Portable Offices

A portable office is a mobile workspace that can be easily assembled and placed to provide a quiet and convenient location for meetings, completing paperwork, or examining plans. They are built using...

Please fill out the following form to submit a Request for Quote to any of the following companies listed on

This article takes an in-depth look at modular buildings.

Read further and learn more about:

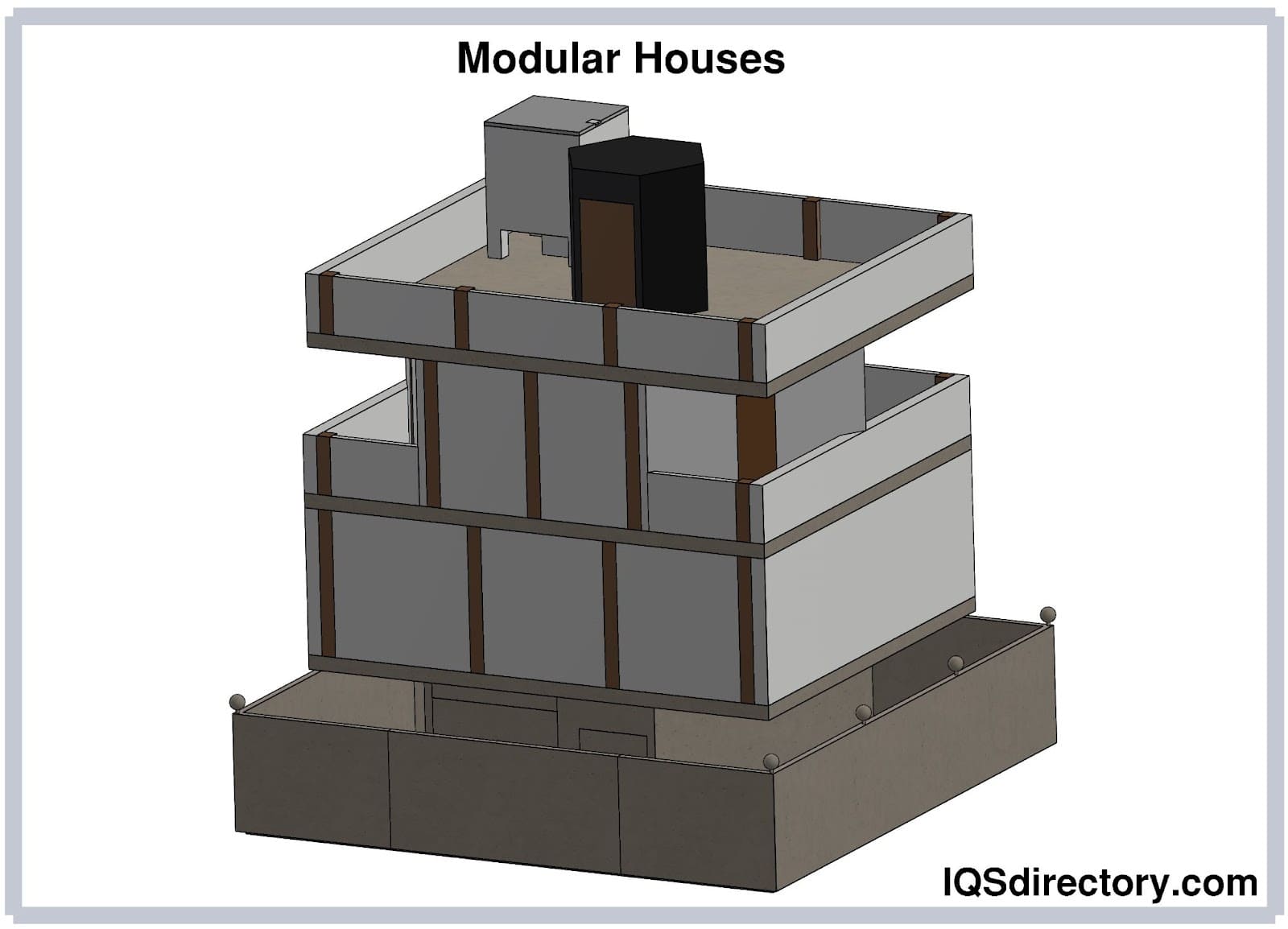

Modular buildings are created from standardized parts called "modules," which are produced in a controlled factory environment rather than on the construction site. These factory-produced modules typically incorporate components like walls, doors, ceilings, frames, and windows. They use the same materials and adhere to the same building codes and regulations as conventional buildings. Upon completion, these modular sections are transported to the construction location and assembled in line with the specific design and plan requirements.

The modular construction approach is recognized for its quick building process, often allowing projects to be finished in half the time required by traditional construction methods, ultimately saving valuable time. Despite the expedited construction timeline, modular buildings are designed to be structurally sound. Manufacturers with specialization in modular buildings, whether intended to be permanent or relocatable, provide extensive knowledge to fulfill specific client demands. Their sophisticated manufacturing processes and strict quality controls ensure these buildings meet and frequently surpass industry benchmarks.

Modular construction companies are typically categorized into two main segments based on their specialization and construction process: permanent modular constructions (PMC) and temporary modular constructions (TMC). Each building system is uniquely designed to address specific architectural, logistical, and operational requirements, further driving the popularity of modular solutions in the modern construction industry. By leveraging offsite fabrication and precision engineering, modular building systems can significantly reduce onsite labor and construction timelines compared to traditional site-built methods while enhancing cost efficiency and quality control.

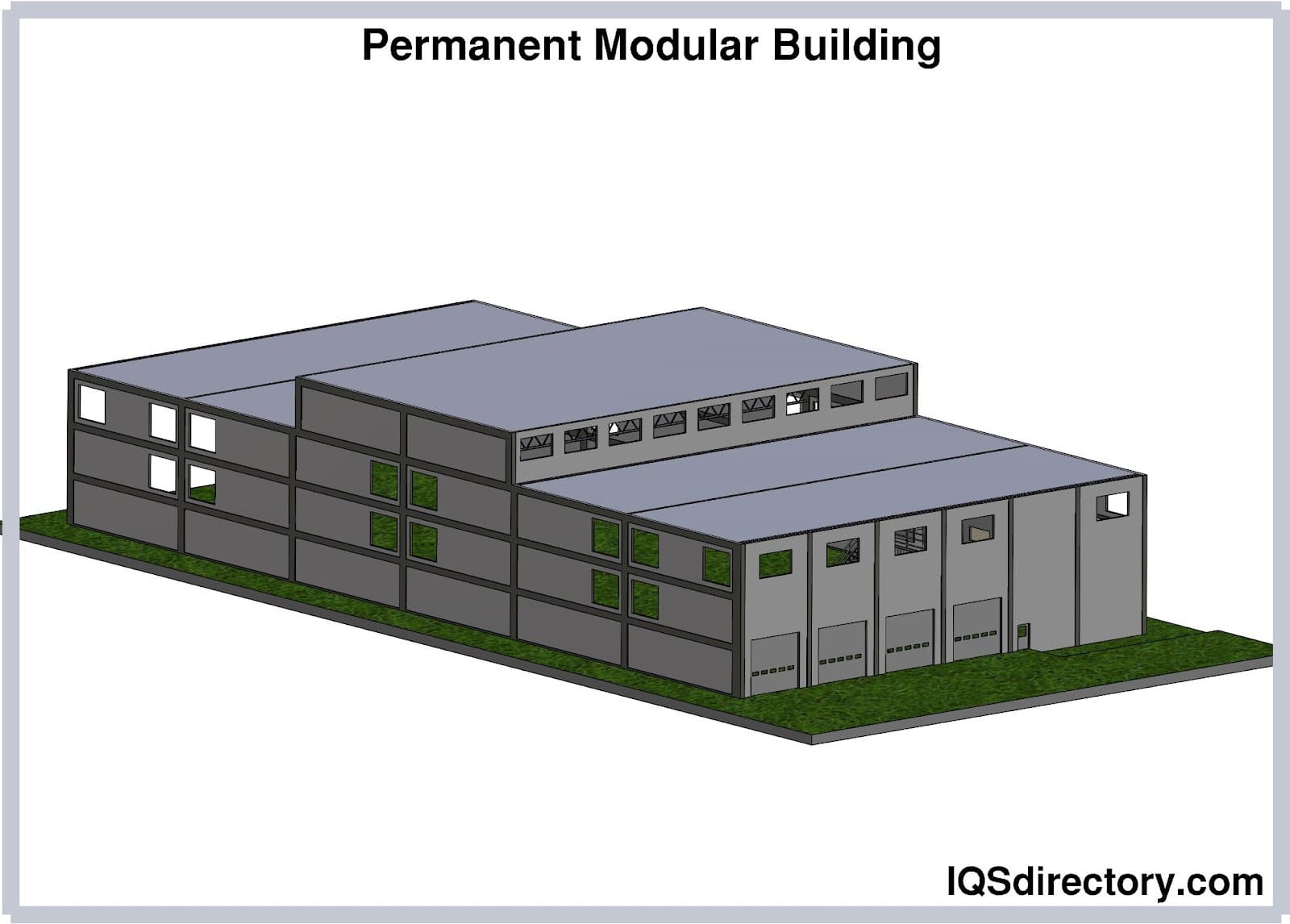

Permanent modular construction (PMC) involves building facilities intended for long-term use and occupancy at their assembled location. Utilizing advanced offsite manufacturing techniques and modular construction technology, building sections are prefabricated in a controlled factory environment to maintain consistent quality and structural integrity. Unlike conventional site-built real estate properties, PMC modular buildings are designed to remain in place and are not meant for relocation, offering lasting value and superior resilience.

PMC buildings are constructed on permanent concrete foundations and can function as standalone facilities or be seamlessly integrated with existing structures through modular integration. Given their intended permanence, they are made from durable construction materials such as galvanized steel, engineered wood, and reinforced concrete. PMC solutions deliver a high degree of architectural design flexibility and extensive customization options, accommodating elements like lobbies, elevators, stairwells, energy-efficient HVAC systems, and green building features. This approach is ideally suited for multi-story commercial buildings, modular schools, modular healthcare facilities (e.g., hospitals, clinics), modular offices, apartment complexes, and residential spaces. However, the assembly process for PMC buildings can be lengthier compared to temporary solutions, depending on the structure's size, design complexity, and the required building code compliance.

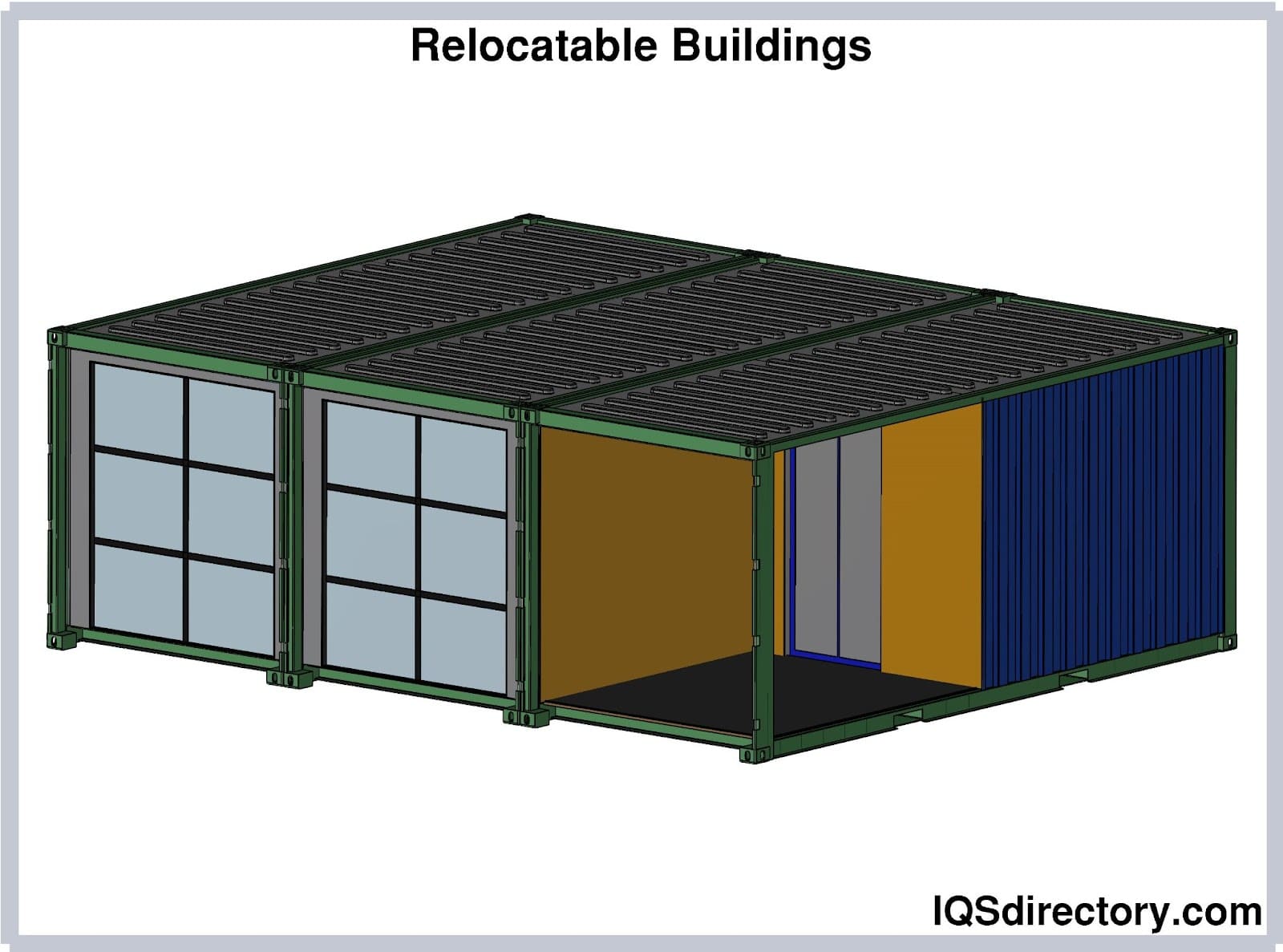

Temporary modular construction (TMC), also known as relocatable buildings or moveable structures, involves creating facilities designed for short-term or changing location use. These modular buildings are engineered for easy disassembly, transportation, and rapid reinstallation across various sites while maintaining compliance with stringent building codes and safety standards. Relocatable buildings share many of the same fabrication techniques as PMC, with each modular component produced in a controlled factory environment to ensure consistent quality and safety.

