Pressure Vessels

Pressure vessels, often referred to as air pressure tanks, are used for the storage and containment of fluids, vapors or gases at pressure levels greater than that of atmospheric pressure. They are designed to operate at pressures more than 15 psi, and are made of a variety of metals, high-strength plastic or fiberglass. The tanks are usually cylindrical in shape with a horizontal or vertical orientation.

Quick links to Pressure Vessels Information

The History of Pressure Vessels

Pressure vessels, as we know them, have been in use since the 1800s, when they were used to generate steam. However, the first documented pressure vessel was described by da Vinci in 1495, in the book Codex Madrid I. There, he described an idea for pressurized containers of air that could lift weights underwater.

The early pressure vessel, unfortunately, was quite dangerous. This was largely due to a combination of poor material quality and inadequate knowledge of the perils of pressurized substances. Sadly, during those days, pressure vessel and boiler explosions killed and maimed people in the United States on a regular, if not daily, basis. For that reason, local governments began drafting construction laws. Finally, in 1914, engineers released the first pressure vessel safety code, the ASME Boiler and Pressure Vessel Code.

After that, engineers began a concentrated effort to come up with safer vessels. In 1919, they designed a model with higher pressure capacities, reinforced steel wire sidewalls and longitudinally reinforced end caps. Later, they began welding vessels instead of joining them with rivets, which made them more stable. Between the 1920s and 1930s, welding became the industry construction standard, and it remains so to this day.

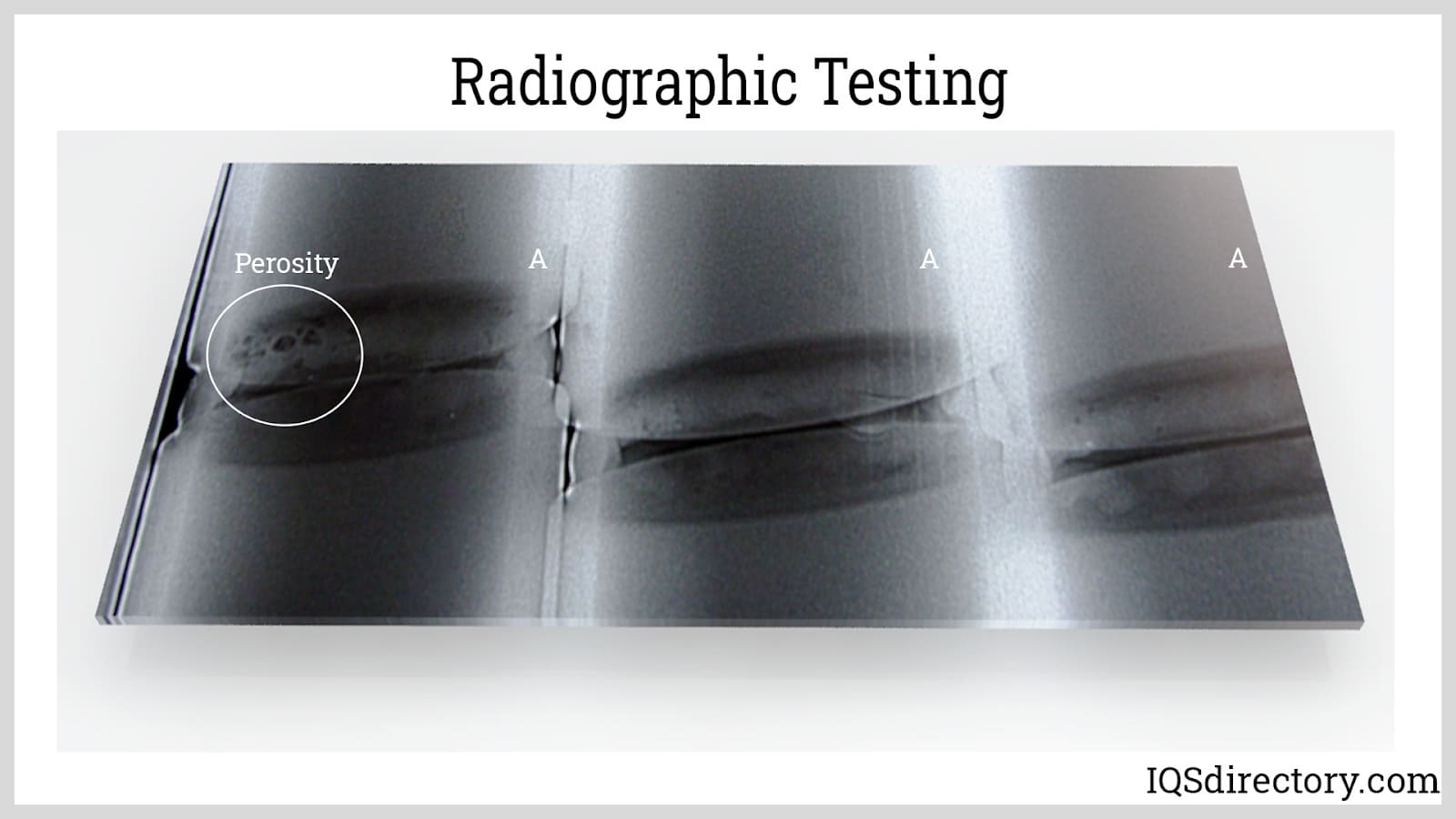

Today, thanks to advances like non-destructive examination, radiography, phased ultrasonic testing, new material grades and new ways to join materials (like explosion welding), pressure vessel engineering and operation is much more reliable and safe.

