Steel Service Centers

Steel service centers are the foundation of the steel industry and a necessary component of steel goods production. They typically buy metal from a metal foundry or another metal manufacturing plant, shape, and tool the metal into a usable form for the final customer, then resell it to specific industries.

Quick links to Steel Service Centers Information

History of Steel Service Centers

Steel service centers have been in operation in the United States since the early colonial period. At that time, steel service providers were called ironmongers. Ironmongers of the colonial age manufactured and sold iron products for domestic use. This term is still used in Great Britain, where it is now used as the equivalent to the American term hardware store. At that time, approximately 10% of all steel products channeled through service centers. Today, approximately 30% of our industrial steel products and 45% of our speciality steel products pass through service centers.

Steel Service Centers Benefits

Steel service centers offer many benefits to their customers. First, they take care of early steel processing. Second, they lift the burden of storing so much metal shaping and processing equipment in one location. With a steel service center, you save so much space that you can measure it by the square foot. By virtue of what they do, they offer great customer service. Also, because these steel service centers have an extensive inventory of steel always ready to process and ship, manufacturers save time and money because they do not have to worry about housing the steel themselves.

Seventy percent of steel purchased by steel service centers undergoes some type of pre-production processing. This allows metal manufacturing plants to focus purely on metal creation, while other factories and facilities can transform.

Design of Steel Service Centers

When designing a steel product or steel shape for a customer, service centers consider all aspects of the customer’s application. These aspects include: required level of finishing, required steel properties (strength, flexibility, hardness, ductility, etc.), request volume, customer budget and customer standard requirements.

Applications of Steel Service Centers

Service centers exist to support and assist metal manufacturing companies. They purchase various alloys of raw steel such as carbon steel, then process and treat them to fit the specific needs of their customers.

Many industries rely on steel service centers, including: construction, automotive manufacturing, electronics, shipbuilding and the aerospace industry.

Steel Service Centers Process

All steel servicing processes follow the same formula:

The service center buys steel material from a foundry or a wholesaler.

They shape/form the steel into a usable shape.

If necessary, they apply finishing processes to the shape.

Once it’s usable, they package and ship the steel to a buyer or store it until they get a request for it.

The exact metalworking process that servicers use depends on what they’re trying to make. We can divide the types of processes service centers perform into two main groups: metal forming and metal finishing.

