Palletizers

Palletizers are materials handling machines used for the loading and unloading of pallets before and after shipping as well as during storage. Pallet loads are frequently used for mass shipping and distribution as a convenient means of consolidating many smaller units into one larger, more easily handled unit.

Many manufacturing and distribution plants use automated palletizers, palletizing systems and robotic palletizers for pallet loading and unloading. Automated conveyor palletizers may be low-level palletizers, which load packaged units from a floor level, or they may be high level palletizers, which move packaged units on an elevated platform. Palletizing Machines may be designed to handle a single type of product, such as bag palletizers, case palletizers, drum palletizers and bottle palletizers, or they may handle several different types of packages. Large-scale distribution centers and manufacturing facilities that handle incoming shipments often use depalletizers to unload packaged units, and palletizing equipment accessories such as pallet dispensers and load transfer stations are used to assist in managing both pallets and loads. Palletizers can also be referred to as case pickers; the terms "case picking" and "palletizing" are used interchangeably by some professionals, though case picking often refers strictly to the picking of individual products by warehouse staff in distribution operations.

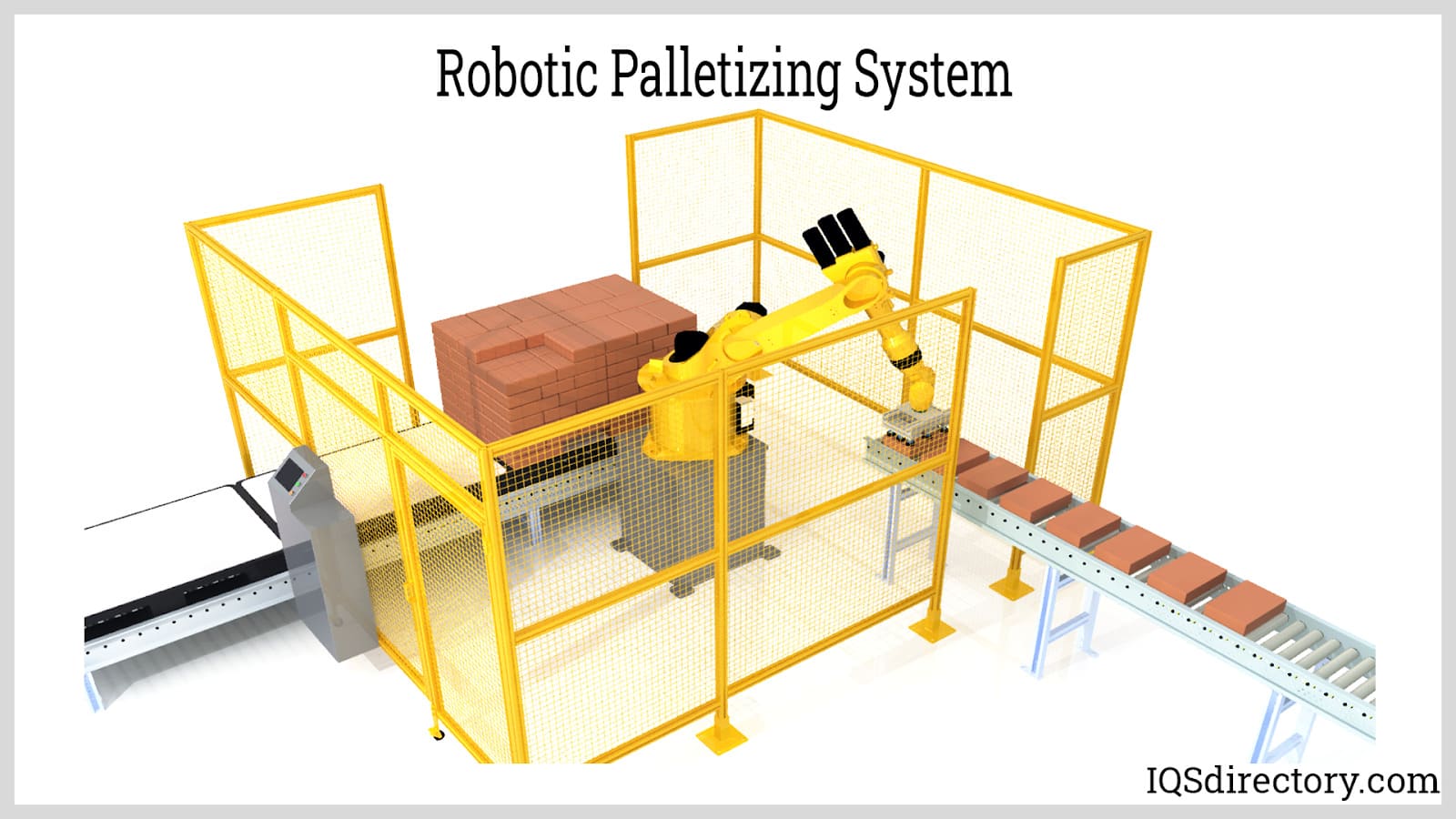

There are three main types of palletizers: robotic palletizers, low level palletizers and high level palletizers. Robotic palletizers are typically stationed between a conveyor line of incoming product units and a pallet dispenser. A hydraulic robotic arm lifts cases, bottles, bags or drums using flat pincer arms or suction cup arms in organized rows onto a pallet, stacking units with extreme precision. Robotic palletizers may be altered to work with different types of product units and are excellent for handling fragile or heavy product units. Even though they can only move one object at a time, they are still dramatically faster than human loaders and can load without becoming fatigued or injured. Low level and high level palletizers are conveyorized palletizers with a feed area that receives the goods that are to be palletized. In low level palletizers, which are also sometimes called floor-entry palletizers, products are loaded from the ground level, while high level palletizers are loaded from above. The packaged units are received by roller conveyors and are continuously transferred and sorted to the pallets by automated conveyor rollers, allowing greater packaging speed than robotic palletizers. Low and high level conveyors may be fully automatic, requiring no manual involvement, or they may be semi automatic, requiring loads to be manually connected and disconnected from the palletizer lifting arm.

Robotic and automatic palletizers have many advantages over manual pallet loading, including precision, load stability and a contribution to a reduction in worker injury frequency. Palletizing units can work faster and have better consistency than a human operator. The repeated lifting, rotating, wrenching and other strenuous movements that palletizers can sustain with ease can cause injury to human workers. Reduced employee injury risk contributes to a more pleasant work environment, which in turn contributes to higher productivity and efficiency. Also, a lower number of employee injuries reduces workplace health coverage costs. The United States Occupational Safety and Health Administration has proposed stiff fines for companies that do not make adequate provisions for employee well being, and many companies look for creative ways to minimize hazards beyond the standard put forth by agencies like OSHA. Palletizers are an investment in productivity and employee safety. Many varieties are equipped with QuickSTOP collision sensors and Smartscan work cell perimeter guards. QuickSTOP sensors are installed on palletizers to detect equipment damage. Upon detection of such damage, the machine would shut itself down, preventing additional damage or product loss. Smartscan systems are used to detect the proximity of humans to palletizer equipment. If a human worker gets too close to a palletizer, Smartscan-equipped machines will automatically turn themselves off in order to prevent employee injury.