Pressure Vessels Benefits

Pressure vessels are specially designed containers for gases and liquids. It holds gases or liquid at a pressure significantly greater than the atmospheric pressures. A standard pressure vessel can endure pressure greater than 15 psi. However, based on the need, vessels can be made to withstand pressure up to 10,000 psi.

How Pressure Vessels Work

In different applications, the pressure in a pressure vessel is achieved either from a direct source or an indirect one by heat transfer. More precisely, pressurization is normally controlled via a series of valves and release gauges. Using these, operators can get pressure to reach the levels they need for their application, whether that be forcing water into a building or keeping air viable in diving cylinders.

Pressure Vessels Images, Diagrams and Visual Concepts

Pressure vessels are sealed containers used to store liquids, vapors, or gasses at greater pressure or less pressure than the surrounding atmosphere.

Pressure vessels are sealed containers used to store liquids, vapors, or gasses at greater pressure or less pressure than the surrounding atmosphere.

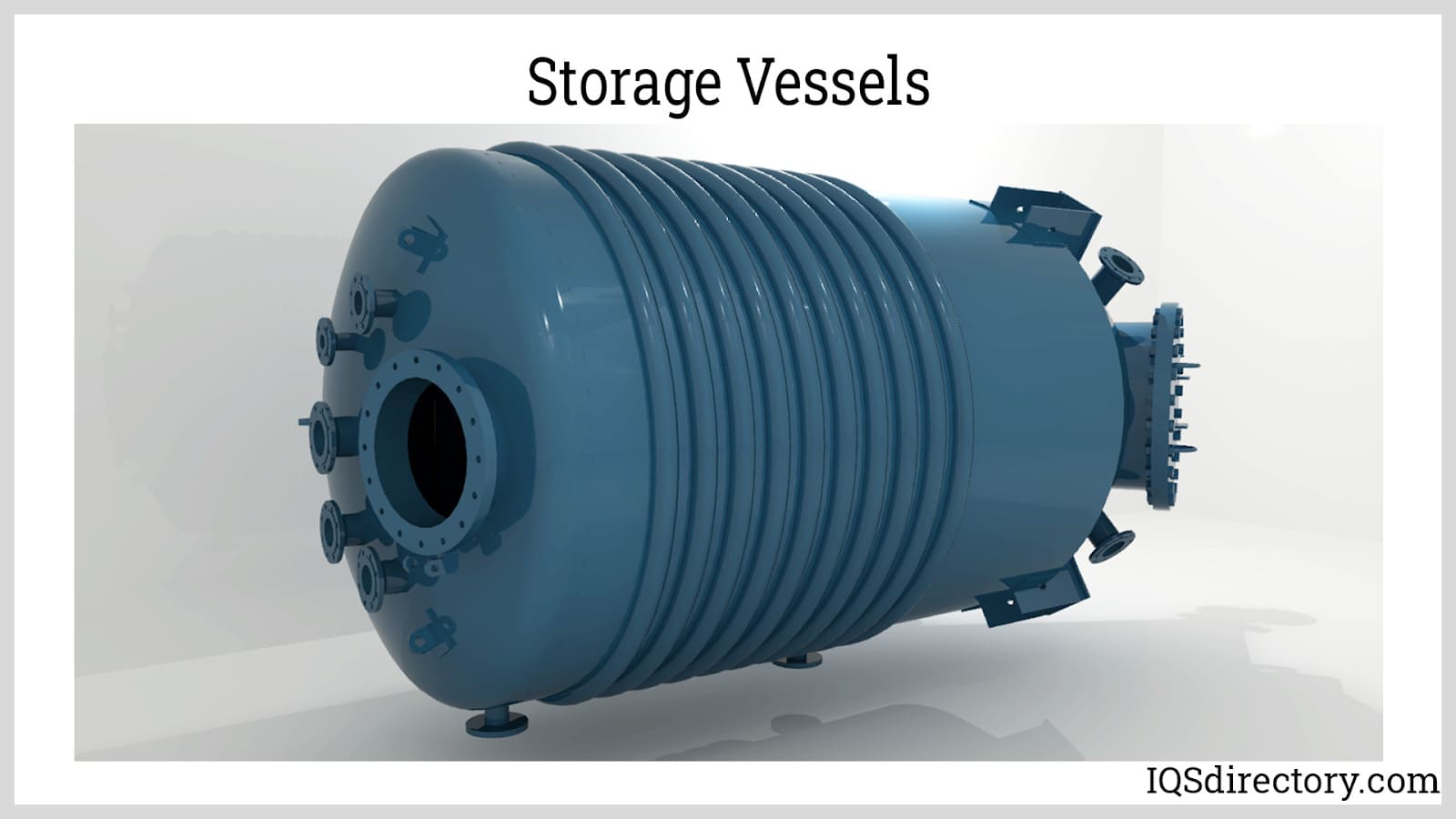

An example of pressure vessels are storage vessels which holds liquids, vapors, or gases as either a finsihed product or for later processing.

An example of pressure vessels are storage vessels which holds liquids, vapors, or gases as either a finsihed product or for later processing.

