Metal Etching

Metal etching, also referred to as metal engraving, is the process of creating grooves, fine lines or impressed designs on metal parts or sheets. Metal etching is used for a wide variety of reasons, including decorative and architectural purposes. Some of the industries that have use for metal etching include jewelry, furniture, architecture, music, art, healthcare, woodworking, aerospace, electronics and arms and defense. For example, manufacturers sometimes employ decorative etching in order to smoke surfaces so that the lines will be more visible. In addition, metal etching can be used to help a metal part meet restrictive weight demands by removing a surface layer of a part through chemical or mechanical means.

Quick links to Metal Etching Information

History of Metal Etching

Etching, with little alteration in technique, has applications in a wide range of industries, from fabrication of micro-electromechanical systems to aerospace components, to printing circuits to the production of missile skins. However, this ever evolving technology was first widely employed back in ancient times.

Etching mainly evolved for aesthetic applications where soft metals, such as copper and zinc, and later strong metal, like steel, were etched with the use of strong acids. Typically, suits of armor, guns, plates and cups were etched to add aesthetic elements.

- Progression of Etching

- During the 16th century, etching had its major effects on modern life when it was applied to printmaking in Germany. In printmaking methods, a metal plate was covered in acid-resistant material-typically wax. An artist then scraped the wax and exposed the metal to create a printing die using a pointed etching needle. After elaborate scraping, the plate was bathed in an acid or etchant. The acid dissolved a part of the metal where it is exposed, resulting in a metal plate with sunken lines and words. The metal plates were then inked and used, in large scale, for printing purposes. The process resulted in the production of printing dies that started the printing revolution, which brought Europe toward an industrial revolution.

- At the same time, the metal etch process was developed as an alternative to metal engraving, which at that time was a preferred method to produce patterns on metal. Soon, chemical etching was used to put trajectory information onto artilleries and canons, as etched plates were found to be very durable. Following this trend, people began to mill and etch equipment, stiletto daggers, and shovels.

- The next milestone in metal etch was achieved in the 18th century, when a Swiss botanist, John Senebier, observed that certain plant resins, after being exposed to light, hardened and lost their solubility to turpentine. This piece of information led to development of present day photochemical etching. However, for almost a century, this method was only used in photography. A resin, which resists acid action, was applied in liquid form to the metal and exposed to light to outline the masked area. Using this method, impressions on metal plates were obtained.

- During the 1900s

- The modern commercial use of photochemical machining came into existence in 1927. A Swedish company, Aktiebolaget Separator, developed this method for producing edge filters. The method was patented, and the technique was used to cut gaps filters. Around the beginning of the Second World War, the method got traction and, and people also began to etch hard metals during machining. With the use of photochemical etch techniques, people could etch metal from both sides, and it was extensively applied to make components from sheet foil.

- Etching technology was later developed to support micro-fabrication, which served as the basis for the information technology revolution.

No matter which technique or techniques you choose, the metal etch process offers many advantages over other machining options. From stencil and metal stamp to semiconductor, metal etching has countless applications.

First, metal etching works on many, many different materials, from hard metals to soft plastics. Second, it doesn’t cause deformation or internal stress. Neither does it leave behind waste or debris like burrs. Because of this, metal etched parts require little, if any, secondary tooling or finishing.

Also, metal etching leaves all material properties, such as hardness, intact. Another great advantage of metal etching is the fact that it can be performed so rapidly and accurately. Plus, if need be, manufacturers can make quick and easy changes to the design. Finally, metal etching requires no hard tooling.

With metal etching, cuts with varying depth are achieved, and the depth is determined by the time spent by the material in the bath. The rate of etching is defined by the ratio of depth of cut to time spent in the bath.

Many factors, such as the material you plan to etch, temperature, the etchant composition and concentration determine the rate. As there are a number of factors that can influence etching, the common practice is to do a test run, where a material is exposed to chemicals and monitored for output performance. Based on the process performance, the chemistry and test are repeated until a desired depth and rate are achieved.

What is a standard metal etching process?

- Cleaning Surfaces

- The first stage is cleaning, which is done at the preparation stage. At this stage, you should ensure that the surface you intend to etch is contaminant free. If contaminants remain, they can alter the reaction and result in inconsistent etching. On a metal surface, you use solvents, which commonly include de-oxidizing and alkaline solutions. Typical contaminants include grease, primer coatings, residue from the marking step, and oils.

