Leak Detectors

Leak detectors are equipment designed to identify and locate liquid or gas system leaks and determine the amount and composition of a leak, using sound, visible indicators, flame ionization or ultrasonic waves. They indicate changes in pressure, flow rates and/or locate excess fluids or gas.

Quick links to Leak Detectors Information

The History of Leak Detectors

- Leak Detectors in the 1800s

- Gas leaks have been a concern since the Industrial Revolution, when the harmful effects of some gases on humans were discovered. Early detection methods were fairly imprecise.

- The first industrial age gas detector is known as Davey’s lamp, or the flame safety lamp. Invented in 1815 by Sir Humphry Davey, it was used to detect the presence of methane, known then as "firedamp," in underground coal mines. It consisted of an oil flame encased within a glass sleeve with a mesh flame arrestor. The flame was adjusted to a specific height that indicated fresh air. If methane was present, the flames would get higher, and if oxygen depleted, the flames would get lower. In some parts of the world, this method is still used.

- During the 19th and early 20th centuries, coal miners also brought canaries down into the tunnel with them to help them detect the presence of gases like methane, carbon dioxide and carbon monoxide. Canaries normally sing quite a lot; when the canaries were singing, they knew everything was fine. However, if gas began to leak, the birds would stop singing. If they weren’t removed quickly, they would die. So, if the birds became silent, the miners would know to leave the tunnels as quickly as possible.

- Leak Detectors in the 1900s

- Fortunately, this inhumane gas leak detection method was slowly phased out after the invention of the first modern gas detectors. Between 1926 and 1927, Dr. Oliver Johnson developed the catalytic combustion (LEL) sensor. At the time, Dr. Johnson was an employee of the company that would become Chevron, Standard Oil Company. His goal was to prevent explosions inside fuel storage tanks by developing a method to detect combustible mixtures in the air. His prototype was labeled the "Model A," while his second model, an electric vapor indicator, was labeled the "Model B."

- In 1928, Dr. Johnson started the world’s first gas detection company with a man named Phil Williams. The company, known as Johnson-Williams Instruments (or J-W Instruments) was based in Palo Alto, California, and became known as the first electronics company in Silicon Valley. J-W Instruments would go on to create many more leak detection devices, such as portable oxygen detectors and combination gas detections.

- During the 1980s and 1990s, electronic household carbon monoxide detectors became quite common. Before then, homeowners detected carbon monoxide using chemically infused paper that would turn brown when exposed to the gas. Since the 1990s, engineers have developed many more electronic devices and techniques to monitor, detect and alert users of the leaking of a wide range of gases.

- Today, gas detectors are much improved and available for a wider range of systems, such as medical diagnostic, monitoring and treatment systems, and automobile air quality systems. They’ve also become much more affordable. As technology advances, engineers are and will continue to be able to modify leak detectors to become more accurate, diverse and small.

The Benefits of Leak Detectors

Often, leak detectors act as literal lifesavers. That’s big benefit number one. They also have many less sweeping advantages. For example, they’re generally equipped with alarms, so that you know the second a leak occurs, and you can get you, and your staff or family to safety. Second, they’re highly accurate. Third, they’re quite easy to maintain; the main thing is to change your sensor or sensor cable regularly and make sure they’re properly calibrated. Also, since manufacturers can customize them to detect one or many types of gas at once, they’re quite versatile.

How Leak Detectors Work

Most leak detectors are hand-held devices that are programmed to monitor specific conditions. The mobility of the leak detectors is important because of the tight and complex networks of piping that are sometimes used to house a gas or a liquid. Most methods of leak detection are operator dependent. Some systems, however, such as those used to detect water leaks, are able to monitor changes in atmospheric conditions without the use of an operator.

Design of Leak Detectors

Factors of design that manufacturers consider include: the type(s) of gas to be detected, the permanency of the detection system, the level of sensitivity required, and system robustness.

- Gases Detected

- Gases for which they most commonly design detectors include: refrigerant gases and Freon, natural gas and methane gas, chlorine, oxygen, sulfur dioxide, chlorine dioxide, hydrogen sulfide and radon.

