Glass Cutting

The term “glass fabrication” encompasses all of the processes used to work or treat raw glass material to turn it into a functional component or product . Examples include cutting, grinding, drilling, polishing, tempering, finishing, and edging.

Glass cutting manufacturers, or glass fabricators, produce a range of glass types which are used across many industries in applications as diverse as transparent barriers, insulators, containers, optical and laboratory instruments. The properties of transparency, heat resistance and relative strength make glass a valuable manufacturing material for applications requiring these features.

Quick links to Glass Cutting Information

The History of Glass

Pliny the Elder wrote about glass being manufactured as early as 5,000 B.C. Archaeological evidence only dates back to 3,500 B.C., when the Egyptians used pure sands of the region to make beads. The first vessels were made around 1,500 B.C. They were formed by winding ropes of ductile glass around a core of sand and clay. These were fused by repeated heating. Once the ropes were completely fused, the core was scraped out and the vessel was ready to use. Early glass making instructions date back to 650 B.C. They were cuneiform tablets found in the library of Assyrian king Ashurbanipal. The glass blow pipe was invented about 1 B.C. in Syria, making glass production faster, easier, and less expensive. Stained glass fabrication dates back over a thousand years. It was historically used for windows in churches and cathedrals. In modern times, it has developed into an art form that offers colorful flat windows and three-dimensional works of art.

In 1932, James Slayter accidentally invented fiberglass when he directed compressed air into a stream of molten glass. This resulted in a mass of wooly fibers that trapped gas or air between them, offering great insulating qualities. This product was patented by the Owens Corning company who named the insulate glass "Fiberglass". In 1936, Du Pont combined the glass wool with polyester resins, creating plastic sheets that could conform to any surface shape and be cured into a hard shell. The first fiberglass prototype of a car, the Stout Scarab, was built in 1946 but did not enter production. Today, fiberglass is used in the making of sports equipment, boats, wire coatings, and storage tanks.

Glass Cutting Images, Diagrams and Visual Concepts

Float glass is the most common type of glass and is manufactured by floating the glass on a lake of molten tin.

Float glass is the most common type of glass and is manufactured by floating the glass on a lake of molten tin.