Palletizers’ automation is the key factor in their contribution to operational efficiency and safety. A properly chosen, installed and maintained palletizer can spark a dramatic increase in productivity. Also, the kinds of product losses that are caused by human materials handling accidents are eliminated when palletizer systems are employed instead. A palletizer can move more quickly and more regularly than can a human with a manual pallet jack or forklift. Palletizers do not become distracted, and the precise repeatability of their motion guarantees consistent, careful loading and unloading of palletized materials. While the initial investment in a palletizing machine can be expensive, many operations recoup that investment many times over during the course of a palletizer’s lifespan. Workplace injuries can be extremely expensive, depending on the nature of the injury; palletizers, by precluding the possibility for such injuries, contribute to healthier and therefore more productive workplaces.

Quick links to Palletizers Information

The History of Palletizers

Cases have been stacked by hand since the advent of the first production lines. However, the increase in production rates to levels of about 20 or more cases per minute necessitated the use of automatic stacking means. This need was addressed by use of a palletizer.

The first automatic palletizer was designed and built by Lamson Corp in 1948. Lamson was later bought by ARPAC, a company that now produces both mechanical and robotic palletizing machines. They produce complete end-of-line packaging equipment systems.

In 1950, row-forming automatic palletizers were introduced into industries and warehouses. Pallet loads were created by having goods arranged into a row-forming area and then they were pushed into a layer forming area. The palletizer repeated the process until a complete layer of goods was formed. The layer of goods was then placed into a pallet when full until the pallet was complete at which point it was removed and another pallet brought.

In 1970, the demand for high speed pushed palletizer manufacturers to design in-line, continuous motion palletizers. These machines use a continuous motion flow to guide the product into the desired location on the layer forming segment. When the layer is complete, it is placed into a pallet.

A robotic palletizer was introduced in the 1980s. These machines use an end-of-arm gripper or tool to pick goods from a layer table or conveyor and place them on a pallet. Both the conventional and the robotic machines are used for goods at a high elevation, up to 124 inches or a low floor level up to 36 inches.

Palletizer Advantages and Disadvantages

- Palletizer Advantages

- With the increasing need of cutting cost and processing time in manufacturing, automation has been incorporated in almost every stage of manufacturing. Whether it is feeding, washing, assembling or packing, there are a myriad of machines that have automated and work with minimal assistance from operators.

- In the packing field that involves selecting, transporting, orienting, counting and stacking, machines called palletizers can automate the process, making it faster and more efficient. Palletizers are also called load transfer stations and pallet stackers.

- In the primary efforts to make palletizing easy, the palletizing equipment was designed with lifts and platen. Lifts make it easy for loaders to elevate the station up to conveyor belt height, whereas platen helps to rotate the palletizing station manually to work on different angles. The table helps to cut bending motion and work laterally, which reduces injuries caused by repeated motion.