- Environments for Detection

- They also design generally for certain environments and the substances most likely to leak there, such as residential buildings, automobiles and furnaces. For example, when designing for the home, they focus on refrigerant gases and natural gas. Refrigerant gasses are compounds that often leak out of refrigerators, freezers and air conditioning equipment. Freon is the brand name given to a whole class of chemicals used in older refrigeration systems that, if leaked out, may cause heart problems for those that breathe it in as well as deplete the ozone layer. Natural gas is a common energy source used for heating, cooking and water heating. It is composed of the highly flammable methane gas, and could start an explosion or massive fire if it is leaked and comes in contact with any sort of spark or flame. If methane gas is inhaled in large quantities, it can also be fatal. When designing for settings like automotive manufacturing, car engines and furnaces, manufacturers focus on detecting and locating vacuum leaks, using helium gas.

- Permanent Detector Designs

- It is important for any heating system that uses natural gas to have permanent detectors. Other detectors, though, may be portable. Many of these have light or audible alarm systems and varying degrees of sensitivity. Some will only detect the lowest amount of methane gas in a room that could cause a fire or explosion, and many systems release a rotten egg smell if a leak occurs.

- Leak Detector Customization

- Leak detector manufacturers can customize your leak detectors in a few different ways. One of them is by tweaking the leak detecting compound. They can adjust them for temperature range, pressure levels, easier leak detection against different surfaces (ex. reflective aluminum surfaces, reflective stainless steel surfaces, vertical surfaces) and environmental friendliness, among other things. For instance, if your home or business sits on uranium-rich soil, manufacturers can add radon detection to your detector. They can also adjust your leak tester and sensor types for automatic or semi-automatic systems. For more information about custom leak detector services, talk to your supplier.

Leak Detector Images, Diagrams and Visual Concepts

Leak detectors, a sensor used to monitor a system that contains liquids, gasses, or other substances to ensure the contained materials do not escape the system.

Leak detectors, a sensor used to monitor a system that contains liquids, gasses, or other substances to ensure the contained materials do not escape the system.