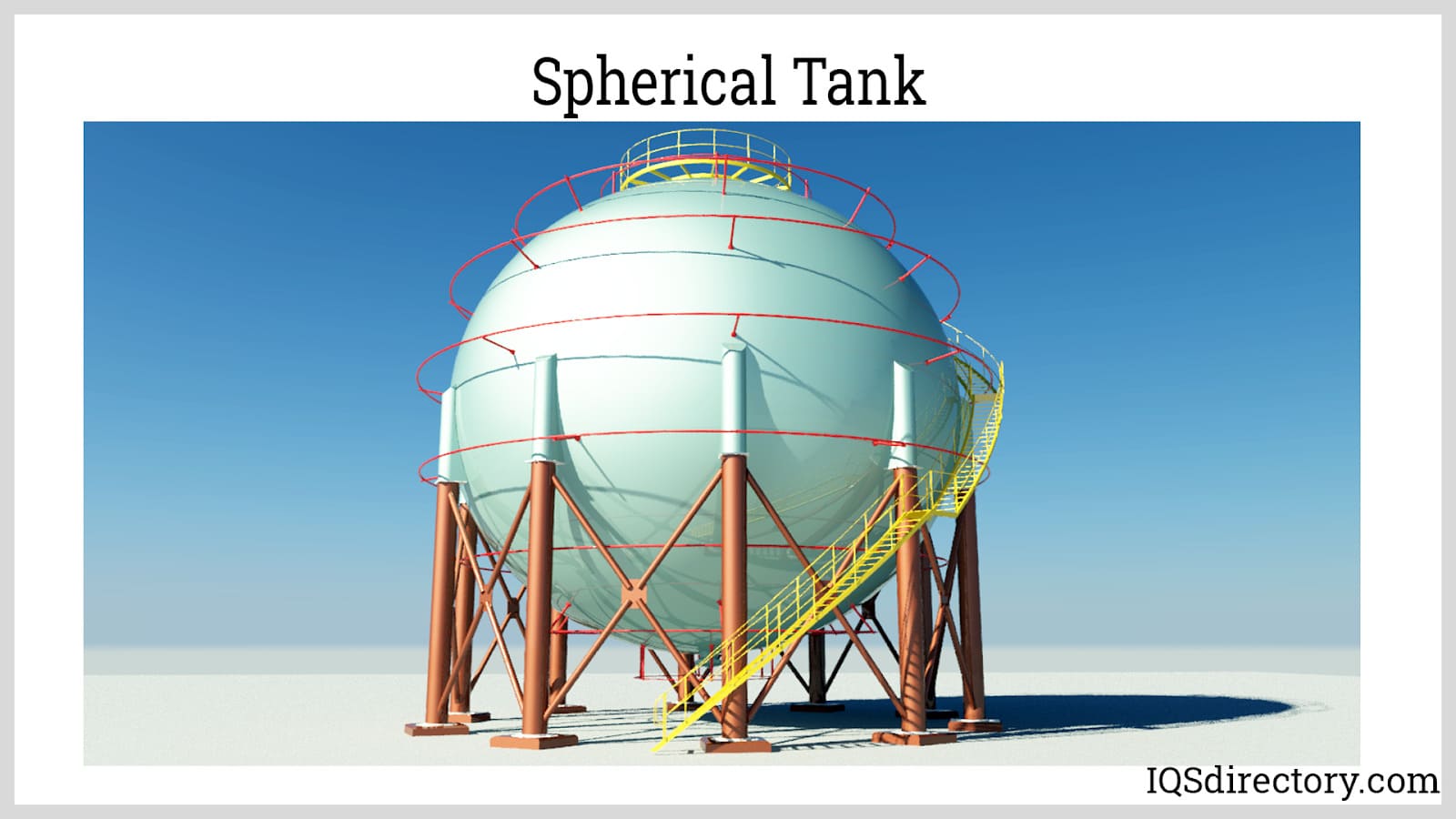

Spherical pressure vessels evenly distributes pressure both internally and externally in the sphere.

Spherical pressure vessels evenly distributes pressure both internally and externally in the sphere.

