EMI Shielding

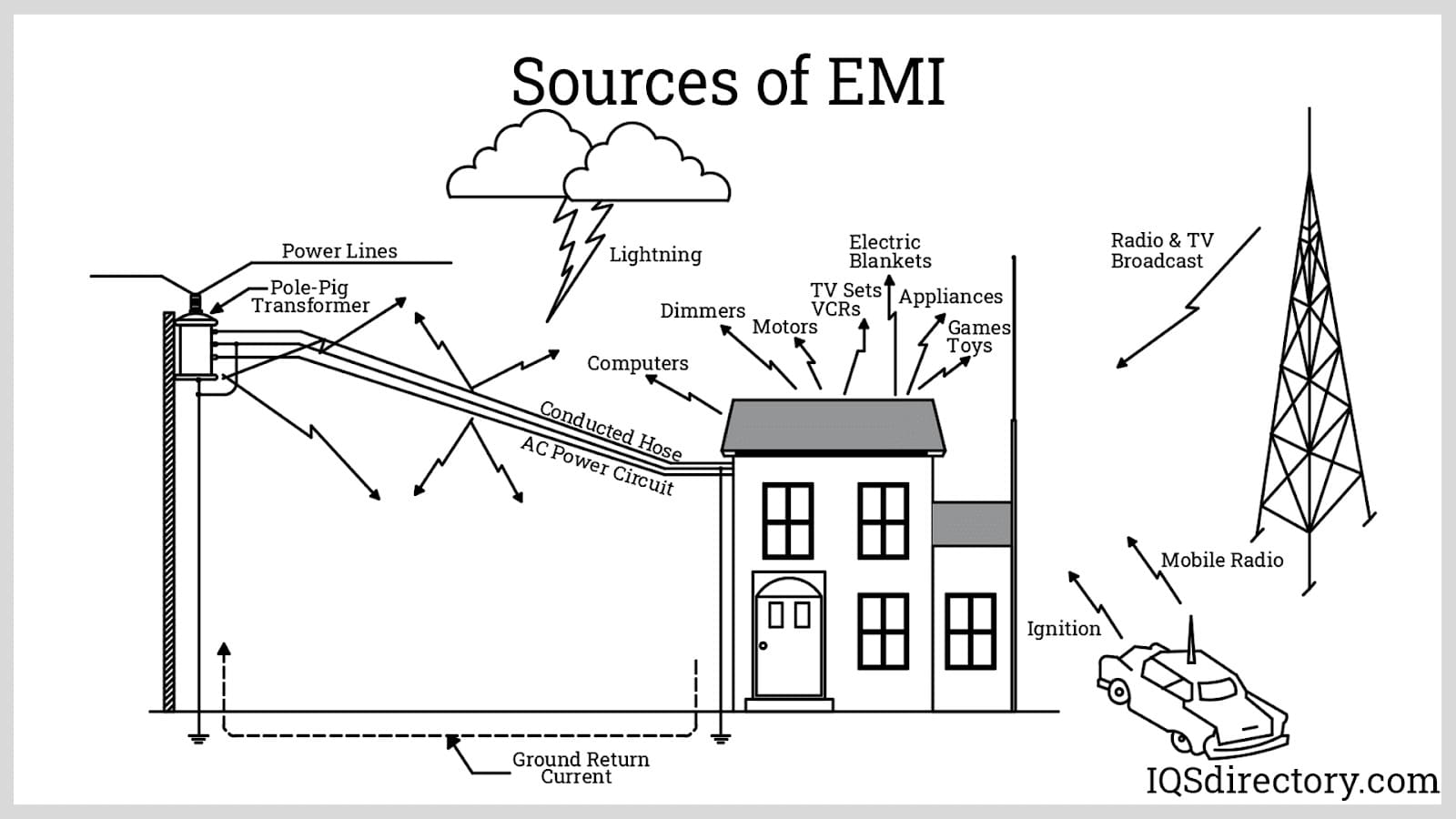

Electromagnetic interference (EMI) shielding is a service that many manufacturers either offer as an add-on or integrate directly into their products. Through various techniques, EMI shielding protects devices from unwanted electromagnetic interference. EMI refers to the magnetic field generated by electrical currents or electromagnetic radiation, which can travel along wires, circuits, conductors, or even through open space. Similarly, radio frequency interference (RFI) consists of electromagnetic noise that moves through the air as radio waves.

While some devices rely on EMI for proper function, most require electromagnetic compatibility, meaning they must operate without interference. For those that do not depend on EMI, both EMI and RFI can cause disruption, interfering with normal operation.

To safeguard electronic devices from these disturbances, manufacturers employ magnetic shielding technologies such as EMI enclosures, RF absorbers, EMI coatings, EMI gaskets, and EMI filters.

Frequently Asked Questions About EMI Shielding

What is EMI shielding and why is it important?

EMI shielding protects electronic devices from electromagnetic interference caused by currents, circuits, or radio waves. It prevents signal disruptions, performance degradation, and potential health risks associated with electromagnetic radiation exposure.

How does EMI shielding work?

EMI shielding works by absorbing or reflecting electromagnetic waves using conductive materials such as copper, nickel, steel, or Mu-Metal®. These materials block interference from reaching sensitive components, ensuring stable electronic operation.

What materials are commonly used for EMI shielding?

Common EMI shielding materials include copper for high conductivity, nickel for durability, steel for magnetic permeability, aluminum for lightweight applications, and Mu-Metal® for maximum magnetic field absorption.