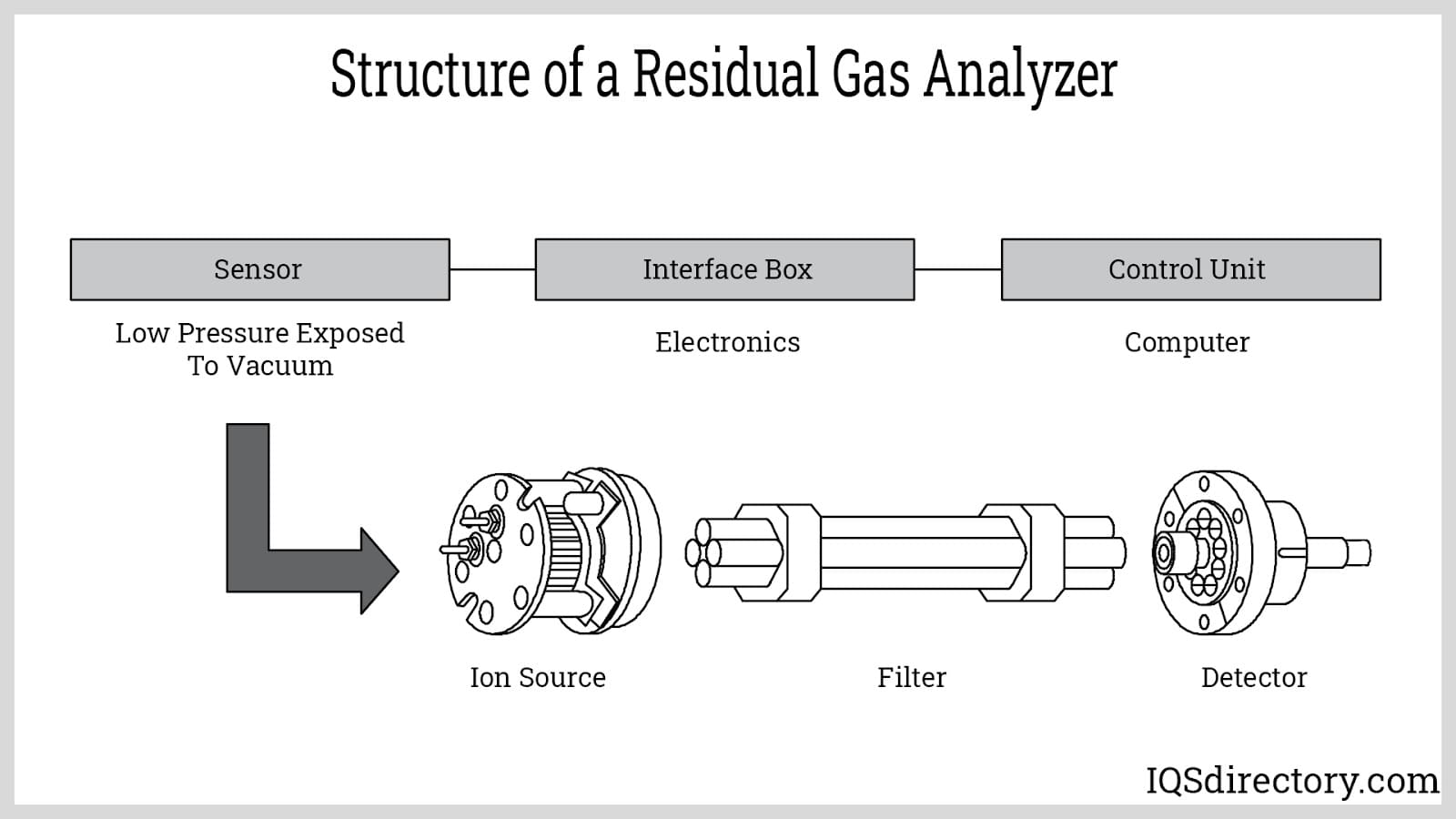

Residual gas analyzer, a small mass spectrometer designed for environmental analysis, process control, and monitoring vacuums for contamination.

Residual gas analyzer, a small mass spectrometer designed for environmental analysis, process control, and monitoring vacuums for contamination.

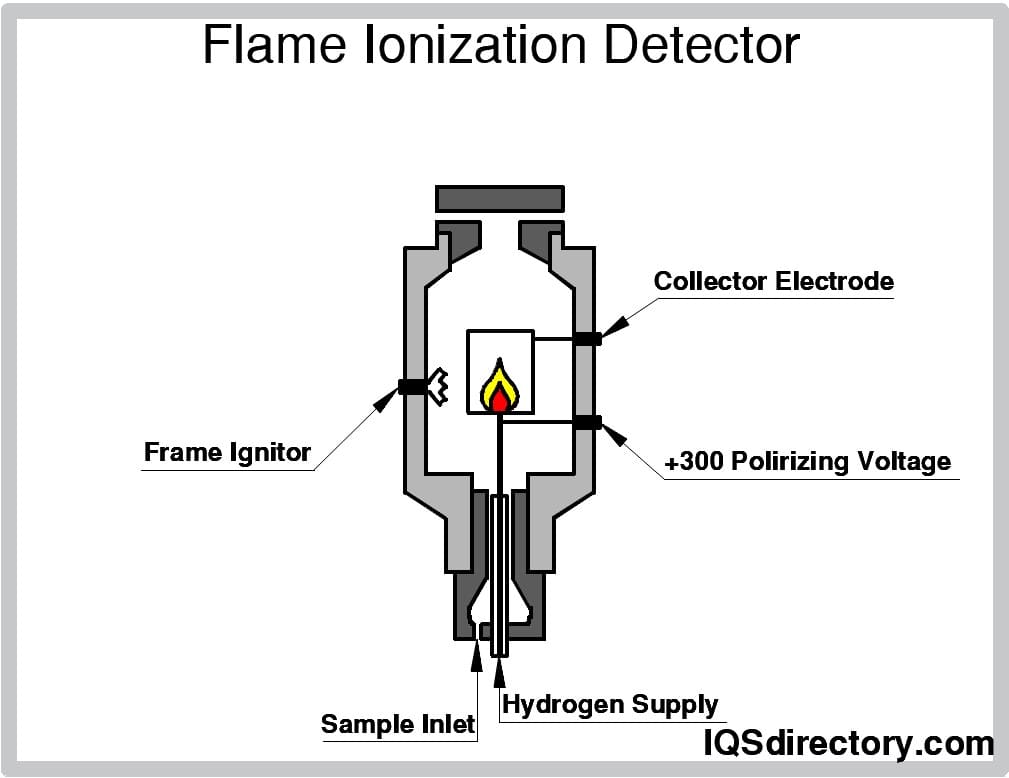

Flame ionization detector, an extremely sensitive detecting device that measures the concentrations of vapors.