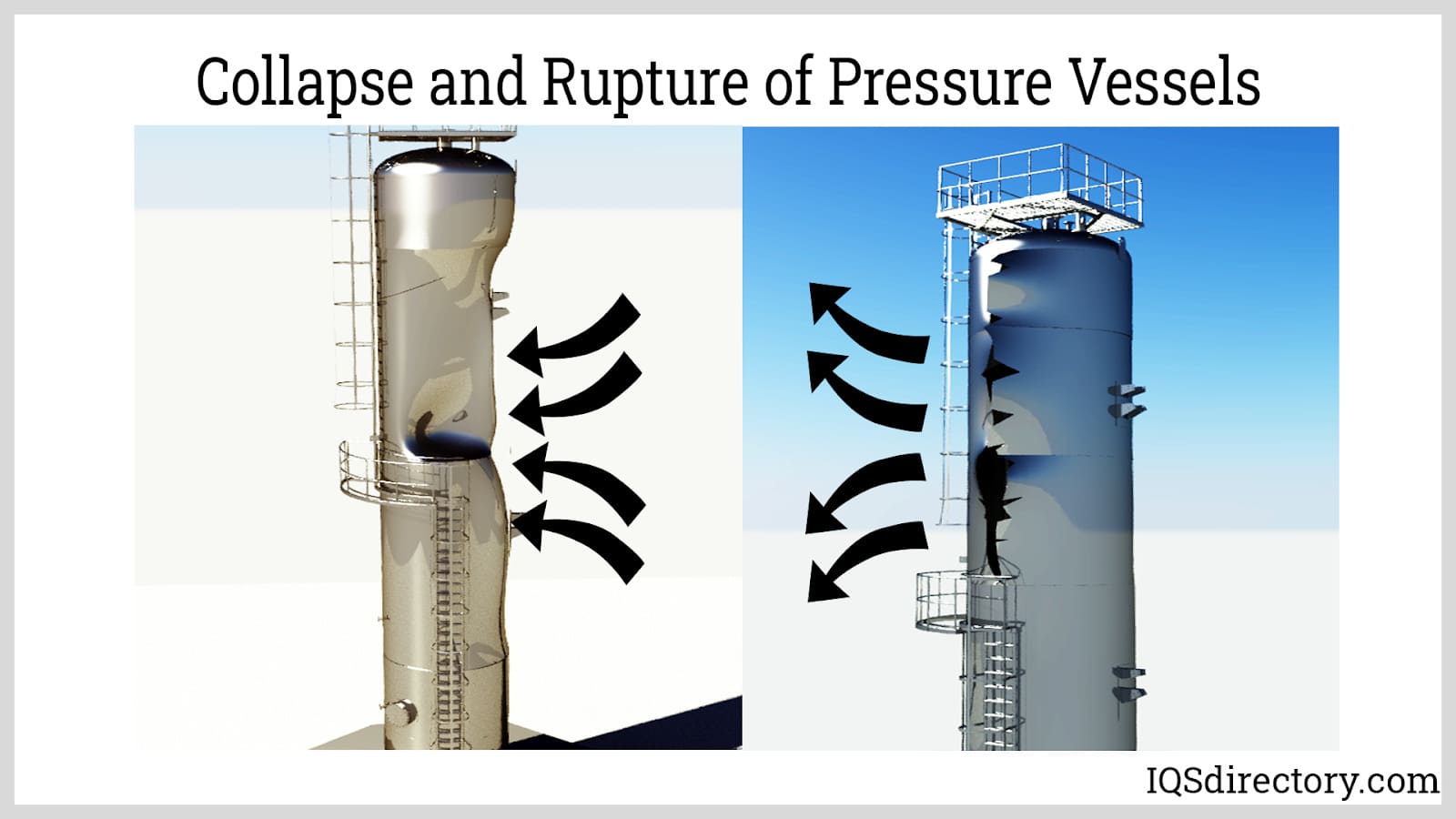

When the pressure exceeds the maximum tolerance safety concerns and damage to the vessels are more likely to occur.

When the pressure exceeds the maximum tolerance safety concerns and damage to the vessels are more likely to occur.

Utilizes x-rays to produce an image of a pressure vessel‘s surface and subsurface, which can detect discontinuities, holes, and difference in density of the vessel.

Utilizes x-rays to produce an image of a pressure vessel‘s surface and subsurface, which can detect discontinuities, holes, and difference in density of the vessel.