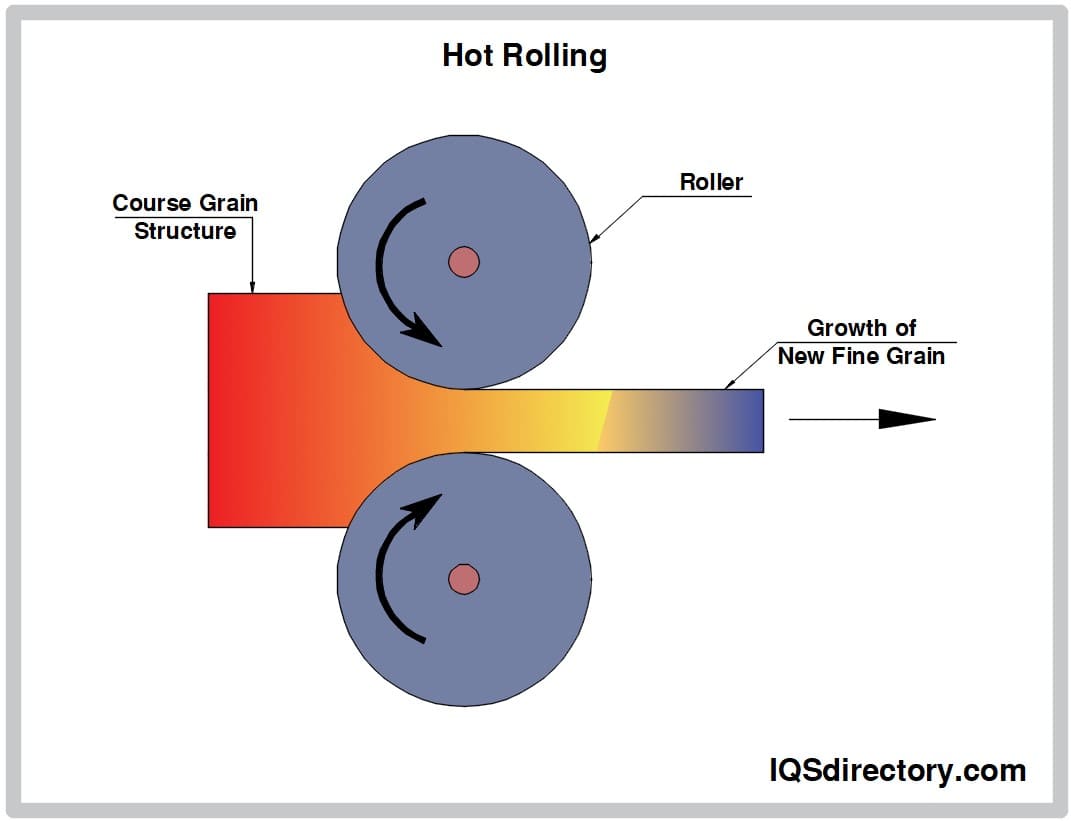

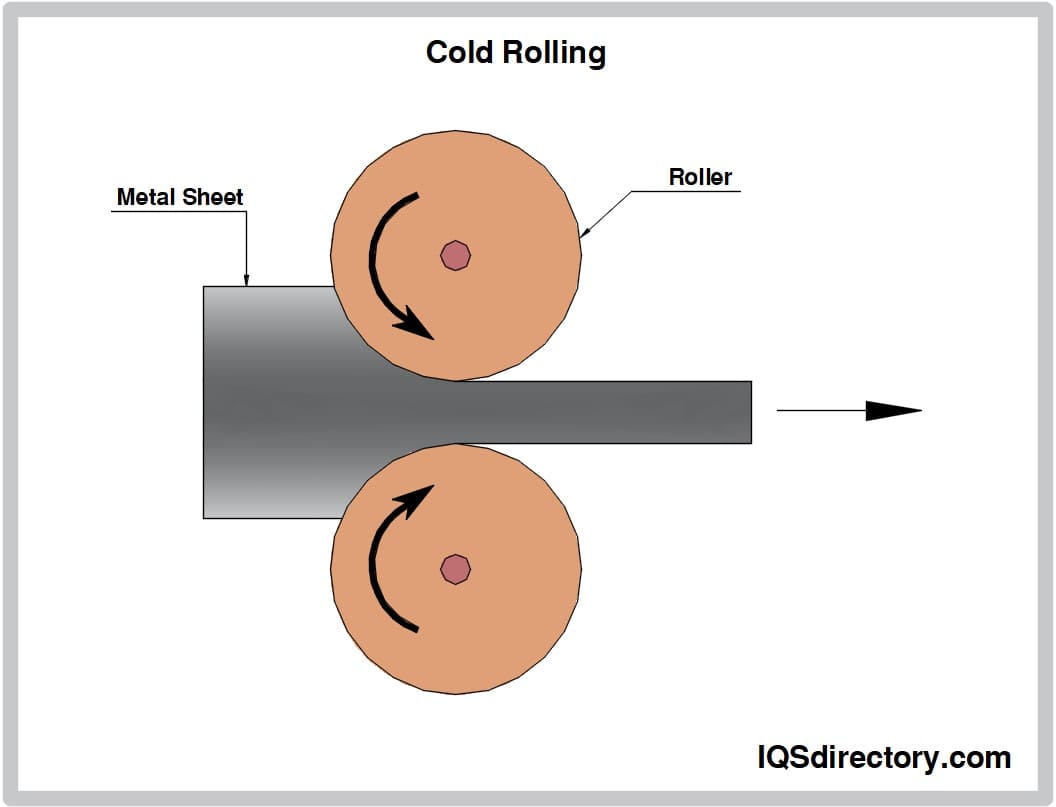

During forming, servicers change the form or shape of the metal. They will do this using processes like metal injection molding, metal casting, metal extrusion, metal spinning, metal stamping, continuous rolling and more. The two main processes steel service centers use, though, are hot rolling and cold rolling.