Flame ionization detector, an extremely sensitive detecting device that measures the concentrations of vapors.

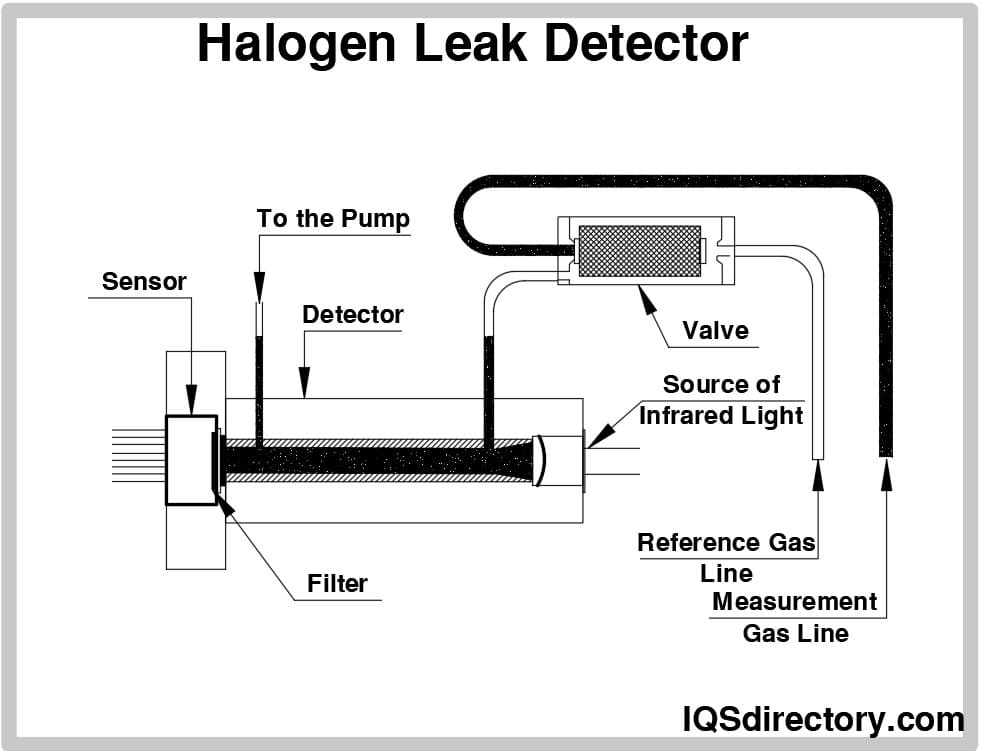

Halogen leak detectors determines the location of halogen gasses outside of the system.

Halogen leak detectors determines the location of halogen gasses outside of the system.

Helium leak detectors helium as a residual gas when testing a closed system.

Helium leak detectors helium as a residual gas when testing a closed system.

Spot leak detectors monitor leaks in a confined spaces and are used to detect liquid leaks.

Spot leak detectors monitor leaks in a confined spaces and are used to detect liquid leaks.

Ultrasonic leak detector uses sound to check for leaks since leaks produce high frequency sound

Ultrasonic leak detector uses sound to check for leaks since leaks produce high frequency sound