- Palletizer Disadvantages

- However, palletizers are far more complex than palletizing equipment, doing a number of functions ranging from metering the incoming load, orientation of load, dispensing pallet, forming layers and many more.

- Based on the level at which feeding is done, palletizers are divided as floor level in-feed and high level in-feed.

Conventional and Robotic Palletizers

Numbers of palletizers have filled the market, ranging from conventional conveyor-based to sophisticated robotic palletizers. However, all have some disadvantages associated with them. Therefore, to overcome the shortcomings, hybrid palletizers are designed, which combine the high rate of stacking of conventional designs with the flexibility of robotic designs. The design effectively takes the best from both designs and provides an option that can palletize multiple loads at once.

Hybrid designs can easily handle the finished products from numbers of production lines and still take less space than the alternatives. They are designed in such a way that it can be fitted with additional palletizing equipment if needed, and they give buyers the option to upgrade even after installation.

In general, three types of hybrid palletizers are available: shuttle cars, rotary tables, and robotic arms.

- Shuttle Cars

- In shuttle car design, shuttle cars, which move with the help of a track or chain-type conveyor, carry the pallets and are employed at a layer forming section. Instead of letting a product flow into the system and be oriented individually, hybrid palletizers aggregate the products, and when enough products are accumulated, it is fed into the layer forming section, where a layer is formed. Once the layer is formed, it is moved to the pallet, just like the conventional machines. As one pallet is filled, another takes its space as they move along the tracks. Pallet Dispensers repeatedly feed shuttles with empty pallets as they move into the layer forming section; the automation makes the job faster and more efficient. Similarly, a loaded pallet is transported to the unload area on a conveyor. For monitoring and metering purposes, a bar code reader is utilized.

- Rotary Tables

- This type of hybrid palletizer works almost similar to the shuttle car design. The only difference is the presence of rotating tables instead of shuttles that move on chains or tracks. This design does not have any apparent advantage over shuttle car design; however, some buyers choose rotary tables based on the type of case to be handled.

- Robotic Arms

- This type of palletizer hybridizes the shuttle design and single robotic arm operation. A robotic arm with three jointed points picks and stacks in tandem with shuttle cars. Just like the shuttle system, the cases accumulate on the in feeding conveyor, and the robotic arm picks and stacks the cases based on the programming. A bar code helps the arm to read different cases and stack them on the empty pallet affixed on shuttles. Tie and slip sheets are also accessed by the robotic arm when needed. The design has flexibility of robotic operation and the speed of shuttle design, and can manage multiple feeding conveyors. The shuttle car then delivers the finished pallet to the transporting point. When the load is transported, the empty pallets are again fed into the system by a pallet positioning system.

- Hybrid palletizers can be costly and are usually used in facilities with multiple product manufacturing.

Palletizer Images, Diagrams and Visual Concepts

Palletizer, an automated material handling machine used to stack and arrange individual products into a single load.

Palletizer, an automated material handling machine used to stack and arrange individual products into a single load.

Robotic palletizer, a type of palletizer that uses a robotic arm to lift, place, and arrange individual products into a single load.

Robotic palletizer, a type of palletizer that uses a robotic arm to lift, place, and arrange individual products into a single load.

