Vacuum Cleaners

Vacuum cleaners are cleaning machines that use suction to collect dirt, dust, waste products from industrial processes, and other kinds of debris for disposal, recycling, or reuse. A vacuum is an area from which air has been fully or partially removed. On the earth's surface, every object is subject to the force exerted by the weight of air. When air pressure in one area decreases, highly pressurized air from nearby enters the lower pressure area until equilibrium is achieved; this is what causes wind. Vacuum cleaners use a fan or system of fans to artificially lower air pressure in the enclosures where they collect debris. The highly pressurized air outside of the enclosure rushes in, bringing with it nearby dust, dirt, debris, or fluid, depending on how strong the vacuum cleaner is.

In general, all vacuum cleaners work using an air pump, such as a centrifugal fan, to generate a partial vacuum capable of sucking dust, dirt, and other particles from floors, furniture, and other surfaces. The main difference between commercial and industrial vacuums is that industrial vacuums work on a larger scale and with a wide range of individual differences. Industrial vacuum cleaners are used exclusively by professionals for building maintenance and industrial workspace cleaning. Commercial vacuum cleaners may be used for similar purposes, but they are characterized more by economy and use in light-duty cleaning processes. Small, portable vacuum cleaners can collect debris in fabric filter bags or removable plastic containers. Sometimes disposable filters are lined with larger, removable filters to provide extra air filtering. Most types of vacuum cleaners are designed to connect with attachments that allow for vacuuming in different places. Vacuums for carpet cleaning usually feature an agitator for easier removal of dirt from carpet fibers and auto vacuums use special attachments that help them clean tight spaces more easily. Continuous duty vacuums feature large collection enclosures that can be emptied quickly and easily so the machine can be put back to work without much delay.

Every manufactured product available has to be made somewhere, and most of them come from companies that use a streamlined process to maximize output. These processes produce debris in huge quantities and something has to clean up after them. Vacuum cleaners can be the perfect industrial cleaning tools. Unlike sweepers, they don't kick up dust, which in some cases can be hazardous, and their use is minimally labor-intensive. Vacuums can be configured to pick up almost anything: fine powders, abrasives, explosive media, litter, non-free flowing media, metalworking chips, toxic media, coolant, oil mist, and welding fumes are all fair game, (however, a vacuum designed for picking up wood chips differs in design from one that vacuums fluid waste). Some of the waste materials produced by industrial processes can be reclaimed and reused after processing. Vacuums are an excellent means of collecting these waste materials for reuse. They don't damage the material and specialized filters can be designed to minimize the number of unwanted materials like dust or dirt collected by accident. After being collected, the waste materials can be cleaned if necessary and then reprocessed for future use. An added benefit of using vacuums to clean workspaces is that they can be fitted with HEPA filters; in environments where a high volume of waste shavings or dust is created, HEPA filter vacuums can remove the large particles as well as fine particulates that degrade workspace air quality.

Quick links to Vacuum Cleaners Information

Applications of Industrial Vacuum Cleaners

There are many vacuum varieties. These include small vacuum cleaners and portable industrial vacuum cleaners, which can be designed for industrial use, though they are mainly used in commercial contexts in less demanding applications. In industrial settings like woodworking, metalworking, or other processes that create a constant flow of debris, vacuum equipment that operates on a higher level than commercial vacuums is needed. Continuous duty vacuums are built to operate 24 hours a day with limited interruption. In settings where dangerous debris is created regularly, explosion proof vacuums may be necessary to reduce the risk of fire or other danger. Sometimes HEPA vacuum cleaners are put to use on manufacturing floors to help filter workspace air while vacuuming. Auto vacuums, some of which can be wet dry vacuums, are high-capacity, specialized vacuums used in the cleaning of vehicles. In building maintenance applications and in some industrial settings, central vacuum systems allow for the collection of debris throughout a building by central vacuums that connect to built-in vacuuming ductwork.

