Ball Screws Industry Information

Ball Screws

A ball screw is composed of two components: a screw shaft which serves as the screw assembly and a ball nut containing ball bearings which acts as the nut. In a traditional ball screw, the screw shaft is threaded, while the closely related thread less ball screw uses a smooth shaft with a carefully configured ball nut to determine the properties of the rotational and linear motion.

A ball screw is one of several types of mechanical linear actuator, designed to convert rotation to linear motion with as little friction as possible.

Quick links to Ball Screw Information

History of Ball Screws

The ball screw exists as a natural innovation over a conventional lead screw with a threaded shaft and nut. At some point late in the 19th century, someone realized they could integrate ball bearings into the nut to reduce friction, improve efficiency, and eliminate backlash.

Despite this relatively early invention, the inconsistency of ball bearing fabrication at the time rendered the ball screw little more than a curiosity—only with improvements in ball bearing manufacture in the middle of the 20th century did production of ball nuts and ball screws become commercially viable and reliable.

Threadless ball screws designs were developed around the same time, but have seen limited usage outside of certain applications over their history.

Applications of Ball Screws

What a ball screw of any type does is fairly simple: it converts radial torque, or rotary motion, into linear motion or thrust. The end is rotated and the shaft moves in a straight line according to the threading and/or ball nut.

A ball screw is simply described as a lead screw with ball bearings in the nut for increased efficiency and reduced friction, which creates a unique application profile where it costs more to produce than a comparable lead screw but lasts longer with less attention.

Many industries have used ball screws over the years since they became commercially viable; a huge number of manufacturing and mechanical industries need to convert radial motion to linear motion at some point, which necessitates either a ball screw or one of the cheaper alternatives. Applications range from the simple screw jack to high precision screw and nut assemblies in cutting age aeronautics.

The Design of a Ball Screw

As ball screws are intended in most cases to be highly precise and highly efficient, it's important that you have them designed and engineered to precise standards. A failure to account for key aspects of design and application will waste the comparatively expensive investment you're making in using ball screws over alternative components.

There are two notable methods of producing ball screw shafts for threaded ball screws, which produce roll ball and ground ball screws.

Rolled bar screws are threaded by pushing the uncut bar stock through a rotating machine tool die in a single operation, deforming the blank to create threads without removing material.

Ground ball screws use a slower process by which threads are cut via an abrasion process a few threads at a time. The nature of the process means the blanks need to be cut to length beforehand.

Roll thread screw systems usually cost less than comparable ground ball screws, while meeting many of the same standards, and thus are usually the better choice. Rolled ball screws end up stronger, but can also end up with rougher surfaces and significantly lower precision than a comparable ground ball screw. Make sure to discuss your needs with your manufacturer and your engineers before committing to rolled ball screws as a cost-saving measure.

Load and preload concerns will also be a factor in many ball screw designs. Some applications demand strict amounts of preload for proper operation, while others may require little preload. Still more may require variable preload, which will require an adjustable system to control load on a case by case basis.

You may also consider materials. Ball screws can be made in stainless steel and various other common machining materials. Depending on load, temperatures, corrosives, and similar factors, different materials will make more sense.

Characteristics and Features of Ball Screws

Ball screws stand out from comparable technologies due to their exceptionally high efficiency; a well-made precision Acme lead screw will achieve an efficiency of 20-40% at best in most cases, while a ball screw in the same application and diameter will achieve efficiencies of 90% or higher. This makes ball screws longer-lasting, lower-maintenance, and more efficient. They're also generally better at handling high load or consistent load, due to the reduction of friction on the shaft.

Ball Screws Images, Diagrams and Visual Concepts

Ball screws, mechanical linear actuators that consist of a screw shaft and a nut that contains ball bearings that rolls between their matching helical grooves.

The main components of ball screws are the screw shaft, the nut, and the ball bearings.