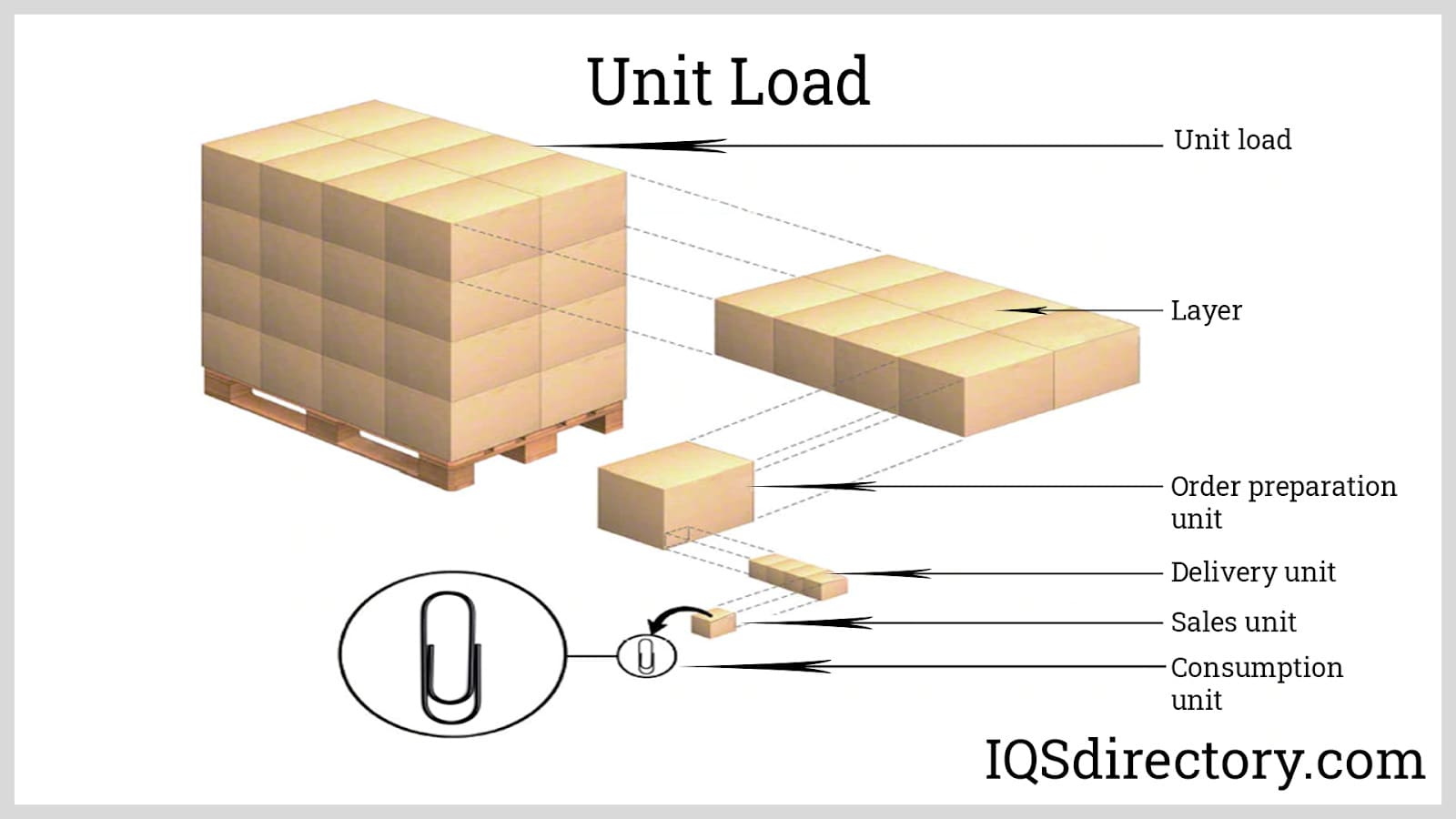

Unit load refers to the assembly of materials combined for efficient handling making it faster and more economical to move large single unit.

Unit load refers to the assembly of materials combined for efficient handling making it faster and more economical to move large single unit.