What are the benefits of EMI shielding in electronic devices?

EMI shielding enhances performance by reducing interference, extends device longevity, improves safety, and protects human health from electromagnetic radiation. Its recyclability and durability make it an eco-friendly and lasting solution for modern electronics.

What industries rely on EMI shielding solutions?

Industries such as healthcare, telecommunications, computing, marine technology, and manufacturing rely on EMI shielding to ensure consistent equipment performance and to prevent interference in sensitive environments.

How do EMI coatings differ from solid enclosures?

Unlike rigid enclosures, EMI coatings are spray-applied to plastic housings or cables, offering flexible, lightweight shielding. They provide effective electromagnetic protection while maintaining design adaptability and aesthetics.

What should be considered when selecting EMI shielding?

Choosing EMI shielding depends on factors like interference frequency, application size, and shield materials. Working with experienced manufacturers ensures the solution fits performance needs and regulatory standards.

The History of EMI Shielding

The oldest form of EMI shielding is the Faraday cage, invented in 1836 by the English scientist Michael Faraday. He constructed a cage coated with metal foil to demonstrate its ability to block an electric charge from reaching its interior. This experiment expanded on Benjamin Franklin’s recorded discovery of the effect in 1755. Faraday cages remain in use today, proving their lasting effectiveness in shielding against electromagnetic interference.

Efforts to address EMI and RF/RFI interference began in earnest in 1933 during a meeting of the International Electrochemical Commission (IEC) in Paris. At that time, experts recommended forming a committee to tackle the issue. This led to the creation of the International Special Committee on Radio Interference (CISPR), which developed the foundation for many of today’s electromagnetic compatibility (EMC) regulations. The United States officially introduced EMI regulations in 1979, with the European Union following suit in the mid-1980s.

Today, EMI shielding and coatings are more crucial than ever. As technology advances, devices continue to shrink while their internal components become more intricate and sensitive. This miniaturization has led to an increase in device failures caused by EMI, commonly referred to as "noise." Managing this interference has become a greater challenge due to the compact size of mechanical parts and the increasing operating speeds of modern electronics. Engineers, however, continue to develop innovative shielding techniques to ensure devices remain functional in an ever-evolving technological landscape.

EMI Shielding Benefits

- Improved Performance

- The primary function of EMI/RF shielding is to minimize electromagnetic interference, which helps prevent disruptions, obstructions, performance degradation, or complete device malfunctions. High-quality and reliable EMI or RFI shielding significantly enhances the efficiency of electronic devices, ensuring optimal performance and longevity.

- Recyclability

- Unlike conductive coatings, EMI/RF shielding compounds are highly recyclable, making them a sustainable option. This recyclability is a major advantage in industries striving for eco-friendly manufacturing and waste reduction.

- Permanence

- Durability is a key characteristic of EMI shielding compounds. Unlike conductive coatings, which are prone to scratches and potential shielding failure, EMI shielding materials offer long-term adhesion and resistance to delamination during thermal cycling. This ensures consistent protection and eliminates risks associated with coating degradation.

- Protection of Human Health

- EMI shielding plays a crucial role in protecting people from potential health risks linked to electromagnetic radiation (EMR) and radio frequency interference (RFI). Acute exposure to electromagnetic waves can cause burns, eye damage from millimeter waves (used in airport security scanners), and human tissue heating from shortwave radio frequencies. Even low-frequency electromagnetic waves have been known to cause tingling sensations and discomfort in individuals exposed to them for prolonged periods.

EMI Materials Process

EMI shields, also referred to as magnetic shields, are made from metals with high magnetic permeability, allowing them to absorb and block electromagnetic interference effectively. Common materials used in EMI shielding include nickel, copper, steel, and aluminum, though the industry standard is Mu-Metal®, known for its superior shielding capabilities.

- Nickel

- A naturally occurring element, nickel is often used in EMI shielding alloys due to its hardness, durability, electrical conductivity, and magnetic properties. While it can be used alone, it is more commonly found as a key component in high-performance shielding alloys.

- Copper

- One of the most effective and widely used shielding materials, copper is highly valued for its ability to block and reduce magnetic and electrical interference. It is easy to form and shape, making it a versatile choice for various shielding applications. However, it is often more expensive than other shielding materials.

- Steel

- Particularly in the form of carbon steel or stainless steel, steel is a preferred EMI shielding material due to its high permeability, allowing it to effectively block low-frequency magnetic interference. It is also durable and cost-effective for many industrial applications.

- Aluminum

- Aluminum is a popular choice for EMI shields because of its lightweight nature, high conductivity, and non-ferrous properties. It is particularly useful for shielding applications that require corrosion resistance and structural integrity.

- Mu-Metal®

- Recognized as the industry standard for EMI/RFI shielding, Mu-Metal® is an alloy of nickel, iron, copper, and molybdenum. It is known for its exceptionally high magnetic permeability, offering the highest level of EMI/RF reduction, making it the go-to material for high-performance shielding solutions.

EMI Shielding Design

Manufacturers design enclosures and shields in a way that often does not require them to be solid. Instead, they frequently use perforated metal materials, as long as the shield surface holes are smaller and closer together than the electromagnetic waves they aim to block. A common example of this application is microwave doors, which effectively prevent microwaves from escaping while still allowing visibility.