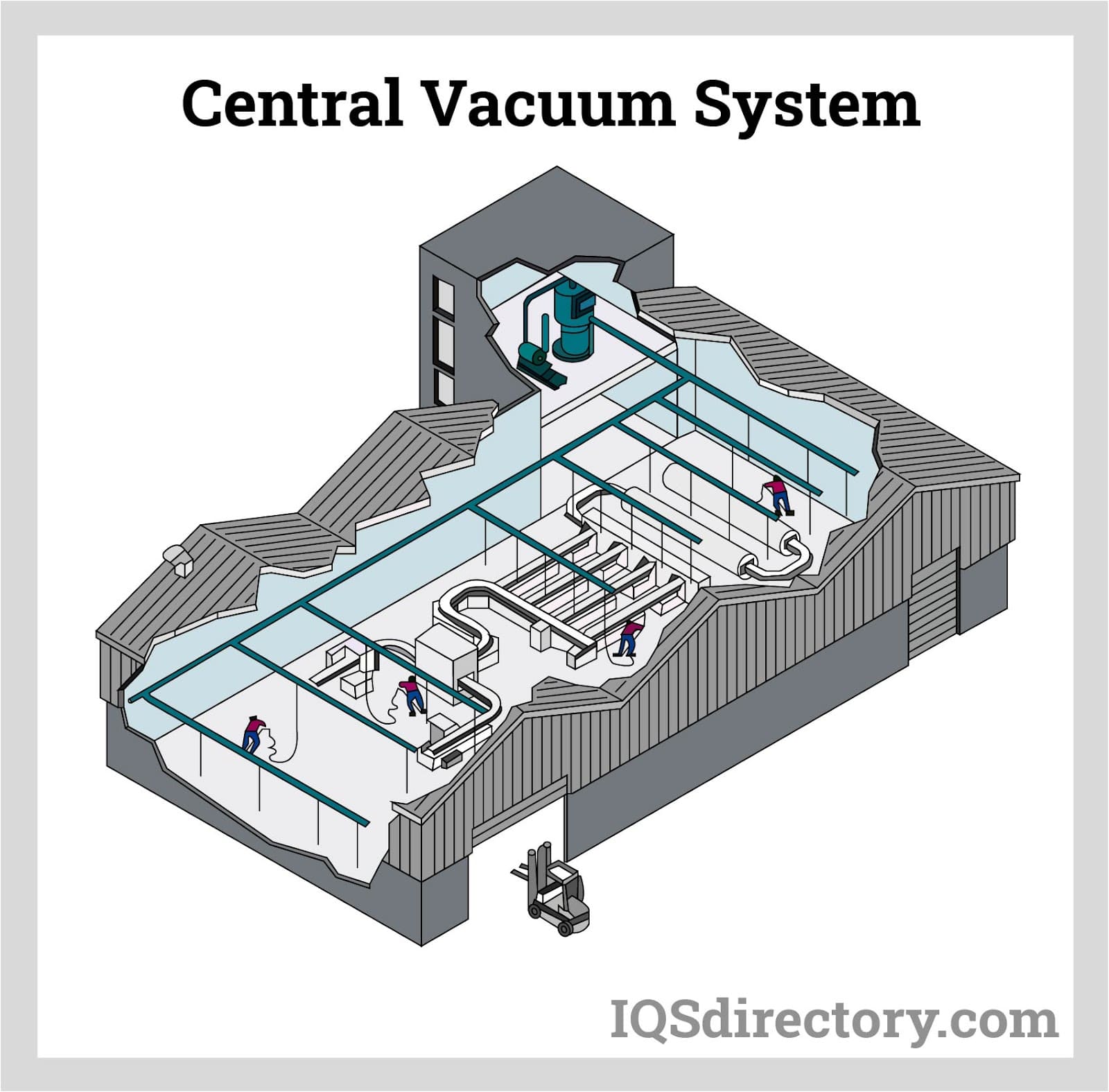

Backpack vacuum cleaners, canister vacuums, rider (or walk-behind) vacuum cleaners, and vacuum cleaner trucks are just a few of the available portable vacuum cleaner configurations. The overwhelming majority of vacuum cleaners are at least semi-portable and most of them are very portable. Even continuous duty vacuums, which can be quite large and are generally used only for the constant cleaning of warehouse or factory workspaces, are often equipped with wheels. central vacuum systems are the least portable of all vacuum cleaner systems. In large-scale building maintenance contexts where constant cleaning is required, central vacuum systems are a good solution to the problem of maintaining efficiency. Through inlets in a built-in system of ductwork, maintenance employees can connect hoses and vacuum attachments to a single central vacuum located in a mechanical closet. Because the central vacuum is isolated and its room is usually located in a basement, the noise generated by vacuuming is very limited compared to most portable vacuums. This feature is invaluable in contexts like colleges where vacuuming is needed even as classes are proceeding. Instead of using many vacuums with many filters, maintenance crews that use central vacuums have only one machine to empty and service.