TMC facilities are highly sought after for applications requiring speed to occupancy, such as disaster relief shelters, temporary clinics, modular classrooms, pop-up retail stores, and emergency commercial spaces. Relocatable modular structures are fabricated from lightweight yet robust materials such as steel frame, wood composites, and high-performance plastics, ensuring durability and resilience for multiple relocations. They are typically available for both lease and outright purchase, offering organizations flexibility and reduced construction costs for temporary space requirements. While design and customization options are more limited compared to permanent modular constructions, modern modular manufacturing still allows for tailored layouts and integration of essential utilities and systems as needed.

The following below are the main types of modular buildings utilized across industries:

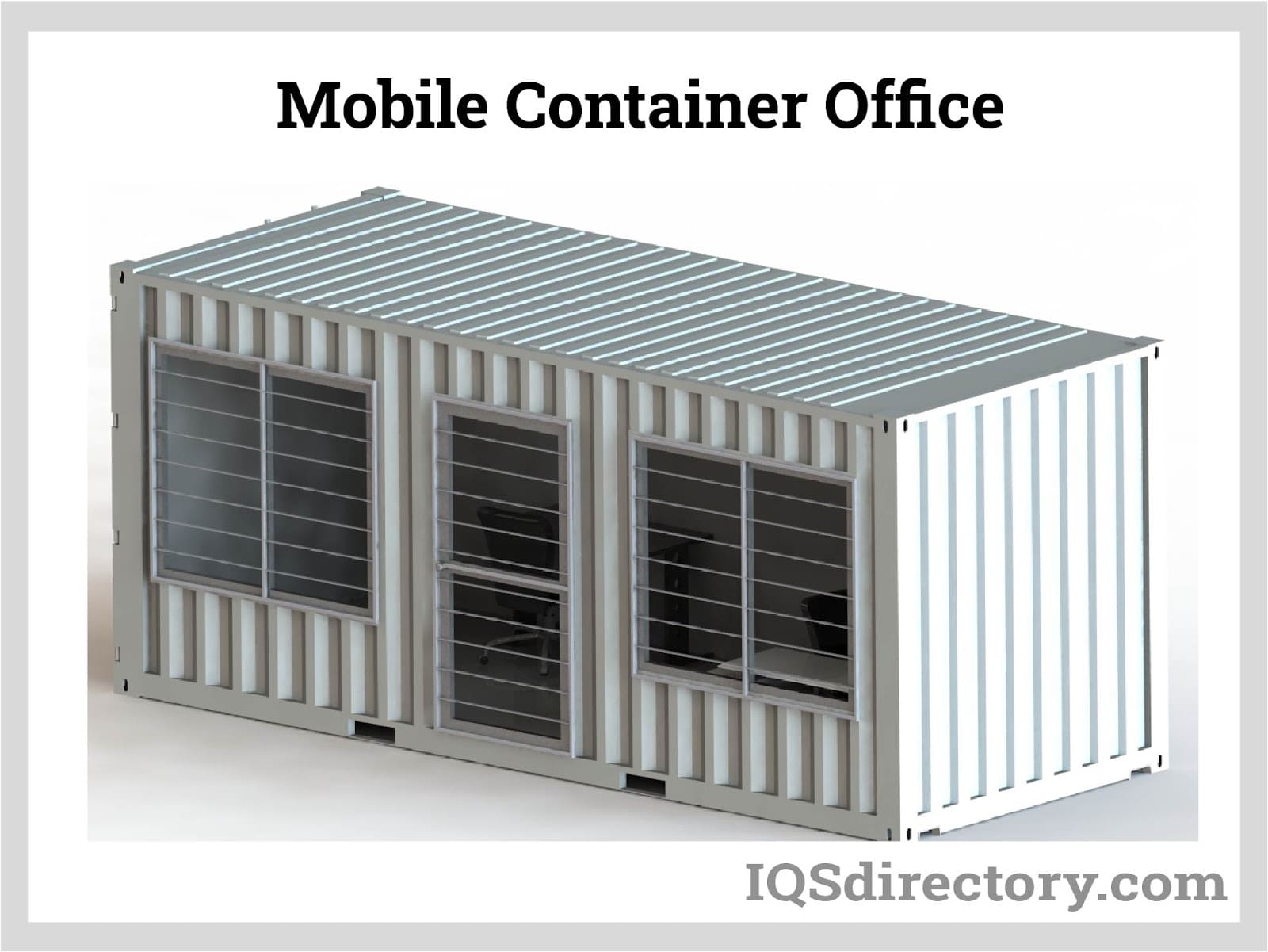

Mobile offices are portable office buildings equipped with mobility features that allow professionals to function as if they are in a traditional office environment, even when on the go or at a job site. Engineered for workspace flexibility, mobile office trailers feature all essential amenities typically found in permanent offices, including modern furniture, electrical infrastructure, lighting, IT connectivity, and climate control. Utilities such as electricity, telecommunications, and internet access are easily set up for temporary office needs.

Mobile offices, which can be quickly transported via trailer trucks or motorhomes, provide adaptable business workspace solutions for companies with dynamic, temporary, or project-based office space requirements. They are a highly economical option, reducing overhead and operating expenses while supporting agile project management. Mobile offices are ideal for use by construction contractors, real estate professionals, event organizers, remote teams, and freelancers who require professional, temporary workspaces that can be relocated across worksites as needed.

Modular offices are versatile, factory-built office facilities designed to provide immediate and scalable space solutions within existing structures such as warehouses, distribution centers, and manufacturing facilities. These modular in-plant offices can be assembled quickly, typically without disrupting ongoing operations, and offer convenient access to plant services and operational oversight—making them ideal for team expansion, project supervision, and quality control tasks. Modular office buildings are highly configurable, allowing organizations to add new rooms, conference spaces, rest areas, or executive suites as their operations grow.

While modular offices are less mobile than mobile offices, their modular panel systems allow for quick installation, future reconfiguration, and relocation if necessary. This flexibility helps companies optimize space utilization and maintain productivity during facility upgrades or transitions. Trusted by industries such as manufacturing, logistics, warehousing, and aerospace, modular offices streamline project workflows and minimize costly downtime associated with traditional construction.