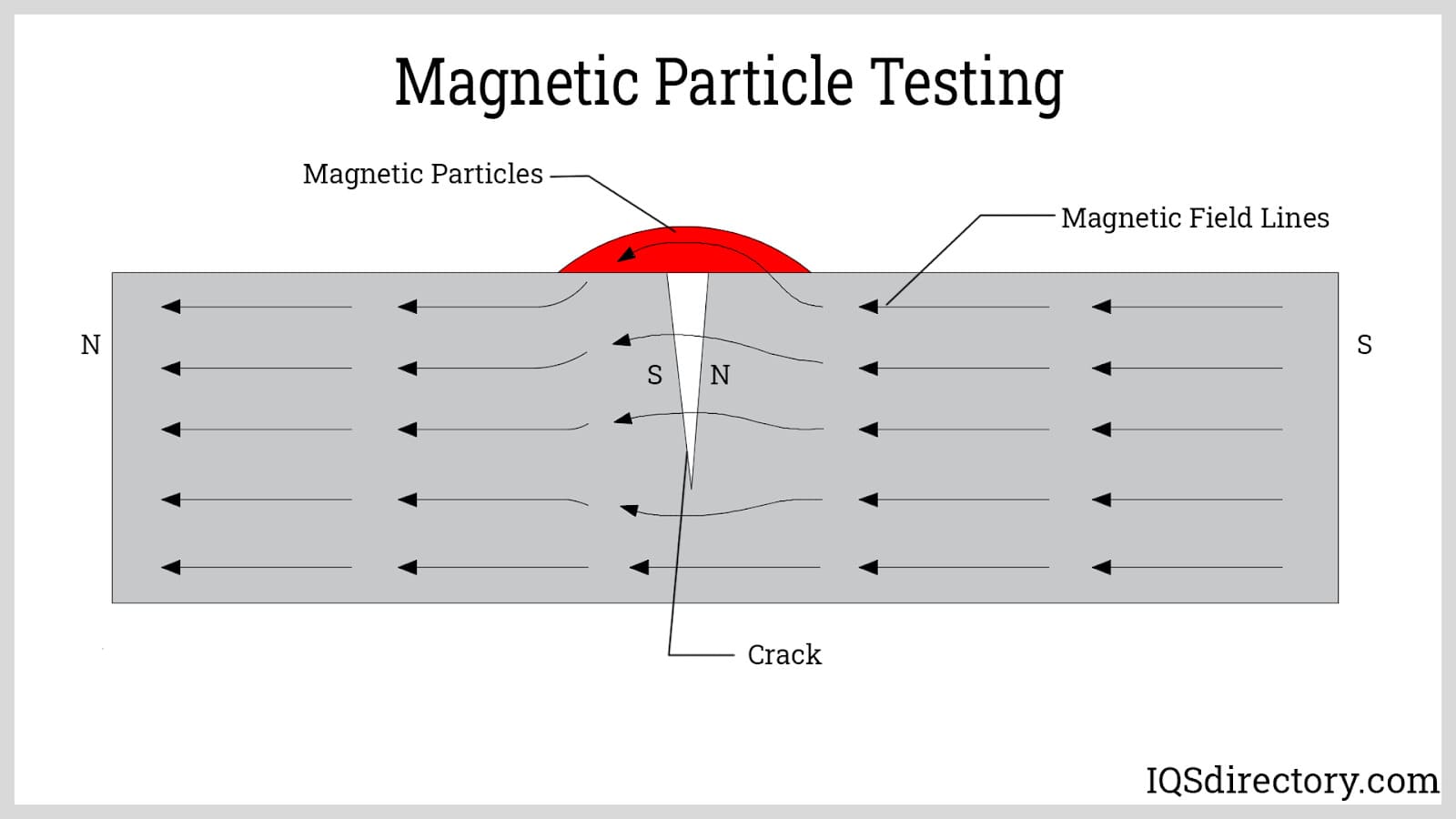

A magnetic current detect any discontinuities on the surface if any imperfections are present, the magnetic instability leaks out of the material.

A magnetic current detect any discontinuities on the surface if any imperfections are present, the magnetic instability leaks out of the material.

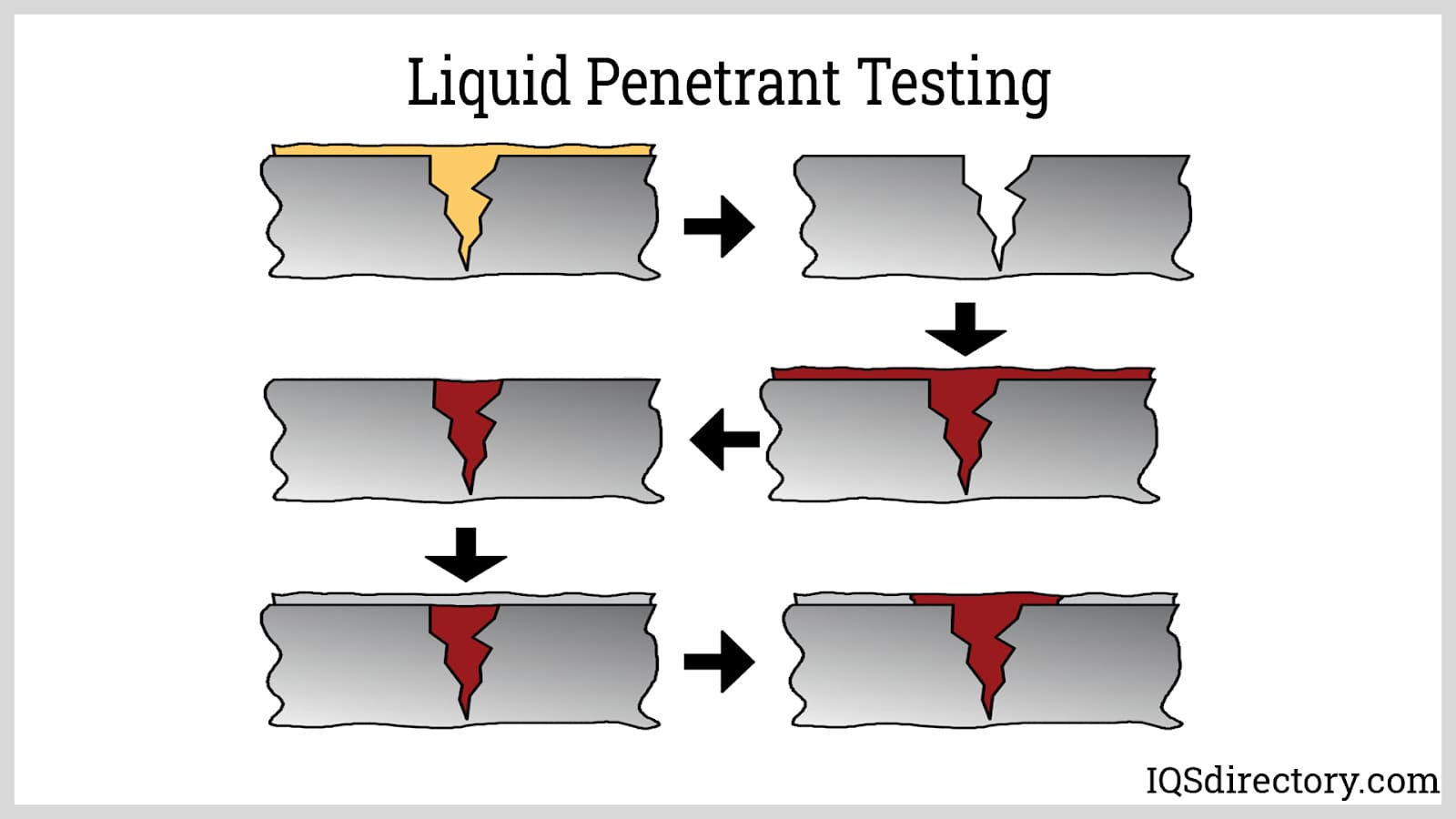

A small amount of liquid, called the penetrant, to an area with a possible flaw, then allowed to settle after spraying and then wiped to clean on the surface, if the penetrant has seeped into the cracks, which revels the imperfection.