- Hot Rolling

- The main process that service providers use to shape steel is hot rolling. During this process, steel is heated past its recrystallization temperature, which is around 1650°F, and it is pushed through rollers. The steel becomes very pliable and easily movable when heated, and as it cools its surface may oxidize, causing it to become less smooth and to take on a blue-grey finish.

- Cold Rolling

- For steel that needs to be strong and has high structural integrity, steel service centers use cold rolling, which is done at or near room temperature. Because no heat is involved in this process, the risk of surface oxidation is eliminated. The shape range is very limited because the steel is not heated anywhere near its melting point.

- Metal Finishing

- During metal forming, servicers seek to alter the state of the metal’s surface. They do this using processes like galvanization, coating, aluminization, oil quenching, air hardening, tempering, heat treating, andoziation and alloying, among others.

- Galvanization

- Articles are coated with one or more layers of zinc to improve strength and corrosion resistance. They are used in industrial, commercial and domestic applications where steel parts are exposed to corrosive materials or are in high use.

- Coating

- Refer to various processes that are used to apply a thin layer of material onto another material, which is often referred to as the substrate. The primary two reasons to coat a substrate are: 1) to protect the substrate from environmental conditions, corrosion and wear-and-tear, 2) or give any desired aesthetic characteristics such as color, tint, scent, and texture to the substrate that it does not already possess.

- Aluminization

- A cost-saving procedure during which cold-rolled carbon steel is hot-dipped in molten aluminum-silicon alloy. The alloy coats both sides of the sheet of metal. Aluminized steel has the lower cost and lighter weight of steel as well as the rust-resistant, conductive and smooth finish properties of aluminum.

- Quenching

- Involves immersing the steel in cold water or oil to cool it. HSLA is alloyed with many metals, including copper, silicon, nickel chromium, and phosphorus, for greater resistance to corrosion.

- Anodization

- Used to increase the wear resistance, corrosion resistance and general hardness of a metal surface. It involves electrolytic passivation.

- Alloying

- During alloying, steelworkers add different materials to raw steel to change its properties. For example, to increase strength, they may add columbium, copper, vanadium, and/or titanium in small quantities. Note: More alloying elements typically increase material production and costs.

Materials Used in Steel Service Centers

Service centers offer a wide variety of steel types to meet manufacturer needs, including:

- Alloy Steel

- Contains elements other than carbon such as chromium, manganese, et cetera. Alloy steels have a higher tensile strength, corrosion and oxidation resistance and ductility than carbon steel does.

- Aluminum Steel

- A metal sheet that has been coated with an aluminum alloy.

- Aluminized Steel

- Steel that has been hot-dip-coated with an aluminum-silicon alloy, and takes on properties of both high strength aluminum and high strength steel. The steel has the lower cost and lighter weight of steel as well as the rust-resistant, conductive properties and smooth finish of aluminum.

- Carbon Steel

- An iron and carbon alloy featuring carbon as its second largest component. Depending on how much is present, the carbon imparts hardness and strength in varying degrees.

- Cold Rolled Steel

- Steel that has been shaped without the application of heat. Cold roll steel has a smooth surface texture and is common in light-duty furniture and objects not needing the strength required of structural steel.

- High-Strength Steel

- Also known as High Strength Low Alloy (HSLA) commonly refers to all steel other than mild low-carbon steel. HSLA is alloyed with a number of metals, including copper, silicon, nickel chromium and phosphorus, for greater resistance to corrosion. Also, columbium, copper, vanadium and titanium can be added in small quantities for strengthening. More alloying elements typically increase material production and costs. It is known for its structural integrity, high carbon, and lighter weight.