History of Industrial Vacuum Cleaners

Previously, industrial vacuum cleaners were a series of small, less powerful vacuum models. This series began with the manual vacuum. Daniel Hess invented the earliest version in the 1860s, with a model that featured a rotating brush and suction-generating bellows. The powered vacuum came next. The first patent for one was submitted in 1898. This model, invented by a man named John S. Thurman, blew dust into a receptacle instead of sucking it. Other models of this type, however, did use suction. A few years later, in 1905, a British manufacturer named Walter Griffiths put the domestic vacuum cleaner on the market. The next year, James B. Kirby developed his first vacuum, called the “Domestic Cyclone.” His inventions would later lead to the now-famous Kirby Vacuum line. Through the 1920s and 1930s, manufacturers continued to revise and improve upon their inventions. Most notably, when hired by Hoover, the industrial designer Henry Dreyfuss reconfigured the entire design of the vacuum cleaner. He made it lighter, more efficient, more attractive, and even added a signal indicating when it was full. It was not until after World War II, though, that vacuum cleaners became common household items. Before that, they were considered luxury items.

Manufacturers began using industrial vacuum cleaners in the latter half of the 20th century. By this time, technology had caught up to the need to clean spills and purify air on a larger scale. Commercial and industrial customers suddenly had the opportunity to clean using powerful vacuums like the wet dry vacuum cleaner, which can suck up both wet and dry debris. Today, industrial vacuums are used in various settings for a multitude of reasons, and they continue to evolve every day.

Industrial Vacuum Cleaner Production and Design

Some of the standard industrial vacuum styles available to customers include auto vacuums, backpack cleaners, canister vacuums, central vacuum cleaners, continuous duty vacuum, explosion-proof vacuums, HEPA vacuum cleaners, rider sweepers (or walk-behind sweepers), and vacuum cleaner trucks.

- Production Process

- Industrial vacuum cleaners are typically assembled on a line with subassembly stations. Small parts made from metal are sent to the manufacturer via a subcontractor. The manufacturer stores these parts and turns to them when they’re ready to assemble one or more new vacuums. On-site, they can make any plastic parts they need, such as exterior housings, hoses, handle parts, wheels, and connections that support the bag. Typically they do so via injection molding.

- Materials

- Industrial vacuum parts can be made from a myriad of different materials. For example, the housings of wet dry vacs are usually made from rotationally molded polyethylene. Other vacuums, particularly the canister vacuum, feature removable canisters made from plastic. Meanwhile, dust bags are usually made from woven or non-woven fabric-like synthetic fiber. If the dust bag is lined, it is likely lined in plastic. Many components of industrial vacuums are made from stainless steel. Certain vacuums, like the tank shop vac, are made almost entirely from stainless steel.

Design Aspects

- Airflow

- Which is defined in this context as the velocity of the air stream produced by a vacuum cleaner's motor, varies in industrial vacuums because some applications require the pull of a stronger airflow than others. For greater suction, manufacturers must use greater air pressure.

- Filter

- One of the major components of industrial vacuum cleaners. Manufacturers design them based on the material they will be sucking up and the level of cleanliness they need to achieve. For example, some are equipped with filters that can only pick up dry material, some are only meant to pick up wet materials, and others can pick up both. In addition, certain air filters are designed more precisely than others. Water filters, for instance, force dirty air through a water bath before it goes back into the atmosphere. This action keeps dust from becoming airborne again. Other industrial vacuum cleaners use activated charcoal filters, which remove odors from the surface they are vacuuming.

- Dirt Storage

- When they pick up dirt, some industrial vacuum cleaners separate the dust particles from the airflow by spinning the air with a separation chamber, while others use a disposable or reusable bag.

Benefits of Industrial Vacuum Cleaners

- Fast, Large-Scale Cleaning

- Industrial vacuum cleaners allow you to clean your space on a large scale. They are also designed to be efficient and equipped with parts designed for your application.

- Improved Air Quality and Health

- With features like HEPA filters, industrial vacuums are more effective at trapping and removing allergens, bacteria, industrial debris, and other contaminants from the air. This means that they will keep you, your staff, and your customers healthier.

- Long-Term Savings

- Industrial vacuum cleaners are designed to withstand tough conditions and be used for hours at a time. While they are more expensive than at-home vacuums, they will last longer and work better. This translates to more money saved over time.

- Deep Cleaning

- Because industrial vacuum cleaners are more powerful than commercial vacuum cleaners, they can pick up a great deal more than them. In general, they can reach down into rugs, carpets, and floors, and generate deep and lasting clean.

Installation of Vacuum Cleaners

Most vacuum cleaners are portable and require no installation, only an outlet. However, some are central systems, and central systems do require installation. A central system would require you or your manufacturer to install your processing lines, hoses, tubing, and all other attachments to your location’s duct inlets. In addition, you will need to be sure you have a suitable outlying location for your vacuum’s motor and dirt filtration unit.