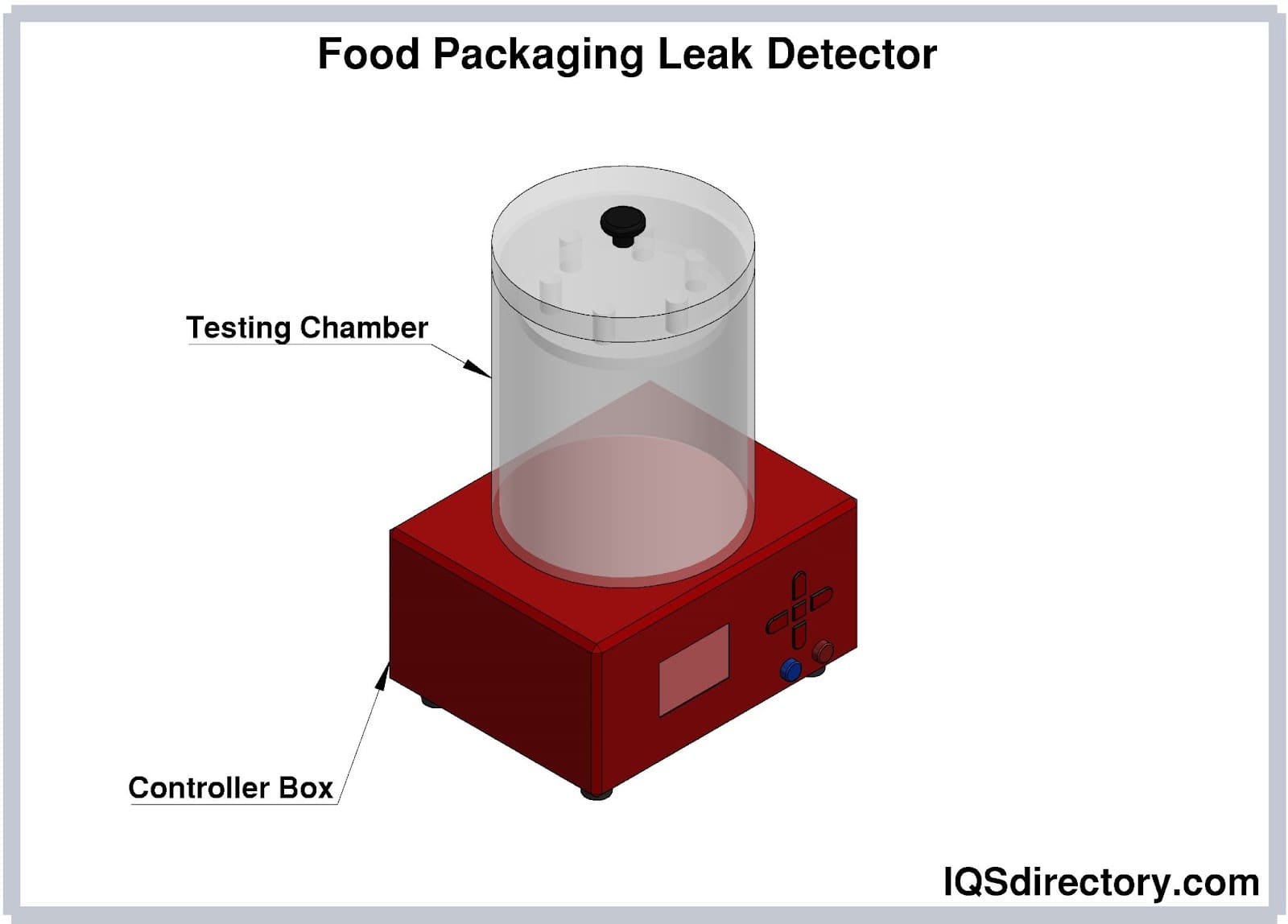

Checks for leaks in food packaging which can cause problems for food production.

Checks for leaks in food packaging which can cause problems for food production.

Leak Detector Types

Leak detection is identified by 4 main types of equipment: electronic leak detectors, ultrasonic leak detectors, flame ionization leak detectors and gas detectors, such as the helium leak detector.

- Water Leak Detectors

- In addition to these are water leak detectors. A water leak detector is designed to detect the presence of water or moisture within a large system or building. Like the other detector types, a water leak detector notifies operators if, and when, a water leak occurs. The use of water leak detector systems is less widespread than the use of gas leak testing systems because it is quite specialized. Most often, you will find them around the base of the floor and the perimeter of rooms in places like banks, data centers, archives, trading floors and similar mission-critical infrastructure.

