Expansion Joints

Expansion joints are designed to permit mobility, as their name suggests. They dampen pipe, duct, and other pipeline component movement brought on by thermal and mechanical vibrations. In industrial applications, expansion devices come in a variety of forms. Thermal expansion and contraction induce length variations in piping systems as they heat up and cool down. The length of the piping run, the temperature difference, and the alloy of the pipe all affect how much thermal expansion occurs. For instance, when the temperature of a 100-foot (30.5 m) run of carbon steel pipe rises from 70 to 300 °F (21 to 148.9 °C), the length of the pipe will grow by 1.82 inches (4.6 cm). However, if the identical pipe were constructed of 300-class stainless steel, it would enlarge by 2.61 inches (6.6 cm). Numerous techniques have been used to account for these thermal movements because the piping system might be subjected to significant strains due to this expansion and contraction.

How Expansion Joints Work

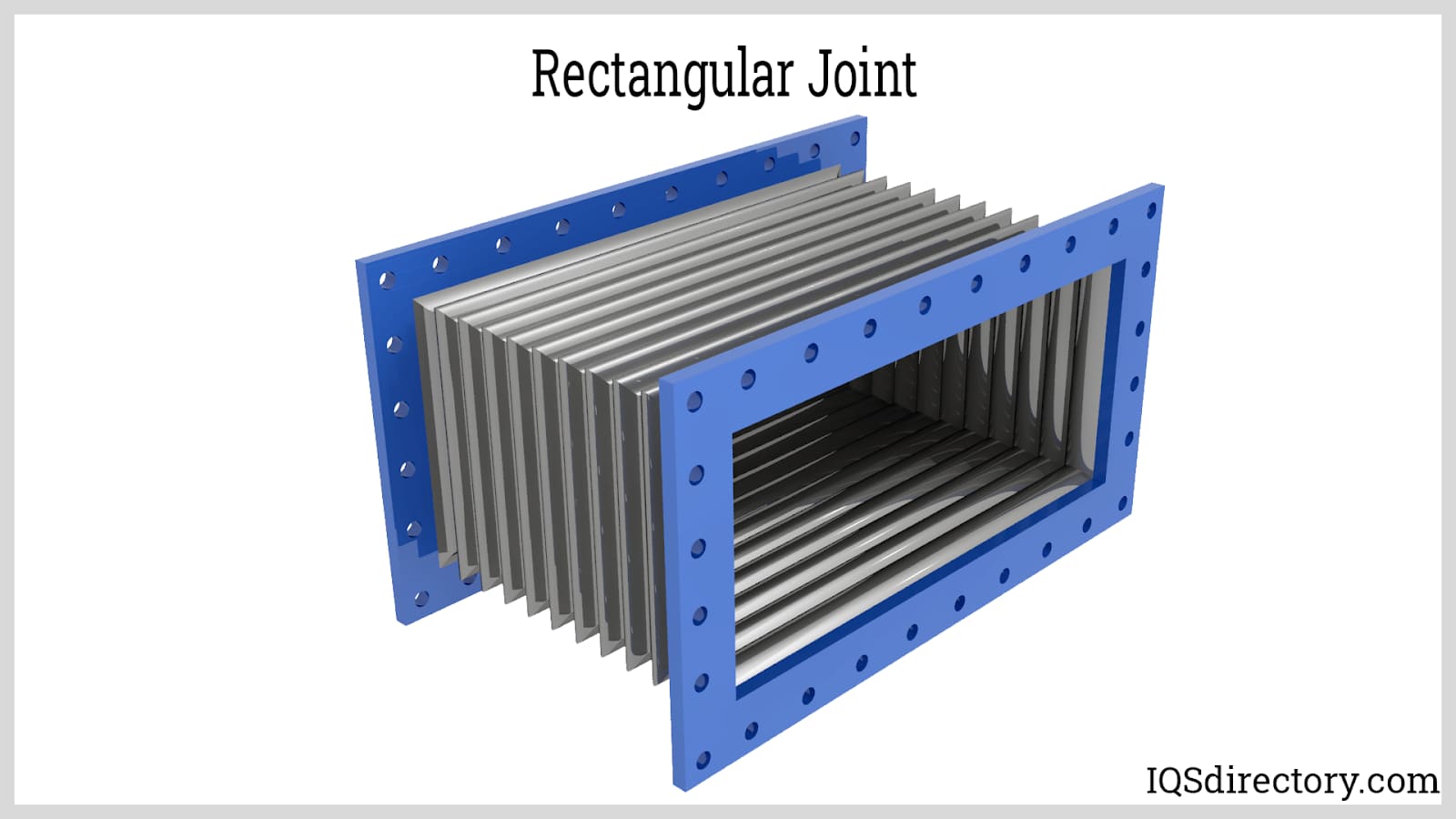

Metal expansion joints compensate for thermal expansion and relative movement in pipes, containers, and machines. Depending on the application, they could have one or more metal bellows, connectors at both ends, and tie rods. Bellows are flexible components that lessen pipe system motion. The bellows must be made of both rubber and metals, which may stretch during expansion and bunch together during contraction. As the pipe temperature rises, metal expansion joints collapse to accommodate movement and release pressure on the pipe. Stainless steel and nickel alloys are only a few materials that can create metallic bellows.

Materials Used for Expansion Joints

Metal Joints

Metal expansion joints are beneficial in applications with a lot of thermal expansion. The metal expansion joint contracts to accommodate the movement as the pipe's temperature rises, alleviating pressure on the anchors and the pipe.

Rubber Joints

Rubber has good vibration and shock wave absorption; therefore, it can be used for thermal expansion. This expansion joint is ideal for minimizing the transfer of noise and vibration from other equipment and protecting equipment like pumps. Additionally, they act as shock absorbers to decrease the harm caused by pressure surges and earthquake disturbances.