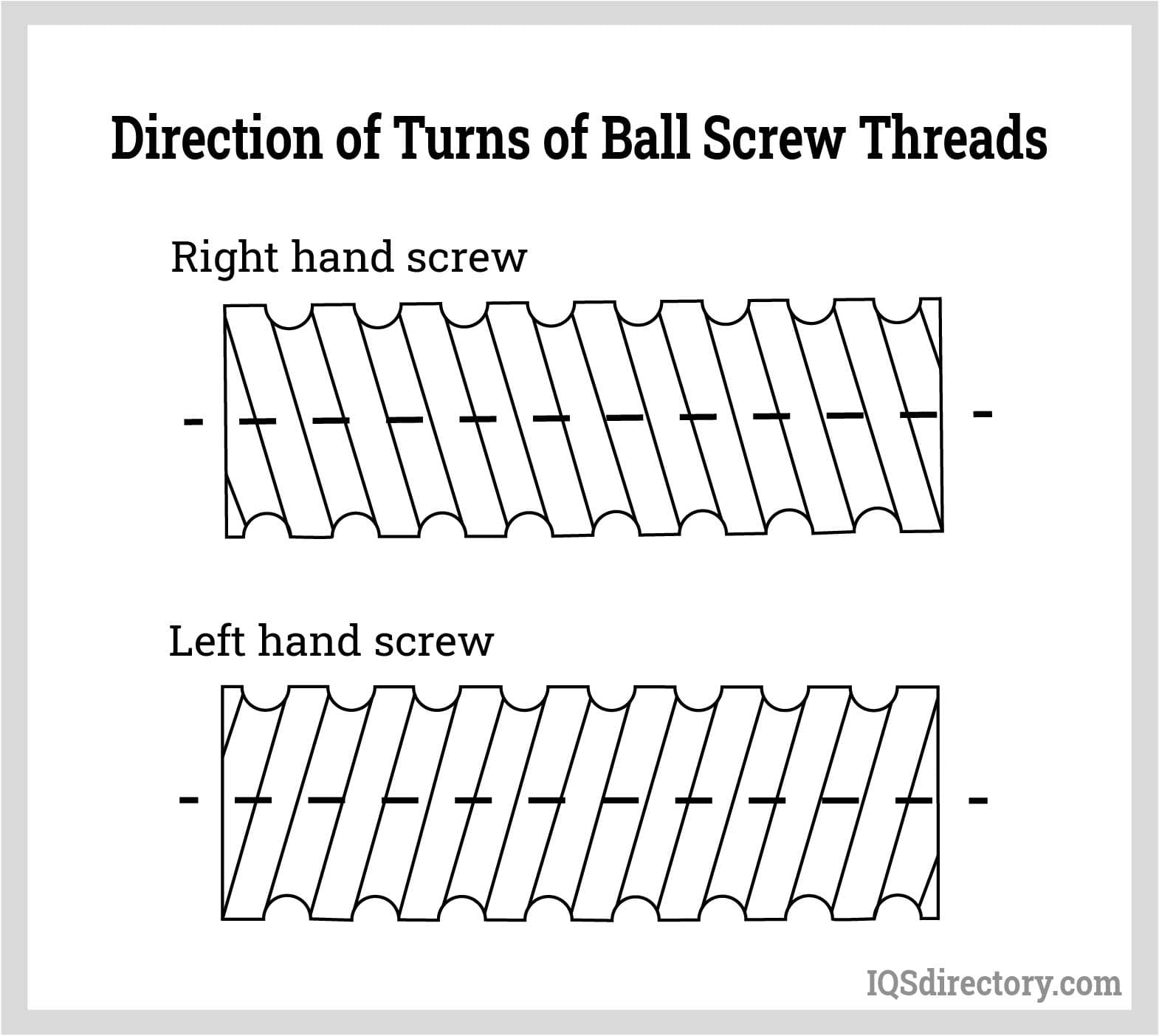

A right-hand ball screw if the groove is in a clockwise direction around the screw shaft and slants right, while a left-hand ball screw if the groove runs counterclockwise and it slants left.