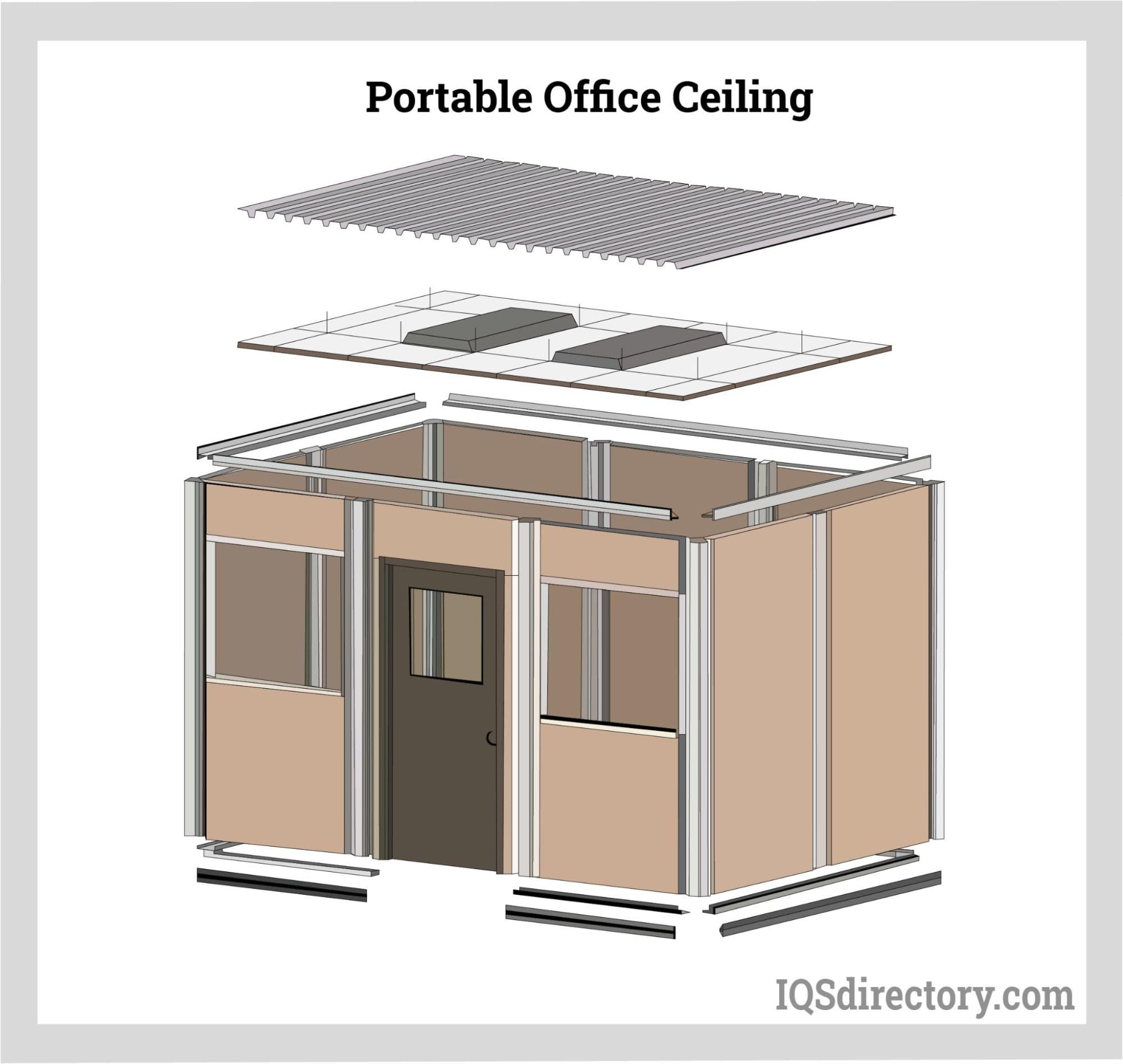

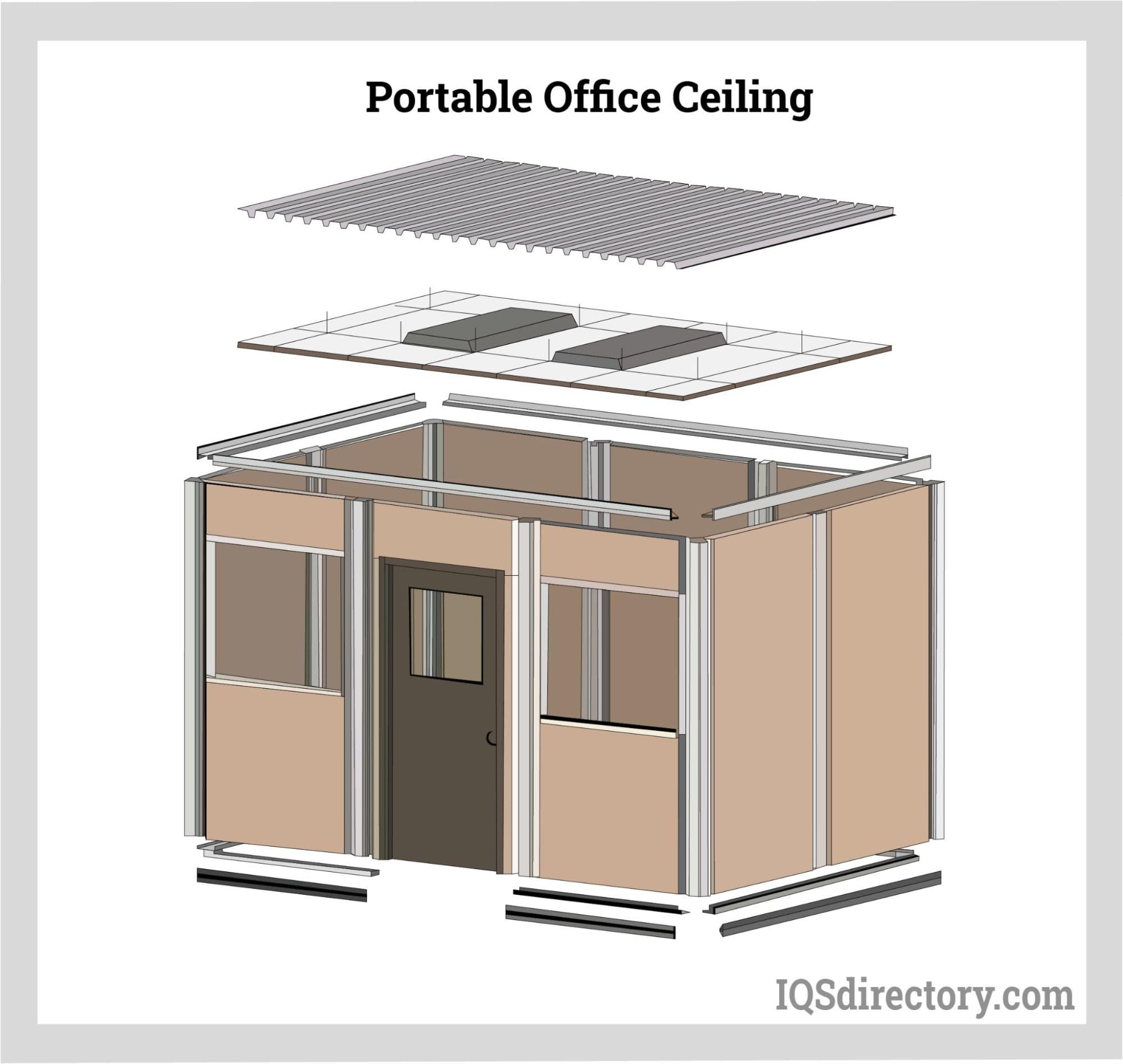

Portable offices are prefabricated office buildings constructed on transportable bases for easy relocation by forklift or truck without the need for major dismantling. These modular office solutions are ideal for accommodating spikes in personnel or space requirements due to seasonal demand, special events, or temporary projects, such as festival booths, mobile classrooms, construction sites, and field offices. They can serve as immediate office space for oil and gas drilling operations, civil engineering projects, and more, providing a comfortable and controlled environment wherever it's required.

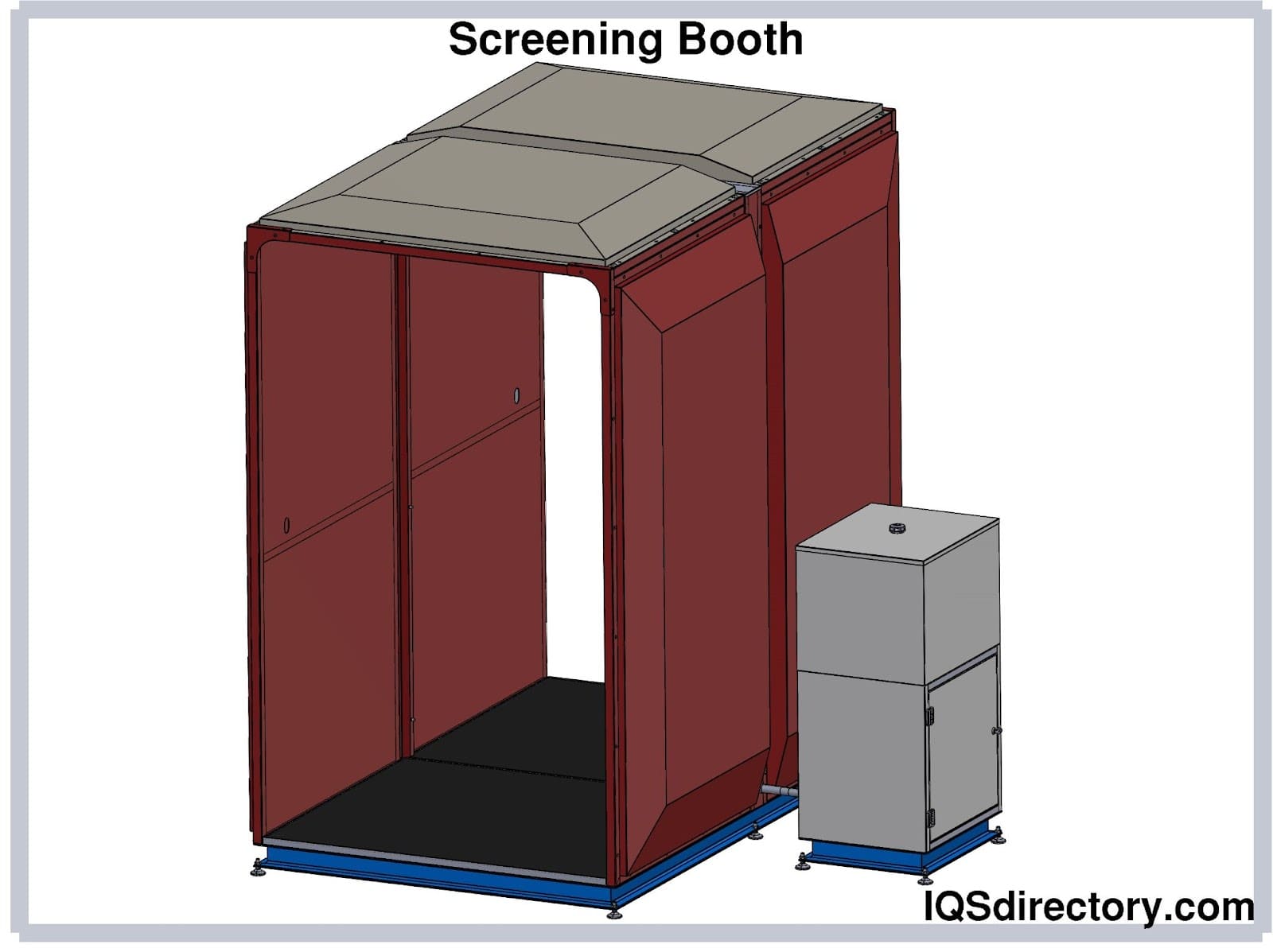

Prefabricated booths are compact, self-contained structures manufactured offsite in a quality-controlled facility and delivered to the installation location for quick assembly. These booths employ modular wall panels, structural frames, and insulated roof systems constructed from welded steel or aluminum. Prefabricated booths support customizable features such as HVAC, electrical systems, plumbing (sinks and water supply), and high-speed internet connectivity, ensuring occupant safety and comfort. Their modular nature also enables rapid installation, scalability, and compliance with local building codes.

Prefabricated booths can be installed either as permanent fixtures or as temporary buildings, depending on user needs and project timelines. A range of booth types are available to match diverse commercial, industrial, and institutional applications:

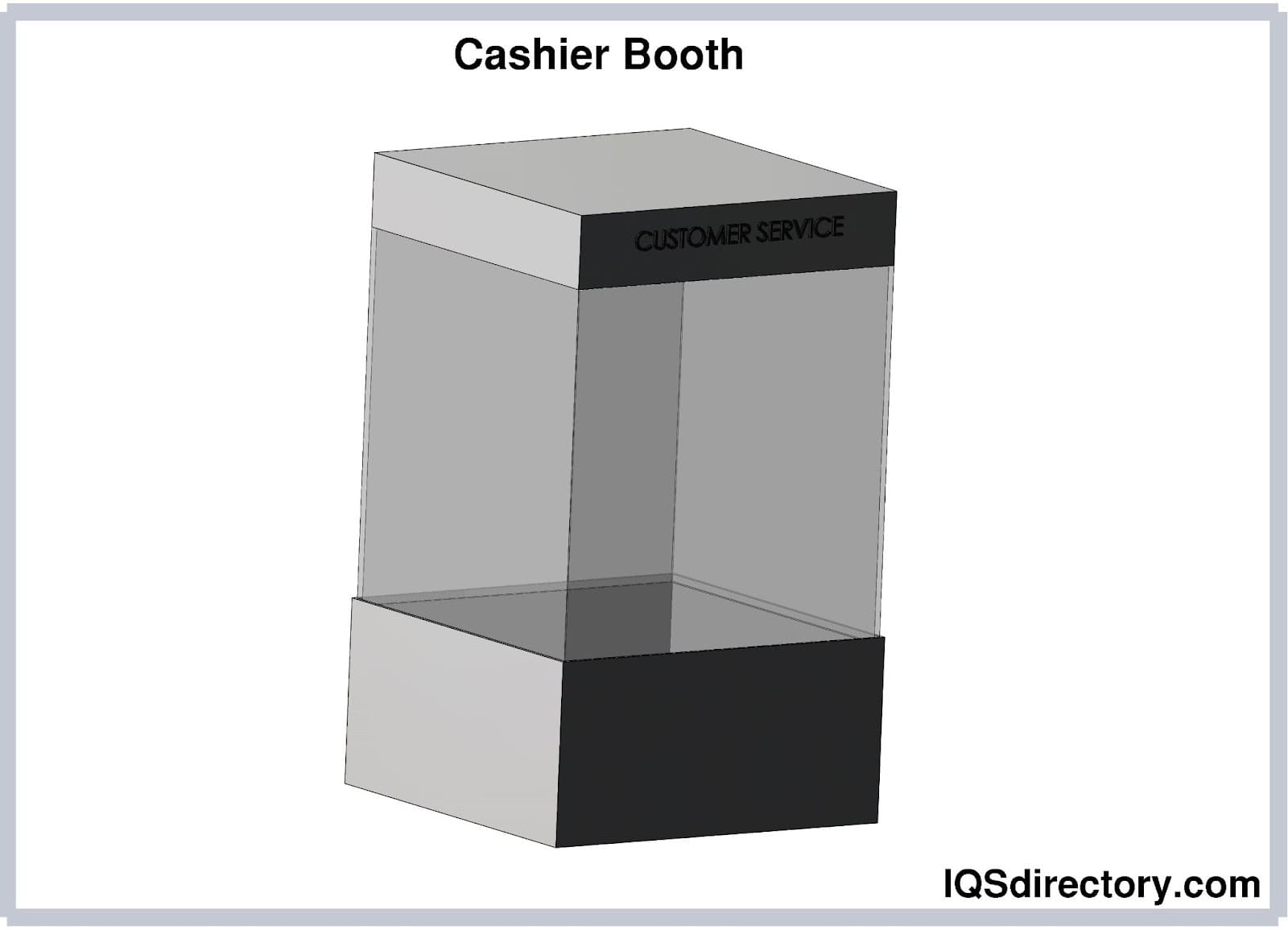

Cashier booths are secure, prefabricated modular units found in commercial settings such as movie theaters, stadiums, amusement parks, gas stations, restaurant drive-thrus, and resorts. Designed for efficient and protected cash transactions, these booths typically incorporate sliding or pass-through transaction windows, bulletproof glass, and reinforced doors. Enhanced with anti-theft and security features, cashier booths are engineered to safeguard assets and personnel in high-traffic environments, streamlining transaction management and customer service.