Industrial Vacuum Cleaner Standards and Compliance

If you are working within the United States, it is vital that you adhere to the standards for industrial vacuum cleaner use put forth by OSHA (Occupational Safety and Health Administration).

If you are working within the European Union in a potentially explosive atmosphere, both you and your manufacturer must follow the ATEX directive. The ATEX directive consists of two directives outlining what equipment is allowed within a potentially explosive atmosphere and what kind of work environment must be maintained. An area such as this is known as an ATEX zone. Atmospheres are divided into different ATEX zones based on their atmospheric conditions. Both you and your manufacturer will need to follow the correct standards for the zone ATEX assigns you.

In addition to these standards, your vacuum will need to be up to the standards of your industry and application. For example, if your vacuum is meant to clean a large restaurant, it must meet the standards of the FDA.

Points to Consider When Selecting an Industrial Vacuum

- Power

- Check the power and performance of a vacuum system. The horsepower is not the true determinant of performance. Instead, factor in the airflow and water lift specifications. A vacuum with high airflow is better to capture powder-like substances with, like dry whey and flour. A vacuum with good water lift will effectively lift heavy pieces. It is used to collect cooking oil, water, and other heavier particles.

- Continuous Duty vs. Intermittent Duty

- Commonly, industrial vacuum cleaners are either continuous duty vacuums or intermittent. Continuous duty vacuums are better suited to picking up heavy debris, while intermittent duty vacuums are better for lighter workloads.

