Load Cells

Load cells are measuring devices that monitor and gauge forces of compression, tension and shear. They are a type of transducer that converts sensed mechanical force into electrical signals for measurement. In other words, a load cell (or loadcell) is a load monitor. More technically, a load cell, also known as a load sensor, is an electromechanical tool used across industries, from medicine to architecture.

Typically, load cell measurements are displayed in newtons (N), meganewtons (MN), or kilonewtons (KN).

Quick links to Load Cells Information

The History of Load Cells

Modern load cells work using a combination of the Wheatstone bridge equation and the strain gauge. The Wheatstone bridge equation was developed in 1833 by Samuel Hunter Christie, and improved upon and popularized in 1843 by Sir Charles Wheatstone. Wheatstone bridge circuits illustrate the concept of a difference measurement. Today, load cells are usually made up of four strain gauges in a Wheatstone configuration.

Before the strain gage, people conducted their industrial weighing applications with mechanical lever scales. After that, they used both hydraulic and pneumatic force sensors. While, as we mentioned, the Wheatstone bridge equation was invented in the mid-1800s, it wasn’t until the mid-1900’s that it was joined with the strain gauge to make effective load cells. The first bonded resistance wire strain gauge was developed in the 1940s. Years later, when modern electronics caught up, load cell development became both technically and economically viable. Once that happened, the industry took off, and it hasn’t slowed down since.

Advantages of Load Cells

One of the many advantages of load cells is their high level of accuracy. With reading accuracies within 0.25%, load cells, sensors and gauges provide accurate mass, weight and pressure measurement of loads both very small and very large, up to several thousand tons.

Another load cell advantage is the fact that they are so efficient; load cells can efficiently perform precise and linear measurement, without showing any differences in data caused by changes in the environment or medium.

Furthermore, today's advanced load cells typically offer a very long life due to their sustainable design. As an added bonus, this sustainable design includes few moving parts. This decreases the chance of damage to both load cells and the machines in which they are operating.

Design of Load Cells

- Production Process

- Load cell instruments aim to highlight the actual mass of a material. They are produced based on the principles of mass measurement under fluid pressure, elasticity, magnetic effect, piezoelectric and zero environments.

- The two basic components of a load cell are the sensing element and circuit. The sensing element is most often a strain gauge, which is composed of coil. Note: a strain gauge is a very small device that measures the strain of an object by converting internal deformation into an electrical signal, precisely measuring weight, force, tension or strain. The sensing element can also be a piezoelectric sensor that utilizes crystals. The circuit is the connection of these gauges or sensors throughout the load cell.

- Load cell output types include analog voltage, analog current, analog frequency, switch or alarm, serial and parallel. The most basic designs consist of four gauges, which make up the measuring circuit. More complex and detailed cells can have up to thirty gauges as part of the measuring circuit.

- Materials

- Load cells are made of various metallic parts, such as: alloy steel, stainless steel, aluminum, and tool steel.

- Each material offers something different in the way of properties; each is suited in one way or another to be used for load cells. Some of their various properties include: high strength, easy machining, low weight, good thermal conductivity, good electrical conductivity, high cryogenic toughness, high malleability, high work hardening rate, corrosion resistance, and attractive appearance.

- Design Considerations

- The more gauges inside the load cell, the more sensitive the cell is in recording and monitoring variance in measurement. When calculating the potential capacity of a load cell, manufacturers consider: the maximum force value, the dynamics of the system (i.e. frequency response), the effect that placing the transducer in the force path will have and the maximum extraneous loads that the load cell will handle.

- When mounting load cells, such factors must be considered: whether the load cell be in the primary load path or whether it will see the forces indirectly; whether there are any physical constraints that should be met for size and mounting; what level of accuracy is required, and what environmental elements the load cell will be subjected to that may cause special problems. These complexities are necessary to have the correct measuring force load cell in place, to ensure the safety and productivity of the industries employing them.

- Customization

- Load cells can vary greatly in size and shape depending on the industrial arena they will be utilized in.