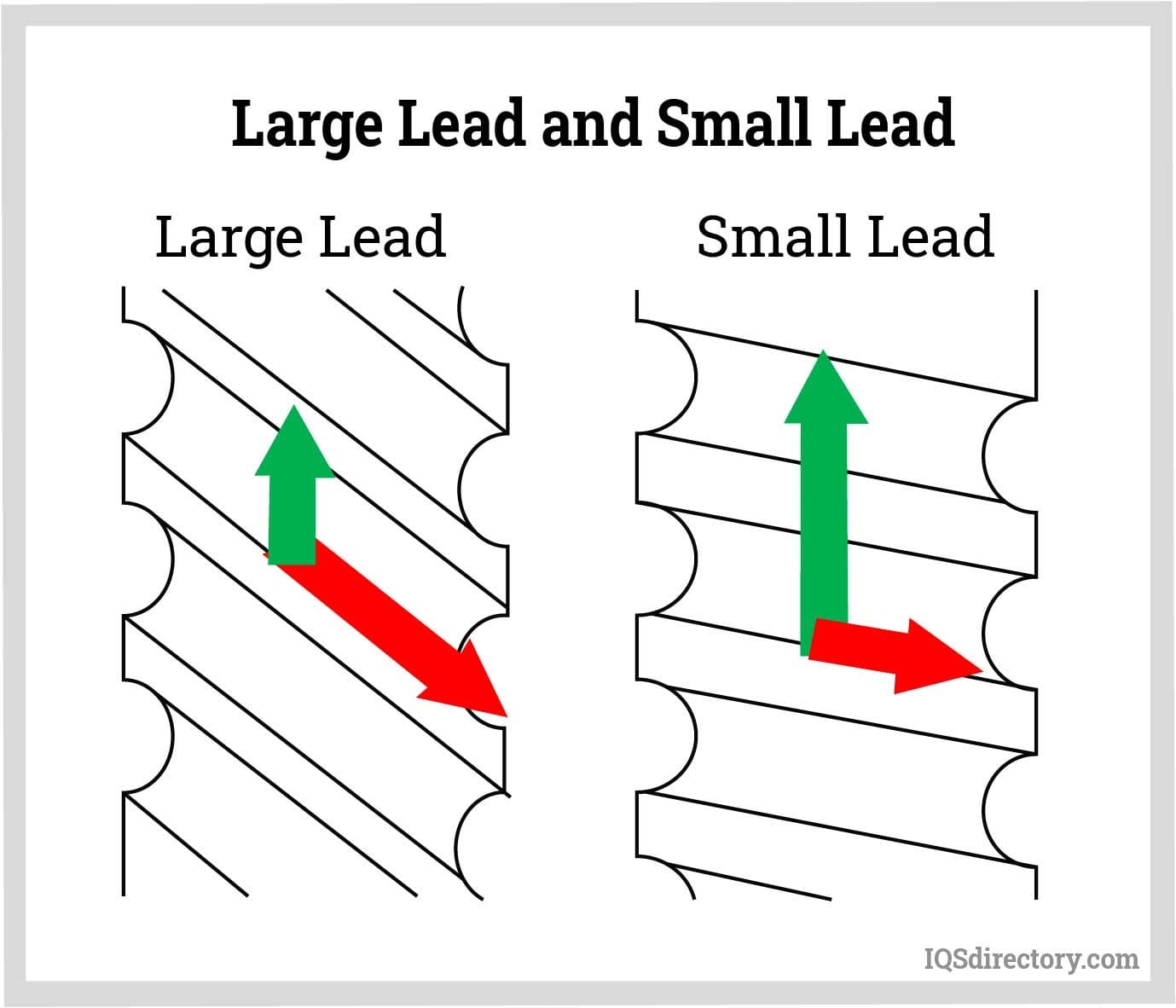

Lead is the linear distance along the axis of the screw which determines linear travel and speed and load capacity.

