Clothing Labels

Clothing labels, which provide necessary information on a garment, are necessary for manufacturing and selling clothing. The various clothing labels also contain varied information, from the fabrics that produced the garment to the garment's proper cleaning and care instructions. In some cases, labels for expensive clothing have even more extensive information to ensure proper garment care.

Additionally, clothing labels can be a safety feature that warns about certain health conditions that should not use a particular fabric or recommend restrictions on the age of those who can wear a garment. Therefore, although clothing labels might be regarded as unimportant or nonessential, they serve a vital purpose and assist in extending the life of a piece of clothing.

In recent years, clothing labels have been designed to exclude tags, paper, or fabric and are instead printed onto the garment. This is especially relevant for undergarments, where tags can be irritating and have been cut off in the past.

Quick links to Clothing Labels Information

How Clothing Labels are Made

The two basic types of clothing labels are woven and printed. Woven labels are weaved on looms, while printing involves using ink to print information on a label. Label printing is a relatively new process, while woven labels have existed for many years.

- Screen Printing Clothing Labels

- Screen printing, introduced in 1907, places images on fabric using a screen, press, and ink. Although it is done professionally, screen printing has also become a DIY project for ambitious hobbyists. The screen printing process can use the full spectrum of the rainbow, though one or two colors are usually used to keep the printing process simple.

-

- The parts of the screen printing process include:

-

- The Screen – When screen printing was invented at the turn of the century, screens were made of silk, which had a short useful life. Modern screen printing uses polyester fabrics with monofilaments.

- The Frame – The frame is what the screen is tightly stretched over. It can be made of wood, steel, or aluminum, with steel and aluminum used for automated industrial screen printing.

- The Emulsion – The emulsion is a light-sensitive photopolymer upon which the information for the clothing tag will be applied. Applying the emulsion requires the greatest care and precision of the various aspects of the screen printing process.

- Exposure – Once the emulsion has dried, the exposure frame adds the text of the clothing label to the screen. The garment industry speeds up this aspect of the process using laser technology.