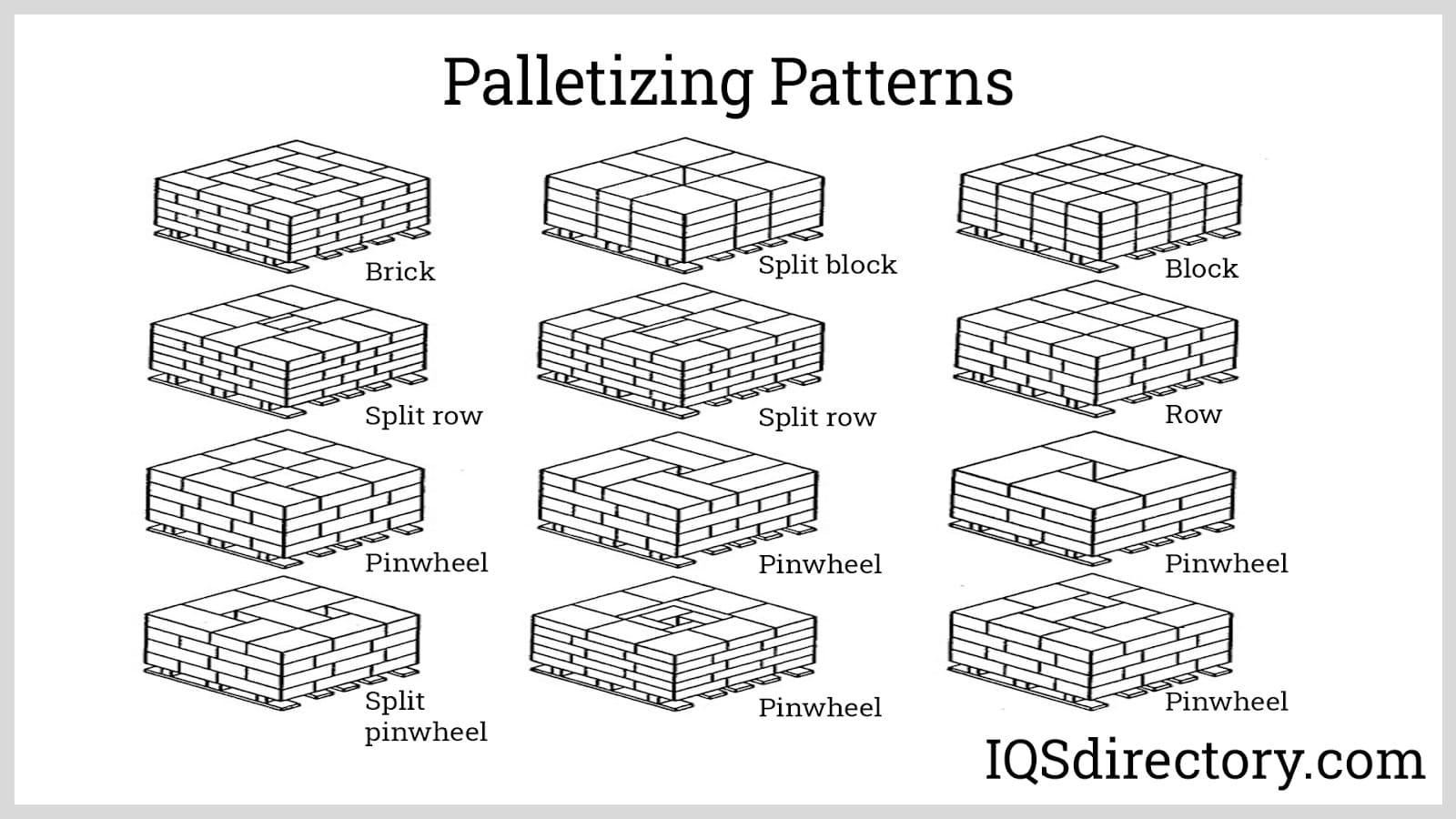

Pallets are designed to be flat, stable structures made of wood, plastic, paper, or steel.

Pallets are designed to be flat, stable structures made of wood, plastic, paper, or steel.

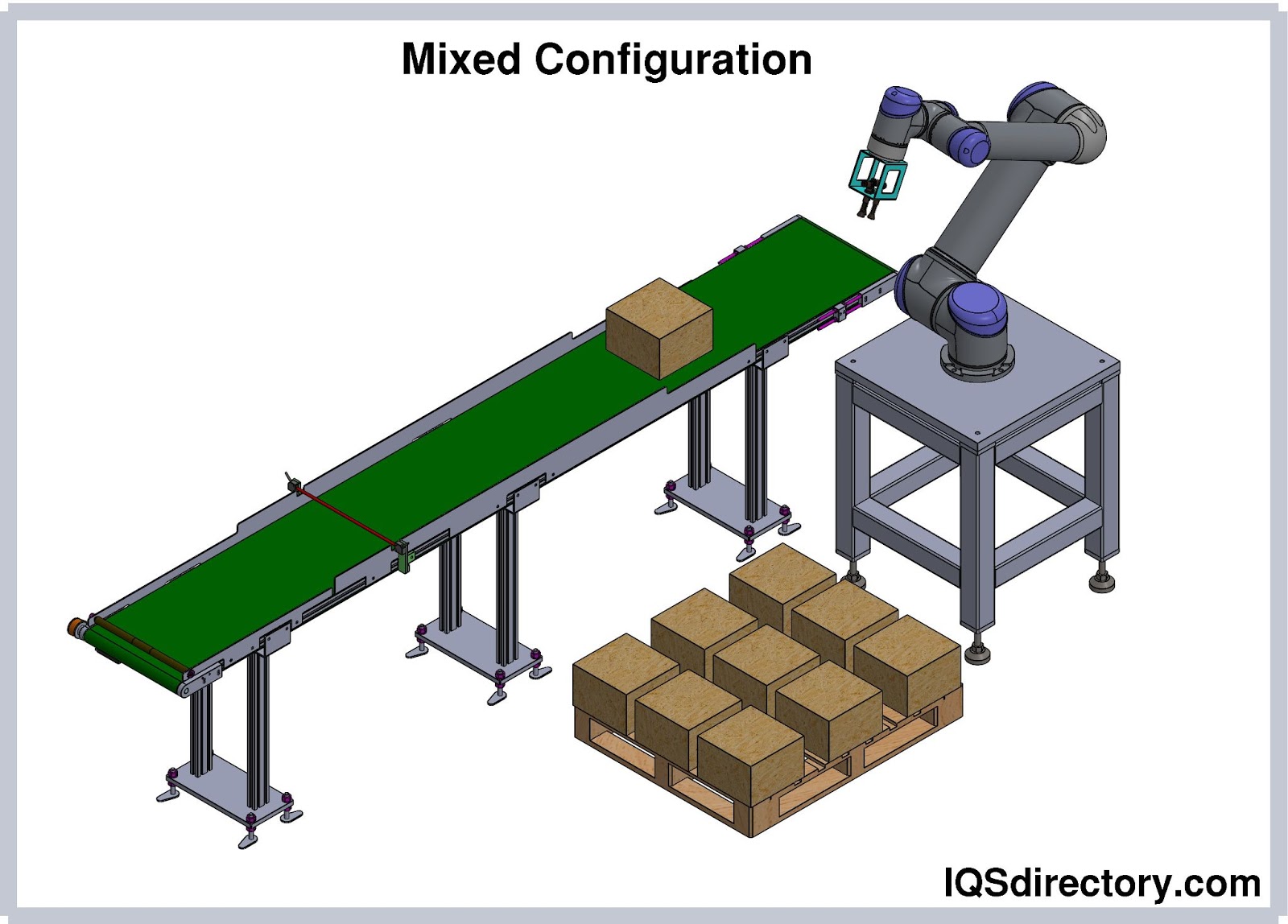

Mixed palletizing refers to the ability of robotic palletizers to accept different products and unitize them into a single pallet.