When greater flexibility is required, manufacturers opt for EMI coatings rather than rigid shields. EMI coatings can be spray-applied to the inside of plastic housings, the outside of wires, or the exterior of standard enclosures, providing adaptable EMI protection without compromising design versatility.

To meet specific application requirements, manufacturers tailor EMI shield designs to individual client needs. Shields are commonly available as one-piece constructions, but they can also be produced with peel-off tops for easier access or as a “fence and cover” configuration, consisting of two separate pieces. Additionally, manufacturers can design and fabricate custom EMI shields to accommodate specialized device structures, environmental conditions, and performance demands.

EMI Shielding Images, Diagrams and Visual Concepts

EMI shielding, a technique of creating a barrier that prevents the leakage of strong electromagnetic fields which interfere with sensitive devices and signals.

EMI shielding, a technique of creating a barrier that prevents the leakage of strong electromagnetic fields which interfere with sensitive devices and signals.

EMI are classified according to the duration of the interference, which the types of interference are continuous which emits a continuous unwanted signal and a pulse which only occurs for a short duration.

EMI are classified according to the duration of the interference, which the types of interference are continuous which emits a continuous unwanted signal and a pulse which only occurs for a short duration.

Metallic properties such as electrical conductivity, magnetic permeability, strength, and ductility are suitable for shielding structural materials.

Metallic properties such as electrical conductivity, magnetic permeability, strength, and ductility are suitable for shielding structural materials.

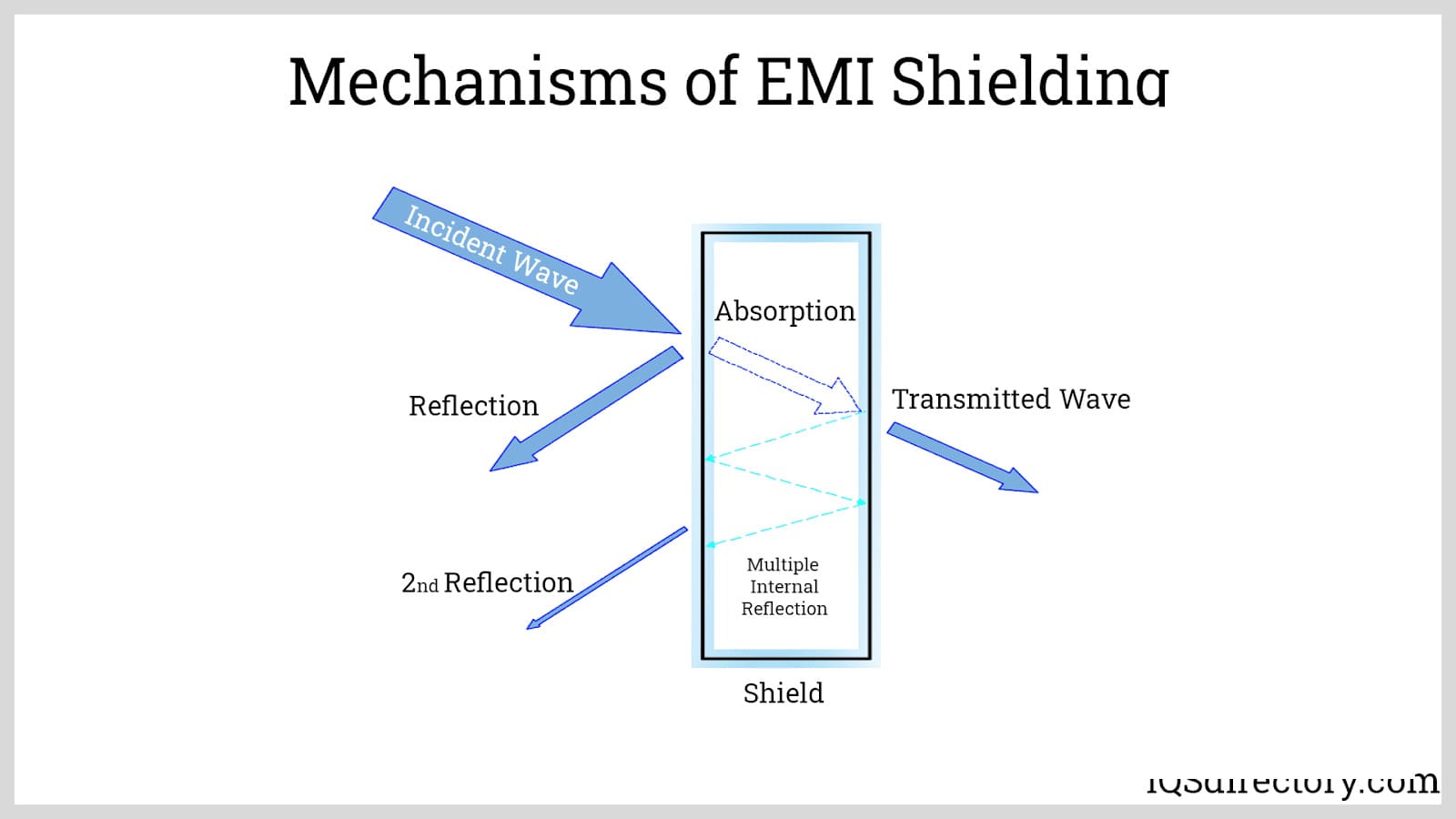

The mechanisms of EMI shielding includes reflecting the incident wave or absorbing the wave.