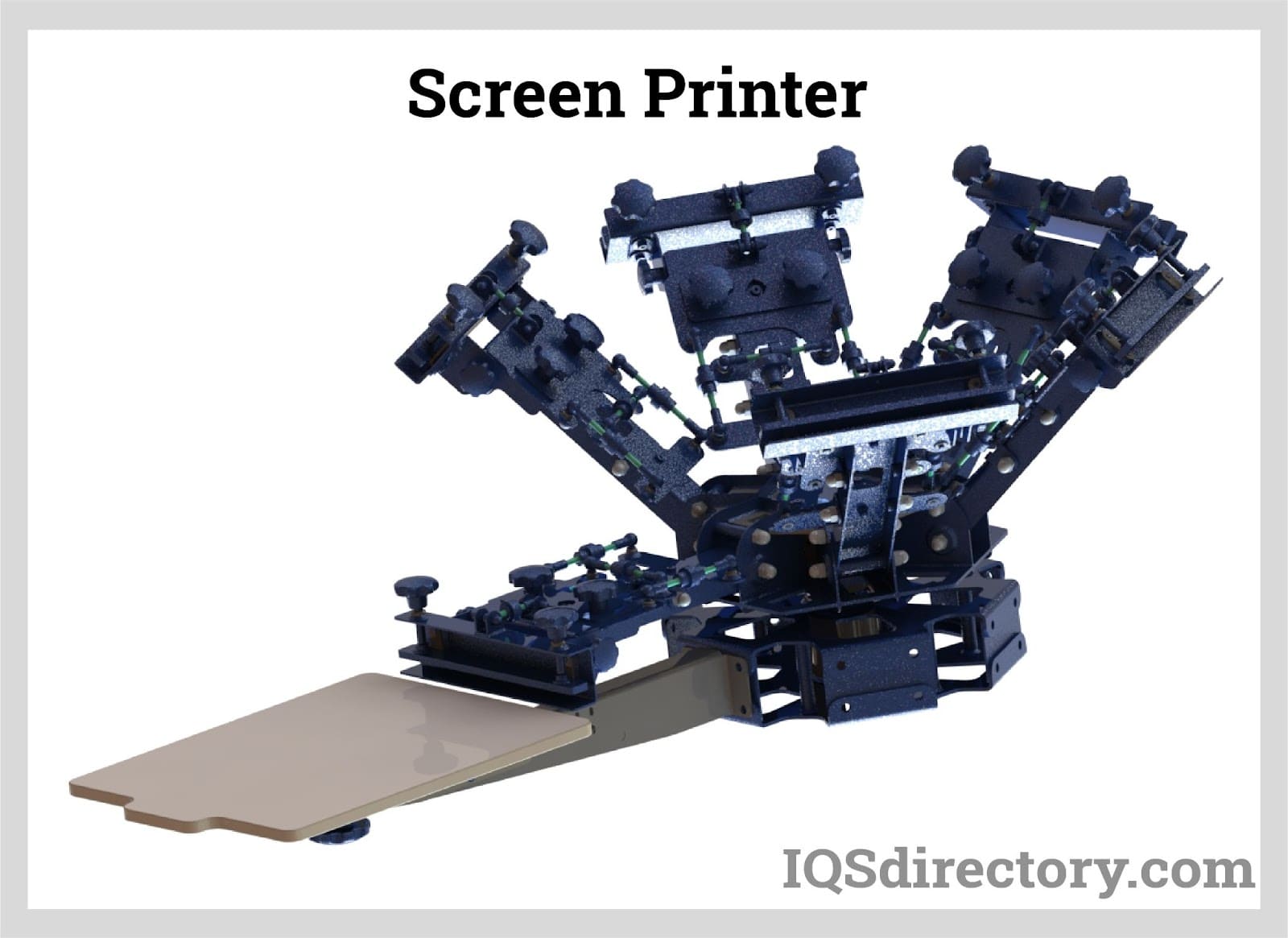

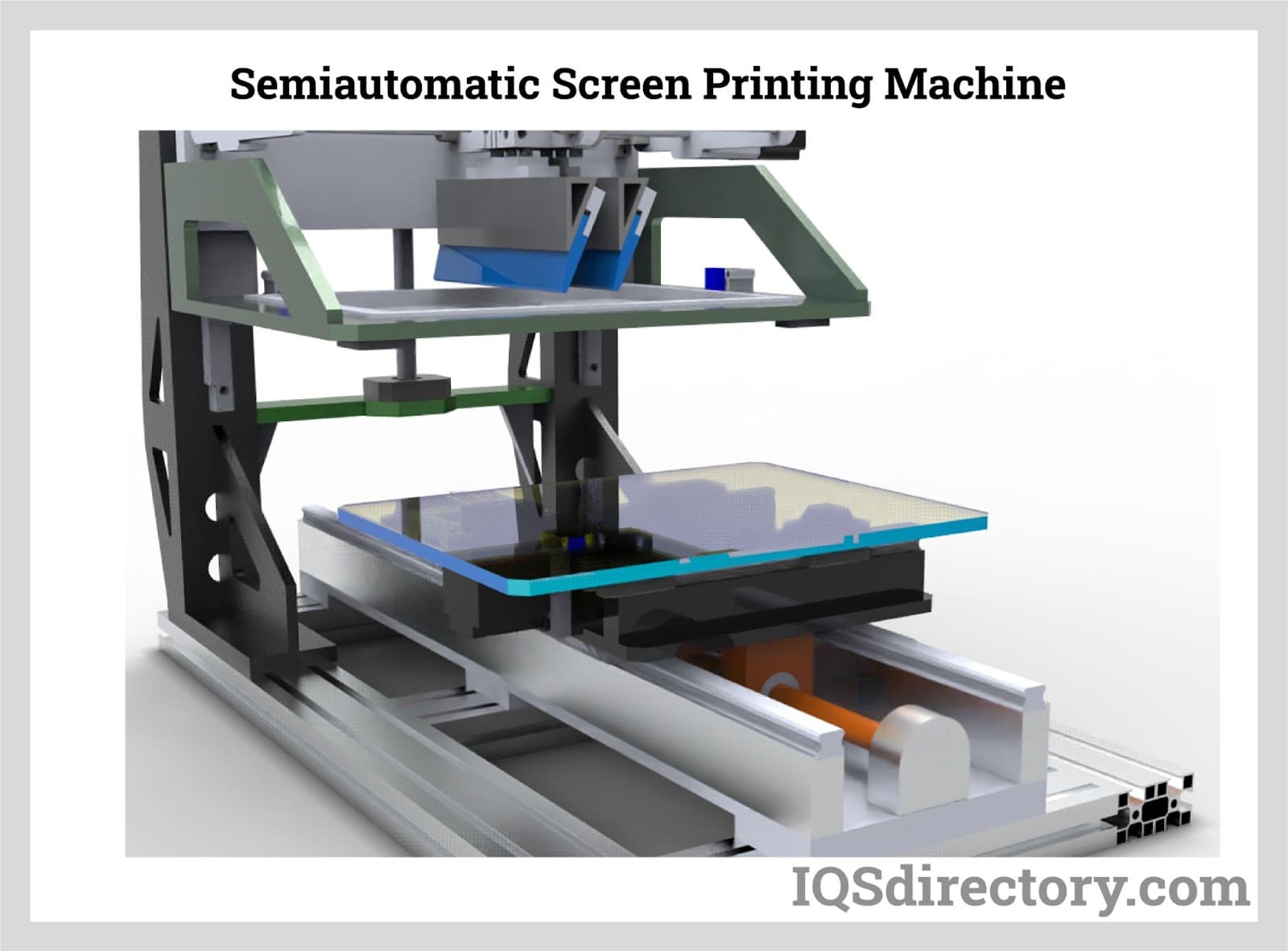

The Press – Screen printing involves using three types of presses: manual, semi-automatic, and automatic. The difference between the three methods is the operator's involvement, with manual requiring the operator to do all of the steps of the process while automatic screen printers operate without assistance.

- Squeegee – In all screen printing processes, the squeegee is used to evenly distribute the ink across the surface of the screen fabric. With manual screen printing, the process is done by hand. Automated screen printing has the squeegee built into the machine.

Ink – The type of ink used to screen print clothing labels depends on the type of fabric upon which they are printed. Screen printing inks have strong pigments to create bright and eye-catching colors. Most commercial garment manufacturers have proprietary ink for their products.

- Woven Clothing Labels

- Woven clothing labels are the traditional form of clothing label and have been used for many years to identify garments. Any material, thread, or design can be created on a woven label. Although hand-sewn woven labels are available, most are produced using automated looms that can produce thousands of labels. Woven labels are made from polyester, cotton, Tyvek, and leather.

-

- Design – Woven labels are created using computer software capable of depicting the thread pattern, such as damask, satin, taffeta, edge, and patches. Some patterns must be produced using special looms.

- Weaving Looms – The process for manufacturing woven labels includes large weaving looms with multiple spools of thread fed into them. Unlike hand looms, automated looms have computer interfaces that allow operators to download the image, set the number of threads, and other factors to ensure the quality of the clothing label. The computer image is programmed into the looms to be recreated on the label material.

- Woven label looms' thread, called the warp and weft, recreates the image of a label. The process includes weaving the labels in strips and cutting them with a laser or cutter. Once the label is cut, the ends of the label are sealed to prevent fraying.