- Electronic Leak Detector

- The fastest way to identify or locate a gas leak. There are two main types of electronic detectors: those that use a heated diode and those that use corona discharge. The detectors that use a heated sensor are less prone to false alarms as opposed to corona discharge, which can be set off by dust, moisture or solvents.

- Ultrasonic Leak Detector

- Fairly new to the leak detector industry and are mostly used for larger gas leaks. They are able to convert the quiet, high-frequency noises that gas leaks make into a louder, lower range that is heard through headphones and audible to the human ear.

- Flame Ionization Leak Detector

- Halide torch leak detection uses flame ionization to detect chloride refrigerant leaks exclusively. If a halogen refrigerant is present, the color of the torch flame changes from blue to green.

- Gas Leak Detector

- Different gas detectors identify certain types of leaks, such as refrigerant leaks like Freon, natural gas, halogen or vacuum leaks. To do so, gas detectors use a tracer gas like helium (making a helium leak detector) or hydrogen (making a hydrogen leak detector), which help detect other gases. After the tracer gas is pumped into the system with a potential leak, the gas detector measures the rate of the leak via a mass spectrometer, which provides test sensitivity.

- Note: Any detector that detects refrigerant leaks, whether it is a gas type or flame ionization type, is known as a refrigerant leak detector.

- Gas Analyzer

- Can confirm the presence of a leak, but they cannot determine its location. Types of gas analyzers include: exhaust analyzers, infrared analyzers and residual analyzers. Exhaust analyzers test the exhaust of machines and vehicles and are the most common type of analyzers. Infrared analyzers monitor CO2 gas, while combustion analyzers monitor installations and measure CO2 and flue gasses. Residual analyzers are suited to monitor contamination and process control, specifically in the semiconductor industry.

- Gas analyzers and leak testers are also available to aid in determining the specific composition of the leaking gas, although they are unable to locate the exact location of the leak. Leak testing equipment is used to detect the existence of a leak, but not the type of gas. They test for differences in pressure and use flow measurement, and are useful for defining and monitoring mass spectrometers.

- Halogen Leak Detectors

- Used to detect and identify the specific location of halogenated refrigerant leaks. This type of leak detector is not always permissible in certain settings. Both the pump and flame methods can give false results depending upon environmental contaminants near the test. Advancements in either technique constantly decrease the room for false positives.

- Vacuum Leak Detectors

- Provide fast, contamination-free, leak detection in closed systems using compressed air to monitor the changes in pressure that indicates the presence and severity of leaks. This particular type of detector is used in a wide variety of industries to test hermetic seals, refrigeration, scientific and medical instrumentation, aerospace technologies, automotive and medical systems.

Leak Detector Applications

Customers use leak detectors in order to detect existing leaks and stop leaks before they start. This function is a crucial part of the industrial sector. Having problems with leaks can not only cause a system to malfunction, but can also be hazardous to health, depending on what chemical or gas is being dealt with. Many different industries have leak problems, and thus need reliable and accurate leak detection equipment to eliminate those health and safety risks.

Unfixed leaks are a major source of economic loss in both the residential and industrial spheres. Leaking liquids and gases can damage surrounding equipment, and neglected leaks are a major health concern for people who inhabit a factory, work or home environment where one is present. Water leaks left unchecked create mold and therefore manifest many allergic responses in employees or customers exposed. The refrigeration industry is very concerned with the efficient and quality detection of leaks, as many of the chemicals, such as the now outlawed CFC (chlorofluorocarbon), can be found in many older refrigeration units still in use. That is why a whole subset of leak detectors have been manufactured for refrigerators.

Some of the many industries that rely on leak detectors include: medicine and healthcare, research science, HVAC, and automotive. In the medical industry, leaks can be found in pumps, containers, fluid transfer devices and other instruments that may play a crucial role in the lives of patients. Industries like research science and automotive use leak detectors on measuring equipment, water pumps, cylinder heads, calibrated volume vessels and hydraulic components.

Leak Detection Equipment Components

Different leak detection systems (LDS) have different equipment components. By and large, though, leak equipment components include: alarms for alerting people of leaks, sensors for detecting leaks and displays for reading. The sensor components they use vary greatly. Internally based systems use field instrumentation like pressure or fluid sensors to detect leaks from the inside. In order to detect leaks from the outside, externally based systems use field instrumentation like: infrared radiometers, thermal cameras, fiber optic cables, vapor sensors or acoustic microphones.