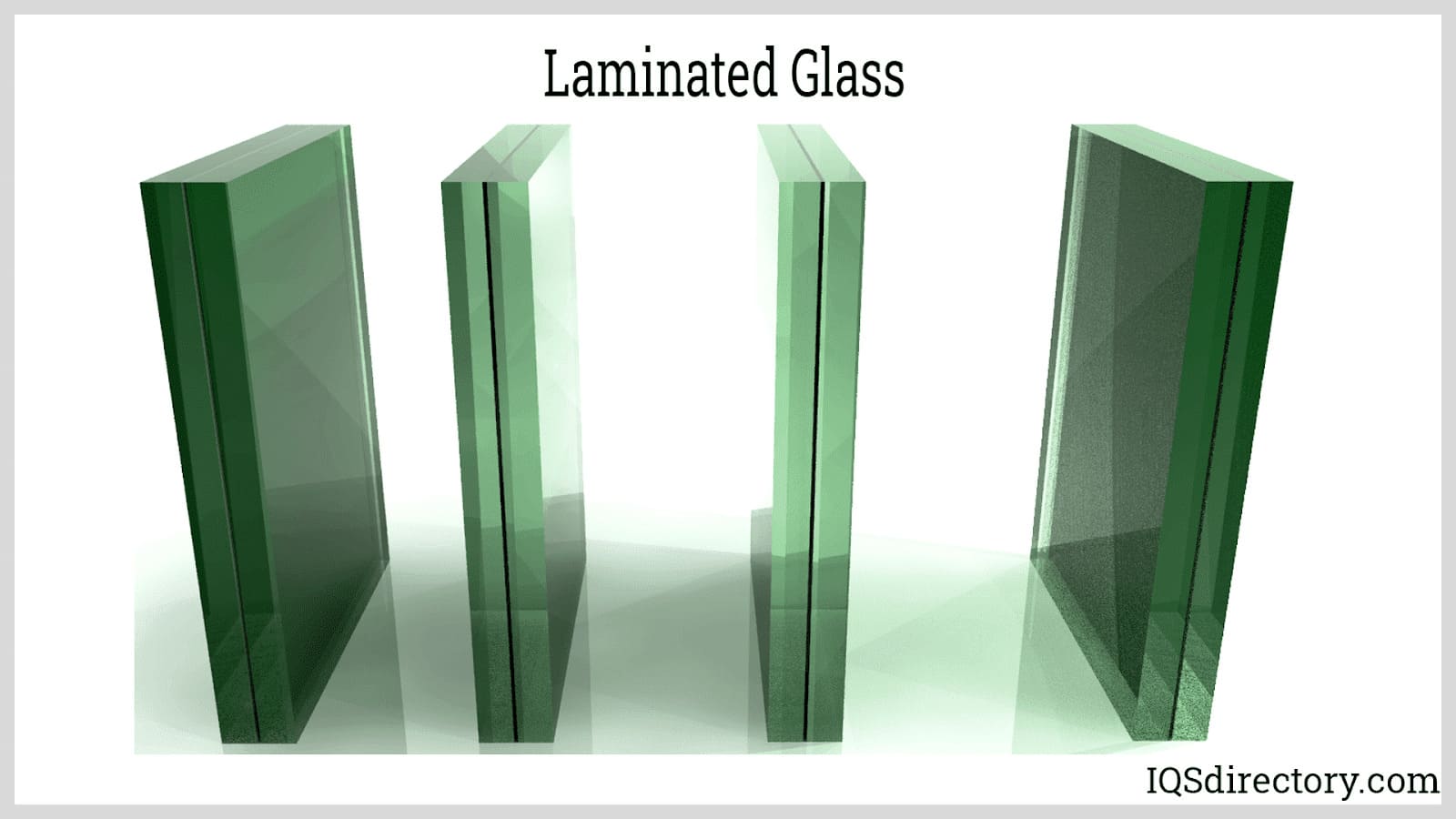

Laminated glass are two pieces of glass with an inner layer made from polyvinyl butyral to prevent shattering and pressed together under heat and pressure to create a strong chemical bond.

Laminated glass are two pieces of glass with an inner layer made from polyvinyl butyral to prevent shattering and pressed together under heat and pressure to create a strong chemical bond.