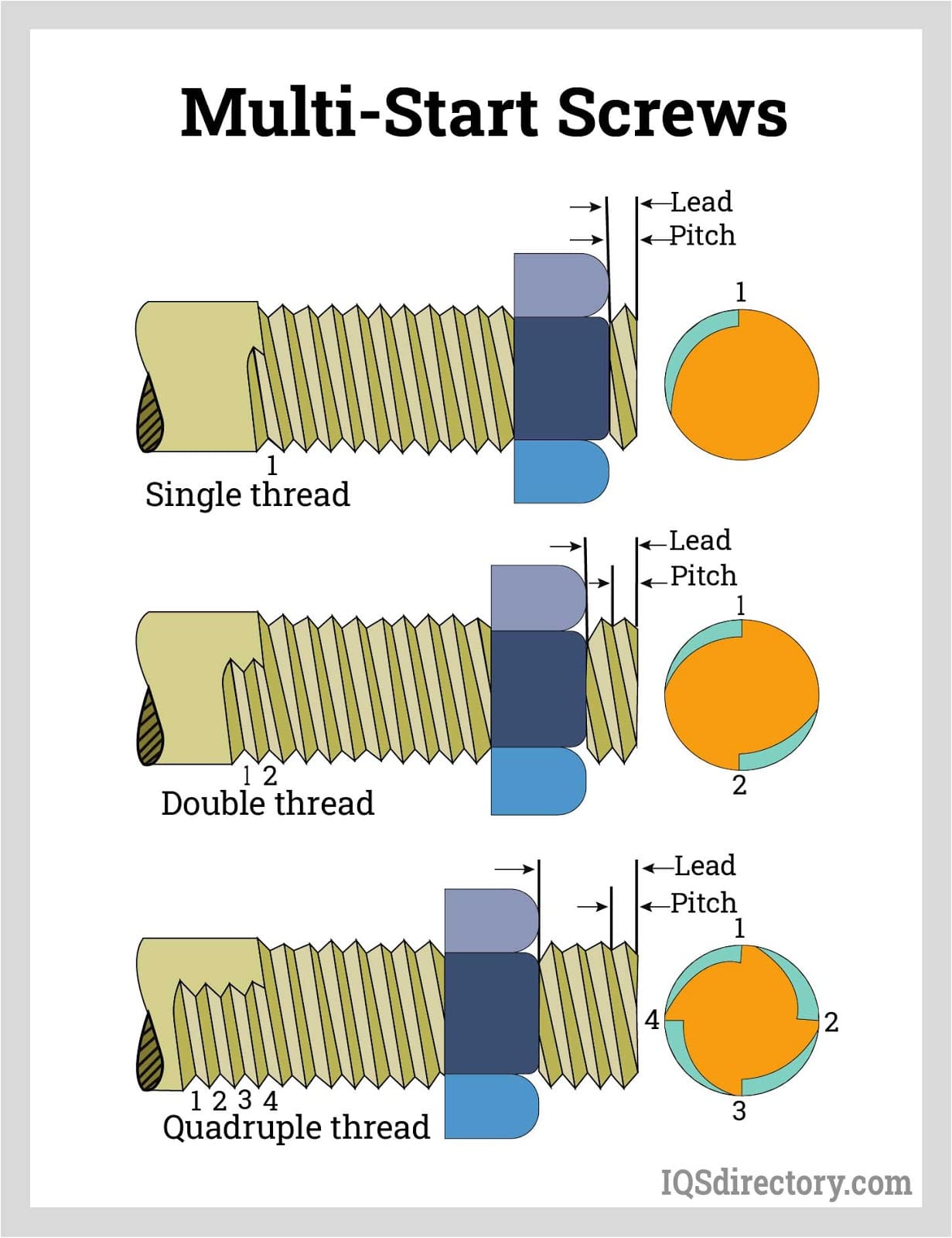

The start, the number of independent helices that runs around the screw shaft, multiple starts uses a lesser number of rotations and a high load capacity.