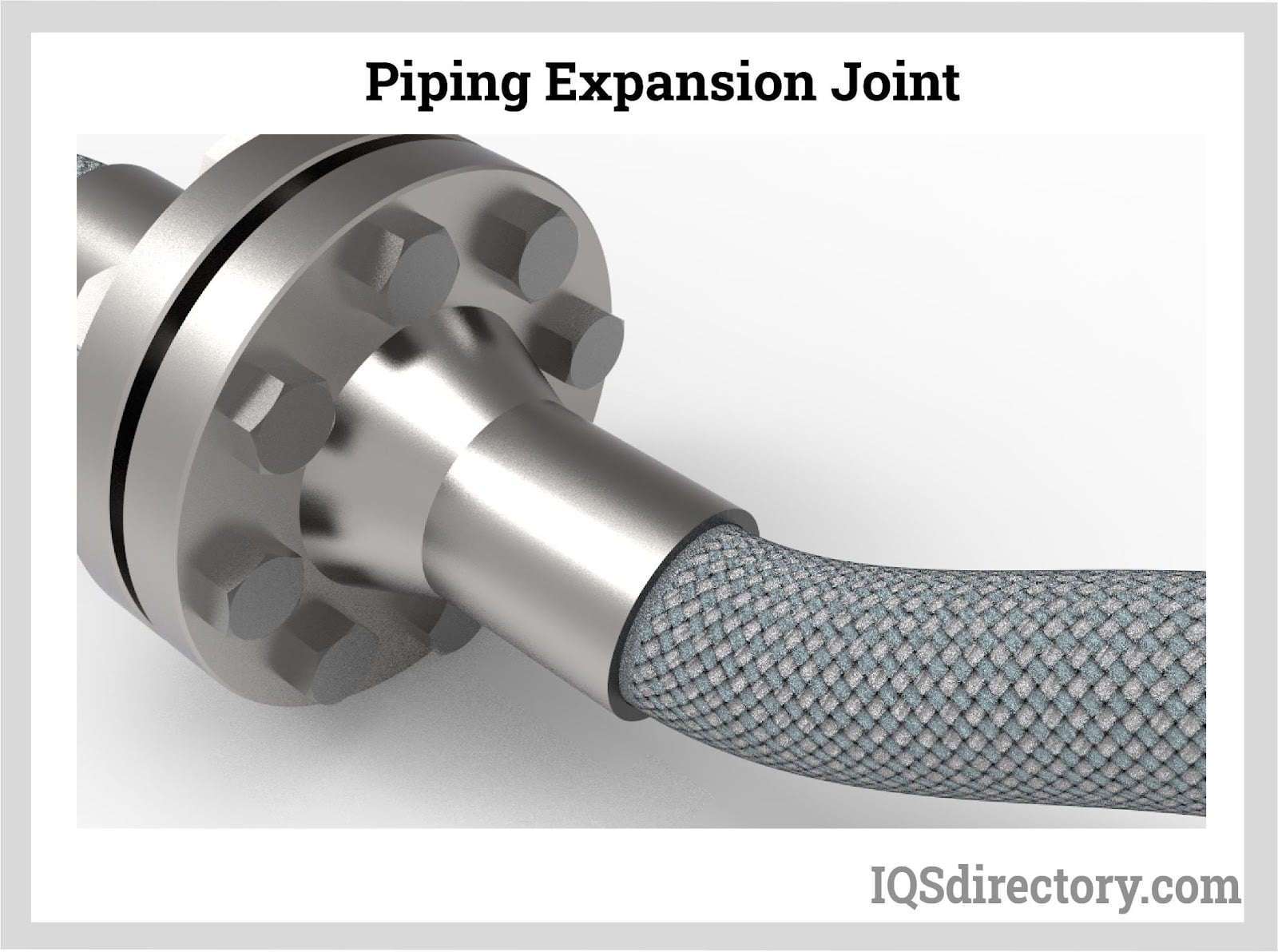

Stainless Steel Braided Joints

Technically, flexible or metal liners on braided stainless steel hoses make them more like flexible connectors than expansion joints. They consequently function well in applications requiring pipe misalignments or vibration dampening in high-pressure and high-temperature settings.

How Expansion Joints Work

Bellow to Tube Construction

The process of creating metal bellows begins with creating corrugated tubes. The coil or sheet stock is cut to the necessary size using precision shearing, then coiled into tubes. Care must be taken to ensure that the tubes are round enough to fit over the dies used to make bellows. Each tube is rolled, and then, using an automatic seam welder, the longitudinal seam is joined. The bellows must be made using this technique.

Forming Method

The most common techniques for corrugating tubes are mechanical die-forming and hydroforming. On the bellows forming machine, the tube is positioned over a die. In the metal forming process known as hydroforming, a pressurized liquid solution is used to shape specific work pieces made of tubes or sheet metal. A hollow aluminum tube is placed into a negative mold that replicates the desired bellow's shape to hydroform aluminum or other metals into bellows. After that, high-pressure hydraulic pumps fill the aluminum tube with fluid under extremely high pressure, forcing it to expand until it fits the mold. The hydroformed bellow is then removed from the mold. The machine is set to make the engineered diameter of the bellows corrugation, and the form of the overall joint results in the creation of additional joint components.

Re-Rolling Method