- Hot Rolled Steel

- Undergoes a process involving large pieces of steel that are heated above their recrystallization temperature and pushed between a set of rollers to form thin, pliable sheets, which exhibit heavy thickness, high strength levels, and good formability.

- Spring Steel

- A low alloy, medium carbon steel with a high yield strength. It is made of silicone, and therefore has elastomeric properties—it can bend and stretch, then return to its normal state. For higher temperature resistance, steel servicers may add materials like nickel or cobalt. Spring steel is an adequate choice for manufacturers who need a strong, heat and abrasion resistant metal to make tools or the molds for plastic injection molding.

- Stainless Steel

- Also referred to as "chromium steel," is the most common type of steel manufactured by steel service centers. This corrosion resistant material is the preferred choice for the food and medical industries.

- Structural Steel

- Also referred to as "plate steel," is low carbon steel containing manganese, which is commonly used in the engineering and construction industry for the production of buildings, bridges and transportation equipment. Structural steel has been hot rolled, often has a rough surface texture and includes steel beams.

- Tool Steel

- Consists of iron and alloys of chromium and other elements to improve steel properties, such as corrosion resistance. Tool steel is used in the production of hand and power tools.

Steel Service Center Images, Diagrams and Visual Concepts

Hot-rolled steels, when steel is pressed at a high temperature which recrystallizes the steel to easily form steel into various products.

Hot-rolled steels, when steel is pressed at a high temperature which recrystallizes the steel to easily form steel into various products.

Cold rolling is the process of feeding and compressing hot rolled steel strips between rollers, which makes the steel thinner.

Cold rolling is the process of feeding and compressing hot rolled steel strips between rollers, which makes the steel thinner.