A small amount of liquid, called the penetrant, to an area with a possible flaw, then allowed to settle after spraying and then wiped to clean on the surface, if the penetrant has seeped into the cracks, which revels the imperfection.

Types of Pressure Vessels

- Autoclave

- Like grease kettles use steam and pressure to cause chemical reactions producing many different substances, including food, lubricants and chemicals, and process tanks are designed to hold and store liquids.

- High Pressure Vessel

- The strongest type of pressure tank, and are used with the highest psi. They are typically stainless steel vessels, which provide the best resistance to pressure, temperature and corrosion.

- While many pressure vessels are used in manufacturing facilities to produce substances, others are used in different applications such as: expansion tanks and heat exchangers found in every residential closed water heating system, water pressure tanks as part of wells, and vacuum tanks as an integral component in sewage applications. These vessels are mostly used to store substances short term.

- Spherical Pressure Vessel

- When a high-performance pressure vessel is required, a spherical vessel can be appropriate, as the shape is roughly twice as strong as a cylindrical pressure vessel. However, only a small number of gas containers are made in the shape of a sphere due to their complex manufacturing, which escalates the construction cost.

- Thin-Walled Pressure Vessel

- Any pressure vessel can be labeled with this design name if they have a cylinder [shell] ratio that is 10% or less of the ratio of the thickness to the diameter. In other words, pressure vessels with the thin-wall design have a diameter that is 10 times or more than that of the thickness.

- Unfired Pressure Vessel

- This vessel design is not exposed to direct heat. Instead, it channels heat generated via electric heat or steam, and, occasionally, through the chemical reaction of vessel contents. Examples of unfired pressure vessels include: air tanks, digesters, steam-jacketed kettles and vulcanizers.

- ASME Boiler/ASME Pressure Vessel

- Every ASME pressure vessel has a stamp of ASME that helps in tracing the manufacturer; it also provides other information related to the vessel. You can call a vessel an ASME vessel if it has received the proper inspection and the ASME stamp.

- Cookers

- Are a type of pressure vessel that are used to bring about a physical change in their contents. Examples of this are digesters, vulcanizers and rendering tanks.

- Fired Pressure Vessels

- Utilize fuel combustion to generate heat. Examples include boilers, furnaces, gas water heaters and autoclaves.

- Heat Exchangers

- Include a variety of configurations of vessel equipment in which heating or cooling is performed on one side of the vessel and the opposite conversion on the other side.

- Kettles

- Are pressure vessels that use steam to heat fluids.

- Pressure Tanks

- Are vessels that hold contents at pressure levels greater than atmospheric pressure.

- Rotating Pressure Vessels

- Usually contains steam, which is then used to dry articles such as paper, fabric or plastics. The materials are passed over the rotating vessel via rollers to come into direct contact with the emitting steam.

- Steam Jacketed Vessels

- Are used to heat liquid to a moderate degree. Steam is distributed between the inner and outer shells of the vessel and is used in the commercial preparation of foods such as candy.

- Storage Vessels

- Include air tanks, hot water tanks, propane or other gas tanks, which contain contents under pressure when needed.

- Thick Walled Pressure

- Vessels are the least common. They are any cylinder [shell] ratio that is 10% or more the ratio of the thickness to the inside diameter.

- Thin Walled Pressure Vessels

- Are one of the most common of the vessels. They are any cylinder [shell] ratio which is 10% or less of the ratio of the thickness to the diameter, or a pressure vessel is thin walled if the diameter is 10-times or more of the thickness.

- Transportable Vessels

- Are in contrast to those that are stationary. Examples of such are those are road or rail tankers; propane and gas tanks are considered to be in this category.

Equipment Components

Pressure vessels are typically equipped with many different components, such as ladders, stairs, removable or detachable lids, sight glass for observation, heating and cooling systems, and propellers or agitation systems for mixing applications.

Other than those features, all vessels are equipped with safety valve fittings that do not allow pressure to exceed the predetermined level. Commonly, the safety valves in question are based on the pressure relief valve. This type of valve sets off when the pressure exceeds the limits and it automatically releases the contained material. This small feature has saved many lives over the years, making pressure vessels safe for a range of roles, such as water pressure tank, mixer, air pressure tank, vacuum tank, storage tank and heat exchanger units.

Applications of Pressure Vessels

Pressure vessels contain a wide variety of substances and can be designed with specific purposes in mind. They are used for various industrial applications within the chemical, petrochemical, aerospace, laboratory, pharmaceutical, food and beverage, oil and fuel and plastics industries.

Their wide range of applications include: compressed gas (ex. oxygen or nitrogen) storage tanks, laboratory autoclaves, hydro-pneumatic tanks and refrigerant vessels. They can be found in oil refineries, petrochemical plants, mining, submarines, and nuclear reactors, among other settings. Airplanes are a unique example of pressure vessels; the entire structure of a plane is a pressure vessel, both enduring the cabin pressure and maneuvering load of the aircraft.

Vessel Materials and Customization

The materials used to create pressure vessels must be high strength and durable, and able to maintain their shape and properties even under pressure. Common materials include carbon alloy steel, stainless steel, titanium, zirconium, aluminum, nickel alloys and niobium. Pressure vessels may also be made from composite materials or concrete material.