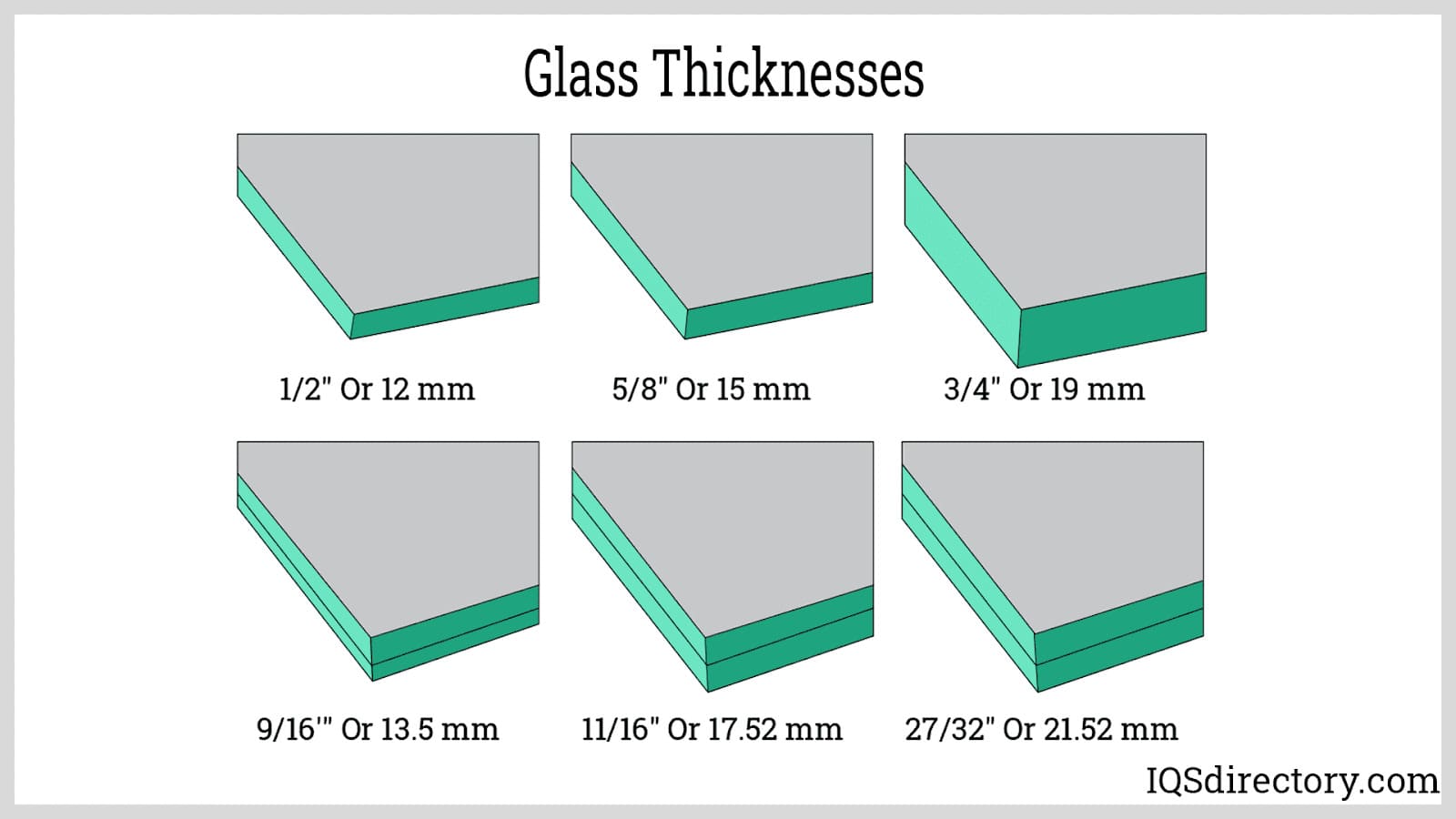

Glass thickness effects the type of tools required to cut the glass for example glass under 0.6 cm not much force is needed and the usage of light tool.

Glass thickness effects the type of tools required to cut the glass for example glass under 0.6 cm not much force is needed and the usage of light tool.