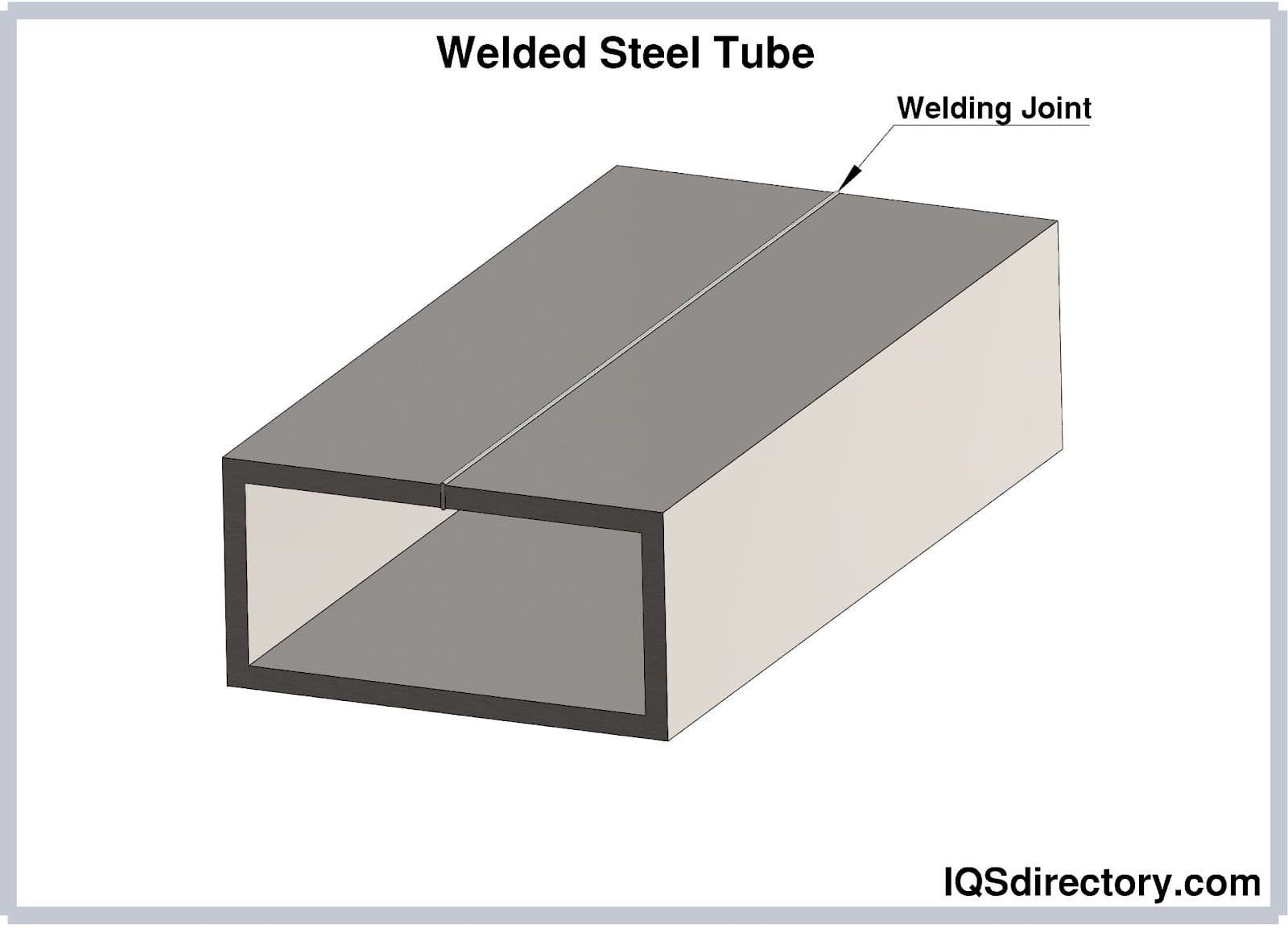

A welded tube is manufactured by forming strips or sheets of steel into tubes and welding them longitudinally.

A welded tube is manufactured by forming strips or sheets of steel into tubes and welding them longitudinally.

A seamless tube s manufactured by an extrusion process rather then welding them.

A seamless tube s manufactured by an extrusion process rather then welding them.

Steel plates are manufactured by flat rolling and is further processed to create new products.

Steel plates are manufactured by flat rolling and is further processed to create new products.

Steel beams are steel parts used to support heavy structures and secure them for harsh weather conditions.

Steel beams are steel parts used to support heavy structures and secure them for harsh weather conditions.

Products of Steel Service Centers

In addition to steel materials, some of the many important steel products processed in steel service centers include:

- Plate Armor

- Steel that has been flat-rolled commonly used in construction and engineering. Plate armor maintains a certain amount of thickness (based on plate width).

- Steel Beams

- Used in the construction and engineering industries. Because they can support great amounts of force and weight without bending, they are key players in the construction of large structures, such as buildings and structural plate bridges.

- Steel Pipes

- Round structures used mostly to transport fluids and to provide structural support to bridges, buildings, and stairs. Steel pipes maintain high strength and uniform thickness during rough industrial applications.

- Steel Strips

- Very thin flat-rolled steel sheets used mostly in trim applications for the construction industry.

- Steel Plates

- Flat rolled and made of stainless steel. Steel plate is available as a hot rolled plate or cold rolled plate.

- Steel Tubing

- And conduits, which provide support to railing, ladders, poles and exercise equipment. They also provide strong protection to conductors and wiring.

- Structural Steel

- A hot-rolled low carbon steel, containing manganese. It is commonly used in the engineering and construction industries to produce buildings, bridges and transportation equipment. Steel beams qualify as a type of structural steel.

Standards and Specifications for Steel Service Centers

In 1909, a nonprofit trade association, Metals Service Center Institute (MSCI), was established and was subsequently known as American Steel Warehouse Association, then Steel Service Center Institute. The organization's 400 members are metal service centers operating from 1,500 locations primarily in North America that inventory and distribute metals for industrial customers and perform first-stage processing. MSCI members purchase about 75 million tons of steel, aluminum, and other metals from metals producers. They are purchased by MSCI members with 300,000 customers primarily in manufacturing and fabrication.