-

Types of Labels

Many labels represent a particular commercial sewing company. However, regardless of the many types, generic labels classify all types. For example, clothing label types are based on the application of the clothing and how it will be used.

- Brand Label

- The brand label contains the name of the clothing company and its logo. It presents an easily identifiable representation of a company's brand. Well-known brands may have just their logo established by customer loyalty.

- "Made In" Label

- The "made in" label has become a popular identifier since it tells customers where a garment has been manufactured and whether a company uses an offshore manufacturing source.

-

- Size Label

- Size labels are necessary for clothing labels regardless of where a garment is made or whether it has a branding label. Additionally, size labels can be complicated regarding the gender for which the clothing was made, the age of the users, and the type of clothing.

- Flag Labels

- Flag labels are sewn into a seam of a garment with extra information. They may describe how to wash a piece of clothing, how to care for it, or other special details. They are called flag labels since they extend out from the seam like a flag.

- Care Label

- A care label, which can be a flag label, offers instructions regarding the washing, bleaching, drying, laundering, and ironing of a garment. They are placed on various fabric types and tend to be long-lasting.

- Pricing Label

- Pricing labels are not traditionally permanently attached to a piece of clothing since they may need to be changed depending on where a garment is sold. They are easily accessible from an external part of the clothing. In the modern era, pricing labels have a barcode with a branding logo and company information.

- Composition Label

- Composition labels outline the types of fabrics or threads that have been used to produce a piece of clothing. The information is normally presented in percentages, with the highest percentage first.