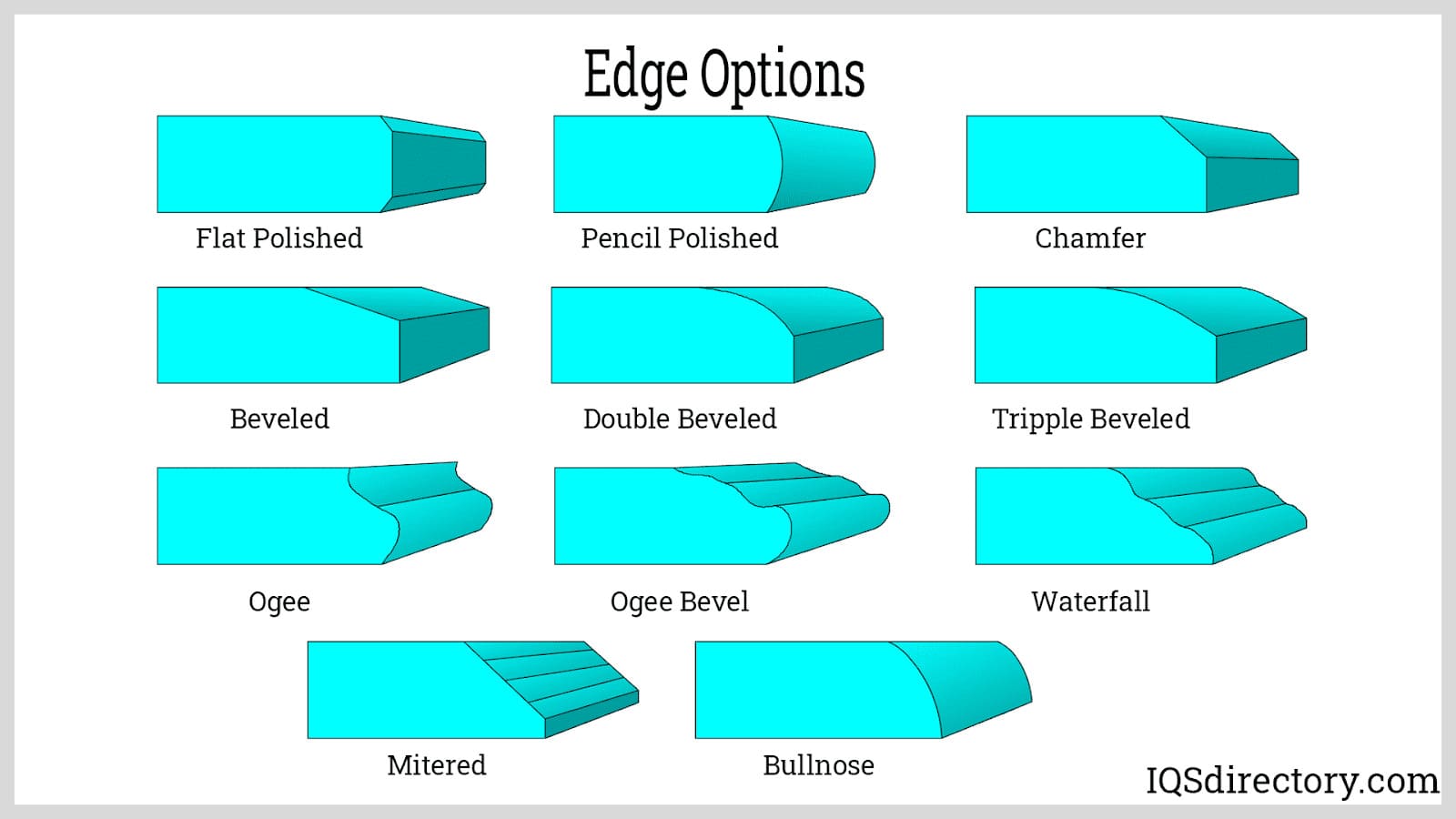

Edge treatments affect the functionality of the finished piece, to improve safety, add aesthetic appeal, improve functionality, and improve dimensional tolerance to prevent chipping and cracking.

Edge treatments affect the functionality of the finished piece, to improve safety, add aesthetic appeal, improve functionality, and improve dimensional tolerance to prevent chipping and cracking.