During the secondary process of re-rolling, the manufactured metal bellows' shape is finished and cold worked to the exact geometry defined by the design engineer. Any metalworking technique known as "cold work" entails plastic deformation of the alloy below the recrystallization temperature. As a result, the bellows are strengthened by cold working, which guarantees they have good dimension control characteristics. Unfortunately, some producers of expansion joints skip this step and compress the bellows to size in a press, reducing the bellows' ultimate performance potential.

Welding Method

The tubes are joined at the bellows' neck by a continuous sequence of overlapping spot welds on multi-ply bellows. Roll seam welding is the term for this technique. The bellows are built first and then welded to the other created parts of the connection.

Benefits of Expansion Joints

- Plumbing systems use bellows and expansion joints. They are built using accessories like tie rods, covers, and flow liners. The metal bellows act like springs despite being restricted to manage pressure. For the best flow, the movement of the connecting pipes is essential.

- If expansion joints were not included in piping systems, the thermal expansion would cause severe strains. Pipes may flex and welds may break as a result of the pressure that can be generated by thermal expansion.

Choosing the Correct Expansion Joint Supplier

To ensure the most productive outcome when purchasing expansion joints from an expansion joint supplier, it is important to compare several companies using our directory of expansion joint suppliers. Each expansion joint supplier has a business profile page highlighting their areas of experience and capabilities, and a contact form to directly communicate with the supplier for more information or request a quote. Review each expansion joint business website using our patented website previewer to quickly learn what each business specializes in. Then, use our simple RFQ form to contact multiple expansion joint companies with the same form.