Mixed palletizing refers to the ability of robotic palletizers to accept different products and unitize them into a single pallet.

Palletizer Types

- Articulated Arm Palletizers

- In articulated robot palletizers, a robotic arm with three rotary joints is installed on the floor, pedestal, or roof, based on the need. For operation, additional palletizing equipment, like a conveyor belt, is needed, which brings the finished products to the robot. Articulated robot palletizers, based on the requirement, pick single or multiple finished products from the conveyor and put them on the pallet. In some designs, pallets are fed in to the palletizer; however, in most designs, the robotic arm itself lifts a pallet when needed. In more sophisticated systems, a slip sheet, a delivery system, is also added to cut down the movement of the arm for additional purpose and increase efficiency.

- Palletizers that do not use robotic arms stack products using a combination of conveyor belts and are further divided based on the design whether they are near the ground and above: floor level infeed palletizers and high level infeed.

- Automatic Palletizers

- Assemble products on pallets by themselves or with little assistance. They can often be part of a larger shipping system.

- Bag Palletizers

- Include gripping modifications specifically designed to allow for the placement of bags on pallets; they can also be used to unload bags from pallets.

- Can Palletizers

- Arrange filled or empty cans onto pallets for shipping or moving.

- Case Palletizers

- Lift cases from tables and place them onto a pallet or previous layer of product.

- Case Picking

- The movement of products in a warehouse in preparation for shipment or during organization. Case picking can refer to such product movement as it relates to the movement of palletized bulk quantities, and it can refer to the movement of individual products.

- Depalletizers

- Remove products by layer from pallets for leveling or stocking purposes.

- Drum Palletizers

- Move filled or empty drums onto pallets for shipping or moving.

- Floor Level Infeed Palletizers

- Also known as low-level palletizers, are automatic palletizers that are installed in the production area and work on the level of production equipment.

- A low level palletizer is advantageous in many industrial applications thanks to its smaller footprints compared to high-level palletizer. This machine does not require the pallet to be lowered or raised. The palletizer organizes the pallet on the bed and then lowers it, or raises it to feed it into the stationary pallet. After the first layer, the bed moves back to position and the palletizer forms another layer. A complete pallet is discharged from the palletizer and another one is placed. Low level palletizers are able to move up to three layers of goods on a pallet.

- This type of palletizer is used when the conveyor that feeds the unit is low to the ground. To be adjacent to the conveyor, the palletizers are designed to be low to the ground and are fitted near the feeding point. This type of installation helps to reduce traffic snag of incoming items, which limits accessibility if not checked. This also makes monitoring easy as the production person and fork operator can monitor the functioning of palletizers. Moreover, if something goes wrong, floor level in-feed components are easily accessible. However, the design has some disadvantages. As the unit is low to the ground, the space below the conveyor cannot be used. However, the most limiting demerit is that it is installed around the production line, and needs passages for movement of forks and other heavy machinery, making the area a bit unsafe for workers.

- Gantry Palletizers

- A robotic arm, which can move linearly in three dimensions, is fitted on a platform. Gantry palletizers are automated palletizing systems and work without any assistance. This type of palletizers is used when a centralized station receives different types of products to be put into pallets. The robotic arm movement is pre programmed and does not have rotary points. The products are delivered to the unit and the whole operation occurs within the platform.

- High Level Palletizers

- Palletizing systems that load or unload pallets at raised elevations. High-level palletizer simply refers to how the machine operates. It receives the goods to be palletized at an elevation or level higher than the pallet. With this system, there is an accumulation station from which the pallet gets fed into the palletizer. The goods will move into a tray or bed and they are arranged into a single tier. The tier arranged is above the pallet and the palletizer will only need to gently place the tier on top of the pallet. After the first tier of goods has been placed on the pallet, the palletizer starts organizing another tier. This normally involves organizing and modifying the position of cases to match the pallet pattern. The palletizer might use a slip sheet or a paperboard to separate layers.

- After the placement of the first layer of goods into the pallet, the pallet is lowered about the height of the first layer and the second layer is placed. The pallet is lowered layer by layer to make the operation of the palletizer easy.

- High Level In-Feed Palletizers

- To make the production area free from the packaging stage, high level in-feed palletizers are used, which receive loads significantly above the ground, around nine feet. As it is above the ground level, an operator has to work on an elevated platform. However, in some designs, the controlling area remains on the ground. A separate controlling area makes it costly. They have some advantages as well. First, they keep the production area clear. Second, the movement of forks is easier, and the distance between the storage area and packaging area can be shortened.

- In-Line Palletizers Systems

- Can stack complete layers of cartons or bags at one time.

- Load Transfer Stations

- Pallet transfer systems that transfer loads from one pallet to another pallet without disassembling.

- Low Level Palletizers

- Or floor level palletizers, are a type of automated conveyor palletizer that can load packaged units from a floor level.

- Manual Palletizers

- Manually-operated machines used to move products on and off of pallets.

- Pail Palletizers

- Include modifications specifically to arrange pails on pallets for shipping and/or movement.