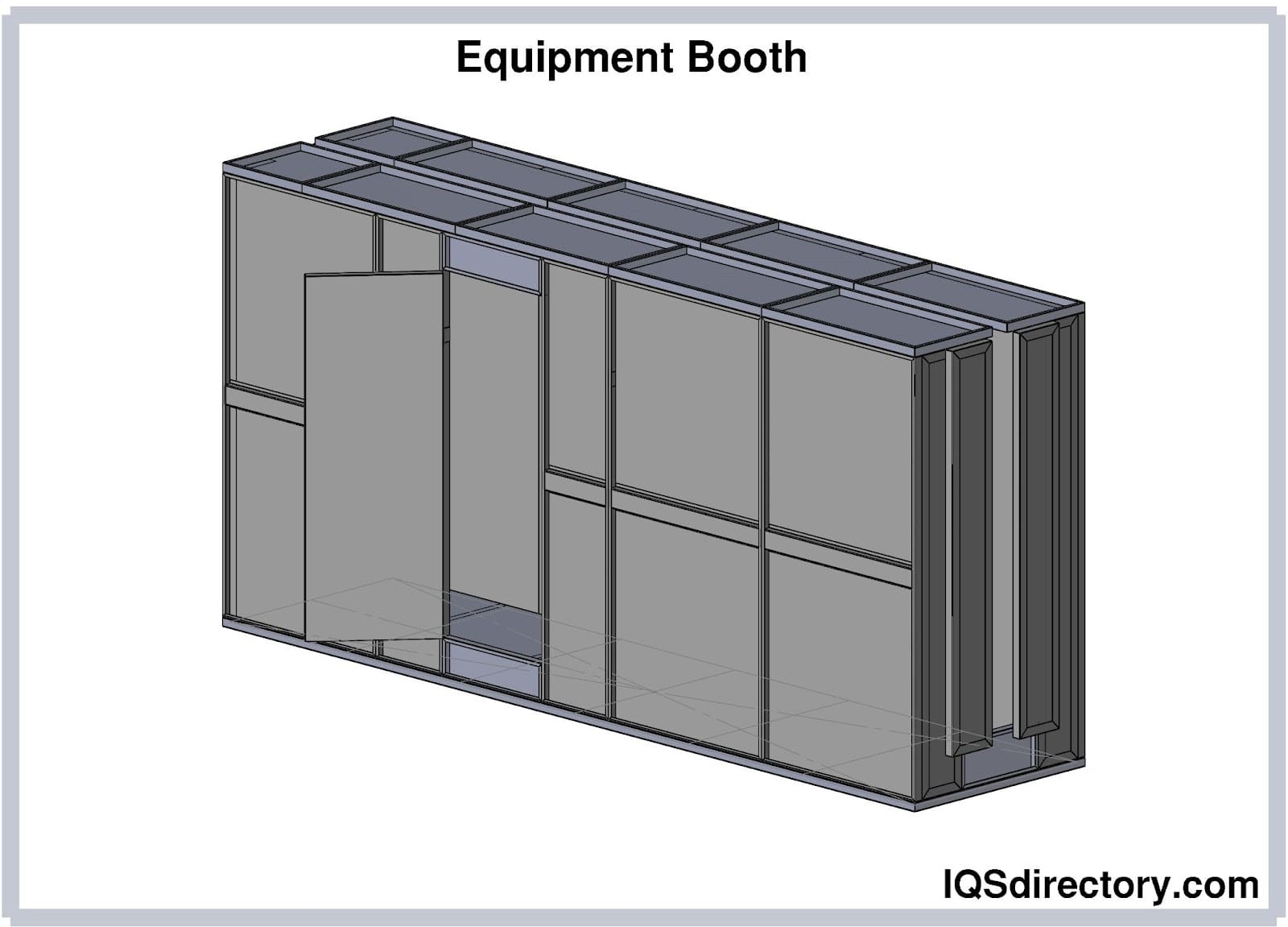

Equipment booths are modular enclosures specifically designed to house sensitive equipment and machinery rather than people. By providing environmental controls such as heating, cooling, and ventilation, these specialized booths protect valuable or delicate equipment from dust, moisture, temperature fluctuations, and other harsh conditions commonly encountered in industrial and manufacturing environments. Equipment booths help extend equipment lifespan and reduce maintenance costs.

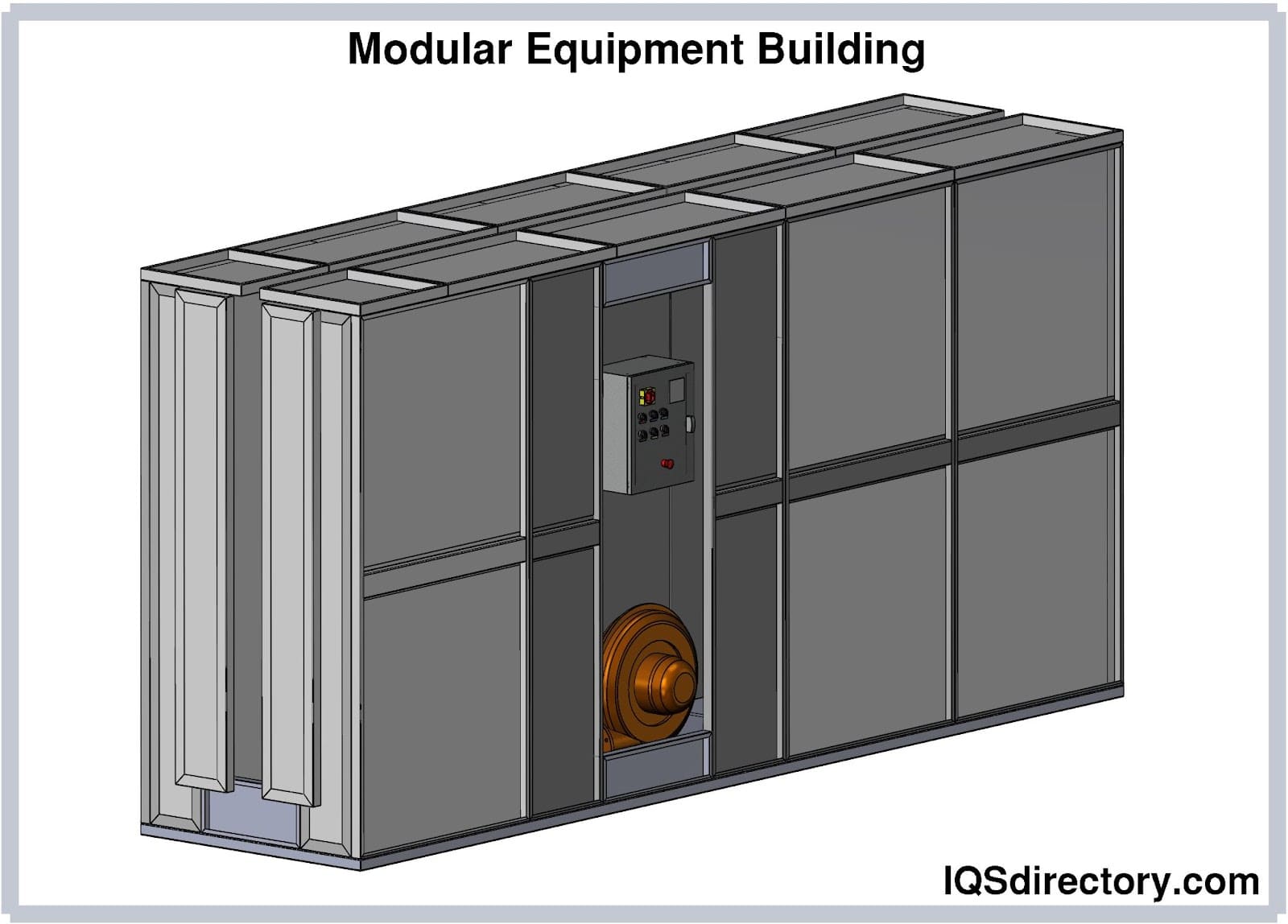

Modular equipment buildings are larger and highly customizable variants of equipment booths built to accommodate industrial systems such as generators, HVAC machinery, pumps, compressors, process control devices, and electrical panels. These buildings can be configured with sound-attenuating material, integrated fire suppression systems, blast- and bullet-resistant panels, and environmental monitoring technologies. Modular equipment buildings meet stringent industry standards for safety, security, and reliability, making them essential for mission-critical industrial and utility infrastructure.

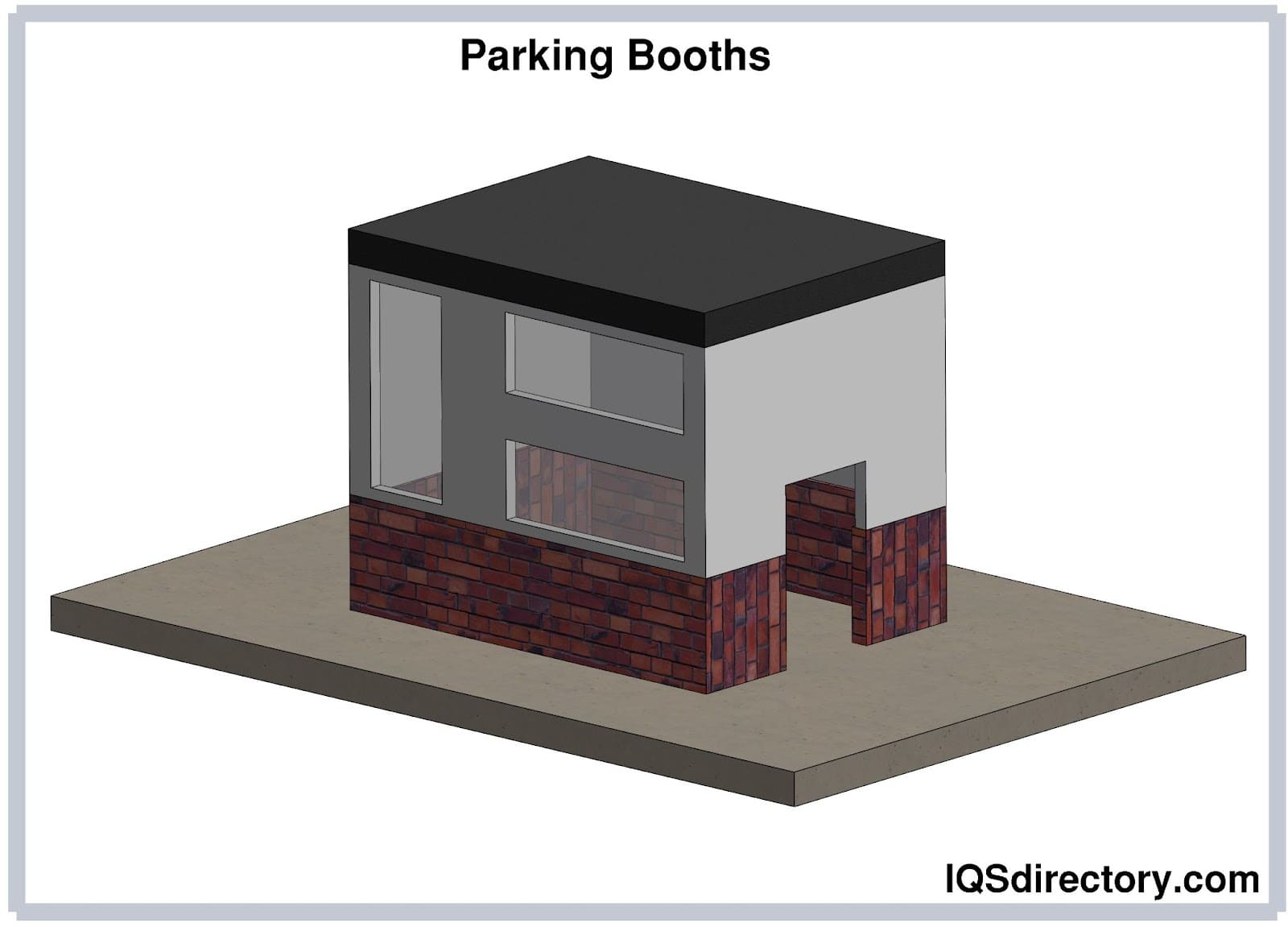

Parking booths are modular structures positioned at access points of parking lots, garages, and commercial parking decks. Serving as workspaces for parking attendants, they streamline the management of vehicle entry, exit, fee collection, and security. Modern parking booths can incorporate cloud-based ticketing systems, RFID readers, surveillance cameras, and mobile payment devices, enhancing both security and operational efficiency for property owners and parking operators.

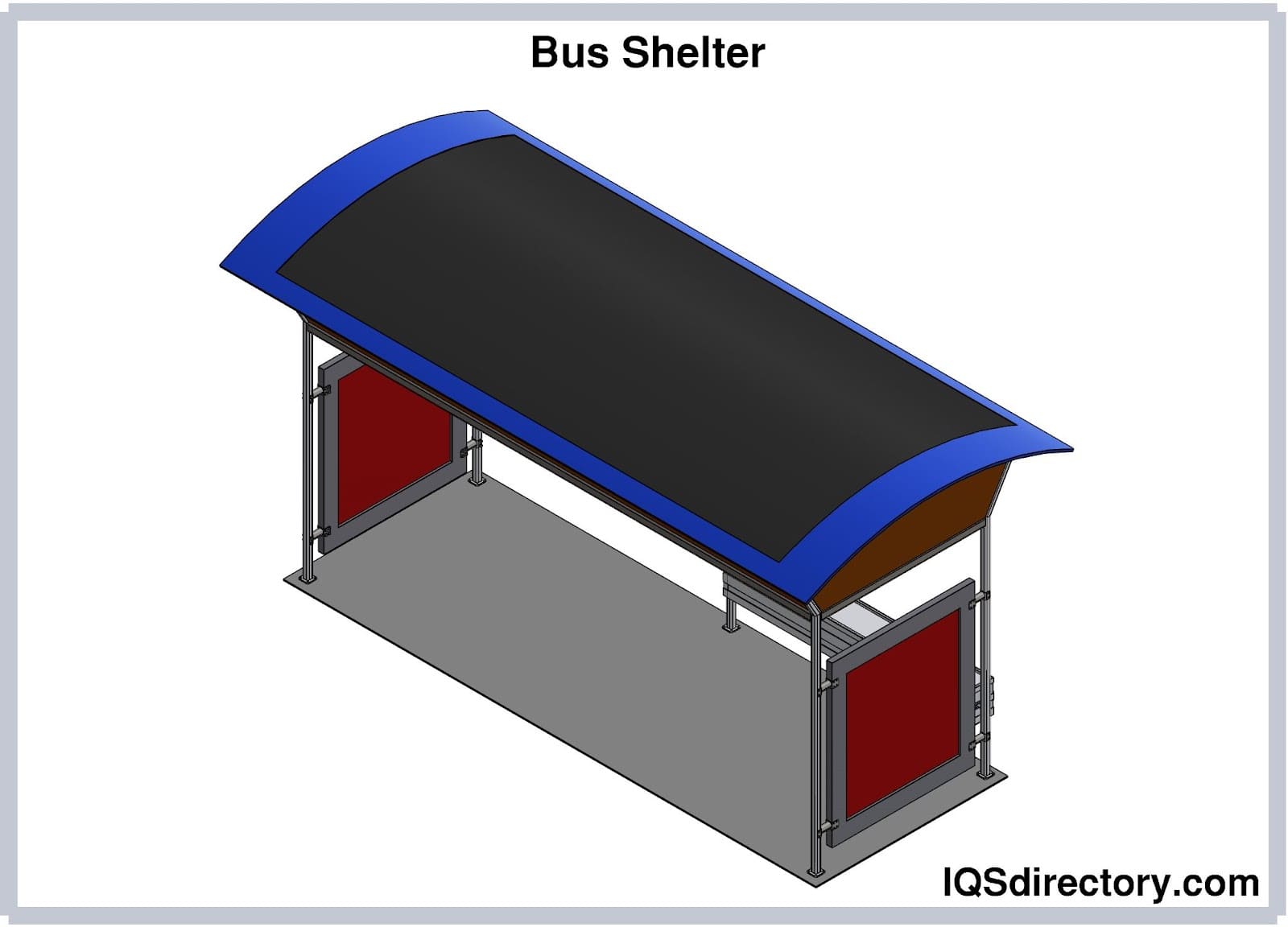

Prefabricated shelters are rapidly deployable modular enclosures that provide protection and comfort for people and equipment from harsh outdoor conditions, including extreme weather, pollution, debris, and rain. Especially popular in urbanized and transport-rich regions, these shelters can be fully customized with heating, lighting, surveillance, and power solutions to meet specific project requirements for transportation infrastructure, public venues, campuses, and workplace environments.