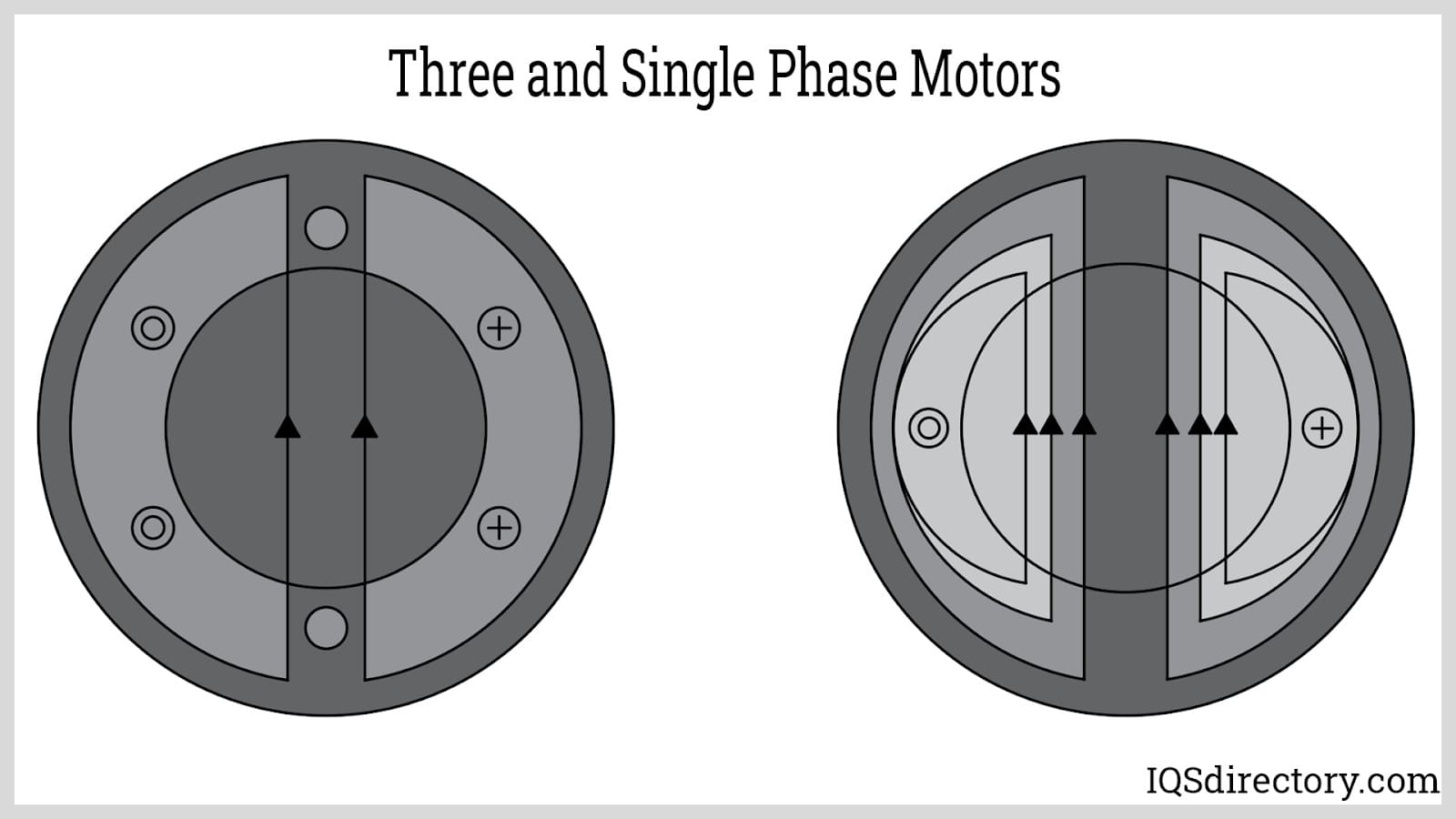

- Single-Stage vs. Multiple Stage

- Continuous three or two-phase units are the most efficient in demanding working conditions. They are also reliable and last long. A good single-phase power option works fine in less challenging conditions; however, they do not last as long. They only should be used for short periods of general cleanup.

- Central Vacuum Systems vs. Portable Vacuums

- If the facility needs regular cleaning in a specified area, it is better to install processing lines with a central vacuum system. A central vacuum helps to cut down the overall time needed to clean, as the waste is disposed of through the processing lines. It does not have any disposal bags or other carriages attached to the units; it consists simply of a suction unit with a connecting hose, which can be attached to various processing points during operation. However, if you need flexibility, you should choose a portable vacuum instead.

Choosing the Right Manufacturer

Look for the manufacturer that takes all of your requirements into consideration and strives to do the best work possible for you. Find that manufacturer by reaching out to one or more of the excellent companies we have listed near the top of this page. Be sure to give them all the details of your application so that they can accommodate your specific needs.

Vacuum Cleaner Images, Diagrams and Visual Concepts

A heavy duty piece of cleaning equipment to remove debris, industrial waste, and matter left behind.

A heavy duty piece of cleaning equipment to remove debris, industrial waste, and matter left behind.