Ball Screws Types

Acme Screws

Lead screws that create a sliding friction between screw and nut. Acme screws are often as much as 30% less efficient than ball screws but are often cost effective. Acme screws are utilized in applications requiring high levels of accuracy at low speeds.

Acme Threaded Rods

Products used primarily as lead screws in a variety of machines and devices. These rods are designed and manufactured with a thread angle of 29 degrees and with a thread height equal to half the pitch.

Ball Screw Assemblies

The combination of a threaded screw and an internally threaded nut; they are filled with ball bearings that travel in matching helical grooves.

Ball Screw Nuts

Important components of a device that converts rotational motion into linear motion. The nut contains ball bearings that run in the helical grooves of the screw shaft that the nut is paired with. Ball screw nuts change torque into thrust without rotating themselves.

Custom Ball Screws

Made to certain specifications that are non-standardized.

Ground Ball Screws

Produced using a grinding wheel instead of the conventional rolling technique. Ground ball screws offer close tolerances, but may be expensive to produce.

Lead Screws

Consist of a threaded shaft and nut and create friction through sliding rather than through the rolling friction characteristic of ball screws. The efficiency of lead screws increases with increased lead. Lead screws are advantageous in managing high shock loads.

Linear Ball Screws

Convert rotational motion, or torque, into linear motion called thrust.

Metric Ball Screws

Designed according to metric system measurements as opposed to the American system of measurements.

Miniature Ball Screws

Consist of ball screws measuring as little as three millimeters in diameter, are used in industrial applications in the computer, electronic, fiber optics, and semiconductor industries. Miniature ball screws maintain high efficiency levels in spite of their size.

Precision Ball Screws

Perform critical functions in the manufacturing industry because of the level of control they allow operators to exert while transporting heavy loads.

Rolled Ball Screws

Assemblies made up of a threaded screw, threaded nut and ball bearings that are manufactured through the process of cold rolling metal.

Screw Jacks

Used in lifting jacks.

Threaded and Thread Less Ball Screw Differences

There are quite a few types of ball screw to consider, given the wide range of applications, levels of precision, and other factors to account for. An exhaustive list of ball screw types would thus be unfeasible. However, we can look at the strengths of the two most significant variations: threaded ball screws and thread less ball screws.

Threaded Ball Screws

When discussing ball screws, you're almost always discussing threaded ball screws. These are essentially lead screws with ball bearings built into the nut, and operate as you might expect. As such, you can use them in many of the same places you might use a lead screw. Which best serves your needs will depend on factors such as wear and tear, ease of access for maintenance, the expected loads, etc.

Thread Less Ball Screws

Thread less ball screws see far less use, despite being nearly as old as threaded ball screw designs. Instead of using threads on the shaft to guide the ball nut and control the rate of linear motion and rotational motion, a threadless ball screw uses carefully configured ball bearing assemblies to rotate the assembly along a smooth shaft. This requires increased precision in the manufacture and creates the potential for slips under excessive loads, but alleviates other problems such as backlash completely. This makes them ideal when loads are on the lower side—and more importantly, consistent and predictable. Unexpected high load can cause slips and create huge headaches.

More advanced thread less ball screw assemblies can be adjusted on the fly for dynamic adjustment of the linear motion, but these are exceedingly rare at the moment.

Ball Screws Versus Lead Screws

Relative to alternative precision screw assemblies, a ball screw is exceptionally efficient and requires a comparatively low amount of maintenance, lubrication, and parts replacement. In many applications, this greatly outpaces the initial high cost of ball screws relative to a similar solution such as an Acme lead screw.

Pros of Ball Screws

- Ball screws are significantly more efficient than lead screws, requiring less torque.

- Run at lower temperatures and add less friction to the system.