The versatility of prefabricated shelters also extends to disaster response, construction job sites, remote area operations, and public health settings where temporary or semi-permanent protection is required. Several specialized shelter types exist to meet unique industry needs:

Screening booths, also known as modular health screening stations, rose to prominence during the COVID-19 pandemic, enabling healthcare and security personnel to conduct temperature checks, symptom assessments, and specimen collections at facility entrances. Outfitted with transparent safety screens, plexiglass windows, glove ports, contactless thermal scanners, and negative pressure airflow systems, screening booths offer high mobility and are easily relocated according to evolving operational demands or during emergency situations.

Bus shelters are modular, weather-protected structures installed at bus stops and public transit terminals to safeguard commuters from heat, rain, snow, and environmental pollutants while waiting for transportation. Designed for high durability and ease of maintenance, these prefabricated shelters may feature seating, wind screens, real-time transit information displays, solar panels, and wireless internet access to enhance commuter comfort and the value of public transit infrastructure.

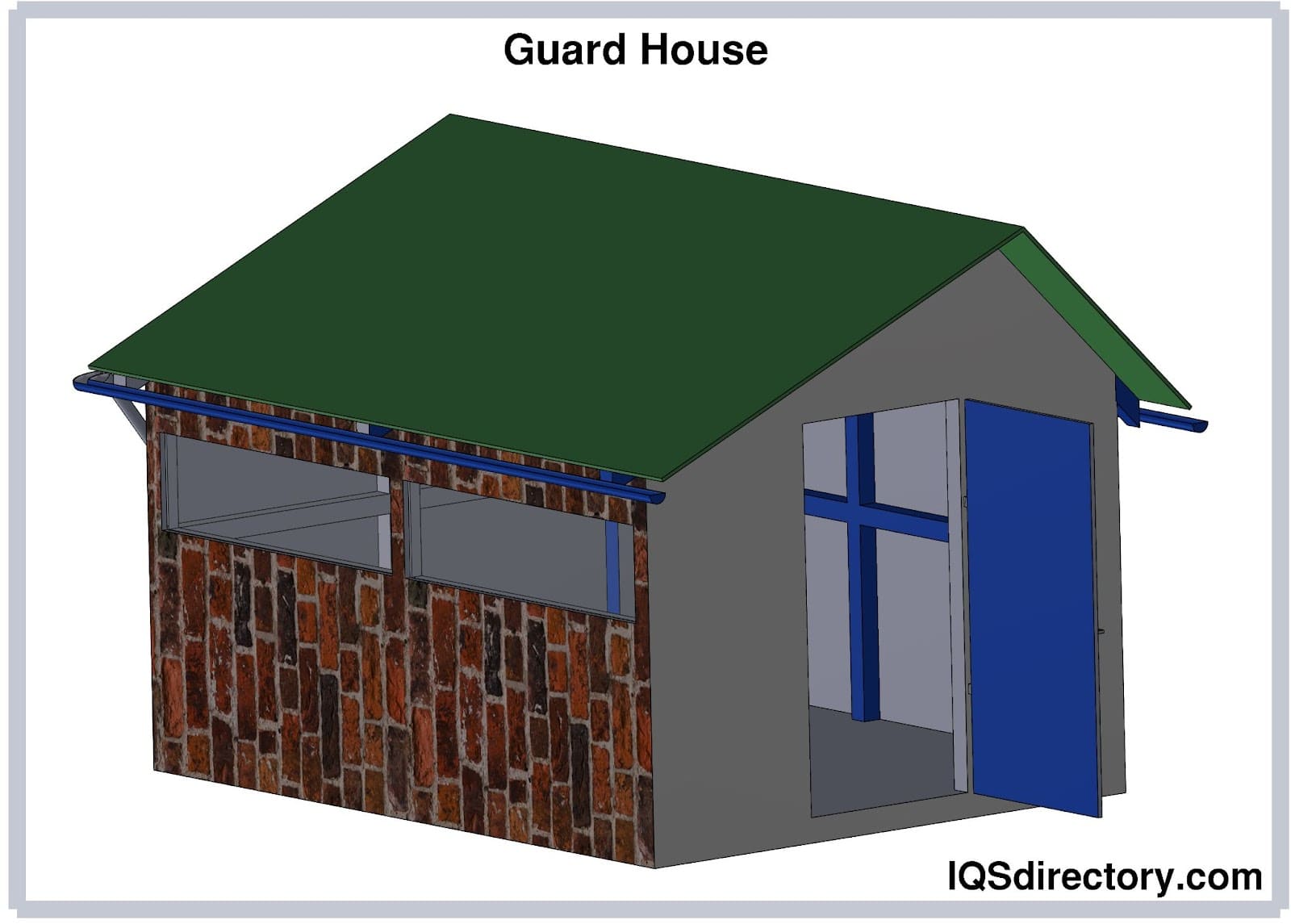

Guard houses, also known as security guard booths or modular security enclosures, are strategically placed at private community gates, commercial facility entrances, industrial properties, and security checkpoints. Engineered for effective site surveillance, these modular buildings provide working space and amenities for security teams, allowing continuous monitoring through CCTV, access control systems, and live visitor authentication. Prefabricated guardhouses feature reinforced walls, secure windows, and, where required, bullet- or blast-resistant protection.

An observation tower is a specialized guardhouse designed to offer security personnel an elevated, 360° panoramic view to optimize site monitoring and perimeter security for military, correctional, or critical infrastructure facilities.

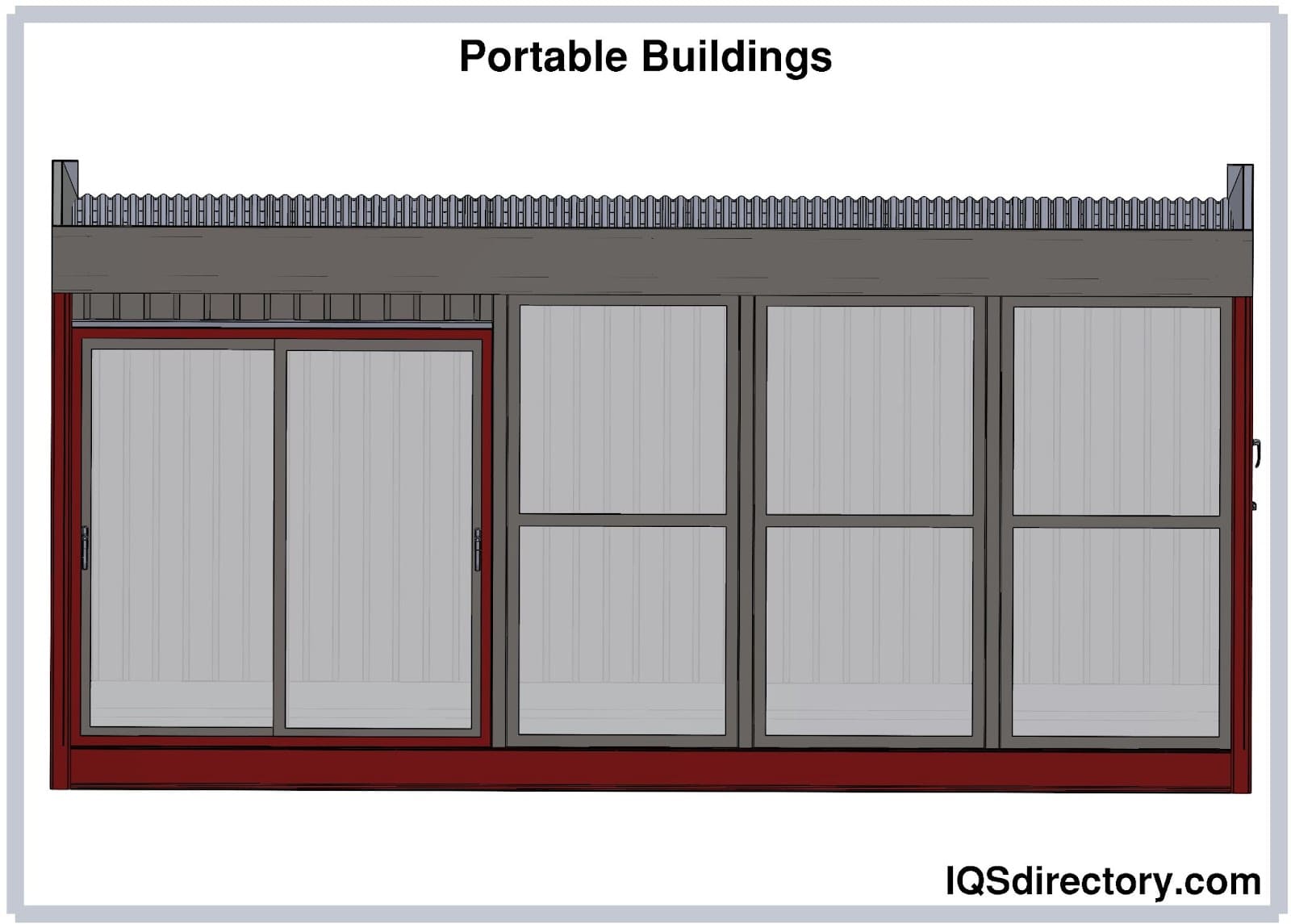

Portable buildings are modular structures fabricated and pre-assembled in a factory setting so they can be easily transported to the required location. These versatile, standalone buildings can be placed at construction sites, used as temporary classrooms, medical outposts, disaster relief centers, storage facilities, or remote workforce housing. Portable buildings are ready for immediate use after installation, offering rapid deployment and flexibility for a variety of business, educational, or community needs. Many portable building manufacturers offer rental, leasing, and purchase options tailored for both short- and long-term space solutions.

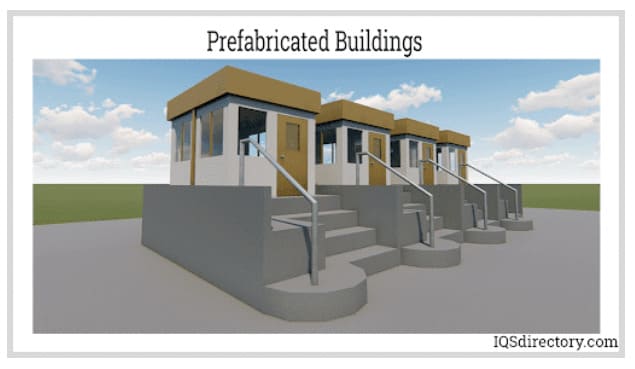

Prefabricated buildings are modular construction projects in which building sections—such as wall panels, roofs, ceilings, and even interior fixtures—are engineered and assembled offsite to precise client specifications. Delivered to the final site for assembly, prefabricated buildings offer reduced construction timelines, minimized waste, and heightened quality assurance. While "prefabricated buildings" and "modular buildings" are sometimes used interchangeably, prefabricated buildings typically emphasize custom, client-specific requirements, while modular buildings may be standardized for fast deployment and mass production.

Prefabricated garages are modular structures specifically designed to protect vehicles from weather damage and theft. Manufactured offsite, these garages are delivered in sections or as complete units for rapid, on-site assembly. Features may include multi-bay layouts, storage lofts, automated garage doors, high-security locking systems, and integration with home or building automation. Prefabricated garages are an affordable, time-saving alternative to custom site-built garages, especially for residential and light commercial markets.