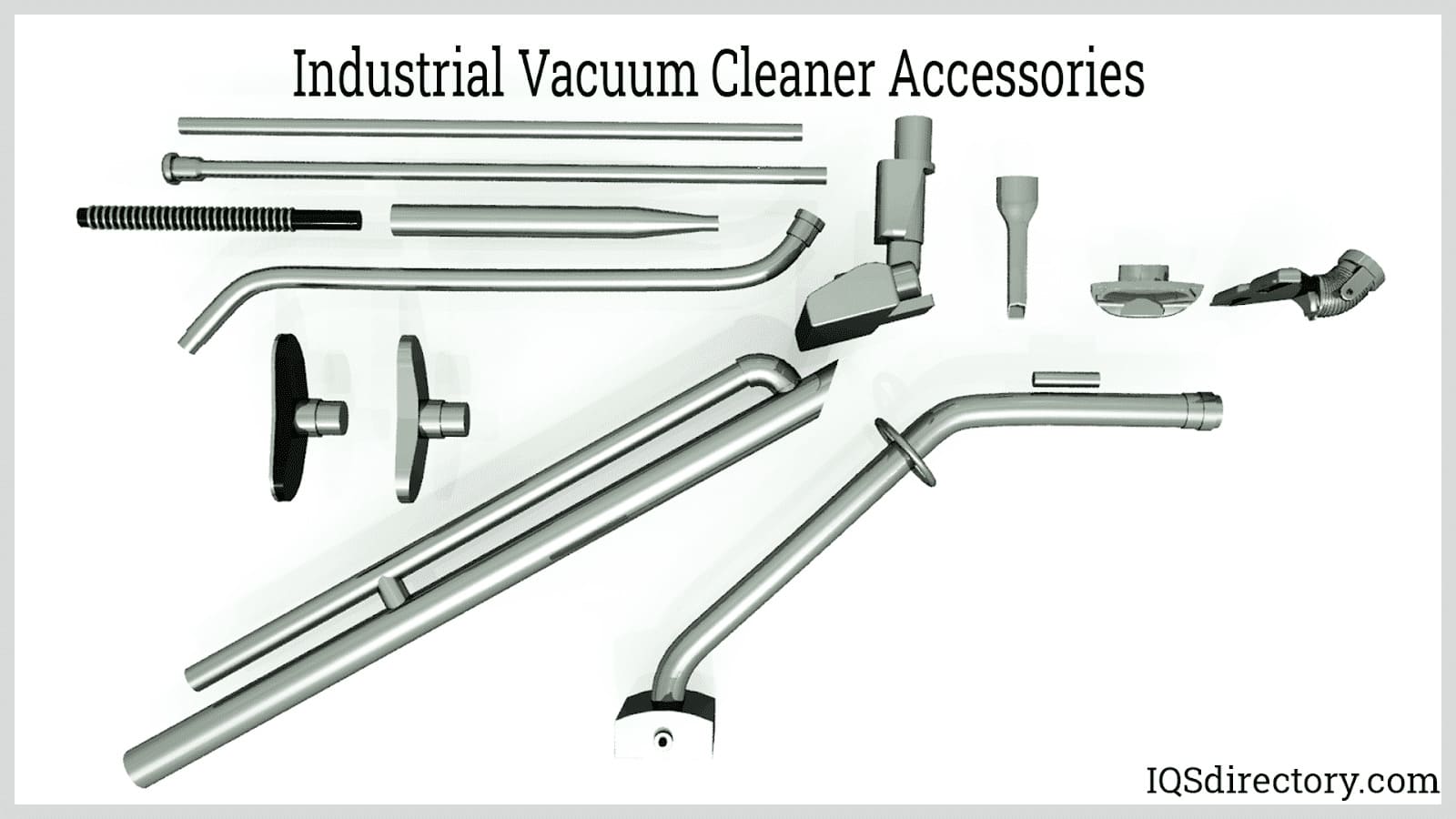

Accessories help adapt to fit the necessary working conditions.

Accessories help adapt to fit the necessary working conditions.