Standards and Specifications for Leak Detectors

If your LDS is for use with a petroleum or natural gas pipe system, we strongly suggest you make sure it complies to API (American Petroleum Institute) RP (Recommended Practice) 1175. API RP 1175 offers system operators a risk-based approach to managing a LDS. Specifically, it offers tips on developing a leak detection culture and strategy, selecting the appropriate leak detection system, and monitoring leak detection program performance. In addition, it helps outline appropriate Control Center procedures and training, as well as the roles and responsibilities of Control Center personnel. Finally, it identifies proper testing of equipment and alarms. API guidelines also help you meet government standards, such as those established by the Department of Transportation (DOT) for pipeline operators.

API RP 1155 (formerly API 1155) outlines the most important requirements for an LDS as:

- Sensitivity Standards

- A LDS must ensure that the loss of fluid as a result of a leak is as small as possible. This places two requirements on the system: it must detect small leaks, and it must detect them quickly.

- Reliability Specifications

- The LDS must be trustworthy. This means that not only must it correctly report any real alarms, but it also must not generate any false alarms.

- Leak Detector Accuracy

- If the LDS is designed to calculate leak flow and leak location, it must do so accurately.

- Detector Robustness

- The LDS must be able to operate even under non-ideal circumstances. For instance, if a transducer fails, the system must be able to detect the failure and continue to operate. If such a failure causes it to operate with reduced sensitivity until the transducer is fixed, though, that is okay.

Things to Consider When Purchasing Leak Detectors

Leak testing systems are incredibly important to have around, whether that be in your home, automobile or industry. In order to ensure that the LDS you purchase is safe, reliable and accurate, you need to work with a trusted leak detector manufacturer or supplier. To help you in your search, we’ve provided a list of vetted suppliers near the top of this page. While they’re all excellent, you can work with only one. So how do you choose from among them? We recommend that you visit their respective websites and check out the products and services they offer. Pick out three or four with whom you’d like to speak, then reach out to each of them with your specifications. Make sure to ask them about customization, standard certifications, budget, timetables and delivery services. Once you’ve spoken with all of them, compare and contrast their answers. Pinpoint a supplier that offers not only high-quality products, but high-quality customer service. Leak testing and detection is a crucial application, and so it’s important that your supplier really takes the time to work with you and learn about your application. Once you’ve determined which manufacturer that is, call them up and get started.

Leak Detector Terms

- Adsorption

- The condensation of gas or vapor on a surface.

- Aerosol

- The suspension of minute particles in the air.

- Analyzer

- An instrument that can determine qualitatively and quantitatively the components in a mixture.

- Blocking

- The conditions that cause leak detectors to malfunction, most commonly a lack of oxygen.

- Calibration

- The procedure used to adjust an instrument for proper response.

- Combustion

- The rapid oxidation of a material that is evolving heat and light.

- Explosive/Flammable Range

- The range of flammable vapor or gas-air mixture between the upper and lower flammable limits.

- Gas

- A type of matter that expands indefinitely to fill a contained space. Gas is characterized by its low density.

- Interference

- A gas other than the one being detected that will cause a false reading on a leak detector.

- Leak Tight

- Leakage that is at an acceptable rate for a system or component.

- Non-destructive Testing (NDT)

- The examination of an object or material with technology that does not affect the object's future.

- Permeation Leak

- A leak through a barrier that does not have a hole or a discrete passage.

- Quantitative

- The total amount of leakage for any particular system or component.

- Sensor

- A device that converts the presence of a gas or vapor into an electrically measurable signal. The sensor is the heart of a gas monitor and can also be used to detect other substances, such as moisture levels.

- Toxic Gas or Vapor

- Any substance that causes sickness or death when inhaled or absorbed by the body.

- Tracer Gas

- A gas that, when passing through a leak, is used by a specific leak detector to help detect the presence of other gasses.

- Vapor

- The gaseous state of a material below its boiling point.

- Zero Gas

- Clean air, and a way of ensuring that a small release of gas is not near the sensor when honing the sensing signal during calibration.