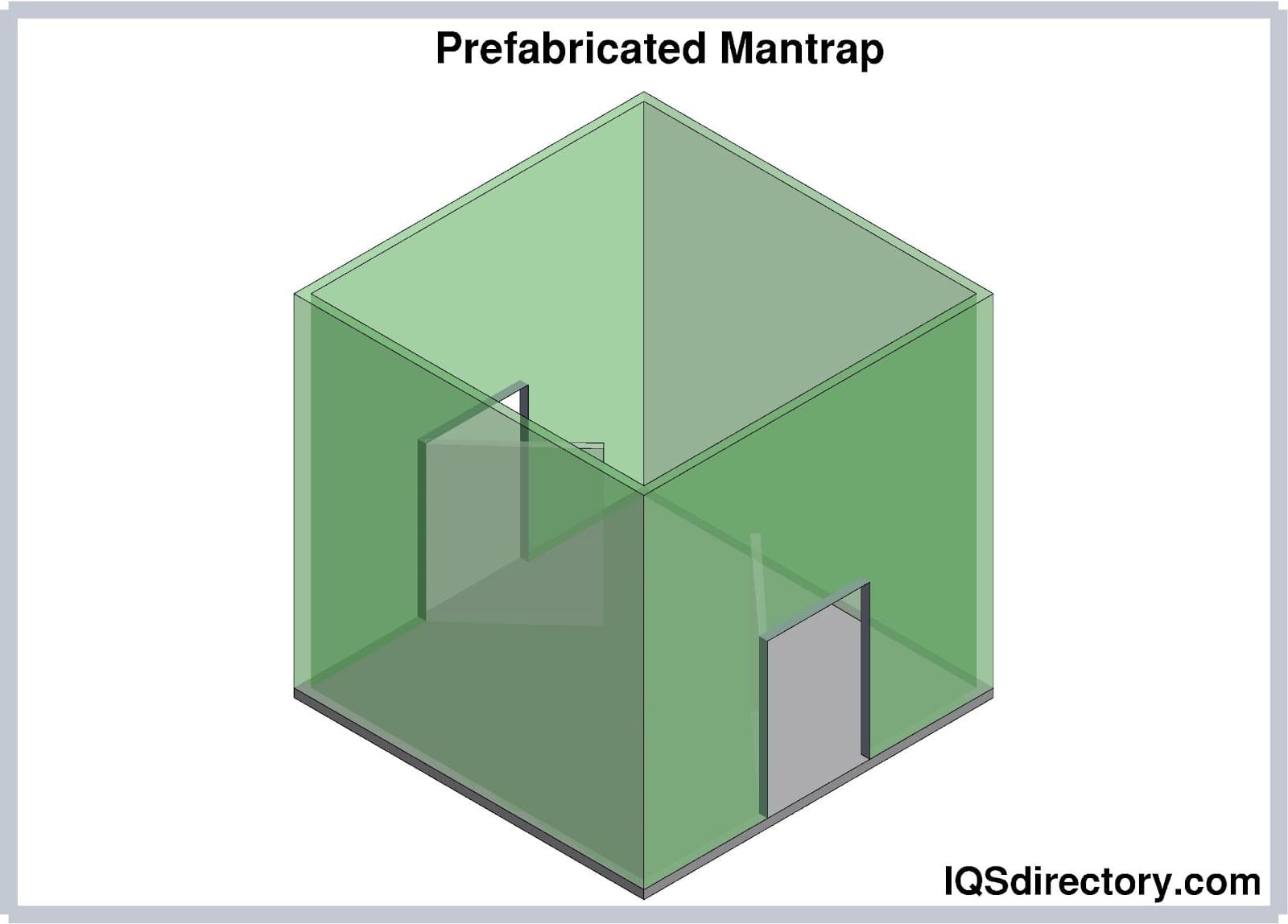

Prefabricated mantraps are modular rooms equipped with access-controlled entrance and exit doors on opposite walls. Primarily used as a security solution in data centers, laboratories, banks, and other sensitive facilities, mantraps provide an effective physical barrier to prevent unauthorized access to restricted areas, support multi-factor authentication procedures, and enhance overall site security.

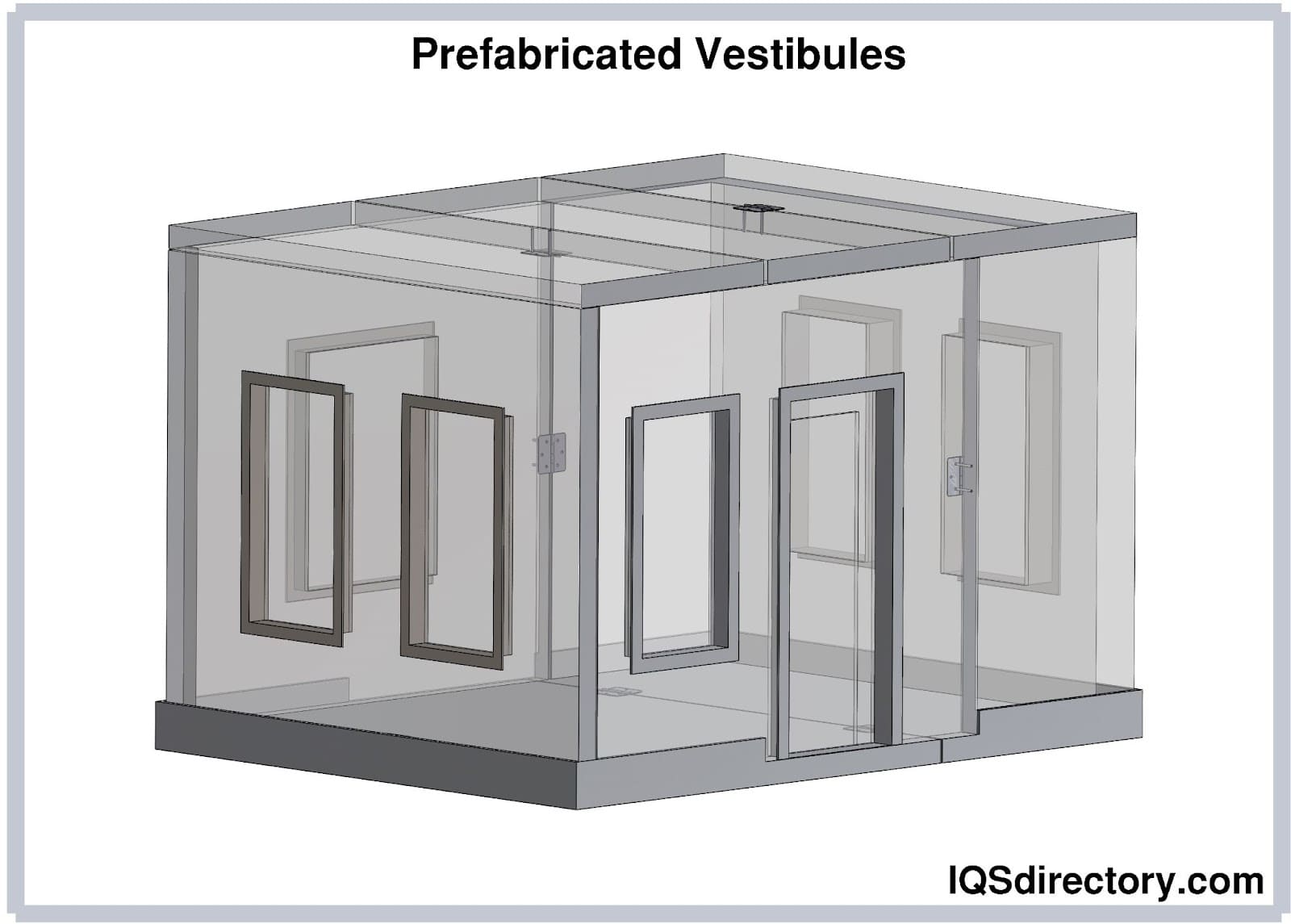

Prefabricated vestibules are modular entrance solutions installed at the exterior of buildings and residential complexes to improve security, energy efficiency, and visitor screening. Vestibules provide a transitional space for welcoming guests, storing outdoor attire, and reducing contaminants before entry. Their air-lock design helps limit heat transfer, improving thermal performance and reducing energy costs for building owners.

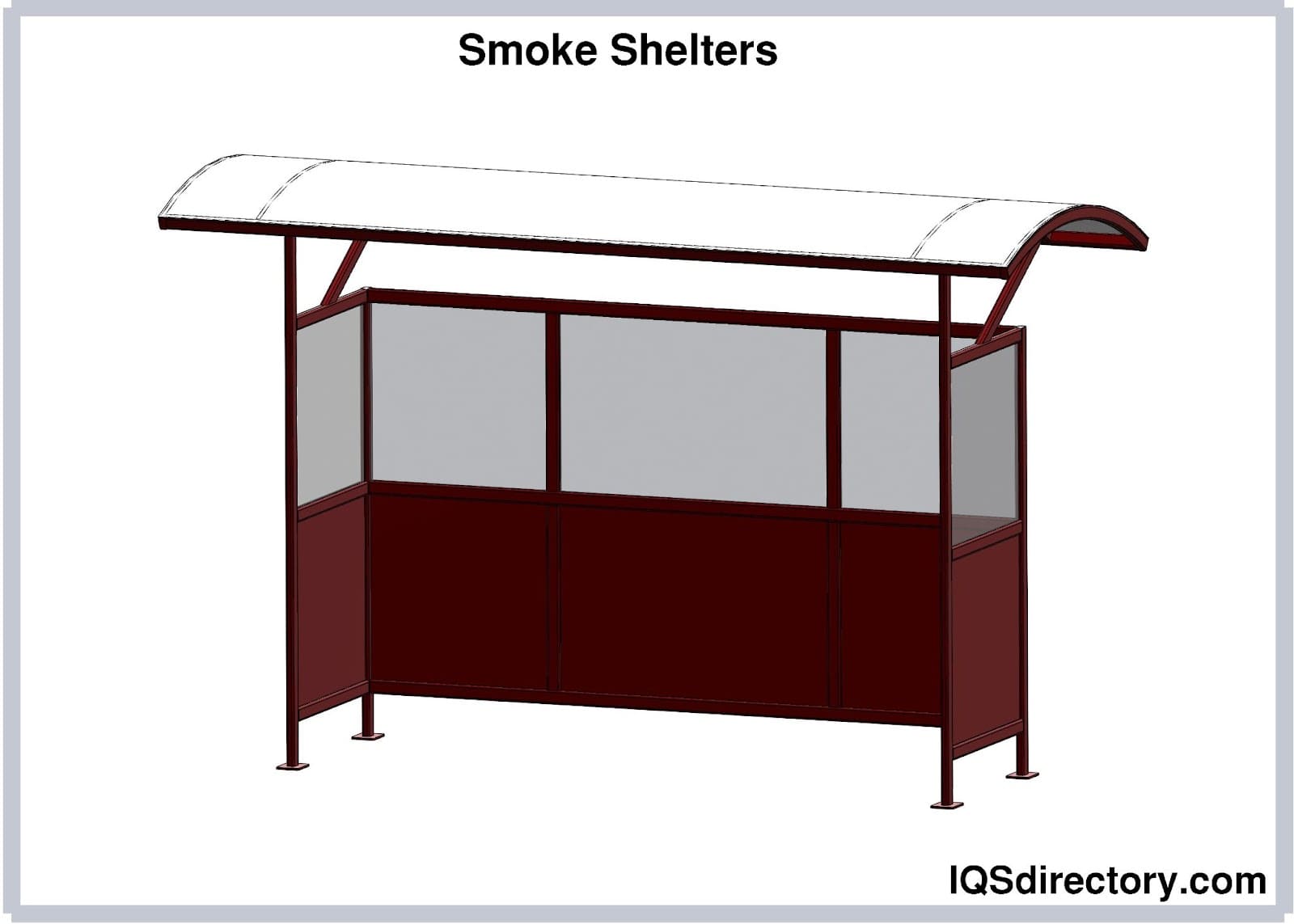

Smoke shelters are modular, semi-enclosed outdoor structures created to serve as designated smoking areas in compliance with workplace, residential, and municipal smoking regulations. Outfitted with durable roofing and weather-resistant frames, smoke shelters help employers safeguard non-smokers from secondhand smoke exposure, maintain clean gathering spaces, and comply with applicable health and safety standards.