The mechanisms of EMI shielding includes reflecting the incident wave or absorbing the wave.

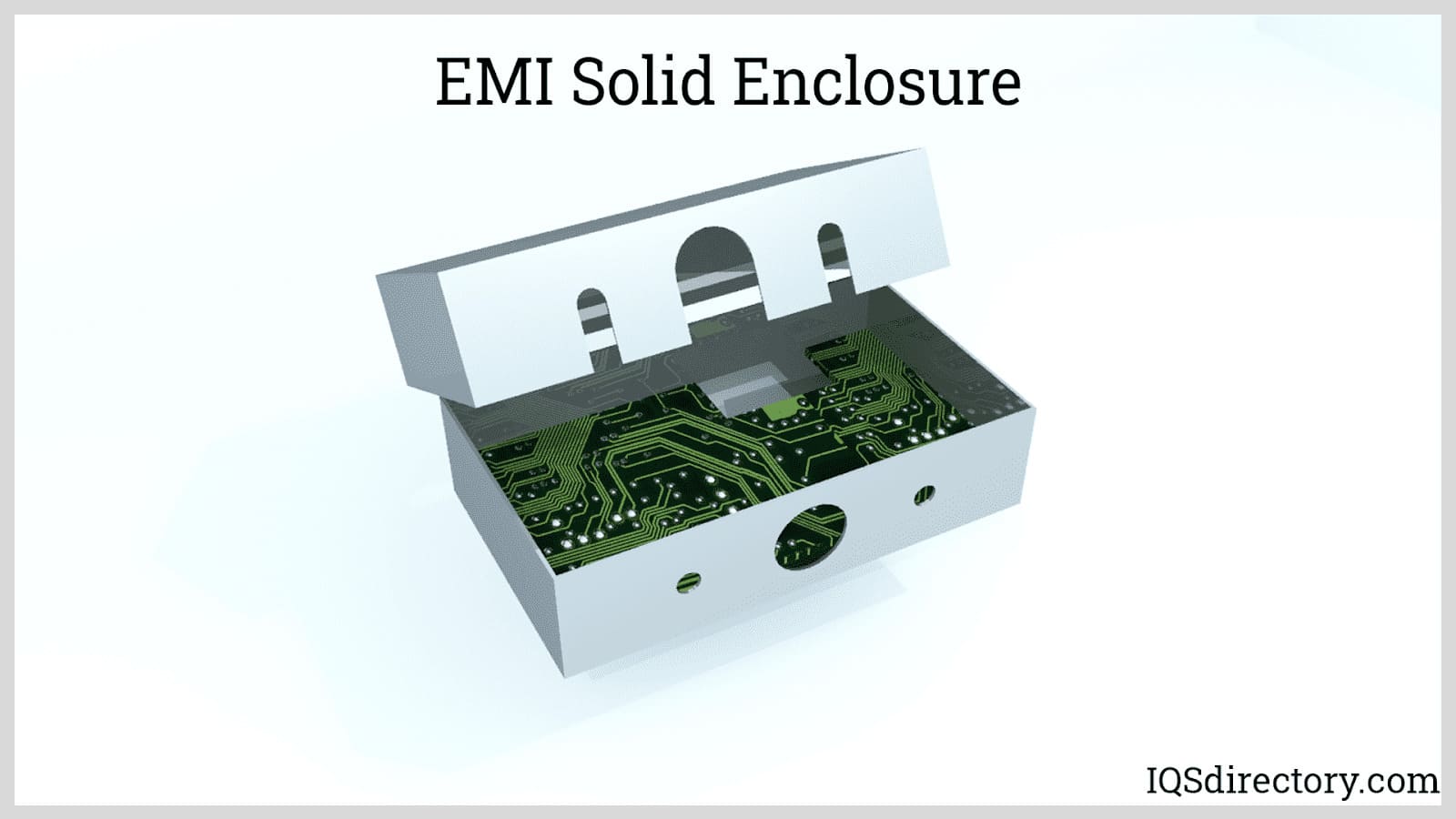

Solid Enclosures prevents electromagnetic waves from getting into or out of the system, the enclosure is grounded so that any stray current is diverted to ground, which minimizes the risk of electric shock.

Solid Enclosures prevents electromagnetic waves from getting into or out of the system, the enclosure is grounded so that any stray current is diverted to ground, which minimizes the risk of electric shock.