Features of Load Cells

To make the load cell work, manufacturers apply it onto a surface, where the strain gauge or other sensor changes its shape or physical status. The strain gauge then measures that shift, stress, tension, or compression on its surface.

The measurement output depends on the recommendations of the Wheatstone bridge circuit concept. Once the bridge circuit is set up, it is excited with stabilized voltage, known as excitation voltage. The difference voltage, which is proportional to the load, is then displayed on the signal output. After that, the sensor sends the interpreted data as a signal to the LED screen of the machine, which displays it in a way that we can understand.

Analog or digital load cell technology is used for the recording and transferring of information. Digital load cells have become more popular than analog load cells in recent years because they work faster, have a higher accuracy rate and better resolution. When load cells are used to measure any variance in certain ongoing systems, the load cells can sound an alarm or shut down the system itself until the discrepancy is corrected.

While there are other types of force and energy measurement and conversion tools out there, like elastic systems, vibration systems, and dynamic balance devices, none of them are as technical as load cells. Unlike load cells, they more closely follow traditional methods of measurement, and thus do not offer the same level of accuracy.

Load Cells Images, Diagrams and Visual Concepts

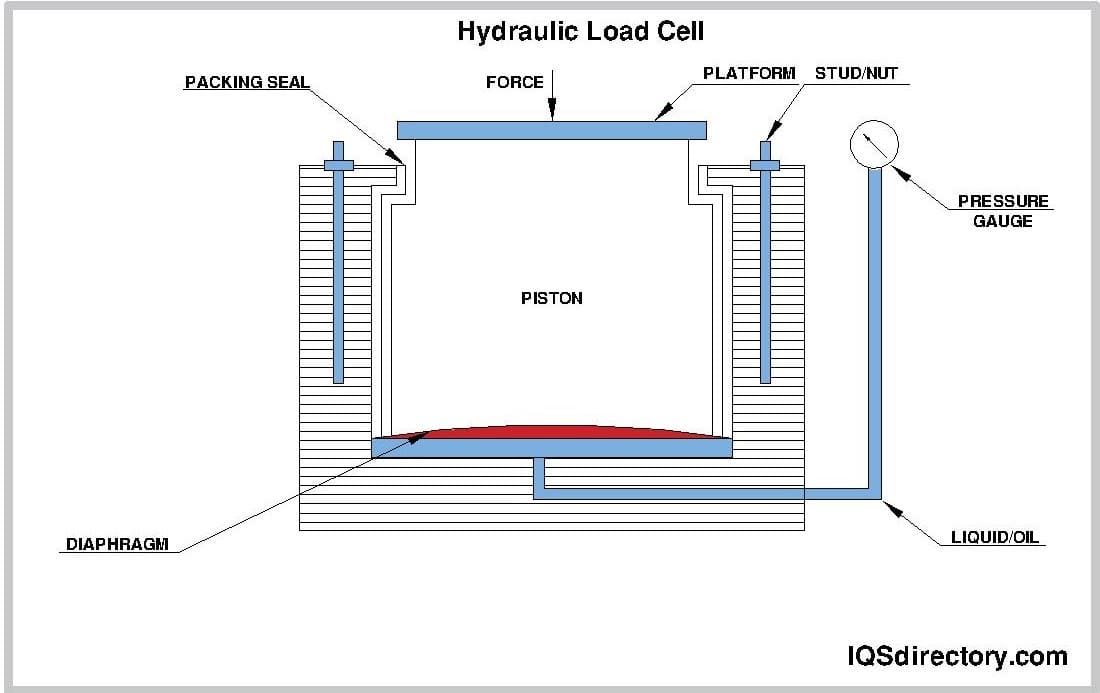

A hydraulic load cell measures a change in pressure in fluid substances.

A hydraulic load cell measures a change in pressure in fluid substances.