- If properly lubricated, ball screws last far longer in most applications than lead screws.

- Can cost less than lead screws over time given reduced maintenance/wear-and-tear.

- Work well in high-speed and high-throughput applications where lead screws may overheat.

Ball Screw Cons

- More expensive on the front end than a comparable lead screw in the same diameter.

- Weak in vertical load applications when compared to lead screws.

- Can create additional noise when compared to lead screws.

- Ball screws require braking systems, while lead screws are self-locking.

Ultimately, neither technology maintains a clear lead overall in all applications. You're best served looking at your needs and making the decision on which to utilize from there. The benefits of ball screws do not always warrant the increased cost, even in applications where they work better than a lead screw; similarly, a lead screw in some cases simply cannot keep up with the throughput of operations, creating a serious bottleneck in your operations.

Generally speaking, lead screws are used in smaller applications or where the screw is more accessible for replacement. Ball screws work best for applications which require a lot of load or a long lifespan for any number of reasons.

Ball Screw Standards and Specifications

There are several common standards governing the accuracy, load tolerances, and general dimensions of standardized ball screws. Notable standards include various ISO standards beginning with ISO 3408, DIN Standard 69051, and JIS B 1192-1997.

The exact standards and compliance issues facing a company utilizing ball screws will depend on the machinery, industry, and environment in which the ball screw is being used; there's no meaningful rule set which applies to all devices utilizing ball screws, so careful research is advised.

Things to Consider When Purchasing Ball Screws

Of course, there are countless other factors to take into account when utilizing ball screws for a project. Only by assessing your initial investment. As we mentioned earlier, ball screws typically cost far more on initial purchase than alternatives at any given diameter.

Best Suited for Application

Ball screws are used in a variety of roles where you need to convert radial torque into linear thrust. Frequently interchangeable with Acme lead screws, you'll want to use one of the many variations of ball screw in areas where the improved efficiency and lowered friction will allow you to recoup the initial high expense of the component.

Environmental Stressors For Ball Screws

In many work environments, you'll need to factor in temperatures, corrosion, load, and other environmental stressors into your assessment of ball screws for your project. You may need to invest more into specialty manufacture, or opt for simpler alternatives due to a high rate of wear-and-tear or exceptionally high load.

Upkeep Cost

The upkeep costs of ball screws are comparatively low in most cases due to high efficiency, but some unique environments may greatly increase the rate at which you go through components. In these cases, the upkeep costs of ball screws can rapidly grow out of control.

Choosing the Right Manufacturer

There are two factors to look at when choosing a manufacturer for ball screws and similar components: whether the manufacturer is a good manufacturer in a general sense, and whether a manufacturer is the right manufacturer for your particular needs. Combine the two, and you'll have the perfect fit for all of your needs.

Manufacturer’s Character

Transparent

Pricing should be clear in any business relationship; you should know what you're paying for, exactly, and what you're getting, exactly.

Professional

Whether it's ball screws or anything else, you don't want to work with a manufacturer you can't trust to keep their word, keep their schedule, and Experienced.

Experienced

Ball screws are usually used in precision ball applications, and excel in large part due to high efficiency. That means you need them to be made right to reap the benefits.

Manufacturer’s Expertise

Familiar With Your Application

Working with a manufacturer that knows your specific application will save you a lot of headache. At the very least, one familiar with similar or related applications or standards will help.

Easy to Communicate With

You want to work with a manufacturer you can communicate with easily and clearly, to avoid mistakes and missteps throughout your relationship.

Can Match Your Logistical Needs

The best manufacturer in the world isn't useful if they can't ship your ball screws when you need them as you need them. Discuss scheduling, production, ball screw repair, and shipping—and keep an eye on future needs as much as current ones.

Repeat Purchases

When you're buying ball screws or sourcing screw repair, it's important to take into consideration the capacity, volume, and reliability of your source. Can you count on being able to procure necessary ball screws from a given manufacturer in the future? If so, will you get better deals, worse deals, or the same deal every time?