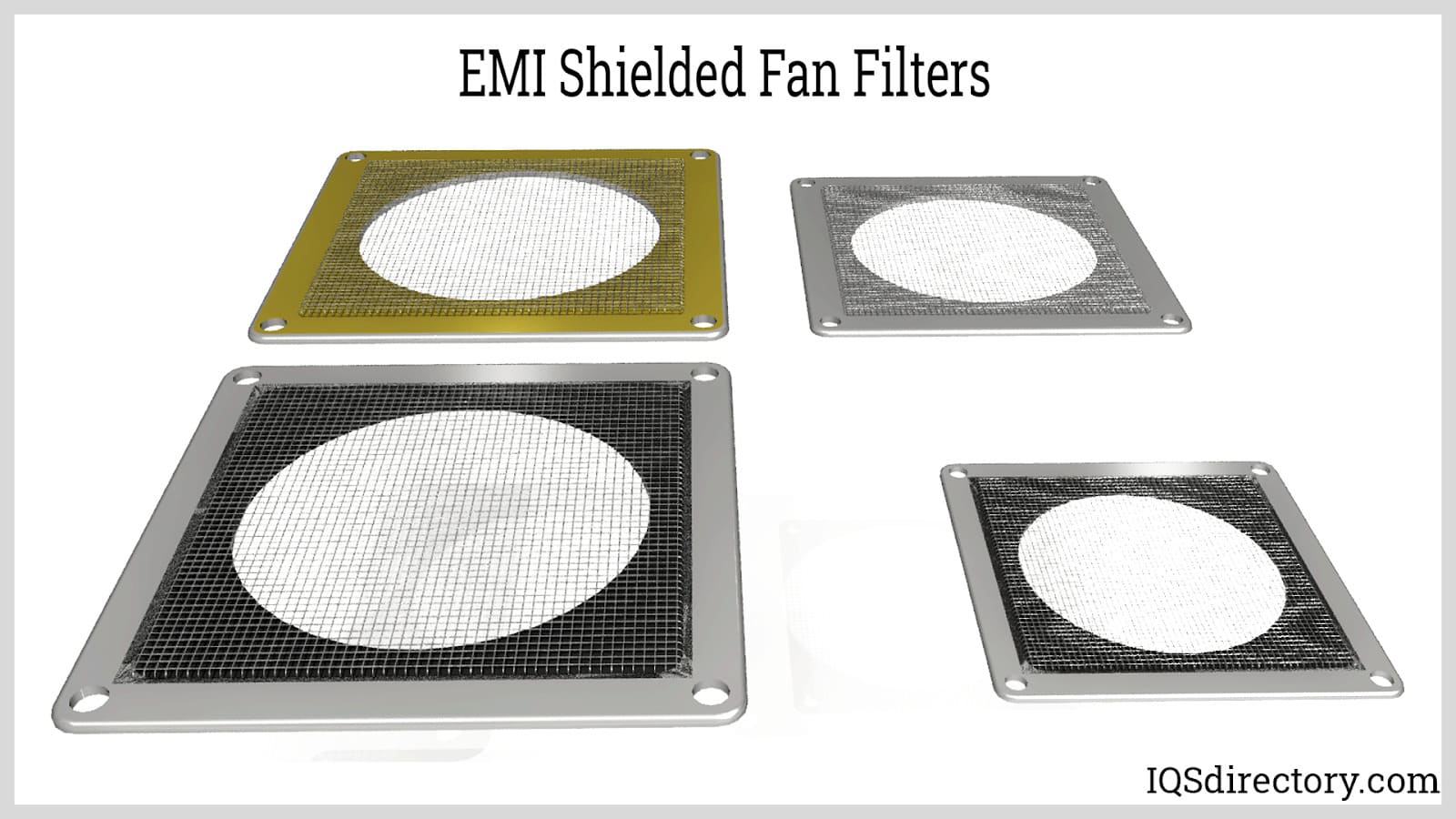

Shielding materials with penetrations or discontinuities less than the expected wavelength of the EMI while allowing ventilation to the system.

Shielding materials with penetrations or discontinuities less than the expected wavelength of the EMI while allowing ventilation to the system.