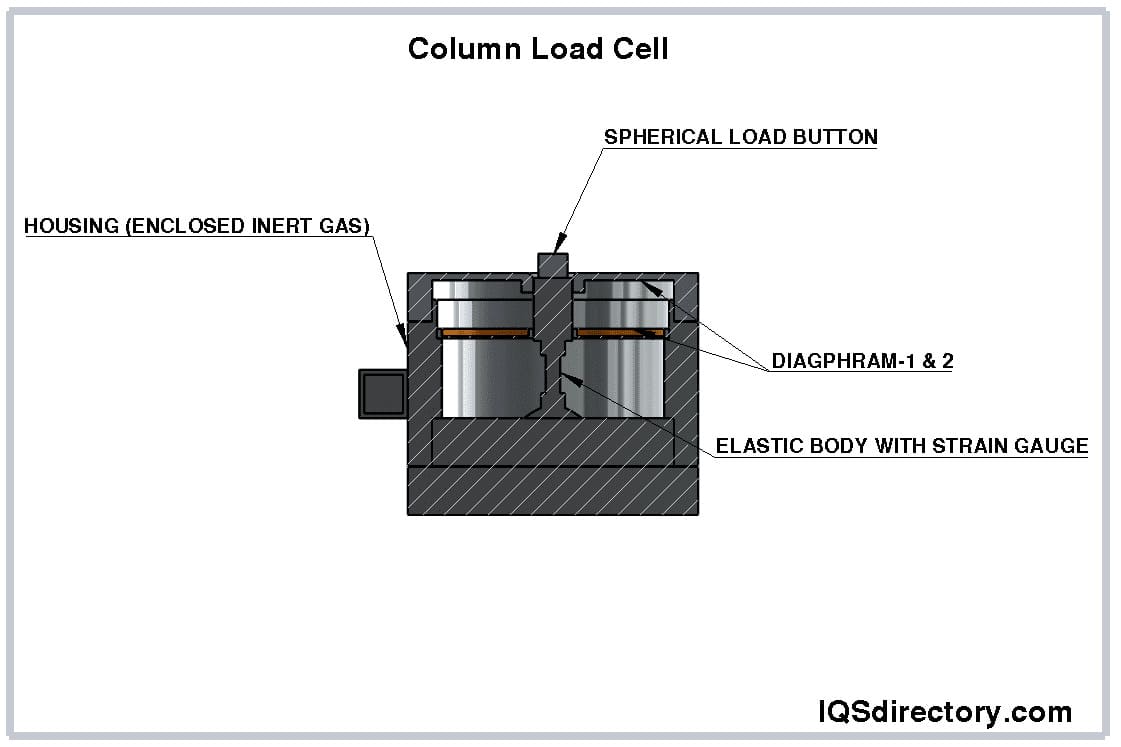

Column load cells measures compression forces and higher rates of load are necessary for the task.

Column load cells measures compression forces and higher rates of load are necessary for the task.