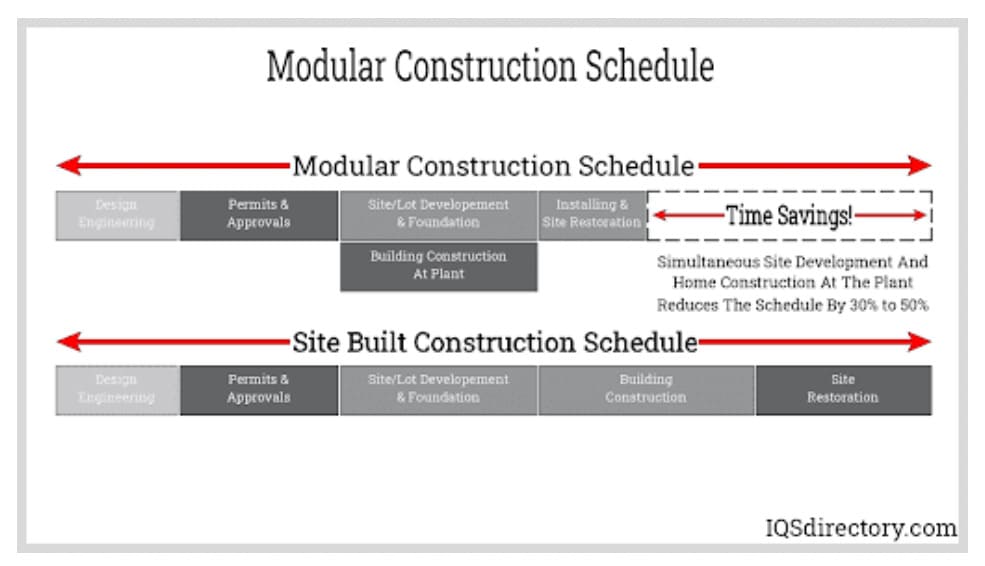

One of the primary advantages of modular buildings is the rapid construction timeline. Modular construction methods can significantly shorten project turnaround times, often allowing complete assembly in half the duration compared to traditional site-built structures. This time savings is due to simultaneous site preparation and offsite fabrication of prefabricated building modules. By manufacturing building components in a controlled factory environment while site work progresses, developers accelerate project schedules and minimize weather-related delays, which can otherwise hinder construction quality, increase costs, and threaten worker safety. Once the prefabricated modules arrive on-site, they are ready for swift installation, further reducing time, labor, and logistical complexity. This efficiency is especially advantageous for commercial modular buildings, educational facilities, and healthcare centers requiring fast occupancy.

Modular buildings are constructed in a controlled environment where materials are protected from moisture, temperature fluctuations, and external weather elements. This off-site construction process enables manufacturers to employ advanced construction techniques, precision engineering, and rigorous quality control procedures. Each modular section undergoes thorough inspection, testing, and certification to guarantee compliance with national and local building codes, safety regulations, and relevant industry standards. As a result, modular structures are highly durable and offer long-term reliability, meeting or exceeding the quality of conventional construction.

Modular buildings are inherently flexible and convenient solutions for various applications. They can be easily relocated, expanded, or reconfigured according to evolving space requirements. This adaptability reduces the need for new construction materials and conserves resources, making modular construction a cost-effective and efficient option. Additionally, prefabricated modular units can be seamlessly added to existing buildings, providing scalable space for offices, classrooms, or healthcare clinics. Their portable design is particularly beneficial for remote locations, temporary work sites, or disaster-relief applications, where traditional construction is both impractical and expensive.

By manufacturing building components offsite, modular construction results in minimal disturbance to the jobsite. Reduced onsite activity means less noise pollution, traffic, dust, and general disruption for adjacent properties and businesses. This is particularly valuable in high-density urban areas, educational settings, or active healthcare facilities, where operational continuity and occupant comfort are priorities during the building process. The reduced onsite construction timeline also shortens overall project duration, leading to fewer safety hazards and a smaller carbon footprint.

Modular construction is a sustainable building method that reduces the environmental impact commonly associated with conventional construction. Factory production enables efficient management and disposal of air emissions, solid waste, and wastewater. These controlled practices limit pollution and conserve natural resources. Additionally, modular buildings are designed with energy efficiency in mind, supporting green building certifications (such as LEED) and promoting sustainable site development. Many modular projects utilize recyclable or renewable materials, further supporting eco-friendly building initiatives.

Lean manufacturing techniques integrated into modular building production minimize material waste and excess inventory. Controlled factory settings allow precise measurement, strong quality assurance protocols, and proper material storage—all contributing to reduced consumption and more efficient use of resources compared to traditional construction. Waste reduction not only supports cost savings but also aligns with environmentally responsible building practices.

Modular building manufacturers leverage economies of scale, mass production, and standardized processes to lower overall construction costs. By reducing labor expenses, speeding up project completion, and minimizing costly change orders, modular solutions allow clients to benefit from more predictable budgets and lower upfront investments. These competitive prices enable schools, businesses, and healthcare providers to maximize value without compromising on build quality or energy efficiency.

Other noteworthy benefits include enhanced safety for workers through controlled factory conditions, improved building lifecycle management due to easy upgrades and expansions, and fast return on investment (ROI) thanks to accelerated occupancy. Modular buildings are ideal for a wide range of uses, including modular office buildings, portable classrooms, construction site offices, temporary workforce housing, and more.

While modular construction promises many benefits, there are logistical challenges related to the transportation of oversized prefabricated modules. Shipping costs can increase with distance from the factory, while large building sections may require specialized vehicles and careful route planning. Risks of potential damage during transport or on-site handling necessitate experienced logistics partners and proper insurance coverage, all of which can impact a project’s bottom line and scheduling accuracy.

Compared to custom-built structures, modular buildings may face certain design and customization constraints. Standardized floor plans and exterior finishes help keep costs low but can sometimes result in limited architectural variety or distinctive aesthetics. Customers seeking unique or highly specialized building features may require additional customization, advanced engineering, or hybrid solutions that blend modular and traditional construction approaches. However, advancements in modular design and manufacturing are increasingly bridging the gap, enabling greater versatility and creative architectural expression in modern modular projects.

Some municipalities and building authorities have zoning restrictions, permitting requirements, or codes that may uniquely impact modular construction projects. It is essential for property owners, developers, and project managers to conduct thorough due diligence on local regulations, secure the proper certifications, and collaborate with experienced modular building providers to ensure code compliance and avoid unexpected project delays.

When considering modular buildings as a solution, weigh the advantages—such as faster construction, cost savings, sustainability, and flexibility—against common disadvantages, including transportation logistics and design limitations. Carefully assess your site’s requirements, project scope, schedule, and budget. Partnering with a reliable modular building manufacturer will streamline planning, maximize benefits, and ensure successful project outcomes. For more details on how modular construction compares with traditional building methods or to receive a custom quote, consult an established provider in the modular construction industry.

Modular buildings are assembled from factory-built modules—walls, doors, frames, and windows—manufactured offsite to precise standards. These modules are transported and installed at the final location, meeting the same codes and quality requirements as conventional construction.

Modular buildings include permanent constructions like offices, healthcare facilities, and residential spaces, as well as temporary, relocatable structures—such as mobile offices, portable buildings, prefabricated booths, shelters, and specialty booths for specific commercial and industrial needs.

Modular buildings offer rapid construction, reduced project timelines, higher quality control, flexibility for relocation or expansion, less site disruption, sustainability, reduced waste, and lower overall construction costs with predictable budgets.

Potential disadvantages include transportation logistics, handling challenges, some constraints in architectural variety, and possible regulatory or zoning hurdles—especially in municipalities with specific modular construction codes.

Portable buildings, mobile offices, prefabricated shelters, and temporary modular construction are ideal for fast deployment and flexible space needs in local or remote areas, supporting applications like classrooms, clinics, and disaster relief.

Modular construction uses controlled factory processes to reduce waste, manage emissions, and support the use of recyclable materials. Many modular projects focus on energy efficiency and sustainable site development to minimize environmental impact.

In addition to the corporate, manufacturing, and trade industries, modular buildings are commonly acquired and utilized by the following sectors:

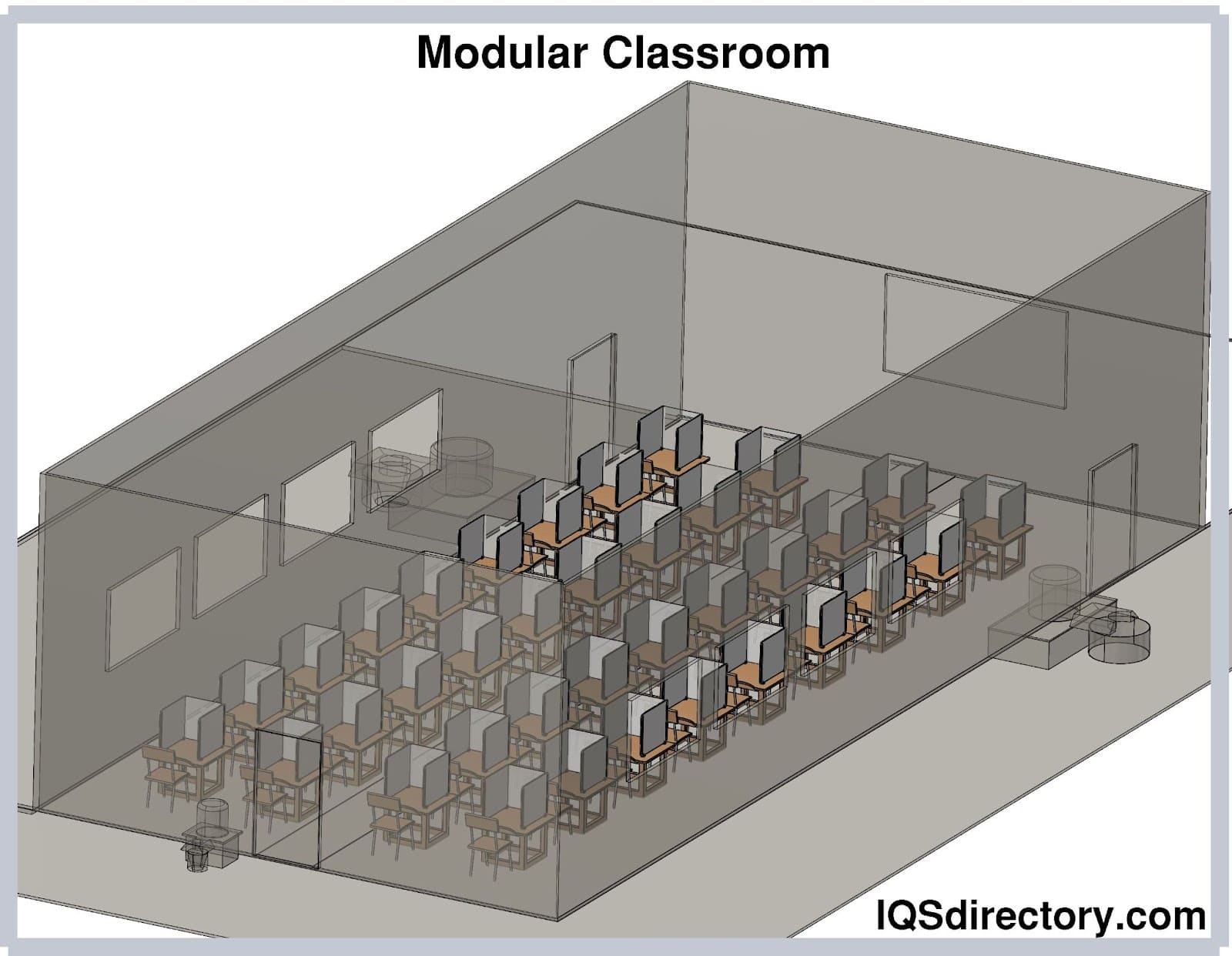

Modular buildings can serve as modular classrooms, equipped to accommodate chairs, tables, blackboards, and computers, and even labs. These buildings can house single or multiple classrooms, making them a flexible solution for schools facing maximum capacity issues. Modular classrooms are particularly useful as they can be adjusted to meet the varying number of students each school year.

Satellite government offices can be set up in various locations to address growing populations, seasonal demands, or increases in staff. These modular offices can be adapted for diverse functions, including administrative and management tasks, training facilities, and as headquarters for firefighters and police, among other uses.

Modular buildings play a crucial role in disaster response due to their ability to be rapidly deployed in emergencies. They can serve as temporary shelters for disaster victims and as operational bases for response teams, providing essential support in the aftermath of calamities.

Modular buildings can serve as temporary extensions for clinics, wards, and laboratories when the main hospital's patient capacity is exceeded. Additionally, relocatable medical facilities are used to provide care in remote areas, expanding access to healthcare services where needed.

Companies operating in remote or hard-to-access areas may purchase modular, prefabricated houses to provide housing for their workers. These modular units can also be used as student dormitories, offering flexible and efficient accommodation solutions.

A portable office is a mobile workspace that can be easily assembled and placed to provide a quiet and convenient location for meetings, completing paperwork, or examining plans. They are built using...

Prefabricated buildings, or prefabs, are buildings with components (walls, roof, and floor) that are manufactured in a factory or manufacturing plant. These components can be fully or partially assembled in a factory which is then transferred at the construction site...