- Pallet Dispensers

- Also known as pallet feeders, are devices that are used to feed or dispense empty pallets to conveyors in larger palletizing systems or automatic palletizers.

- Palletizing refers to the packaging process of arranging products on a pallet for transportation purposes.

- Palletizing Equipment

- Refers to the various machines used to pack and transport pallets.

- Palletizing Machines

- Automated machines or conveyor systems that arrange a maximum load of packaged product units onto a pallet for distribution.

- Palletizing Systems

- Material handling systems that arrange a maximum load of packaged product units onto a pallet for distribution.

- Robotic Palletizers

- Lift and move goods to pallets automatically or semi-automatically, relieving workers from the potential hazards of heavy, repetitive lifting.

- Row Stripper Palletizers

- A type of in-line palletizer that organizes a row and pushes it aside until another row is formed and put on top of the previous row, which is done until a full pallet is completed.

- Selective Compliant Articulated Robot Arm Palletizers

- A type of robotic palletizer that use a mast and cross arm to place products.

- Semi-Automatic Palletizers

- Allow an operator to stack layers of heavy products with no lifting.

- Vacuum-Head Unit

- A type of in-line palletizer that clutches products with air powered suction cups and places the items on the pallets.

Palletizer Characteristics

Like many other processes, stacking in manufacturing is also automated with the use of palletizers, machines that count the feed, orient the incoming load, and put loads in rows and in layers. The machine mimics the assembly line where multiple conveyors of different types are designed together to accomplish stacking, effectively.

There are a number of operations included in standard palletizers. The first step is counting or metering a product when it is on the in-feed conveyor, and as it moves forward, the product is rotated or oriented in a desired position; then the product is moved into a predetermined place to form a row or layer. Once the layer is formed, the layer is compressed for tight packing with the help of a layer compression device. When the layer is made, it is moved to a load hoist by a layer stripper. Once the pallet is made, forklifts take it away, and pallet dispensers replace an empty pallet automatically.

In general, two types of palletizers are available on the market, one that does not employ robotic arms and the other that does.

Both articulated and gantry arm palletizer machines are considered pick-and-place units. They are designed to pick cases from different locations and place them at designated positions on the pallet. They are fitted with basic computing features with sensors allowing them to distinguish between different cases. Granted, the units are able to separate a wide range of package outputs.

Unlike the low level and high level machines, the robots are able to automate more than one production line with a single machine. Goods from multiple production lines will only need to be placed near the location of the robot, which will identify and place the cases of goods where they are supposed to be.

These machines can produce more than a single pallet load based on shape, size and a couple of other identifying characteristics that the palletizer might be programmed to sense on multiple finished goods cases.

The machines, sometimes referred to as end-of-arm palletizer, are able to rotate to pick cases from different parts of a production house. This is unlike the conventional units, which are stationary. However, even with their ability to rotate and sort goods, they are relatively slow, handling up to thirty cases per minute.

Like any other robot, these machines are named by the type of arm fitted on them. Lighter applications will need an articulated arm designed with the capability for multiple axis. The gantry palletizer, on the other hand, is needed for heavy duty applications in industries. However, the gantry arm palletizer is relatively less flexible. The distinction between articulated and gantry arm palletizer machines is not absolute and there are cross models.

Data Collection in Palletizer Machines

These computerized controls also allow the machines to collect data and report. The machines from different manufacturing companies feature real time reporting, alarm and downtime reports and production among others. The information collected, helps firms enhance their supply chain.

Companies producing these machines offer them with schematics and manuals, helping industries repair them without necessarily calling the manufacturer. The computer interface is designed to walk the operator through routine maintenance and troubleshooting. Again, the interfaces have allowed palletizer manufacturers to create high speed machines to handle small case sizes.

As many stores move towards small size packaging, the handling demands are increasing. This has been brought by suppliers and retailers looking to minimize wastage to deliver the largest amount with less packages.

Palletizer Versatility

HMIs are used to upgrade palletizer machines, making them more versatile. For instance, a robot palletizer has shown great flexibility in handling multiple goods variations; they can handle up to five production lines.

Gantry type palletizers, besides handling heavy duty applications, are being used in distribution centers to handle a large number of production lines. They are able to produce a layered rainbow pallet where different layers on a pallet are made of different product types. Picking operations can be automated for different applications, such as palletizing soft drinks where different flavors are placed in different layers for transport to different stores.

For smaller suppliers, palletizer machines are bringing ergonomics. The rotation, repetitive motion and lifting that occurs when goods are placed on pallets by hand is minimized.

Palletizer units are still improving with engineers working with suppliers to make them more convenient. These machines are now being made to organize goods at the case level, placing them at the heart of production. However, this is still undergoing refinement. Palletizer machines are facing the high demand for speed and intricacy.

Custom Designs of a Palletizer

When requesting custom palletizers for given applications, companies will offer clients the chance to view their CAD designs. The client, especially if they happen to be engineers, will work with the company to come up with the design that meets their needs.

These, like their name suggests, are designed to handle unique material. The bulk palletizer is the most common of them all. This unit is used to create loads of cans for shipment at the can manufacturing plants. They are used to load and unload cans of different materials. The cans are placed in layers on the pallet with a slip sheet in between them. Before transport, the load is banded to keep it secure.