To help them bring their design to life before manufacturing, many manufacturers design pressure valves using computer-aided design (CAD) programs. Whether they use one of these programs, or draft their design by hand, when mapping out their plans for pressure vessels, manufacturers consider a few key elements, as they relate to the vessel application and the substance contained in the vessel. These include: vessel material, lining material, vessel thickness, shape, and manufacturing process.

- Steel in Vessels

- Typically, pressure vessels are manufactured from carbon steel; however, when the application is demanding, manufacturers use better versions of steel, such as hardened steel and stainless steel. When pressure vessels are used in a cold environment, steel is required to have high impact resistance. In facilities where the environment is corrosive, corrosion resistant steel, such as stainless steel, is used for making vessels.

- Composite Materials

- When very high pressure is not involved in an application, manufacturers turn to composite materials like carbon fiber. Composite pressure vessels are made by a fabrication technique called filament technique, in which filaments are wounded on a metal liner. Vessels made with this technique have high tensile strength but are lighter. However, the process is complex, and thus can be expensive. Polymers like polyethylene terephthalate (PET) are also used for making carbonated containers.

- Concrete in Pressure Vessels

- Pressure vessels can also be made from materials that are weak in tension, such as polished concrete veneer. To reinforce the structure, cables are wounded around the structure or within the wall of the vessels.

- Lining Material

- The lining material of the vessels is important, as it endures a portion of the pressure and helps in making the structure leak proof. Many materials, such as polymers, ceramics, and even metals, can be used for lining pressure vessels.

- Wall Thickness

- According to a mandate, the thickness of pressure vessels should be proportional to the radius and pressure of the vessel. Moreover, the thickness of the wall should be inversely proportional to construction materials' normal stress. A pressure vessel that has such properties will have enough tensile strength to hold gases effectively. This is a basic relationship. Based on this relationship, for different applications, the wall thickness of a vessel scales with the radius of the tank, and similarly, the mass of the vessel scales with the volume a gas occupies in a vessel. However, the relationship varies with the shape of a vessel, which, based on the requirements, can be spherical, cylindrical, or conical.

- Shape of Pressure Vessels

- Manufacturers can fabricate a pressure vessel of practically any shape. Most often though, pressure vessels are made into cylinders, cones, or spheres, as these shapes withstand pressure more efficiently than rectangular or square shapes. The most common pressure vessel shape design consists of a cylinder with hemispherical end caps as heads. Also common are cylinders with torispherical head domes.

- With cylindrical pressure vessels with caps on each end, the cylindrical part is typically made from a pipe. Even larger cylindrical vessels that have a diameter of, for example, 600 mm, are made from seamless pipe, so they are stronger and need inspection less often. However, they are more expensive.

- For different shapes, there is a different formula to calculate the mass of a vessel, and there are other factors too that should be considered, such as density of the pressure material, maximum shear stress that can be allowed, and pressure and volume of a vessel.

- Manufacturing Processes

- Engineers usually create vessels using one of three manufacturing processes: forging, welding and brazing, all of which involve heating pieces of metal and joining them together. Forging refers to the formation of metal parts through the application of heat and pressure. Welding involves melting two similar metals together by heating their edges until molten. Finally, during the brazing process, metals are joined by filling the space between them with a non-ferrous metal.

- In addition, most of the cylindrical and spherical parts are made from cold rolled metal, as cold rolling creates a stronger metal than hot rolling. Pressure vessels are also often galvanized, quenched or tempered to increase temperature resistance and tensile strength.

- Customization of Vessels

- Using these same considerations, as well as corrosion resistance and vessel abrasion potential, engineers can customize: pressure vessel shape, size, material, pressure capacity and temperature capacity. Pressure vessel manufacturers fabricate a range of pressure vessels; from a few hundred pounds per square inch (psi) to measuring up to 150,000 psi.

Safety and Compliance Standards for Pressure Vessels

Many tanks are required to be registered ASME pressure vessels and to adhere to strict safety and quality standards put forth by the American Society of Mechanical Engineers. This includes ASME Section VIII code, or the Boiler and Pressure Vessel Code (BPVC), upon which American engineers must base their designs. Certified ASME tanks are important because due to the nature of pressure vessels, even the tiniest stress or leak can cause a major explosion or shrapnel damage.

All pressure vessels are designed by following a "leak before burst" philosophy. This design allows them to crack under higher operating stress, in order to allow gases and fluid to leak out. This way, pressure vessel blasts, which have taken many lives in the past, can be avoided. Under pressure vessels standardizing agency codes, including ASME code, pressure vessels are required to leak before blast.

Although the ASME code remains the most common standard code, engineers also follow other code sets, such as those of the American Petroleum Institute (API), National Board of Boiler and Pressure Vessel Inspectors (NBIC) and the American Institute of Aeronautics and Astronautics (AIAA). Rigorous analyses for complex pressure vessels are created when standard design rules do not apply. In such instances, engineers conduct intensive mathematical and scientific analyses to ensure design and construction methods meet the stringent requirements of pressure vessels.

Also, different authorities across the world govern the operation, manufacturing, design and inspection of pressure vessels. As many authorities and legislations are involved in pressure vessels at the global level, the code that defines a pressure vessel and the parameters for its safe operation vary from region to region. Make sure that your pressure vessel is up to code for your region.

Note: While testing and certification approval ensure that your initial vessel design is sound and your vessel itself is healthy, it’s also very important that you inspect your vessel regularly. Regular post-purchase inspection is a way for you to know for sure that your vessel continues to meet industrial standards and safety requirements.