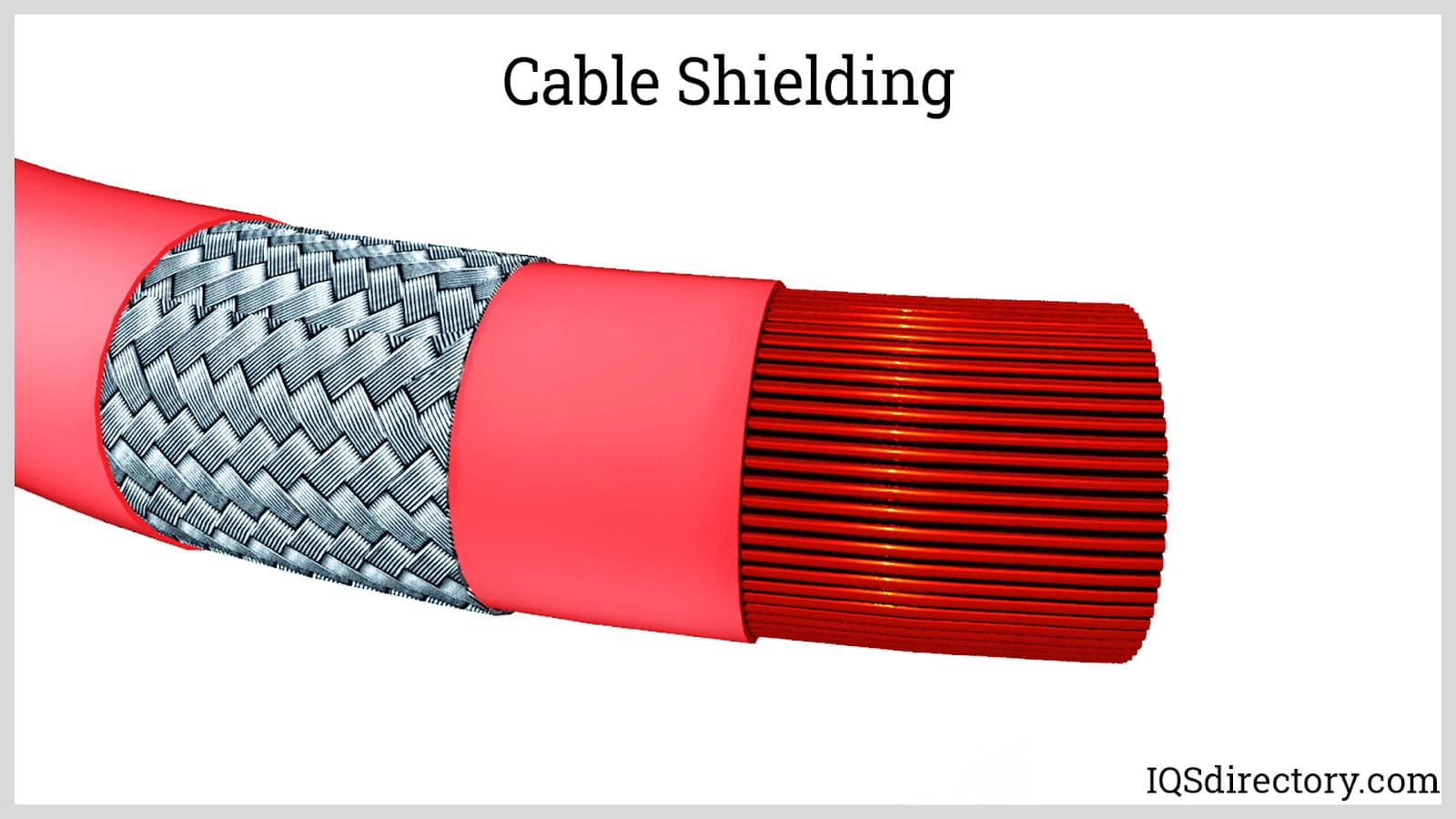

Tapes or wire braids that cover the insulated conductor of a power or instrument cable.

Tapes or wire braids that cover the insulated conductor of a power or instrument cable.

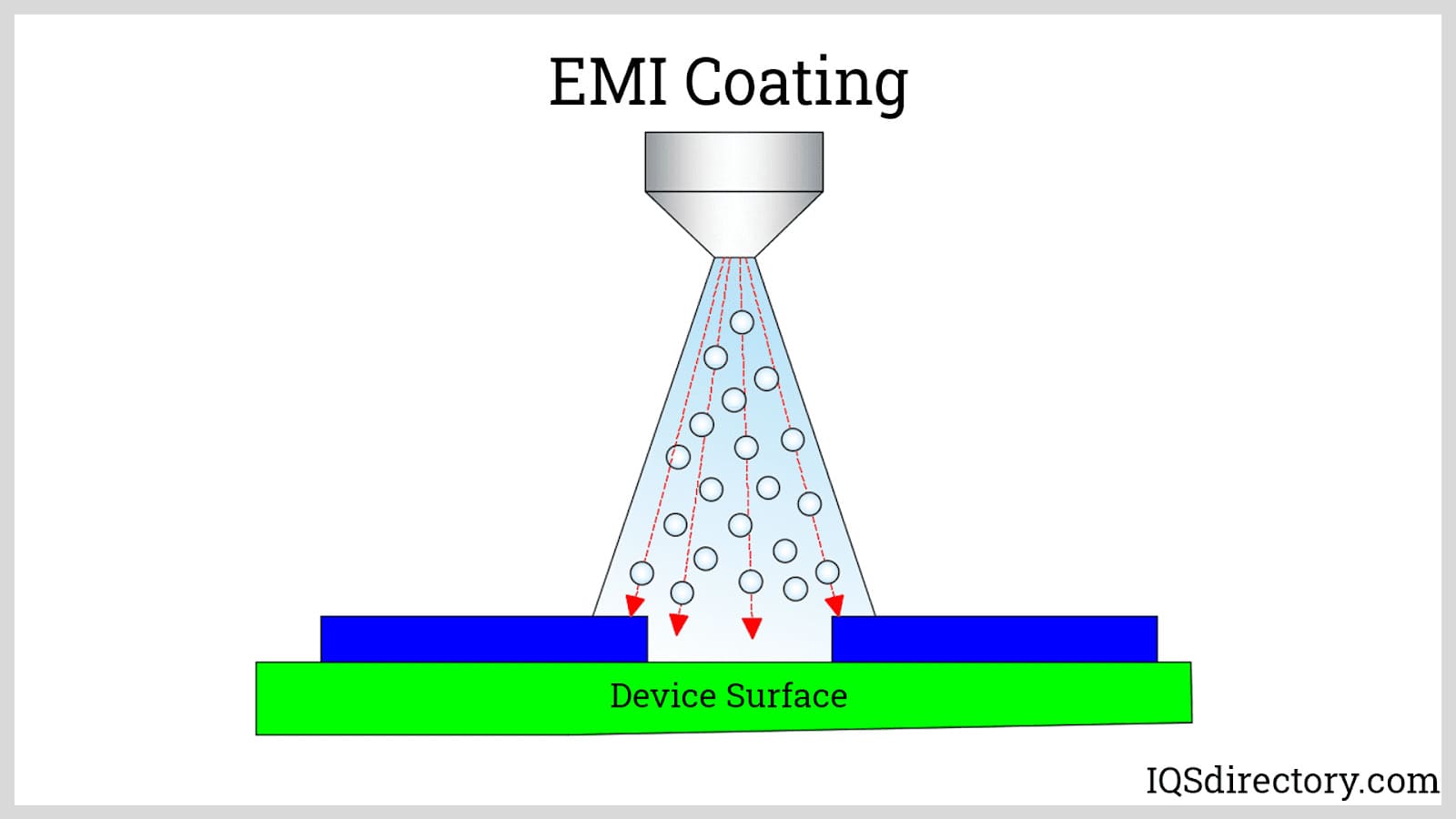

EMI shielding materials can be coated through painting, spraying, dispensing, and electroplating when metallic shielding would be impractical.