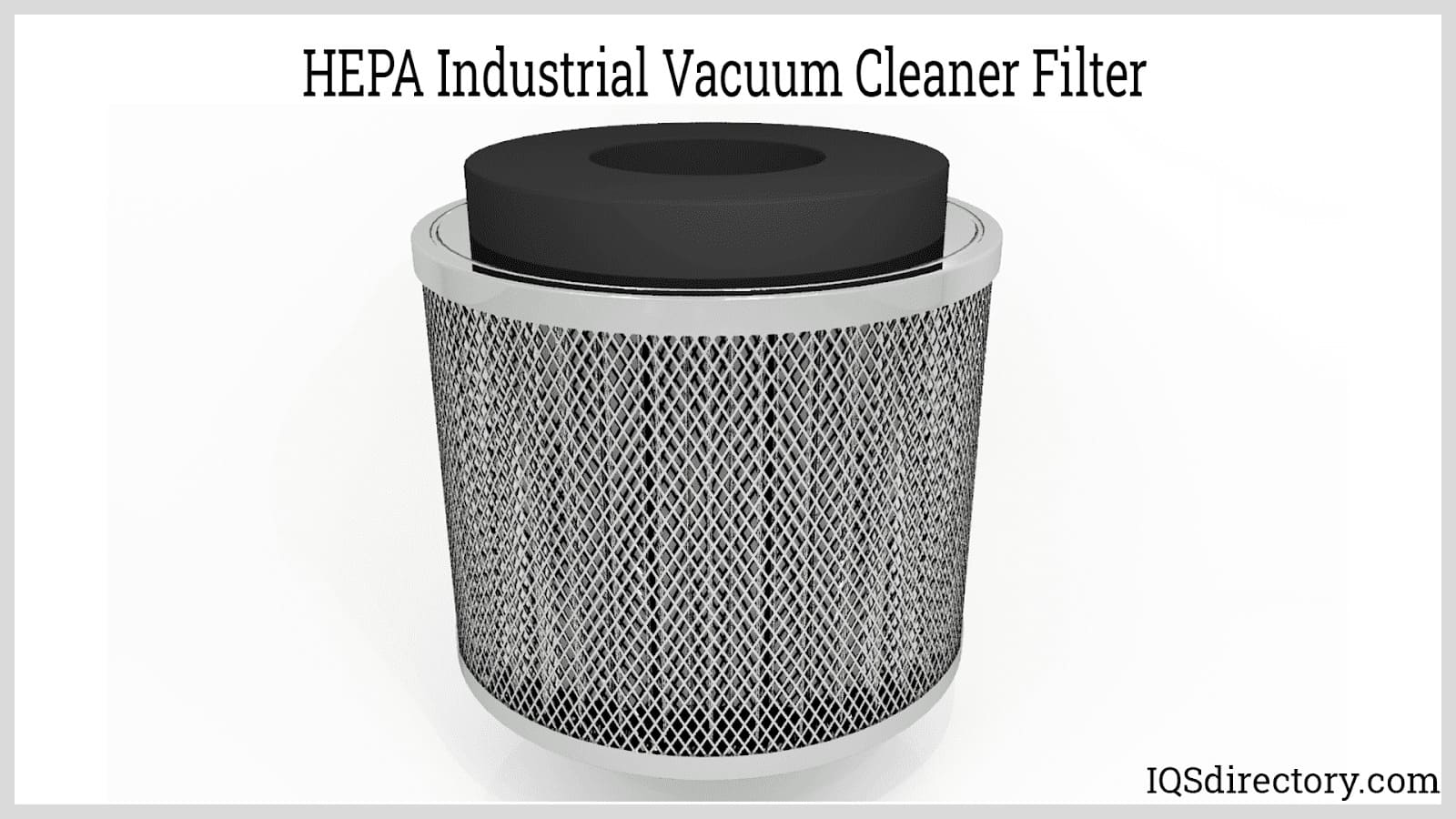

Filters out large particles into a collection unit and has an efficiency rating of 99.99%.

Filters out large particles into a collection unit and has an efficiency rating of 99.99%.

The two types of motors produce different outputs of power, with three phase motors being more powerful, while the single phase motor has a longer lifespan.

The two types of motors produce different outputs of power, with three phase motors being more powerful, while the single phase motor has a longer lifespan.

A vacuum system that is built into the building to provide an efficientive method for removing of debris.

A vacuum system that is built into the building to provide an efficientive method for removing of debris.

Designed to handle tougher cleaning tasks with resilient debris.

Designed to handle tougher cleaning tasks with resilient debris.

Vacuum Cleaner Types

- Auto Vacuums

- Designed to clean the interior and upholstery of automobiles. They are manufactured for general vehicle cleaning and use at automotive service centers and car washes. They may be portable or stationary. Like many other industrial vacuum cleaners, they have removable attachments that are designed specifically for their application. In this case, the attachments are designed to clean vehicle interiors.

- Backpack Vacuum Cleaners

- Machines worn on the back of the user. Backpack vacuum cleaners provide mobility along with higher cleaning capabilities for awkward areas such as stairways.

- Canister Cleaners

- Not the standard walk-behind units. They have wheels that allow the unit to be pulled behind the user as they walk with a separate suction attachment. These wheeled canisters house the suction motor and filtering system.

- Central Vacuums

- Vacuums to which networks of ducts are connected for use in large-scale cleaning operations. Central vacuum cleaners and central vacuum systems are used to tackle the cleaning of large buildings, such as college dorm halls or academic buildings. Typically, the motor and dirt filtration units are mounted in an outlying location, where they are connected to a series of ducts that are built into the building itself. To operate them, workers can connect hoses, pre-separators, tubing, and other vacuum attachments to the duct inlets dispersed intermittently around the building.

- Central Vacuum Systems

- Networks of ducts connected to a central vacuum for use in large-scale cleaning operations.

- Commercial Vacuum Cleaners

- Designed for use in commercial and industrial environments.

- Continuous Duty Vacuums

- Vacuums used for the constant cleaning of industrial workspaces.

- Explosion Proof Vacuums

- Industrial vacuums used in the vacuuming of materials that pose a fire or explosion risk. Explosion proof vacuums are also able to clean flammable liquids and other hazardous media, such as combustible dust, without sparking an explosion or fire.

- HEPA (High Efficiency Particulate Air) Filters

- Installed in industrial vacuum cleaners to act as secondary filters, removing any potentially harmful dust before it reaches the operator. They are also known as ultra-fine air filters.

- HEPA Vacuum Cleaners

- Use HEPA filters during the vacuuming process. These vacuums are used extensively in the food industry, where they remove ultrafine food dust from production lines and processing equipment, and rid pipes, walls, and beams of debris.

- Industrial Vacuum Cleaners

- Vacuum cleaners used exclusively in industrial contexts.

- Portable Vacuum Cleaners

- Portable cleaning machines that use vacuum suction for cleaning purposes that require both mobility and maneuverability.

- Rider Sweepers

- Similar to walk-behind sweepers. Rider sweepers are motorized and ridden by the user. They also have large storage tanks and a large cleaning capacity in terms of area.

- Small Vacuum Cleaners

- Vacuum cleaners that are used in light-duty vacuuming applications and are usually very portable.

- Truck Mounted Vacuum Cleaners

- Any vacuum cleaning machine mounted on the back of a truck. Vacuum trucks are specifically designed to load and carry bulk materials; loading involves the use of vacuum suction to move material from an area into a storage compartment on the truck.

