Conveyor Systems

Conveyor systems are any combination of material handling equipment that move, or convey, different packages, products, parts, foods or equipment from one point to another, or several others points within a facility. Typically, the goal of this conveyance is to move goods through different stages of finishing, through different stages of automated manufacturing or simply to different locations.

Quick links to Conveyor Systems Information

Benefits of Conveyors

- Material Handling

- The basic job of a conveyor is to carry the loads of machine parts, products, packages and a variety of materials from one place to another. Moving products manually takes a good amount of time and, of course, requires valuable labor. By employing material handling technology, you can reduce huge time and cost consumption. A number of industrial processes require feeding of materials periodically. Conveyor systems are used for this very purpose. They supply the material without stopping or causing any delay in production.

- Safe Handling

- When moving or feeding the material manually, there are safety concerns associated with products and workers. On the other hand, with a right conveyor system, there are no such likelihoods. The speed of rotation can be programmed according to the application requirement. The wide platform and robust belt, chain, or roller safely move the product to the desired area in the plant.

- Automation Adds Precision

- Modern-day conveyor systems automate your material handling process. Meaning, having this machine can reduce the chances of human errors in an industrial production or business process. In fact, they add precision to your process and help save plenty of expenditures.

- Increased Productivity and Plant Production

- When you choose to introduce a conveyor system in your process, you take the unnecessary burden from the shoulders of your workers. Then, you can employ them in other core activities. This way, you can increase their productivity and the overall production of your plant. Additionally, you will also be keeping them away from possible accidents.

- Flexibility and Scalability

- The biggest advantage of having a conveyor system in your production process is flexibility and scalability. Whenever there is a need to upgrade or downgrade the system, you can call on your engineers to proceed.