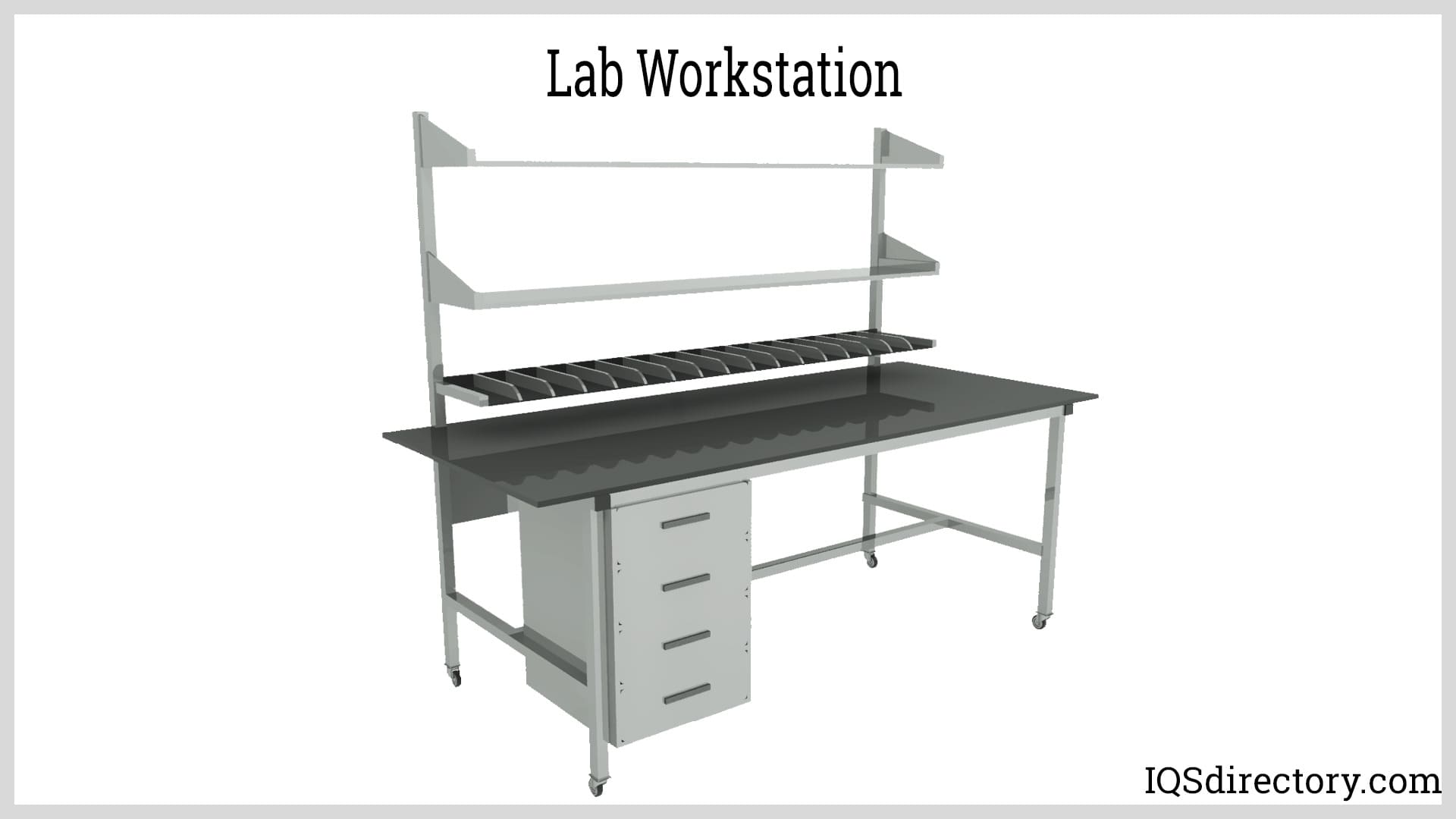

An adjustable work bench is a tool that allows the user to adjust and regulate the height of the work surface to a more ergonomic and comfortable position for the safe and effortless performance of work...

A lab bench is a specially designed bench or table that is able to assist in the performance of laboratory experiments and tasks, including the handling of reagents and test samples. Part of the design process for...

Metal grating is a metal product produced by perforating metal sheets or joining bars of metal to form a grid. They are a metal product that is widely used in various industries as stairs, platforms, scaffolding, and protective coverings...

A mezzanine is an intermediate floor installed in a building between the main floor and the ceiling that is partly open to the main floor. They have a low ceiling and project out over the main floor but do not completely cover it...

A mezzanine floor is a middle floor that is installed between the ceiling and the ground floor to provide extra space for storage, assembly operations, or office space. The normal design for a mezzanine floor is 25% of the flooring of a building or smaller...

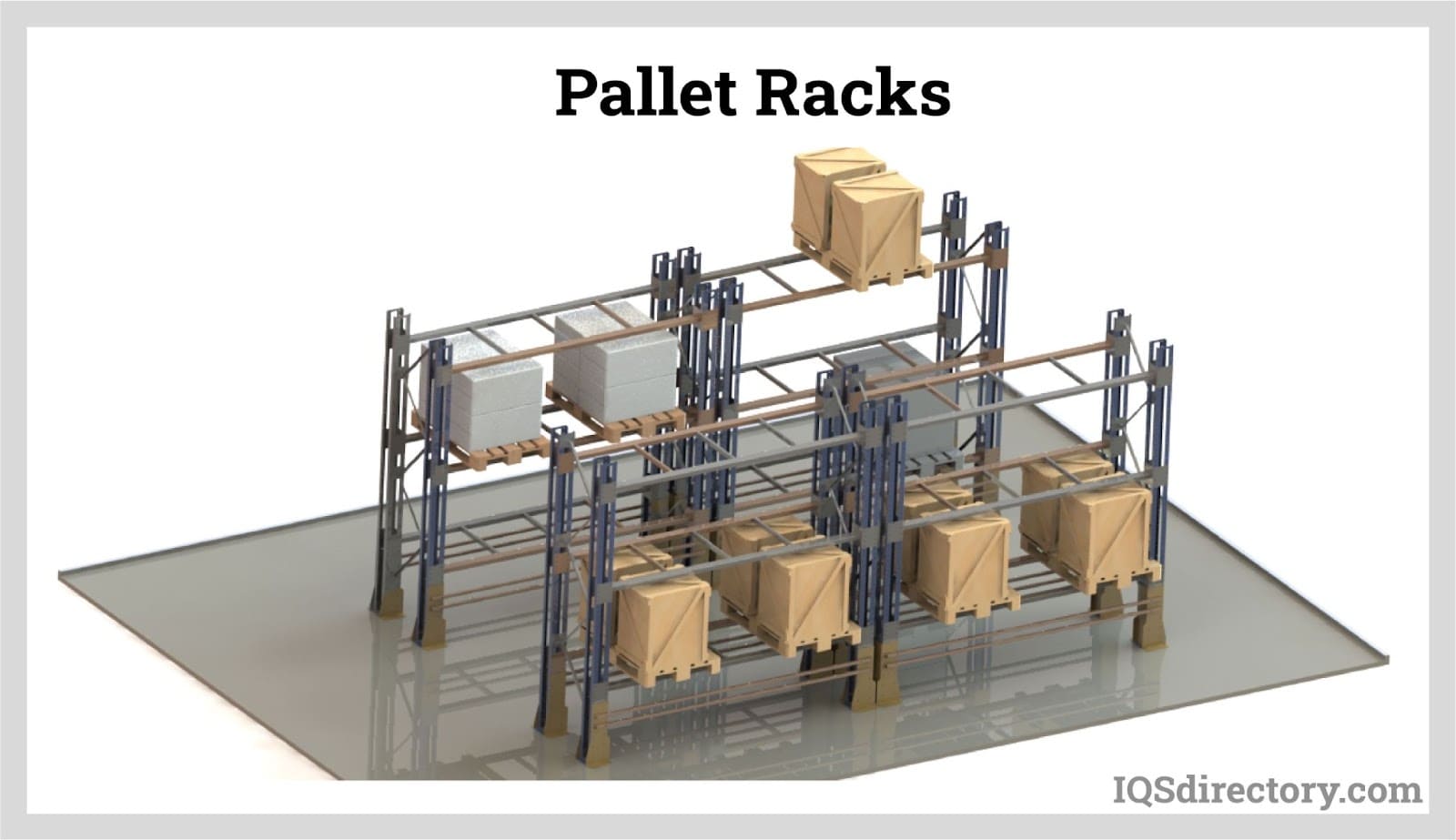

A pallet rack is an upright structure made of steel framing with beams and connectors that are bolted, welded, or clipped together to form a shelving unit to store inventory and equipment. In warehousing, pallet racks are...

A portable workbench is a flexible and mobile work surface that is designed to function in multiple environments for the purpose of preparing, constructing, or servicing a wide variety of industrial and commercial applications...

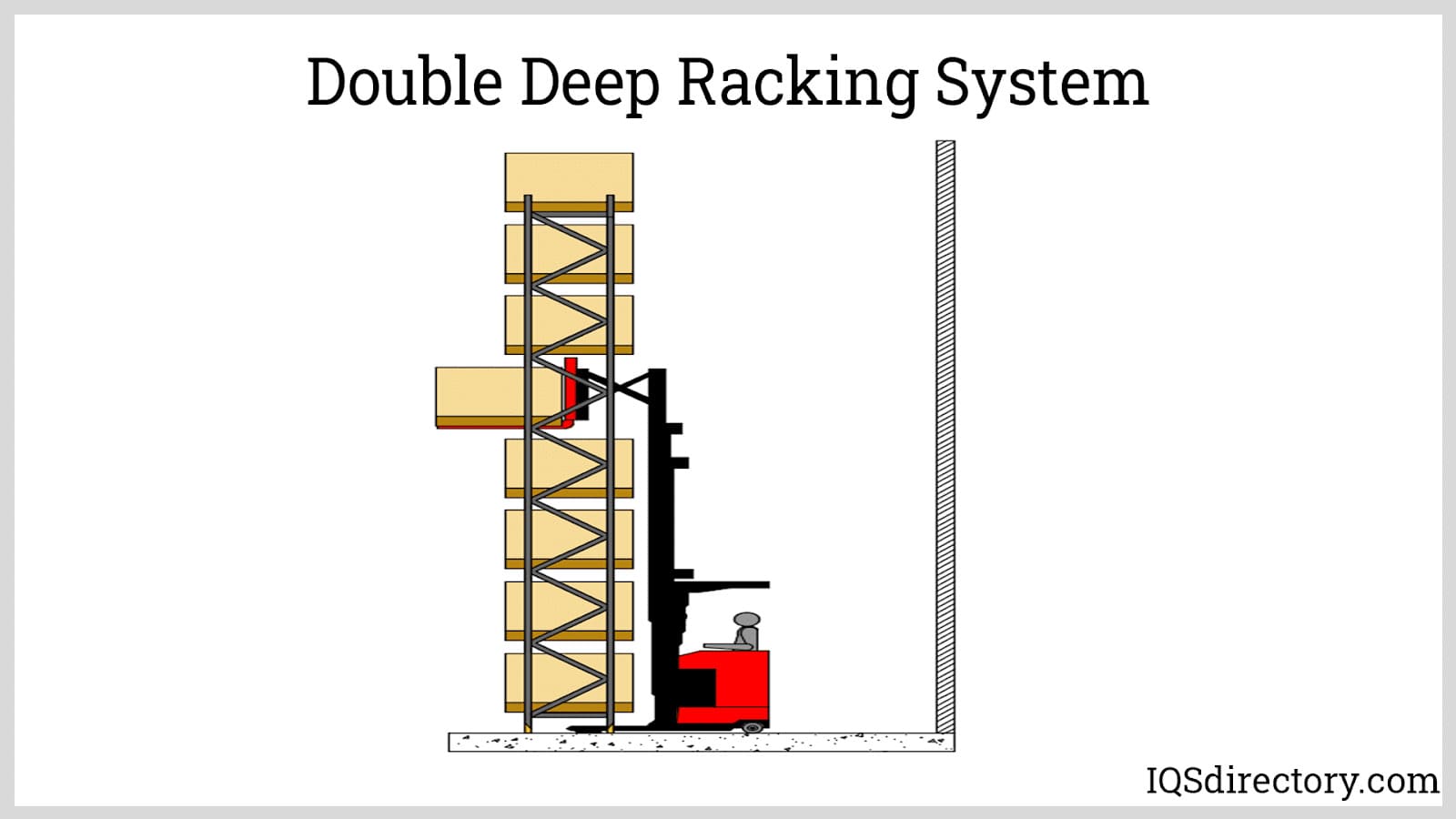

Storage rack, also known as racking, is a structure that stores items and materials and comprises at least two upright (vertical) frames, horizontal beams, and some sort of decking (bars, panels, meshes, or none)...

Warehouse racking, also known as storage or pallet racking, is a material handling system suitable for mass storage of goods unitized on skids or pallets. It allows efficient utilization of space while providing easy access to stockpiled items for better inventory control...

A workbench is a sturdy flat, smooth, molded surface that comes in a variety of sizes designed for specific tasks. They can be very complex for engineering design work, complicated machining, and intricate precision tooling or be a highly finished wood table for woodworking, metal work, and project design...

A work equipment platform is an elevated platform or surface in a manufacturing or production site that provides easy access to equipment and machinery. The raised space of a work equipment platform...