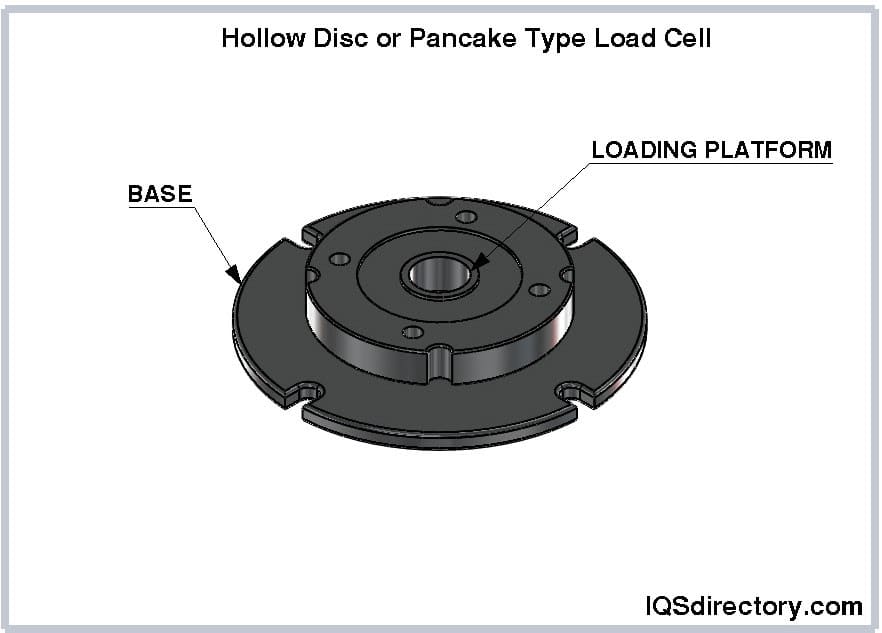

A pancake load cell used for both tension and compression measurements in materials.In addition to, component fatigue testing and axial force measurements.

A pancake load cell used for both tension and compression measurements in materials.In addition to, component fatigue testing and axial force measurements.

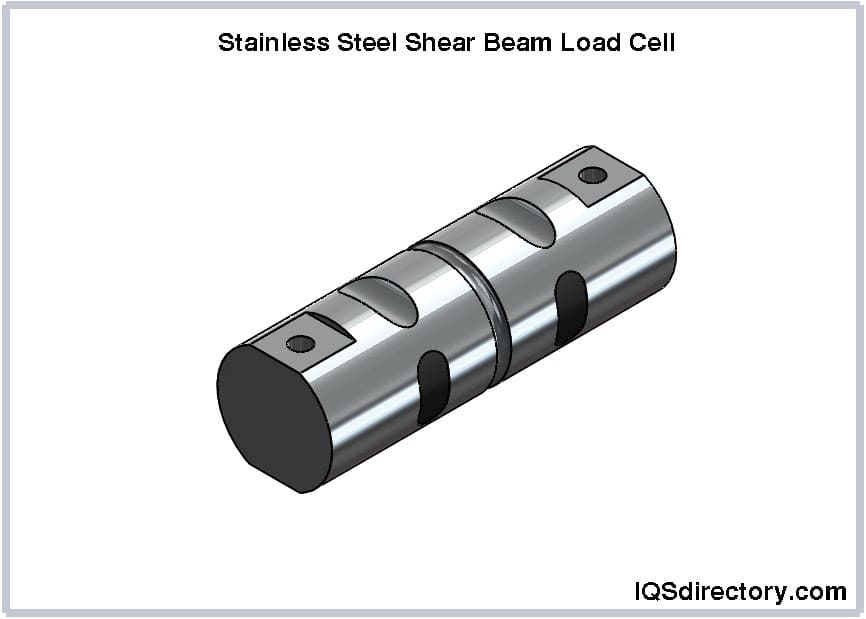

Beam load cells also known as bending load cells primarily used for industrial weighing.

Beam load cells also known as bending load cells primarily used for industrial weighing.

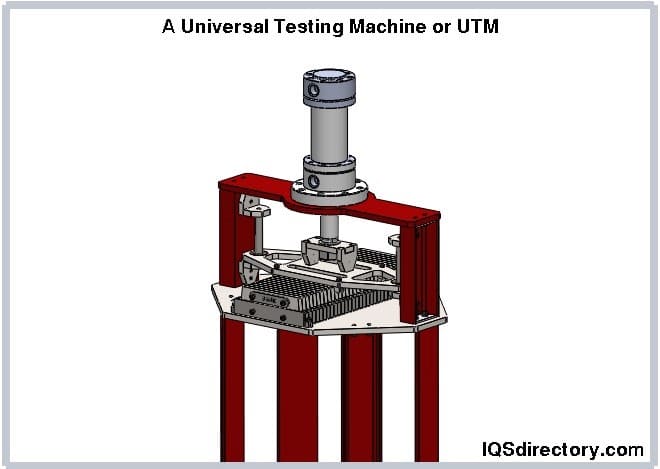

This equipment uses a load cell to test the tensile strength of products.

This equipment uses a load cell to test the tensile strength of products.

Types of Load Cells

Load cell manufacturing is dominated by three major categories: load cells that measure force, load cells that measure compression, and load cells that measure tension. However, some load cells can measure objects using more than one of these. Learn more about the various load cell types below.