- Applying Masking Agent

- Typically, in industrial settings, the masking material or maskants, include isobutylene-isoprene copolymers and neoprene elastomers, which are inert in nature and do not lose their structural integrity during chemical reactions. In the masking stage, these polymers are applied on the surface in a predetermined fashion that gives the required pattern. Masking can be done through either dipping or flow coating. In dip masking, the parts are immersed into a maskant, whereas in masking by flow coating, the parts are coated by flowing the solution over a surface.

- Immersion in Etchant

- This is the stage where you actually metal etch the part. The chemical reaction takes place, as metal parts are immersed into corrosive material, such as ferric chloride. The parts remain in a tank for a specified period to achieve definite width. There are a number of factors that determine the width, and these have been discussed above.

- Removing the Mask

- This stage is also called demasking whereby products of the reaction and maskant are removed from a surface to reveal the desired pattern and design. A specific procedure is followed to remove etchants from parts. Typically, cold water is used for specific etchants and specialized processes, such as a de-oxidizing bath. The de-oxidizing bath removes the oxides left by the chemical reaction. Similarly, ranges of methods are utilized to remove the maskant; however, commonly, the maskant is removed manually with the help of scraping tools.

Metal etching removes metal using different methods to configure complex, intricate, and highly accurate shapes.

Metal etching removes metal using different methods to configure complex, intricate, and highly accurate shapes.

The different types of metals are affected differently by the etching process.

The different types of metals are affected differently by the etching process.

Acid etching, a chemical process where a strong acid is applied to a piece of metal to remove a segment of the metal’s surface to create a design or component.

Acid etching, a chemical process where a strong acid is applied to a piece of metal to remove a segment of the metal’s surface to create a design or component.

Photochemical etching, uses photographic and chemical techniques in order to shape the metal.

Photochemical etching, uses photographic and chemical techniques in order to shape the metal.

- Abrasive Etching

- The process of using controlled, high-pressure compressed air to direct an abrasive, such as sand or aluminum oxide, at the surface of a material to create the etched effect.

- Acid Etching

- Uses acid to engrave the surface of sheet metal.

- Aluminum Etching

- Used to create aluminum industrial parts that require many small grooves or holes, or a decorative finish.

- Brass Etching

- Used to create brass industrial parts that require many small grooves or holes, or a decorative finish.

- Chemical Etching

- Uses acids, bases, and other chemicals to etch into the surface of metal.

- Chemical Machining

- Used in many metal manufacturing industries to etch, cut or engrave metal plates in a number of capacities as it provides delicate and precise design capabilities.

- Chemical Milling

- A chemical process used by many industrial metal parts manufacturers to etch, cut, or engrave extremely delicate or precise lines into metal.

- Copper Etching

- Used to create copper industrial parts that require many small grooves or holes, or a decorative finish.

- Dry Etching

- Any etching process that does not employ the use of chemicals.

- Electroetching

- An etching process that involves the use of chemicals, along with the employment of direct electric current.

- Laser Etching

- Employs the use of a laser for the removal of a specified pattern on a metal piece. Laser etching is often used in the jewelry industry.

- Metal Engravers

- Metal tools used to carve designs into metal surfaces.

- Metal Engraving

- The process by which metal tools are employed to carve a design into metal.

- Photo Engraving

- Uses photosensitive material that is resistant to acid and applies it to the surface of a metal sheet. Acid is then applied, creating an image by burning through the areas where the acid-resistant material is missing.

- Photo Etching

- The most common metal etching process and otherwise referred to as "metal chemical etching," "chemical milling," "photochemical etching," "chemical etching" or "photochemical machining," is the process in which a desired image is etched on the surface of the metal part via a photosensitive template. The piece is then exposed to an appropriate acid (or etchant) that removes a layer of metal in areas left unprotected by the template, after which the piece is cleaned and the photoresist template removed.

- Photofabrication

- Combines photographic processes and materials with chemical machining to etch, cut or engrave metal parts for a variety of industries.

- Reactive Ion Etching (REI)

- Also known as "plasma etching," is a dry etching technique. REI involves the use of electrical circuits and high-energy gas made up of ionized particles containing fluorine or chlorine.

- Sputter Etching

- A type of REI etching but without the employment of ions.

- Stainless Steel Etching

- Used to create stainless steel industrial parts that require many small grooves or holes, or a decorative finish.

- Vapor Phase Etching

- A dry etch technique that uses reactive gases to achieve the desired etching pattern.

Metal etching is a very versatile procedure; almost all metals can be processed using chemical milling, photo engraving or mechanical etching including: aluminum, brass, copper, beryllium copper, nickel, nickel silver, carbon steel and stainless steel.