Conveyor Systems Images, Diagrams and Visual Concepts

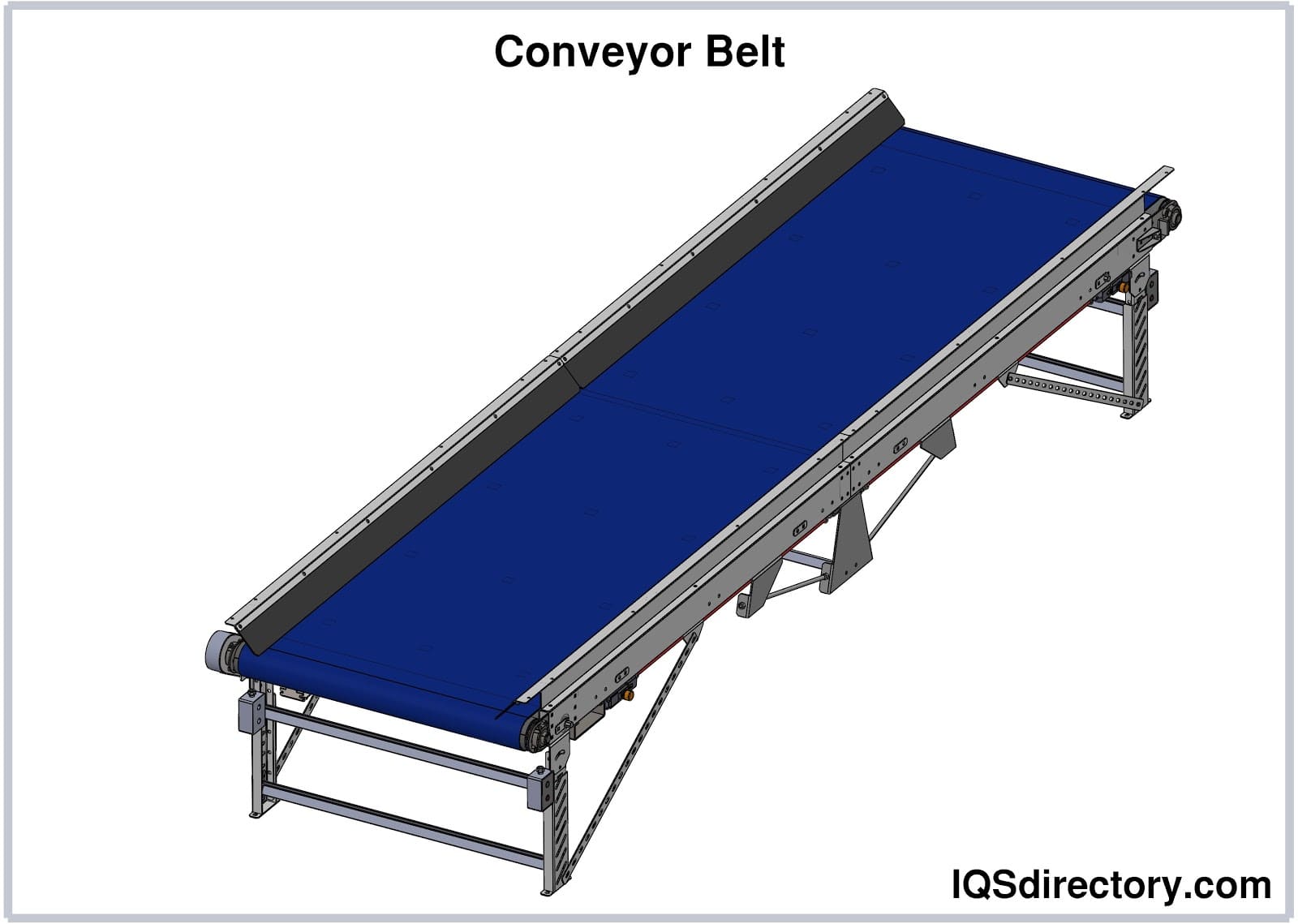

Conveyor system, a method for moving packages, products, parts, and equipment for production, shipping, or relocation.

Conveyor system, a method for moving packages, products, parts, and equipment for production, shipping, or relocation.

The components needed in a conveyor system operation.

The components needed in a conveyor system operation.