EMI shielding materials can be coated through painting, spraying, dispensing, and electroplating when metallic shielding would be impractical.

EMI Shielding Types

- Electromagnetic Shielding

- A protective barrier that prevents electronic devices from being affected by ambient electromagnetic interference.

- EMF Protection

- Utilizes magnetic shielding materials or protective products to absorb or redirect electromagnetic fields (EMF), preventing interference with sensitive devices and reducing human exposure.

- EMI Coating

- A specialized spray applied to the interior of electronic housings to shield sensitive components from electromagnetic interference. Commonly made from acrylic-based materials, EMI coatings may include metal inks containing copper, nickel, or chromium alloys, allowing EMI shielding on plastic and non-metallic surfaces. Brush-on paints and coatings are also available for field applications.

- EMI Enclosures

- Also known as Faraday cages, these enclosures surround sensitive electronic equipment, effectively absorbing and blocking harmful EMI and RF/RFI interference.

- EMI Filters

- Passive electronic devices that suppress conducted electromagnetic interference generated by surrounding electronics. Installed within power lines or switches, EMI filters allow low-frequency signals to pass while blocking high-frequency EMI. Though effective in managing EMI from power sources, filters must be used alongside enclosures, coatings, and gaskets for complete EMI protection.

- EMI Gaskets

- Create stronger EMI and RFI shielding by sealing seams and gaps in an enclosure, preventing EMI leakage. Made from electrically conductive rubber materials, EMI gaskets are often combined with shielding metals to enhance protection. As electromagnetic and radio frequencies increase in power, EMI gaskets play a crucial role in ensuring robust shielding for advanced electronic systems.

- EMI Shields

- Materials or engineered shielding products designed to redirect or absorb electromagnetic interference, protecting sensitive electrical devices from performance disruptions.

- Magnetic Shielding

- Also known as electromagnetic (EMI) shielding, this technique protects electronic equipment from external magnetic fields and electromagnetic waves, reducing interference.

- Magnetic Shields

- Protective materials or shielding products that block interference from electromagnetic fields (EMF) or magnetic fields, ensuring stable operation of sensitive electronics.

- Mu Metal®

- A high-permeability nickel-iron alloy used to shield electronic components from disruptive magnetic fields. Recognized as the industry standard for magnetic shielding.

- RF Absorbers

- Also known as radar absorbers or microwave absorbers, these materials prevent radio frequency interference (RFI) by absorbing magnetic energy before it reaches electronic equipment.

- RFI Shielding

- A protective measure that blocks radiated electromagnetic "noise", preventing radio waves from interfering with sensitive electronic devices.

- Cable Shielding

- A protective layer inside cables that encapsulates wires, minimizing electromagnetic noise and interference. Shielding materials can include braided copper strands, aluminum foil, copper tape, or conductive polymers. Proper shielding must fully cover all splices to be effective.

- Radiation Shielding

- Reduces radio frequency interference (RFI) affecting an electronic device. Commonly used in mobile phones, which operate in the microwave band frequency, to prevent performance disruptions from wireless communication signals.

EMI Shielding Applications

In today's world, where electronic devices dominate our daily lives, millions—if not billions—of magnetic field waves are present at any given moment. These electromagnetic signals create a constant risk of electromagnetic interference (EMI), RFI Shielding problems, and radio frequency interference (RFI). When multiple electronic devices operate simultaneously, their signals can interfere with one another, disrupting normal functionality.

Consider a scenario where a radio is switched on and a cell phone nearby receives a call. You may notice noise or static coming from the radio. This interference occurs because the radio receiver picks up some of the cell phone signal, causing unwanted disruptions. While this example is relatively minor, similar signal interference in industrial or medical equipment can result in serious malfunctions or even total device failure.

Beyond operational disruptions, many household and industrial electronic devices emit electromagnetic radiation (EMR), which can pose potential health risks. Prolonged exposure to high levels of EMR has been associated with tissue heating, eye damage from millimeter waves, and even nerve irritation at extremely low frequencies. To minimize exposure and protect human health, manufacturers incorporate EMI shielding and magnetic shielding techniques into device designs.

A vast range of industries depend on EMI and RF shielding solutions to ensure optimal device performance and prevent interference. These include healthcare, telecommunications, stage production, sound engineering, radio broadcasting, marine applications, medical device manufacturing, electronics, computing, process control, and home appliance industries. As technology continues to advance, EMI shielding remains a critical component in ensuring the safe and effective operation of modern electronic devices.

Service Details for EMI Shielding

Manufacturers effectively protect electronic equipment from electromagnetic interference (EMI) by enclosing it in a conductive, EMI-absorbing material—a process known as electromagnetic shielding. Another widely used approach involves coating enclosures with an EMI shielding layer, ensuring that devices are safeguarded from both external and internal electromagnetic disturbances.

The process of shielding employs several methods, including foils, conductive fabrics, metallic inner shields, and plastics with a conductive coating. One of the most common techniques is the application of conductive paints, which create a conductive surface layer on plastic enclosures. These coatings effectively absorb or redirect electromagnetic waves, preventing interference with nearby electronic components.