Other safety inspection tests and standards adherence inspection tests that your pressure vessel manufacturer can conduct include: leak and strength tests (hydrostatic, pneumatic, vacuum, radiography, ultrasonic wave, and magnetic practice tests).

Things to Consider When Purchasing Pressure Vessels

Pressure vessels are very sensitive equipment; for not only the success of your application, but the safety of you and your staff, you must select yours very carefully. To help you make an informed decision, we’ve provided a list of suppliers that we trust near the top of this page. Find the right manufacturer for you by perusing their websites and reaching out to a few in whom you’re interested. Talk to them about your specifications, your timeline, your budget and your standards and restrictions. Make sure they’re willing to conduct the necessary inspection procedures. Compare and contrast what the suppliers say to you, and pick out one to do your vessel design based on not only who is the most skilled, but who offers the best customer service. Remember, you can’t go wrong with a talented supplier that wants the best for you.

Pressure Vessel Terms

- Agitator

- Device used for agitation of the product or substance found inside a pressure vessel.

- Atmospheric Pressure

- The amount of force the atmosphere exerts upon the earth's surface, measuring 14.7 psi at sea level.

- Baffle

- Primarily used in pressure vessels with agitators. Commonly used to increase the amount of agitation or mixing.

- Boiler

- Pressure vessel that heats water and creates and heats using combustible fuels or energy.

- Brittle Fracture

- Fracture of steel associated with exposure to very low temperatures often in circumstances in which stress levels have not exceeded yield strength.

- Corrosion Allowance

- An increase in pressure vessel shell thickness designed to compensate for the corrosion and abrasion of certain pressure vessels; protective coatings and linings are also added to pressure vessels to prevent corrosion.

- Creep

- Permanent deformation of steel caused by strength reduction resulting from exposure to high temperatures.

- Cryogenic Temperatures

- Extremely low temperatures, ranging from -250° C to -100° C (-418° F to -148° F).

- Design Pressure

- The maximum internal and external pressure limits that a pressure vessel can withstand, usually equivalent to 110% of pressure vessel operating pressure.

- Design Temperature

- The temperature of the pressure vessel metal when the vessel is subjected to the design pressure.

- Dewar

- Pressure vessel created to sustain cryogenic temperatures.

- Ferrule

- A nozzle made for sanitary and low pressure applications. A ferrule contains an inset gasket surface and is designed to work with clamps instead of bolting.

- Fluid

- Any substance, whether liquid, gas or vapor, in which the particles move freely, resulting in no permanent shape and low resistance to pressure.

- Fusible Plugs

- Pressure relief mechanisms initiated with rapid pressure increases resulting from a fire.

- Heat Transfer Surface (HTS)

- Broad terminology for providing a pressure vessel or pressure tank with a means of temperature control.

- Hydropneumatic Tanks

- Pressure vessels in which both liquids and gases are collected.

- Hydrostatic Test

- Test in which pressure vessels are subjected to 150% of the design pressure.

- ID (Inside Diameter)

- Diameter of the pressure vessels measured from the interior of the pressure vessels surfaces. This dimension does not include the material thickness.

- Lifting Lugs

- Lugs attached to the outside of the pressure vessels specifically placed to help aid lifting of the pressure vessels.

- Manway

- Access port to the internal region of the pressure vessels.

- Megapascal

- Unit of measurement equal to 1,000,000 pascals, used to express tensile strength and yield strength.

- National Board Inspection Code

- Worldwide standard for pressure vessel inspection, alteration and repair.

- Newton

- Unit of force producing an acceleration rate of one meter per second per second on a one-kilogram mass.

- Nozzle

- The spout through which fluid is released from or introduced into pressure vessels.

- Operating Pressure

- The pressure at which pressure vessels operate while in use.

- Pascal

- Unit of pressure measurement equal to a Newton per square meter.

- Psi (Pounds per Square Inch)

- Unit that measures the amount of pressure applied to an object.

- Relief Valve

- Pressure relief mechanism that automatically releases liquids from pressure vessels when vessel pressure exceeds set pressure, and closes when the pressure level returns to normal.

- Rupture Disks

- Pressure relief mechanism designed for single usage that instantly relieves pressure in a pressure vessel. These can be used in conjunction with other pressure relief mechanisms.

- Safety Relief Valve

- Pressure relief mechanism that automatically releases liquid and vapor streams from pressure vessels when vessel pressure exceeds set pressure, and closes when the pressure level returns to normal.

- Safety Valve

- Pressure relief mechanism that automatically releases gases and vapors from pressure vessels when vessel pressure exceeds set pressure, and closes when the pressure level returns to normal.

- Set Pressure

- The predetermined pressure at which a pressure relief device begins to discharge fluid.

- Straight Flange

- Small, cylindrical pressure vessel component consisting of a bolted rim connected to the body of the pressure vessel.

- Strain

- The change in an object's dimensions, resulting from the application of force.

- Stress

- The force responsible for causing a change in an object's dimensions.

- Stress Corrosion Cracking

- Fracture resulting from the combination of corrosion and tensile stress.

- Tensile Strength

- The maximum stress level exerted upon a test specimen before the specimen fractures.

- Tensile Stress

- The force applied to a test specimen to produce strain.

- Vessel Heads

- The end of a pressure vessel, including flanged and dished, ellipsoidal, flat, conical and hemispherical.

- Vessel Shell

- The pressure vessel body.

- Yield Strength

- Amount of stress producing an inelastic strain in a pressure vessel. Exceeding the yield strength can result in permanent deformation of the vessel.