Some of the corrosive chemicals, or etchants, that manufacturers use during chemical milling, chemical machining, photo engraving and the like include: ferric chloride (best for copper or zinc), ferric nitrate, nitric acid (best for zinc or steel), copper sulfate, hydrochloric acid and citric acid, nitroxyl (HNO) phosphoric acid.

Machinery Used with Etching

To achieve the ideal cut and pattern during etching, manufacturers may use any number of machines.

For example, they use milling and grinding machines to achieve certain etching finishes on metals, especially on larger sheeting used for architectural decorative or furniture purposes.

They also use lathes or CNC machines with fine tips to process a range of materials and dimensions, including straight or curved surfaces.

For some smaller processes and more intricate, decorative purposes, they still use hand engraving equipment. Typically, this is restricted to jewelry, firearms, small decorative pieces and some musical instruments.

Widely available engraving machines are fairly simple to use and are able to engrave a number of surfaces such as metal, glass or plastic. Engraving equipment consists of three parts: a stylus or marking tool, a controller, and a surface. Diamonds are typically used as the stylus, especially for machines required to engrave on harder materials and metals.

If you’re trying to figure out the best metal etching method for you, or if metal etching is even right for you at all, there are a number of things you can think about in order to gain clarity. Mostly, you need to think about your specifications and if they match up with the capabilities of metal etching. What level of design precision are you seeking? What are your industry requirements? How deep or thin of cuts do you need?

The best way to get clarity, though, is by talking to the right manufacturer. How do you choose the right manufacturer? The right manufacturer needs to be more than skilled. They also need to be willing and able to manufacture your vision. They need to care about your budget, time frame and overall wishes. To find the right one for you, start by browsing the companies we have listed above. Get a feel for them by reaching out with your questions.

Commonly used metal etching techniques include laser etching, electro discharge machining, chemical milling (chemical machining), acid etching (photochemical etching), mechanical milling, wet etching and dry etching. Along with these metal etch techniques, manufacturers can stamp, laser engrave or water-jet cut the metal piece. All of these techniques are faster and more accurate than hand engraving.

- Laser Etching

- Able to create very fine, clean lines in surfaces with little need for secondary finishing.

- Electro Discharge Machining (EDM)

- Another method of metal etching which is able to achieve close tolerances. During the process, the metal part is exposed to streams of corrosive electromagnetic discharge. Any resulting imperfections, burrs or marks may be smoothed and polished away after you etch the metal.

- Chemical Milling/Chemical Machining

- Manufacturers begin the chemical milling process, also known as chemical machining or photochemical milling, by taking a piece of metal sheet and covering it in a masking compound. The masking compound, which is inert, protects, or masks, the covered material from the etchant. Manufacturers choose what they cover carefully, in order to achieve the shape and cuts they desire. Once this is done, they bathe the metal in the etchant of their choice. The etchant chemically reacts with the exposed material, and cuts it via dissolution.

- Acid Etching

- Very similar to chemical milling. Manufacturers use this method to create grooves, images, lines and holed surfaces. When they etch with acid, they are able to achieve precise lines and specific depths. They begin the process by stripping the sheet metal they plan to etch of all oils and chemicals. They first strip organic matter, using cleansers such as alkaline cleaners, then remove chemical residue by using an acid cleaner. Note: neither of these cleansers can be too strong, or the polished surface of the metal will be scratched.

- Next, they apply a maskant to the entire surface. In this case, they usually use masking types such as tapes, paints, elastomers (rubber) or plastics. They cut a pattern into the masking in the same shape the metal is to be cut, then remove the masking from the areas they will etch. After that, they apply the chemical, or "reagent."

- Finally, after the acid has achieved its desired etch, manufacturers strip both the reagent and the remaining maskant from the metal part to reveal the final design. The length of time they let a chemical react with a metal part depends on the desired depth of the grooves, and the strength of the acid.

- Photochemical Machining

- To start the photochemical machining process, manufacturers print the desired shape of the product onto photographic film. Then, they select a metal material, cut it down to size, coat it in photoresist, place it between two sheets of film and vacuum seal them together. After that, they expose the plate to a UV light that causes the photoresist to harden. Once it’s ready, manufacturers wash away the extra photoresist, leaving only the areas they plan to etch. After this, they add the etchant, which rapidly eats away at the exposed metal. After it’s been sufficiently etched, they neutralize the etchant and rinse it away, leaving behind a finished part.

- Mechanical Milling

- A common method used to metal etch, uses a lathe or CNC machine with fine tips which are able to process a range of materials and dimensions, including straight or curved surfaces. The computer of these machines controls the laser's or cutter's direction, pressure and speed resulting in a precise image or design with clean, fine lines. This method achieves precise and consistent results, but the initial tooling costs are high, and maintenance of the machines requires qualified personnel.