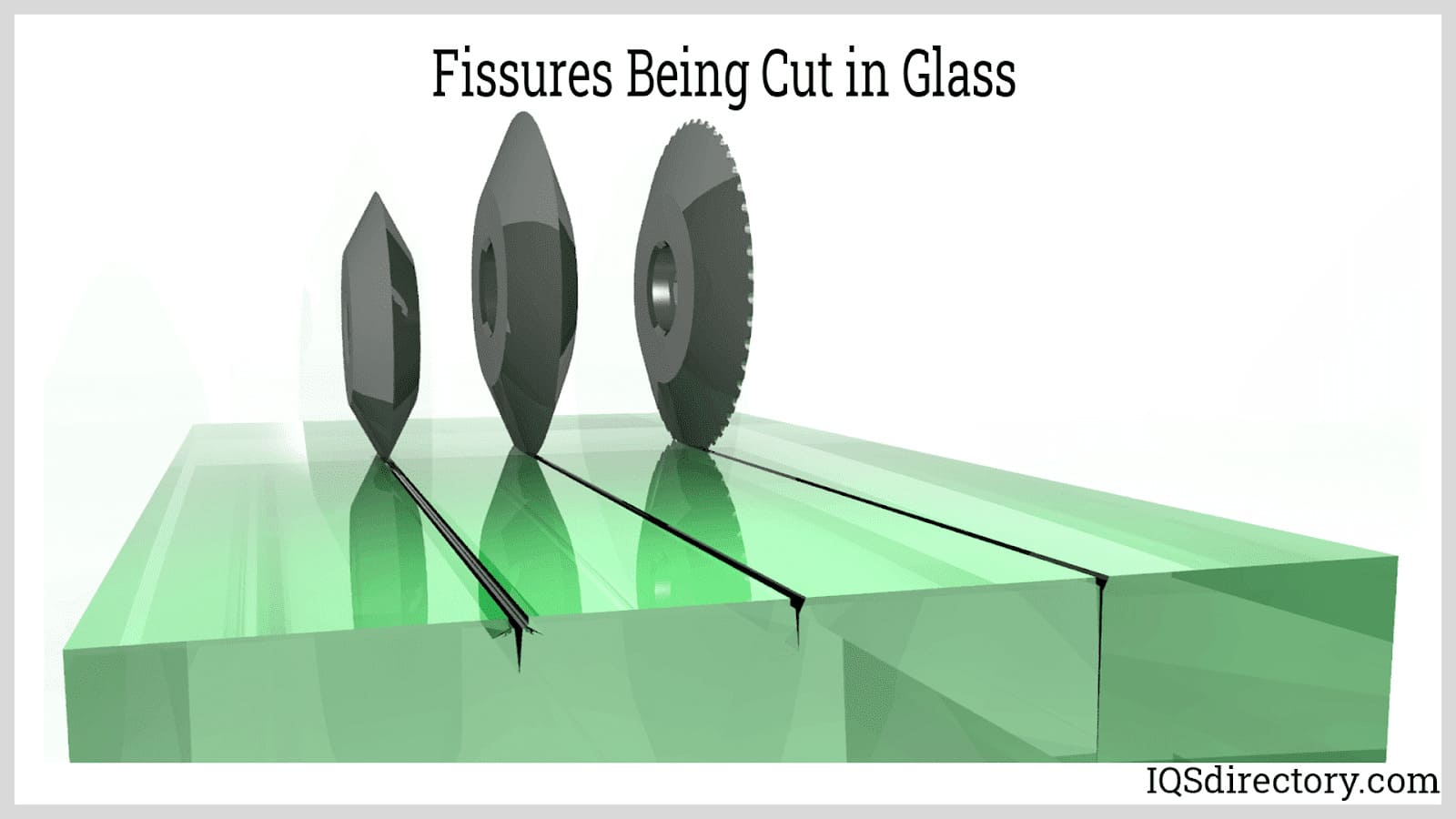

As the cutting wheel crosses the glass surface, it fractures the surface of the glass to create a fissure.

As the cutting wheel crosses the glass surface, it fractures the surface of the glass to create a fissure.

Every glass cutter has a cutting wheel that does consistent, precise, and accurate scoring.

Every glass cutter has a cutting wheel that does consistent, precise, and accurate scoring.

Glass cutting machines have servo motors, drivers, CNC control systems, and many forms of cutter wheels designed for a wide range of cuts.

Glass cutting machines have servo motors, drivers, CNC control systems, and many forms of cutter wheels designed for a wide range of cuts.

Laser cutting machines are programmed using CNC G codes, which are used for cutting flat and curved glass.

Laser cutting machines are programmed using CNC G codes, which are used for cutting flat and curved glass.

Glass Cutting Types

- Blown Glass

- Glassware shaped and created by air pressure; this has commonly been done by mouth in the past or by compressed air through a metal pipe. Pieces are often made in mass quantities such as bottles, via a highly automated system, which both moves and injects air into the glass gob to form the finished piece.

- Cut Glass

- Any glass object decorated by cutting or grinding facets and is for purely decorative purposes, like decorative plates or other assorted knick knacks.

- Flat Glass

- A wider classification of glass that includes wired and tempered glass. The main processes by which flat glass is made are the rolled and float glass procedures: rolled glass is made when a continuous stream of molten glass is poured between water-cooled rollers, while the float glass process is the most widely used process and consists of the glass being held in a chemically controlled atmosphere at a high temperature for a long enough time for the surface to become flat and parallel.

- Glass Blowing

- The process of shaping glass with air.

- Glass Cutting

- Includes various methods, including diamond saw cutting, thermal or hot cutting, score and break cutting, and laser cutting.

- Glass Rods

- Long, cylinder-shaped pieces of glass.

- Glass Tube

- A cylinder made of glass material.

- Heat Strengthened Glass

- Exposed to a heating and cooling cycle and is typically doubly strong as standard annealed float glass of equal measurements. Breakage of this glass results in larger pieces than with completely tempered glass.

- Precision Optics

- Offer superior clarity and precision to meet the very specific demanding needs for high-tech lenses, prisms, medical internal visual systems, etc.