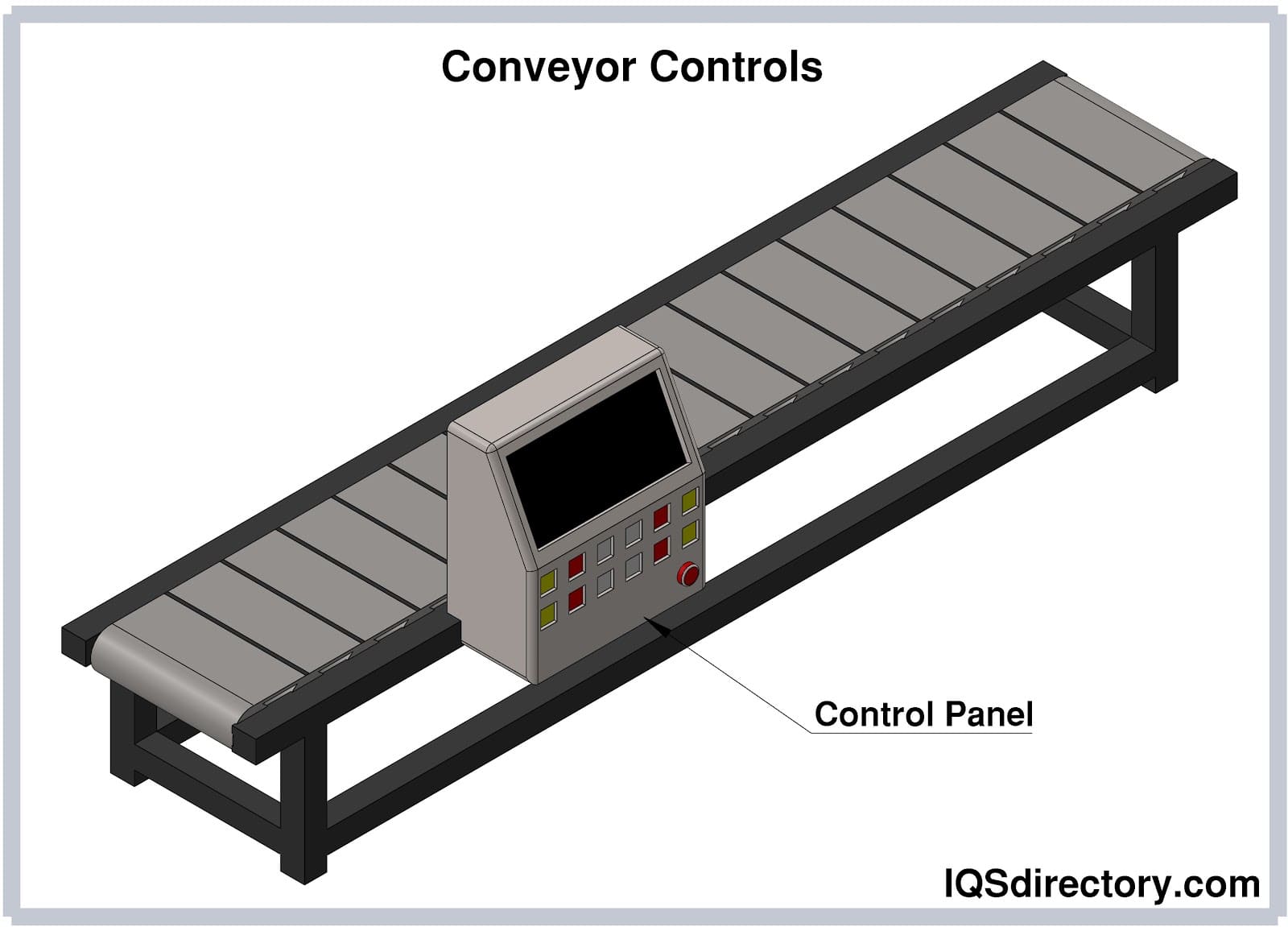

Conveyor systems are required to have an emergency stop button, a keyed motor activation, and symbols displaying conveyor operation.

Conveyor systems are required to have an emergency stop button, a keyed motor activation, and symbols displaying conveyor operation.