In addition to all of these, there are two main kinds of etching processes: wet and dry etching.

When specific design configurations are required for metal, manufacturers can employ either wet or dry metal etching. The assignment is based on the etchant used for dissolving the metal. Etching via chemicals is similar to chemical milling, but the depth and rate of metal etching achieved is significantly greater in chemical milling.

Etching can be either or both isotropic and anisotropic.

- Isotropic

- When an etchant removes material in all directions uniformly.

- Anisotropic

- When an etchant removes material in a vertical direction.

Anisotropic etching can be completely anisotropic and partially anisotropic. Commonly, anisotropic dry etching achieves etching with a higher aspect ratio and finer resolution in comparison to isotropic etching.

- Wet Etching

- When an etchant is in liquid form, the metal etching is called wet. The patterns that are required to be saved are masked, and the exposed material is etched away by liquid etchant. Lithography is used before the fabrication step to mask the patterns and configuration.

- In wet etching, multiple chemical reactions take place, as the original reactants are consumed and new reactants are produced.

- The wet etching process can be simplified in three steps:

- In the first step, the liquid etchant fuses on to the structure that needs to be removed.

- In the second step, the liquid etchant and the material react and the material is etched away. The reaction is typically reduction-oxidation, where the target material is oxidized and dissolves.

- The third step is the diffusion of by-products.

- When Silicon is used to etch anisotropic shapes, the common wet etch agents include ethylenediamine pyrocatechol (EDP), potassium hydroxide (KOH), and tetramethylammonium hydroxide (TMAH). However, in isotropic wet etching using Silicon, manufacturers use acetic acid, nitric acid, and hydrofluoric acid in combination. The rate of etching is defined by the concentration of etchants.

- Dry Etching

- To achieve a dry metal etch, instead of a solution, plasma or gas is employed to remove the material. The kinetic energy of particle beams, which is usually high, and the chemical reaction, or the combinations of these, etch the material.

- Dry metal etching is further categorized as physical or chemical based. In physical dry etching, the kinetic energy of ions, electrons, or photons etch the substrate. In this type of etching, no chemical reaction is involved and particles kick the atoms out while the material evaporates.

- Chemical dry etching or vapor phase etching, as their names imply, involve chemical reactions to attack a silicon surface. The chemicals that are usually utilized for dry etch are fluorine, tetrafluoro methane, nitrogen trifluoride, sulfur hexafluoride, and chlorine gas.

- As mentioned before, physical and chemical metal etching can also be in a combination and is called reactive ion etching. The reactive ion etching is the most extensively used technique in industrial settings as well as in labs. As both actions are used, the etch process is more rapid than normal. The process involves positively charged ions, which are produced from the reactive gases. The cations are exposed to the substrate at high speed, which then react chemically with the silicon.

- Acid

- A substance that, when dissolved in water, forms a solution with a pH of less than seven.

- Bend Lines

- Lines that are partially etched into the surface of the metal, which aid in the bending of the part in a subsequent operation.

- Burn-In

- The process of heating a developed photoresist image until the resist coating becomes chemically resistant.

- Chemical Blanking

- A term originally used to refer to the process of photo chemical machining (PCM).

- Chlorine Regeneration

- A process in which ferric chloride acid is regenerated to maintain high quality acid for the etching process.

- Coating

- The dipping, rolling, spraying, laminating, spinning, printing or flowing of the substrate surface layer of a photoresist material in order to cover it with a resist.

- Contact Printing

- A photographic process in which an image is transferred from one substrate to another.

- Conversion Coating

- The subjection of a substrate surface to high temperatures or the pickling process in order to improve photo resistant adhesion.

- Dry Film Resist

- Photoresist in the form of rolled sheet laminate.

- Etch Band Design

- Designing artwork for parts to be photochemically machined so that all shapes are outlined with a controlled line to be etched.

- Etchant

- An acid used to dissolve a layer of metal to form the component.

- Fret

- A series of etched parts that are tagged into a frame. Blanks usually have several frets etched into them.

- Halogen

- Non-metallic elements fluorine, chlorine, bromine and iodine.

- Intaglio

- An image etched/sunk into the surface of a piece.

- Ion

- An electrically charged atom or group of atoms, the electrical charge of which results from a neutral atom or group of atoms losing or gaining one or more electrons.

- Liquid Resist

- A photoresist applied to the substrate by dipping, roller coating or spraying.

- Photodiode

- A device that receives optical power and changes it into an electrical signal.

