Prototyping)

- An early step in the design process of assembly systems in which a small-scale prototype is developed to test out certain key features of the design. RP, which can include sketches, low-fidelity physical prototypes, CAD visualization, rapid application development or video prototyping, is extremely useful for large-scale projects, as it speeds up the entire development process.

- Robotics

- The study of the design and use of robots, particularly for their use in manufacturing and related processes. Check out what the companies listed on IQS Directory are able to do in this area by visiting this site.

- Sensor

- A device that measures the motion of, or forces/torques acting on, a body or joint.

- Systems Integration

- When various automation functions work together in one system to get a specific thing done.