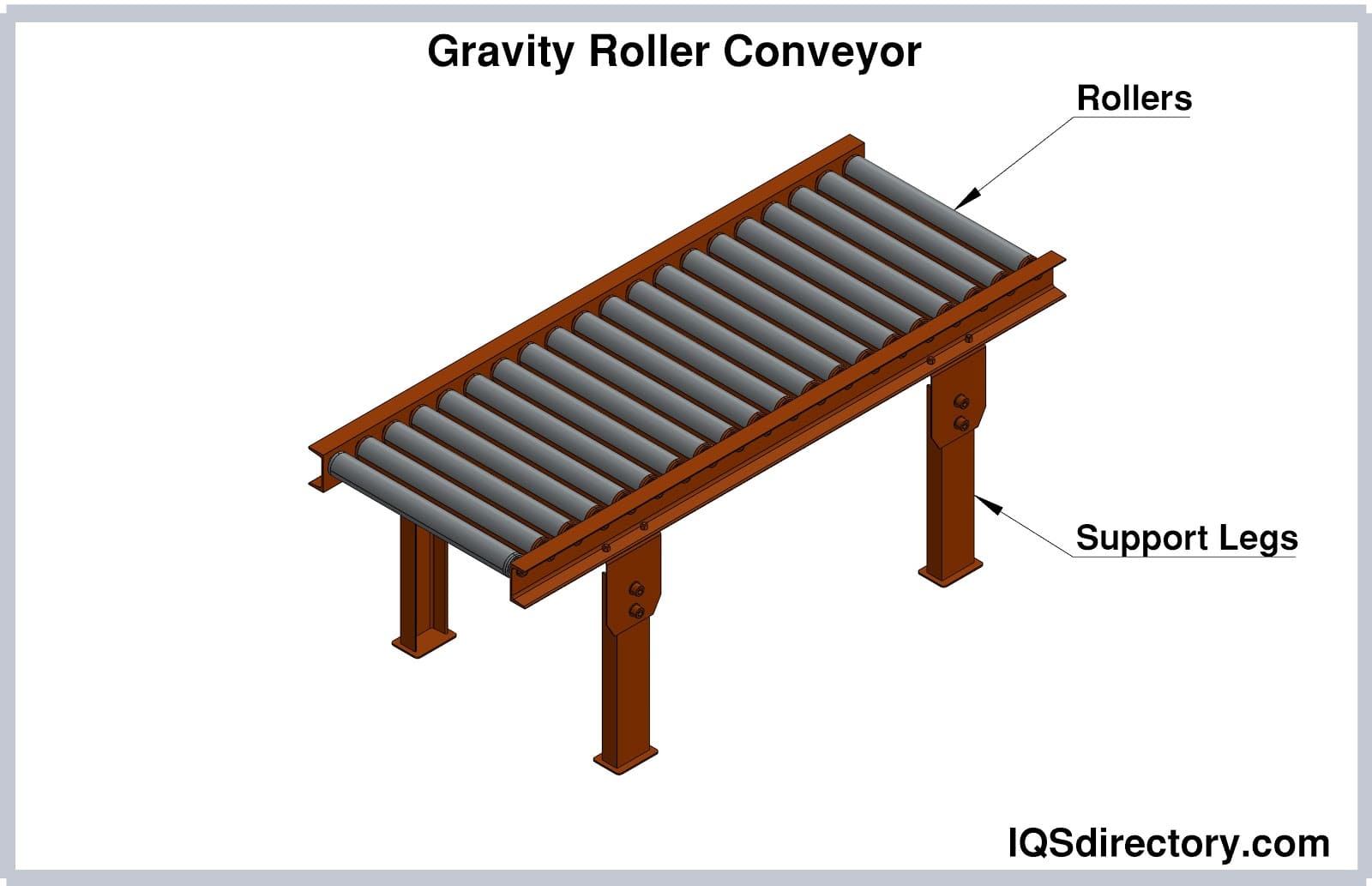

Gravity roller conveyors have a set of equally spaced rollers connected to the side frame, the position of the rollers provides a surface to for movement which moves the materials by gravity.

Gravity roller conveyors have a set of equally spaced rollers connected to the side frame, the position of the rollers provides a surface to for movement which moves the materials by gravity.

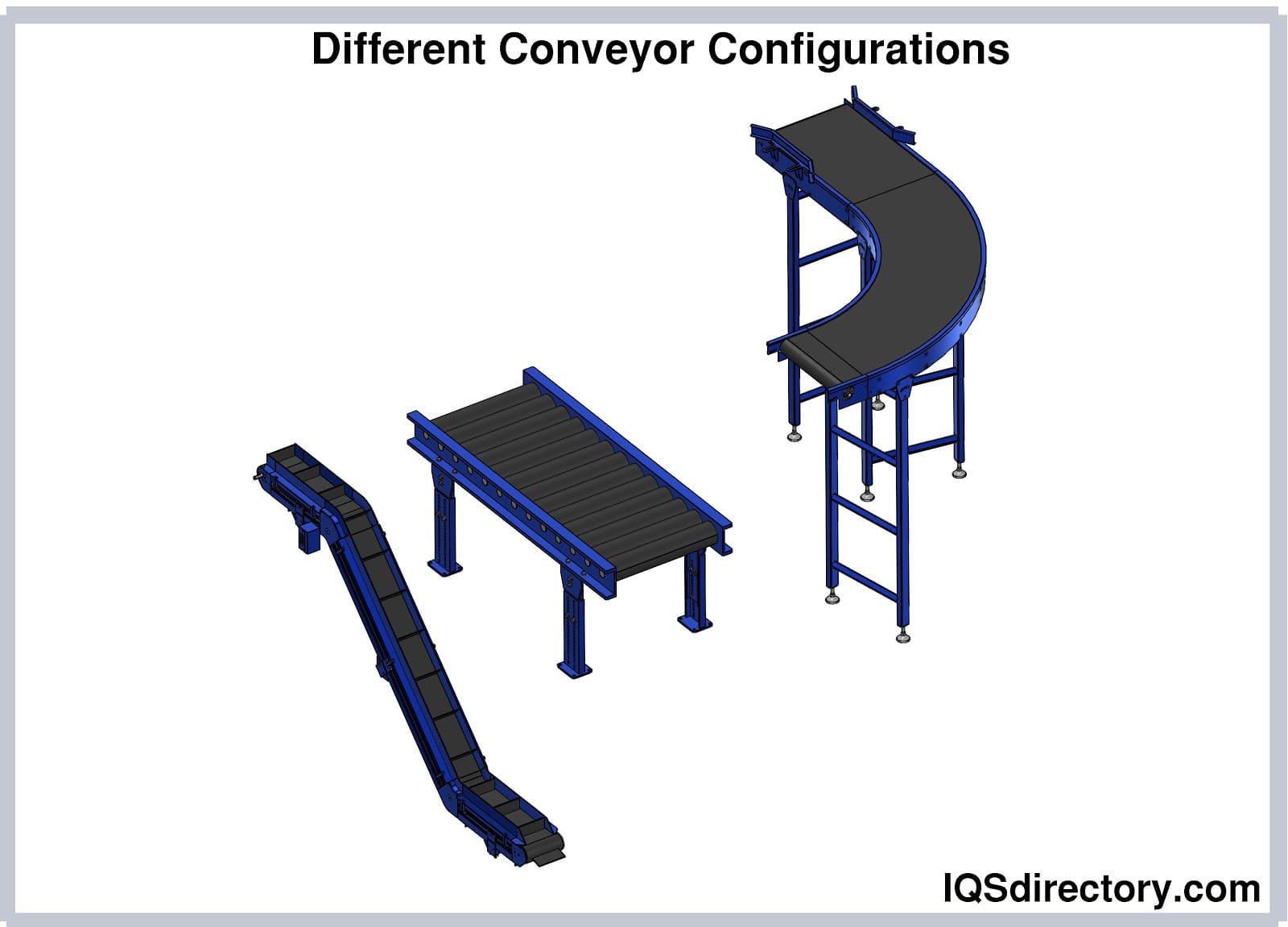

Configuring a conveying system can be vertical, angled, horizontal, curved, include pockets, slats, and z-frames to fit a special application.