- Vacuum Equipment

- All of the machinery and accessories related to vacuum cleaners.

- Walk-Behind Sweepers

- Machines used for cleaning large floor spaces. They can be used for hard or carpeted floors. They are battery or gas-operated and many of them have rechargeable batteries.

- Wet Dry Vacuums

- Specialized types of canister vacuums that can be used to clean up wet, or liquid, spills, as well as removing dry debris.

Vacuum Cleaner Terms

- Air Watts

- A specification that rates the output power of vacuum cleaners rather than their input power, as measured at the vacuum cleaner inlet by airflow suction. This is also referred to as “sucking power.”

- By-Pass

- A characteristic of vacuum motors air-cooled with a ventilator that is independent of the cleaning air. Usually found in either tangential exhaust systems or peripheral systems.

- Certified Energy Manager (CEM)

- An international professional designation available through training and testing by the Association of Energy Engineers (AEE).

- CFC (Chlorofluorocarbon)

- A family of chemicals used as refrigerants. They are tightly regulated and were phased out of production due to stratospheric ozone depletion potential. Examples: R-11, R-12, R-113, R-114, R-115.

- Clean-Air Design

- A design of a vacuum cleaner in which the filtering system cleans the dirt in the airflow before it goes through the fan or fans of the suction motor. This prevents damage to the fan that results from material carried by a dirty-air system and usually creates considerably more suction, particularly when a hose and attachments are used.

- Cyclonic Filters

- Cyclonic systems separate the dust particles from the airflow by spinning the air with a separation chamber. The spinning causes centrifugal force to move the dust particles outward while the air exits from the inner part of the chamber. Some cleaners utilize multiple chambers and most cleaners add filters to increase the total system filtration efficiency.

- Direct Air System

- A design of a vacuum cleaner that has the air carrying the dirt pass through the fan of the suction motor into the bag. Typically, this does not create as much suction with attachments; it creates more airflow when operating with big openings and short airflow distances.

- Dirty Air Design

- A design of a vacuum cleaner in which the airflow passes through the fan of the suction motor before it is cleaned by the filtering system.

- Electric Hoses

- A special type of vacuum cleaner hose with internal wires that carry electrical current to the power nozzle’s motor. These hoses reinforce the hose (though not always, as with crush resistant hoses).

- Electrostatic Filter

- A kind of filter media consisting of fine synthetic fibers on which a static electric charge builds as air passes through. The charge draws the smallest allergen and dust particles, helping the filter to retain them.

- Fan

- The fan or impeller that creates the suction necessary for the vacuum.

- Filtration Efficiency

- The percentage of particles retained by the primary filter as air passes through it. The efficiency increases as the size of the particles increase.

- HEPA (High Efficiency Particulate Air)

- A filtering efficiency specification whose purpose is to effectively remove radioactive dust from plant exhausts without redistribution. This filter must be able to capture 99.97% of all particles 0.3 mm (micrometers or microns) in size or larger from the air that goes through it.

- HEPA Type Filter

- A type of filter or paper bag that uses similar construction or fibers to that used in a true HEPA filter. While being a significant improvement over regular filters, the vacuum that uses it may not have a completely sealed filtration system, so there is no guarantee that the stringent HEPA specification will be met by it.

- Micron Filter

- A kind of filter able to capture micron-sized particles at an extremely high efficiency rate.

- Peripheral Exhaust

- The exhausting of cleaned air through many small openings on the vacuum motor perimeter.

- Resistance

- In regards to the airflow in a vacuum cleaner, resistance is the opposition to a passage of air.

- Spun Aluminum

- The molding of a flat aluminum disc to make a deep container from one piece of metal without soldering so that all parts made this way are free from air leaks and ensure the highest vacuum strength. This manufacturing process creates dust recovery tanks along with other vacuum equipment.

- Tangential Exhaust

- The exhausting of cleaned air through a single exit on the side of the motor.

- Thru-Flow

- A characteristic of certain vacuum motors in which the cleaning air flows through the casing to cool it.

- ULPA (Ultra Low Penetration Air)

- A filtering efficiency specification for filters utilized in environments that require the maximum degree of clean air (like pharmaceutical labs). Specifically, these filters must retain particles 0.12 mm or larger with the efficiency rating of 99.999%.

- Velocity of the Air Flow

- The speed of air at any given point in the vacuum cleaner system. It is the force of the air that collects the dirt and moves it into the bag or dirt receptacle.

- Water Lift

- In terms of vacuum cleaners, the water lift is a measurement of how high water is lifted by a vacuum hose attached to a tube placed in water.