- Photoresist

- A material that, when applied to any of a variety of substances, becomes sensitive to portions of the electromagnetic spectrum and, when properly exposed and developed, masks a portion of the material.

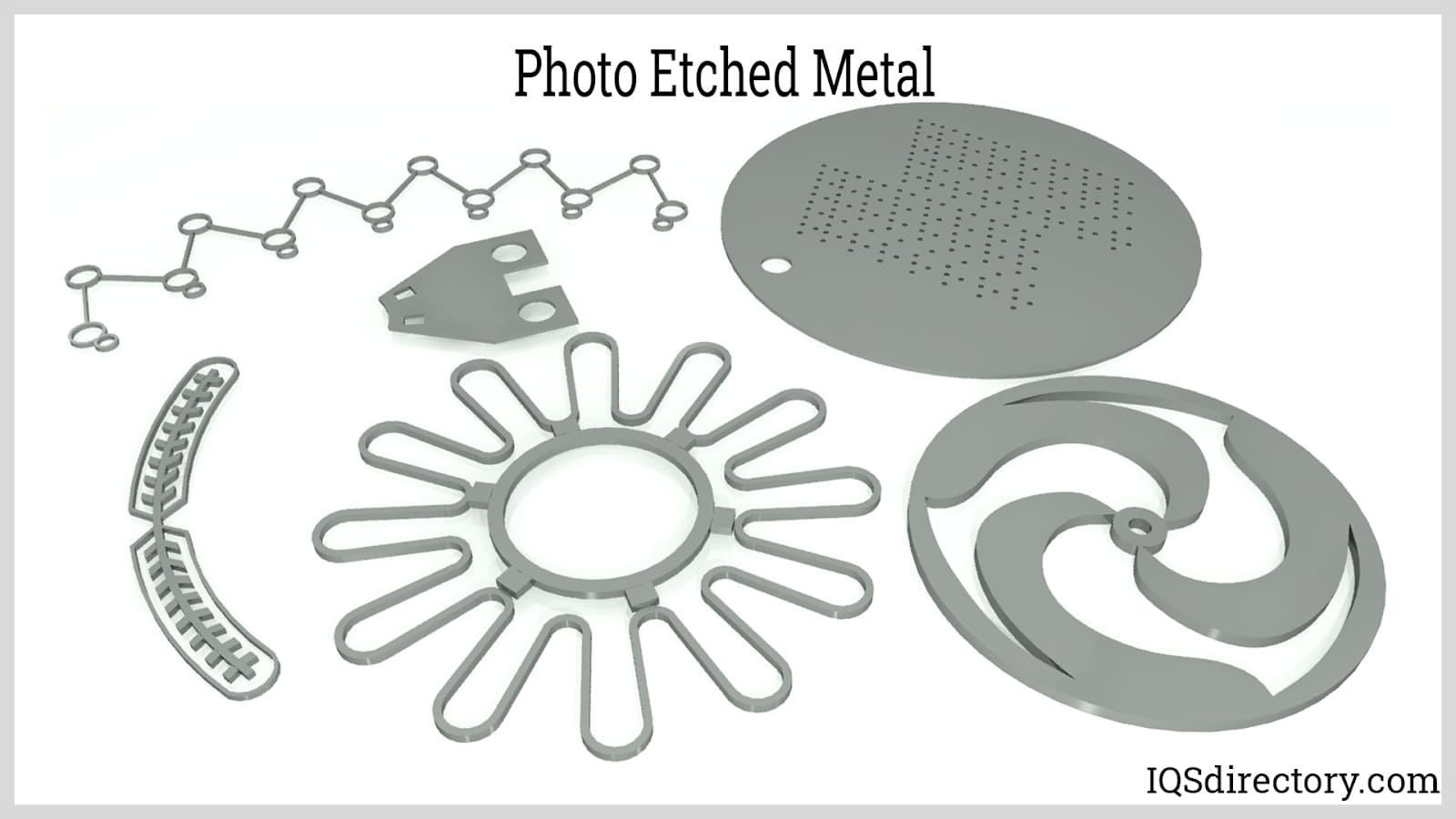

- Photo Etched Parts

- A process which uses chemicals and precise light exposure to create all kinds of metal parts. Photo etching goes by several other names, including chemical etching, chemical milling, photochemical machining, chemical machining and chemical etching.

- Spectral Sensitivity

- The rate of response of a photographic material to a particular range of the electromagnetic spectrum.

- Substrate

- A structure that underlies and supports or forms base material on which coatings are applied.

- Ultraviolet (UV)

- Invisible electromagnetic radiation.