You can return to the top of this page in order to find a convenient list of ball screw manufacturers.

Proper Care for Ball Screws

The high efficiency and low friction of ball screws lead to a relatively low amount of maintenance, but proper care still extends the lifetime and efficiency of the component. A ball screw which isn't kept clean and lubricated according to its needs can lose as much of its efficiency—eliminating much of the advantage you've paid for in choosing a ball screw over a traditional lead screw.

Lubricants should be determined by the machine manufacturer or your ball screw manufacturer, depending on the particulars of your applications. Once you've determined what you need, you can connect with a manufacturer listed on IQS Directory who has it. Hand-testing your ball nut for clean, easy rotation can also help minimize mistakes and failures in alignment. Misalignment under torque can severely damage your ball screw. It's also worthwhile to consider preload in ball screw systems.

For this same reason, you'll want to keep your ball screw assembly in its factory sealing until you're ready to install it, to minimize the presence of dust and other debris on the unit beforehand. Ball screws stored for lengthy amounts of time should be rotated every few months to keep oil distributed across the surface.

Accessories for Screws

There are a variety of support bearings and similar components which work with your ball screw. If you're using standard designs for your ball screws, you'll be able to use standardized support bearings. These and other accessories can minimize the need for customization in your designs, simplify ordering and assembly, minimize various inherent risks, address specific challenges, or reduce maintenance. Make sure to discuss potential accessories for your application with your manufacturer.

Ball Screws Terms

Backdrive

The conversion of thrust motion back to torque motion. Backdrive can be reduced through a self-locking mechanism.

Backlash

The movement of a screw and nut from its initial position. Unlike creep, backlash is not caused by vibration or heavy loads.

Creep

The movement of a screw and nut from its initial position due to vibration, shock, or intense loads.

Column Strength

When a screw is loaded in compression its limit of flexible stability can be exceeded but may end in failing due to future buckling or bending.

Critical Speed

Revolving screw shafts will develop normal frequencies of vibration depending upon their length, size and end shape. The speed at which this vibration occurs is predictable and is called the critical speed.

Efficiency

A measurement, expressed as a percentage, representing the comparison of power output to power input of a screw assembly.

End Fixity

This refers to the method by which the ends of the screw are supported. There are three basic types of end fixity as follows; free, simple and fixed.

Freewheeling

A condition that occurs in ball screw assemblies involving continued screw rotation, but no linear movement.

Friction

A screw’s and nut’s resistance to movement. Different types of friction exist, including sliding friction that is characteristic of Acme screws and lead screws, and rolling friction characteristic that is of ball screws.

Lead

The measurement of a nut’s movement across the screw, measured in inches per revolution (in/rev).

Pitch

The axial measurement between threads. Pitch also refers to the number of full rotations a screw makes in order to produce one inch of movement of the nut along the screw.

Root Diameter

This is reference to the minor diameter of a screw thread or the major diameter of a nut thread.

RPM (Revolutions Per Minute)

The rotary speed of a ball screw, represented by the number of full rotations of a screw occurring in one minute.

Screw Starts

Referring to the number of independent threads found on a screw shaft, usually found in configurations of either 1, 2, or 4.

Self-Locking

A characteristic of Acme screw and other types of screws in which back drive is prevented by the disallowance of thrust to torque conversion.

Shaft

The portion of the screw that contains the threads.

Speed

The measurement of the pace of linear movement in ball screw assemblies, expressed in inches per minute. Speed is calculated through the multiplication of screw lead by RPM, or revolutions per minute.

Stroke

The measurement, expressed in inches, of a ball screw system’s linear motion or thrust.

Thread

The raised helical rib going around the shaft of a common screw.

Thrust

Linear movement achieved by the torque produced from ball screw assemblies.

Torque

Rotational motion of a ball screw system that translates into linear movement, known as thrust.

More Ball Screws Information

Ball Screw Informational Video