- Hydraulic Load Cell

- This load cell type measures weight as a change in pressure of the internal filling fluid. Typically, hydraulic load cells are used for tank, bin, and hopper weighing.

- Canister Load Cells

- Built for compact and cost effective weighing applications. These load cells can accommodate a variety of capacities and are used for weighing applications in tanks, hoppers, and vehicles.

- Compression Load Cell

- Used to measure straight line pushing force along a single axis. This pushing force is often denoted as negative force. Since they engage in load cell compression, compression load cells are perfect for applications with limited space. Also, they offer great long-term stability.

- Tension Load Cell

- Used for measuring the pulling apart or positive force along a single axis. Both compression and tension load cells typically work using strain gauges.

- Strain Gauge Load Cell

- These are the most common types of load cells. Having a capacity rate between 5 N to more than 50 MN, a strain gauge offers high-res digital indicators and meets ideal force transfer standards.

- Force Sensor

- Or force gauges, use strain gauges to test push-pull and measure flow.

- Pressure Sensor

- And force sensors are transducers very similar to load cells that measure pressure, applied force and strain in gas pressure, altitude and liquid pressure. These sensors are often piezoelectric sensors.

- Piezoelectric Crystal Force Transducer

- These cells are used for measuring crystalline materials. Whenever a force is applied to a crystalline material, electric charges are generated. A piezoelectric force transducer with its charge amplifier measures the electric charge and converts the measurement into a digital signal that a user can read on the indicator. A load cell manufacturer typically also offers multi-component piezoelectric, hydraulic and pneumatic load cells.

- Miniature Load Cell

- Built to provide precise measurements for much smaller applications.

- Donut Load Cell

- Also known as thru-hole load cells, are made to measure compressive forces. They are called donut load cells because of their shape; they are smooth and round, with a hole in the middle that allows for application parts or bolts. Most often, they are used in oil and gas pump applications.

- Shear Beam Load Cell (S-Beam Load Cell)

- Consists of a straight block of material fixed on one end and loaded on the other. Members of the beam load cell family (also known as bending load cells) are typically used for industrial weighing applications. Examples of these applications include: industrial floor scales, tank and silo weighing, and on-board vehicle weighing.

- Low Capacity Transducer

- These miniature transducers are employed in medical testing equipment, wind tunnel sensors, weight counting machines, etc. Since they are low capacity, they have some limitations as well. For example, you can only gauge the weight between 0.9 ounce and 150 pounds. However, this specific feature makes them suitable for residential and retail machine applications.

- Mid Capacity Transducer

- These load cells have the capability to accurately measure weight between 200 to 20,000 pounds. They are an ideal option for all types of industry and manufacturing applications. Some common uses include industrial scales, truck, and truck weighing scales, bolt force measurement machine, and massive platform scales.

- Micro Load Cells

- Falls under the category of the resistive load cells which work with the principle of zero piezo-resistivity, meaning that when a load/force/stress is applied to the sensor, the resistance is changed. Because the resistance is changed, the output voltage is also changed (because the input voltage has been changed).

- Multi-Axis Load Cell

- Designed and manufactured to measure a multitude of forces and/or moments simultaneously with a single load cell sensor. These sensors provide multiple bridges that precisely measure the applied force from one direction with little or no cross-talk from the other forces or moments when installed and used according to specifications.

- High Capacity Transducer

- These load cells can perfectly measure even a very high weight. To be specific, these devices can measure anything more than a weight of 25,000 pounds.

- Specialty Transducer

- Varieties of transducers that can be used underwater and in space. Depending on their application, they may measure compression, tension, pressure, capacity, or something else.

- Pin Load Cell

- A type of strain gauge load cell that is constructed with load measuring pins. A load measuring pin, or load pin, senses the force applied across it using strain gauges installed inside a small bore that runs through the center of it. This type of load cell is used in anchors, shackles, sheaves, bearing blocks, and pivots. Also, pin load cells work well underwater. This is because: 1) the pin is protected, and 2) the pin load cell is made with load cell cable, stainless steel, and end caps that hermetically seal it.