Special palletizer machines also include bag palletizers, case palletizers, and drum palletizers. Each of these is created for a special function as its name suggests.

- Hybrid Palletizer

- The demand to reduce secondary packages is increasing and this has informed the design of palletizer machines. Granted, designers are combining robotics and conventional technology. This has enhanced simultaneous operations where a palletizer can palletize and stretch-wrap. Most applications need automated palletizer machines as they offer great flexibility.

Things to Consider When Purchasing a Palletizer

- Future Needs

- Returns on Investment are better with conventional palletizer machines. However, robotics have the advantage of handling different packages, and there are even some applications that can handle up to 60 cases per minute. The industry needs to dictate the best design. For instance, a bottler might choose robotics as they offer gentle handling.

- Safety Standards

- There is over-emphasis on the part of the suppliers and palletizer producing companies to use devices that are safety rated including PLCs, automatic air dumps and VFDs. Wide palletizer equipment is being faced off to give way for convenient and ergonomic designs. When requesting for a custom machine, safety should be a first priority.

- Consumer Level Developments

- Display type pallet loads are becoming common, eliciting the need for graphics-out pallet placement. This requires the use of tier sheets between the different layers on the pallet. This is where hooding and stretch wrapping are weighed and chosen based on convenience and applicability.

- Shrink-Wrapping

- When loads are shrink wrapped, they require special handling methods within the palletizer as compared to paperboard or corrugated cases packages. When the loads are very small or relatively large, they need a very flexible palletizer.

- Costs and Complexity

- Lightweight packages combined with the need for speed and flexibility are influencing the cost and the complexity of these machines. This has also upped the use of robotic technology.

- Risk Assessments and Controls

- Even as the complexity of the machines is increasing, users need units that are easy to use and also safe. The machine builders must give their risk assessments to users. At the very least, risk assessment information should be disclosed to OSHA.

Choosing the Right Palletizer Manufacturer

There are many companies that design and produce palletizer machines. The right manufacturer will allow clients to specify the features, size, weight, power and other details when requesting for a palletizer. Some have CAD software to showcase the modular design before production. While there are many companies that do not offer custom machines, most companies will offer a wide range of machines, making it easier for the consumers to choose one that will meet their needs. The cost of palletizer machines will be determined by the type and features. However, the designers and suppliers will have a relatively similar price for the same type of palletizer. A palletizer manufacturer that puts more emphasis on safety features for industrial applications is preferred.

Some palletizer manufacturers will also offer pallets, which are designed to work in sync with the palletizer. The majority of pallets are made of plastic, some wood and others metal.

Palletizer Accessories

Most palletizer machines are offered complete with no need for accessories. However, the units might require:

- Pallet Dispenser

- Sheet Dispenser

- Turning Devices

These accessories are meant to customize the machine to increase speed and performance. While they may be purchased from the palletizer manufacturer, these accessories are widely available.

Palletizer Terms

- Captive Pallet

- A pallet that stays within a facility and is not exchanged, traded or delivered off site.

- Deck

- The top or bottom surface of the pallet.

- Deflection

- The amount of bending in a pallet or one of its components when under a load.

- Fork Entry

- The place for forks to enter and move the pallet, usually between decks or under the top deck.

- Line Load

- The weight of a unit load concentrated across the entire length or width of the pallet or along a narrow area.

- Load Bearing Surface

- The area of material that is in contact with and is supporting a unit load.

- Mast-Equipped Automatic Guided Vehicles (AGVs)

- Vehicles that move unit loads and storing or retrieving pallets and unit loads.

- Pallets

- Platforms used to stack goods on for shipping, storing or moving. They can have two-way or four-way entry by fork trucks.

- Pallet Conveyors

- Industrial equipment used to more efficiently transport goods loaded on pallets through a factory or manufacturing plant.

- Pallet Design System (PDS)

- A computer-aided design program that helps determine safe load carrying capacities, performance, life and economy of wooden pallets.

- Pallet Jack

- A manual wheeled platform used for lifting palletized unit loads.

- Pallet Inverters

- Used to turn heavy loads of merchandise 1280 degrees to exchange one pallet for another with as little hassle as possible. Pallet inverters are usually used on their own and utilize a rotating frame to transfer pallets or stack them in a warehouse, or move them to a shipping container.

- Raked Across Deck Boards

- The maximum load carrying capacity and deflection of a pallet where, at the ends of the deck boards, the rack frame sustains the pallet.

- Racked Across Stringers

- The maximum carrying capacity of a pallet where, only at the ends of the stringers or stringer boards, the rack frame sustains the pallet.

- Slave Pallet

- A panel used to support the base of a palletized load in rack-storage facilities.

- Strapping

- Bands that secure the goods or load to the pallet.

- Throughput

- The amount of output or production in a given period of time.

- Top Cap

- Panel placed on top of goods on a pallet that protects them from damage when strapping occurs.

- Unit Load

- The collecting of goods to be moved or shipped onto a pallet.