Configuring a conveying system can be vertical, angled, horizontal, curved, include pockets, slats, and z-frames to fit a special application.

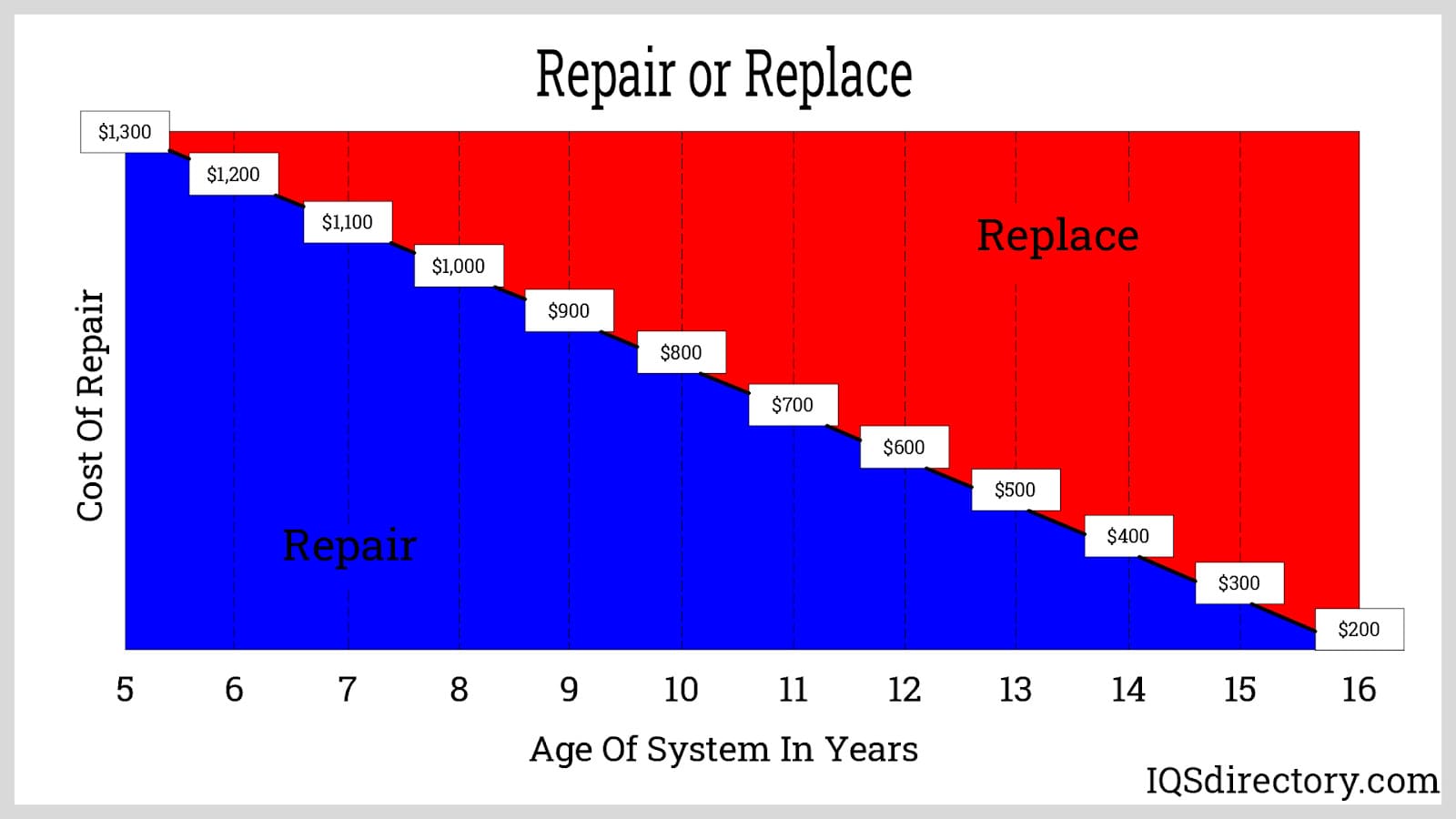

Replacing components on the system has several cost factors, the downtime of the system, finding the right component, and hiring a specialist which offsets with regular maintenance and monitoring of the system.