Every steel product passing through a steel service center or steel company must be approved by the American Society for Testing and Materials (ASTM) , a non-profit organization dedicated to setting strict standards and ensuring the quality of products, materials systems, and services, including all steel products, processes, and materials.

The ASTM's annually-updated book of standards covers steel pipes, tubes, and fittings, steel plates, steel for machine structural use and steel for special purposes. More recently, the ASTM has developed new standards for annealed steel conductors. By combining the standards of annealed copper clad steel wire and hard drawn concentric-lay-stranded copper clad steel conductors, ASTM will raise awareness about copper clad steel as an alternative to solid copper, increasing its production within steel service centers.

Things to Consider When Choosing a Steel Service Center

IQS Directory provides an extensive list of steel service center companies. Utilize our website to review and source steel service centers with our easy-to-use features, which allow you to locate steel service centers that will provide steel processing services for your exact specifications.

Our request for quote forms makes it easy to connect with leading steel service centers. View company profiles, website links, locations, phone number, product videos, customer reviews, product-specific news articles and other production information. We are a leading manufacturer directory who will connect you with the right manufacturers whether you are looking for steel services, steel service tubing, or metal service centers.

Steel Service Center Terms

- Air Hardening

- Also called "self-hardening," it is steel that is hardened through air cooling to reduce possible deformation.

- Bloom

- A semi-finished steel form with a rectangular cross-section that is more than 8". This large cast steel shape is broken down in the mill to produce the familiar I beams, H beams and sheet piling.

- Carburizing

- The application of carbon to a low-carbon steel surface to increase the strength of the steel. Carburizing is achieved through heating the steel in a substance containing carbon, followed by hardening the steel through heating and quenching the steel.

- Casting

- A method of steel formation in which a part is formed by the shaping of a molten material in a mold; it is commonly used for more specific parts. Casting is not used for the general production of steel types.

- Composite

- A solid material that consists of a combination of two or more constituents in which the individual components retain their separate identities.

- Case

- Surface of steel that has a different composition than the original makeup resulting from the application at elevated temperatures of carbon, nitrogen or another element.

- Case Hardening

- Steel treatment resulting in a steel surface hardness greater than that of the internal region of the steel.

- Cold Working

- Metal deformation process in which the metal is subjected to temperatures low enough to prevent re-crystallization of the metal during cooling.

- Core

- The internal region of a steel part that remains unaffected by case hardening.

- Decarburization

- The process whereby steel loses carbon from the steel surface layer due to contact with a chemical substance. Decarburization reduces steel hardness and strength.

- Ductility

- The ability of steel to accept deformation without fracturing. Ductility is a notable benefit of alloy steel.

- Edge Rolling

- The rolling of the edge of steel to smooth edges, which would be damaging or minimize functionality of a piece.

- Hot Rolling

- A steel production process in which steel is heated, pressed and shaped into the required form.

- I-Beams

- steel beams shaped like majuscule letter I’s that are used in construction.

- Normalizing

- Steel heat treatment performed to refine grain size and to alleviate stress in the interior by heating the steel to temperatures ranging from approximately 800°C to 900°C (1472°-1652°F) and air cooling the steel.

- Quenching

- Rapidly cooling a metal from a high temperature.

- Secondary Steel

- Steel rejected by the first customer due to flaws, at which point the steel manufacturer or steel company must find another buyer.

- Steamless Tubing

- Tubing is used to move fluids or to protect electrical wires and cables housed within it. There are many different kinds of tubing and methods for manufacturing tubing. One of these types of tubing is called seamless tubing, where extrusion or rotary piercing is used during the production process. A seamless pipe is created by drawing a solid billet over a piercing rod to create a hollow shell. Most seamless tubing is pulled through a die that reduces its diameter in the final stages of manufacturing.

- Specialty Steel

- A class of steels including stainless, tool, alloy and silicon electrical steels, as opposed to carbon steel.

- Tensile Strength

- The extent to which steel or another substance can accept bending or stretching without fracturing.

- Yield Stress

- The applied stress at which irreversible plastic deformation is first observed across the sample is called the yield stress, usually represented as sy.