- Pancake Load Cells

- Suitable for use in weighting and force measurement applications. They can be used for both tension and compression and are usually used in materials testing and component fatigue testing applications for axial force measurements where a high accuracy, low-profile device is required.

- Dynamometer Load Cell

- A device used to measure force, torque, power. When you combine a dyno with load cell sensing technology, you get a dyno load cell. Dyno load cells are used primarily to measure engine power output. Because dynos are rather expensive, dyno load cells are usually only used when absolutely necessary.

- Single Point Load Cell

- Have and use only one operating load cell. Usually, single point load cells are used in individual device applications, such as supermarket scales.

Applications of Load Cells

The purposes of load cells, also known load transducers, are to help the user measure the physical quantity or mass, and to convert force or energy into another form (ex. force, light, torque, motion, etc.).

Various types of load cells are used in mechanical testing, ongoing system monitoring and as components in devices such as industrial scales. They are popular in a number of automation, sensor, and control systems across a wide range of industries.

Industries in which load cells are used include:

- Food Processing

- To precisely measure ingredients and to properly distribute the products during packaging.

- Industrial Warehousing

- Where they are used to determine the precise weight of loaded pallets, which is crucial for the filling and accepting of orders.

- Building and Construction

- Testing of building materials, such as beams, for tension and structural strength.

- Transportation

- Railcar weighing and truck scales.

- Research Laboratory and Pharmaceutical Production

- Weighing equipment, calibration systems, fatigue testing.

- In addition, load cells can be found in applications such as: security systems, electrical weighing scales, personal scales, thermometers, machines in the defense sector, industrial automation, submarine pressure sensing, and material testing.

Load Cell Installation

Each load cell is unique, and requires that special caution be taken during installation. To learn just exactly how you should install yours, talk to your supplier.

Standards and Specifications for Load Cells

No matter your industry, you want a high-quality load cell. That’s why we recommend that you look for load cells from a company with an ISO certification. In addition, look for load cells that adhere to ANSI/J-STD-001B and/or SAE AS9102 standards. It’s also a good idea to make sure that your load cell is put through insulation resistance testing before you bring it back to your facility. This quality control measurement will make sure that your load cell is safe and ready.

For products that may be used in the European Union, request RoHS certification. From there, standards depend on your industry. For example, if your load cell will be used by NASA, it must meet NASA-STD-8739.3.

Things to Consider When Choosing Load Cells

In today's society, the efficacy and accuracy of balancing scales are at their best. Scientific explorations have made it possible for us to accurately assess the weight even to the hundredth and thousandth of a decimal. There are no chances of inaccuracy when measuring the weight of an item on an electric scale.

However, there are a number of factors, whether intended or not, that may have an effect on the accuracy of scales. These include:

- Correctness of Load Cell

- A balancing scale gets its accuracy from the load cell. For accurate results, you need to pick a machine that has been produced using high-quality load cells. Only the correctness of the load cells can ensure that you get the most clear-cut weight measurement of your commodities.

- Load Application Process

- When assessing the G-factor of an item, you need to make sure that you are applying or putting on the load correctly on the machine, as per the suggestions provided with a user manual. This process is easier if you are using a low capacity home or small business machine. Heavy items pose a greater intricacy in loading and unloading weight on a scale. To check the accurate weight of a heavy item and to avoid strain gauges, the load should be applied correctly and evenly on the machine. The load points should be aligned properly.

- Weighing Environment

- When measuring hefty loads, ensure that only the load is being applied on the scale. Keep any and all environmental factors such as wind and temperature in check. That is why choosing a safe site to install the mid and large level balancing scale is important. All these factors can result in a massive change in the gross weight. While doing this, you also have to avoid pressure differentials.

- Installation and Use of Weight Controller

- Improper installation can be the key reason behind inaccurate poundage and a hefty loss in time and materials. You should ensure that proper balance is applied to your scale and surrounding environment. Refer to the installation guide provided by the machine supplier for more information. Further, you can intelligently deploy a weight controller system to reduce the noise and other similar effects during the mass check routine.