Regardless of the specific method used, the primary goal remains the same: to establish a protective barrier around electronic enclosures, cables, and other electrical components, such as EMI gaskets. This shielding barrier ensures that sensitive equipment is insulated from external electromagnetic interference while also preventing the emission of disruptive electromagnetic frequencies (EMFs). By implementing these shielding techniques, manufacturers enhance the reliability, performance, and safety of electronic devices across various industries.

EMI Variations and Similar Processes

Several alternative shielding materials and techniques are vying for prominence in EMI/RF protection. Materials include copper and other metal foils, plastics with conductive coatings, conductive particle-filled silicone, fabrics with conductive adhesives, and metallic inner shields. Shielding methods range from vacuum metallization to specialized coating solutions like Master Bond MB600S.

- Vacuum Metallization

- Vacuum metallization is emerging as an advanced EMI/RF shielding method. This process involves heating metal in a vacuum until it reaches its boiling point. The resulting metal vapor condenses onto a substrate, forming a thin, conductive shield that effectively blocks electromagnetic interference. This method is increasingly popular due to its lightweight application and cost-effectiveness.

- Master Bond MB600S

- Master Bond has developed MB600S, a conductive coating system offering EMI shielding, high-temperature resistance, and ease of application. Made from a single sodium silicate component, this silver-colored, fully conductive coating withstands temperatures up to 700°F. As a water-based, non-toxic formulation, it is easy to handle and apply.

- The coating provides shielding effectiveness of 95 to 105 dB between 100 MHz and 2 GHz, with effectiveness decreasing to 60 to 80 dB above 2 GHz. It can be brushed or sprayed onto surfaces, with spraying yielding better shielding performance. After application, the coating requires approximately 48 hours to fully cure before becoming an effective EMI shield.

Things to Consider When Choosing EMI Shielding

Whether you need to block millimeter waves or radio waves, EMI shielding is an essential service. However, selecting the best shielding solution can be challenging. That’s why it is crucial to work with a service provider who is not only skilled and knowledgeable but also dedicated to finding the best solution for your needs. You can start by browsing the companies listed above to find a manufacturer that meets your requirements.

Once you have chosen a reputable manufacturer, take the time to discuss your application in detail. The effectiveness of EMI/RF shielding depends on several factors, including:

- The materials used for the shield

- The frequency of the EMI being blocked

- The size of the application requiring shielding

With the right service provider and shielding solution, your device will perform better, and your health will be safeguarded for years to come.

EMI Shielding Terms

- Anechoic Chamber

- A room designed to eliminate acoustical reflections or echoes. The walls, ceiling, and floor are lined with a metallic substance to block electromagnetic waves.

- Attenuation

- The reduction in an electrical signal’s strength as it passes through a medium, measured in decibels.

- Canted Coil

- A round-wire spring with elliptical coils that deflect independently when compressed, ensuring consistent loading at each point of contact.

- CE Marking

- A mandatory certification mark for many products sold in the European Free Trade Association (EFTA) and European Union (EU) markets. It is sometimes called the "Trade Passport to Europe" for non-EU products.

- Double Shielded Enclosure

- A shielded enclosure with inner and outer walls that are isolated from each other, except at the filter penetration point.

- Electromagnetic Compatibility (EMC)

- The ability of electronic equipment to operate without generating or being affected by EMI.

- Electrostatic Discharge (ESD)

- The release of electrical energy caused by the transfer of electrons between objects when they come into contact and separate. Also known as a triboelectric charge.

- ESD Shielding

- Protects electronic equipment from failures caused by electrostatic discharge.

- Emission

- The release of electromagnetic waves from electronic equipment, which can contribute to EMI.

- Filtering

- The process of removing unwanted signal components through attenuation, while allowing desired signals to pass.

- Impedance

- The resistance to electrical current flow in a circuit at a given frequency, measured in ohms. The lower the ohmic value, the higher the conductor’s quality.

- Insertion Loss

- A measure of a filter’s effectiveness, representing the difference in power reception before and after filtration.

- Radiation

- The movement of electromagnetic energy in the form of particles, rays, or waves.

- Radio Frequency

- A low-frequency range of electromagnetic radiation used for communications.

- RFI (Radio Frequency Interference)

- A type of interference in the radio frequency range that affects communications. Unlike EMI, RFI is transmitted through free air space rather than circuits or power lines. The term EMI/RFI shielding covers all interference caused by electromagnetic radiation.

- Shielding Effectiveness

- The ability of a shielding material to block electromagnetic radiation, expressed as a ratio comparing signals with and without the shield.

- Skin Effect

- The tendency of high-frequency current to travel along the outer surface of a conductor rather than through its core, increasing effective resistance at high frequencies.

- Slot Antenna

- A radiating element created by a slot in a conducting surface or the wall of a waveguide.

- Vacuum Deposition

- A process in which thin material coatings condense on cool surfaces inside a vacuum.

- Waveguide

- A medium that directs the passage of electromagnetic energy and signals.

- Magnetic Shielding Foil

- A thin shielding material used in sensitive electronic equipment, such as industrial controls and circuit boards. Due to its thinness, it can be easily cut and installed in tight spaces.

- Wire Shielding

- A type of EMI shielding that protects wires and cables from harmful electromagnetic energy. It is also used to prevent electromagnetic waves from affecting external equipment.