Replacing components on the system has several cost factors, the downtime of the system, finding the right component, and hiring a specialist which offsets with regular maintenance and monitoring of the system.

Types of Conveyor Systems

Conveyor systems serve a variety of applications, and for that reason, conveyor system manufacturers offer a variety of standard system configurations. These include belt conveyor systems, chain conveyor systems, roller conveyor systems, overhead conveyor systems, vertical conveyor systems and chute conveyor systems. Most of these systems are automated, though a few, such as chute and roller systems, are not. Conveyor systems can be made up of any number of unique combinations of conveyor configurations, allowing them to move items vertically or horizontally and/or to divert, lift, curve and sort products with high levels of efficiency.

- Belt Conveyor Systems

- The most common type of conveyor system, the belt conveyor system, uses multiple belt conveyors to move objects. These belts are wide, made from rubber or a polymer and, to move, they are wrapped around uni-directional rollers. The belt of a belt conveyor consists of one or more layers of material, such as PVC or the aforementioned polymer or rubber. The belt is typically first supported by an over layer, known as the cover, and an under layer known, known as the carcass. The cover is typically made of polymers, combination plastics or rubber. However, for speciality applications, it can also be made of more unusual materials. One such material, gum rubber, for example, provides traction. Likewise, another choice, silicon, conveys heat. The carcass is made of plastic web, polyester, nylon, cotton or mesh. It provides the belt with linear length and shape. Similarly, chain conveyor systems move items using at least one length of chain wrapped around a set of wheels.

- Roller Conveyor Systems

- Like belt and chain systems as well; they consist of several heavy-duty rollers arranged parallel to one another. Depending on their arrangement, they can be powered by an electric motor or by gravity itself. Typically, they are most popular for the conveyance of heavy items around a warehouse or manufacturing facility, and/or movement down an assembly line. Examples of these heavy items include industrial containers, pallets and grid boxes.

- Overhead Conveyor Systems

- Overhead conveyor systems and vertical conveyor systems both tend to be more complicated than their afore-detailed cousins. First, overhead conveyor systems, which are overwhelmingly preferred by parts manufacturers, move parts from an elevated level. While many floor-level systems use belt-driven conveyors, overhead conveyor systems are almost always chain-driven. The items they transport are held securely in units called trolleys. Usually, these trolleys come in the form of hooks, rings, hangers or baskets. Overhead conveyor systems can be used to transport parts and products not only from one area of a factory to another, but to and through various processing stations, such as ovens, dryers or spray paint booths.

- Vertical Conveyor Systems

- Next, vertical conveyor systems, also known as material lift systems or freight lift systems, are used to move products and materials up or down from one level of a facility to another. To this end, they consist of two parallel and adjacent conveyors that move upward together. They may be manually or automatically controlled. Also, they are outfitted with all sorts of accessories around their belts or chains, such as buckets, platforms, magnets or grippers. All of these accessories serve to facilitate the movement of products from one level to another. Note that vertical conveyor systems are not suitable for transporting humans.

- Other Types of Conveyor Systems

- In general include: heavy duty rear conveyor systems, spiral conveyor systems, vibrating conveyor systems, gravity skatewheel conveyor systems, gravity conveyor systems, electric track vehicle systems, drag conveyor systems, vertical conveyor systems, flexible conveyor systems and pneumatic conveyor systems. Conveyor systems are critical to the function of many processes. To find out which one is right for you, consult with an experienced conveyor manufacturer today.

Applications of Conveyor Systems

In addition to material handling, conveyor systems benefit applications including shipping and receiving, distribution, sintering, finishing, parts washing, packaging and warehousing. These applications reside in, among others, industries such as aerospace, automotive, commercial and retail manufacturing, food processing, industrial manufacturing, military and defense, paper and pharmaceutical.

Conveyor systems are one of the most used machines in manufacturing facilities, packaging, and warehousing businesses. In simpler terms, a conveyor is a material handling technology that offers the convenience of moving heavy and bulky materials from one place to another, systematically. This plant and facility equipment offer a wide range of benefits to businesses. This article explains some of the biggest benefits of conveyors, after listing a few popular variations of these machines.