- For the best results, no matter your application, you need a high-quality load cell that is well matched. To get this, you need the right manufacturer. How do you find the load cell manufacturer for you? We recommend you start by browsing the websites of the companies we have listed above. If and when one interests you, reach out to them with your specifications. Make sure that they’re willing to work within your timeline and budget. Also make sure that they are willing and able to meet your specifications. Customer service is key.

Proper Care for Load Cells

Load cells are extremely sensitive, so it’s very important that you treat yours with care. Here are a few tips for proper load cell care:

- To prevent high voltage surges, use a stable power supply.

- Do not remove or tamper with sensor covers.

- Monitor the temperature environment, making sure that it doesn’t exceed what your load cell can handle.

- Do not pinch, kink, yank, or overbend your load cell cable.

Accessories for Load Cells

Load cells are pretty self-sufficient, so they don’t come with many accessories. However, they do have a few. These include load cell bases and load cell buttons. Bases allow end-users to bolt their load cells to a reliable, stable surface. From here, the load cells can work from a simple interface. Load cell buttons are perfect for use where there are misalignments of applied load.

Load Cell Terms

- Axial Load

- The load applied to the length of, or parallel to, the primary axis with which it shares a common axis.

- Calibration

- Load cells output comparison against standard test loads.

- Creep

- The output change of load cells that occurs over time while the load cell is under load, while all environmental conditions and other variables have remained constant.

- Dead Volume

- The volume inside the pressure port of force sensors, or transducers, at room temperature and barometric pressure.

- Deflection

- The change of length along the primary axis of load cells involving no-load and rated-load conditions.

- Diaphragm

- The membrane part of force sensors that changes its value under pressure-induced displacement.

- Drift

- An unexpected change in output under constant load conditions.

- Driveline Shaft

- A steel tube with a u-joint at each end of load cells that transfer torque from the output of the transfer case to the axle.

- Eccentric Load

- A load, which is applied parallel to, but not having a common axis with, the primary axis of load cells.

- Electrical Excitation

- The current or voltage that is applied to the input terminals of a transducer.

- Flush Diaphragm

- A sensing device of load cells that is located on the very end of a transducer with no pressure port.

- Full Scale

- The amount produced equivalent to the maximum load for a specific load cell application or test.

- Full Scale Output

- The numerical distinction between the least output and the rated capacity of load cells.

- Hysteresis

- The greatest difference between load cell output readings for the same applied load. One load cell reading is obtained by escalating the load from zero, the other load cell reading by lessening the load from rated output.

- Input Impedance

- The resistance measured across the excitation terminals of a transducer at room temperature at the point where there is no load applied and the load cell output terminals are open-circuited.

- Load

- The force, weight or torque that is applied to the transducer, load cell or force sensors.

- Load Cell

- The round shape of the top surface of load cells, transducers or load sensors where the load is applied.

- Measured Media

- The physical number, property or circumstance that is measured by load cells, such as acceleration, force, mass or torque.

- Piezoresistance

- The change in resistance caused by an applied strain of the load cell diaphragm.

- Primary Axis

- The geometric centerline (axis) along which load cells are designed to be loaded.

- Pull Plate

- An attachment to load cells, which allows tension or compression forces to be directed at the center line of load cells through a threaded center hole.

- Safe Overage

- The maximum pressure or load that may be applied to the transducer, load cells or force sensors without causing permanent damage or a change in the load cell performance specifications.

- Shear

- Force that tends to divide an object along a plane parallel to the opposing stresses within load cells.

- Strain Measurement

- The ratio of the change of the length of a structure when force is applied to it to the dimension of the original length.

- Torque Sensor

- Measure the rotary movement of a force or system of forces that cause rotation in an engine. They gauge the torque transferred along the drive-line axis at the place where the sensor is positioned.

- Zero Balance

- The output signal rated excitation of load cells with no load applied, usually expressed in percent of rated output.