- Quartz Glass

- The result of melted silica, and it can resist extreme or quickly changing temperatures and is typically transparent to ultraviolet radiation. This product is utilized in fiber optics, analytical instruments, semiconductor technologies and casting processes.

- Sight Glass

- A type of tubular or lens-shaped optical glass manufactured for the transparent observation and level gauging of liquids within manufacturing processes.

- Specialty Glasses

- Include any number of glass products fabricated for specific purposes, including bent, bulletproof, silk screened and colored glass and glass parts for industrial and commercial uses.

- Tempered Glass

- A type of safety glass that is heat treated and approximately five times stronger than similarly measured glass standard annealed float glass; breakage results in small, rectangular-like pieces, beneficial for general and safety glazing like storm doors, building entrances, sliding doors and bath and shower doors.

- Textured Glass

- A product with various patterned and uneven surfaces.

- Wired Glass

- Created by inserting a wire mesh into sheets of glass, which has a resistance to impact forces like normal glass, but wire holds broken pieces in place. This has customarily been accepted as inexpensive fire safety glass.

When Glass Gets Stranded

In its pure form, glass is clear and transparent to a full spectrum of light. Strands of glass thinner than a human hair can be spun from pure silica to create optical fibers. These fiber optic threads are bundled into hollow cables clad inside a mirrored shell. Light is passed through the hollow core, reflected indefinitely through the transparent cables, and used to transmit communication signals in a process known as total internal reflection. An estimated 300 million fiber kilometers are responsible for global telecommunications today.

Coloring Glass

Metallic oxides are added to color the glass. Cobalt, nickel, and manganese give glass blue, violet, and purple hues. Sulfur, lead, cadmium, and uranium create yellow. Chromium or copper compounds can be added for green coloring. Carbon oxides give glass amber or brown hues. Tin compounds are added to make white glass. For many centuries, selenium was added to make red glass, but the color tended to fade over time. A formula using gold to make the ruby color permanent was noted as early as the 10th century A.D., but was considered alchemy and did not come into wide use until the 15th century.

Glass Blowing

Hand blown glass manufacturing is primarily reserved for art glass, custom glass, and specialty fabrication projects due to its small scope and inherent dangers, including burns or toxic fumes. Free blowing occurs when short puffs of air are passed through the blowpipe into the gather, molten glass that has been spooled around one end of the blowpipe. The glass blower then inflates the piece creating a hollow blob that can be worked into custom glass fabrications.

There are three major phases of mechanized glass blowing, using state-of-the-art equipment to produce bottles, jars, or other containers. The first, batch processing, is handling of the raw materials. The batch house is a large silo filled with enough material to run for 1 to 5 days. These may be screened, dried, or pre-heated prior to being measured and mixed with other components. The combined ingredients are fed into a furnace. The batch enters the furnace via the batch charger, and is fed slowly and consistently into the glory hole, operating at temperatures up to 2,867 degrees Fahrenheit.

The hot end is where molten glass is formed into functional shapes. In the blow and blow method, a stream of molten glass is cut into a predetermined length, called a gob. Each gob is the equivalent of one container and is fed into a two-piece mold that is clamped and sealed with a baffle. The baffle is fitted with an air valve so that precisely measured blasts of compressed air may be applied. The first blast forms the outer aspects of the container, such as cap sealing lip or screw threads. A second blast hollows out the shape. The third blast finalizes the shaping of the vessel. In the press and blow method these first three steps are performed with the use of a plunger.

The final shapes, or parisons, are smaller than the finished product. As they leave the hot end, the parisons are given a final blast of air to bring them to the appropriate size. Once they are fully formed, the containers may then be treated with sulfur or fluorine gas, mixed into the compressed air or directly fed into the open end. This de-alkalizes the interior to provide chemical resistance. The finished glass products are transported through an annealing oven where they are evenly cooled. During the cold end of processing, an inspector checks each piece for defects. If none are found, the piece is packaged and shipped.

Creating Float Glass

Float glass is primarily used for windows, mirrors, and glass construction panels. In 1952, Sir Alastair Pilkington discovered a method of flat glass fabrication that would revolutionize the glass industry by floating a bed of molten glass over a bed of molten metal, usually tin. In a combined process, the raw materials are slowly melted into a viscous liquid. The mixture is homogenized to eliminate impurities and bubbles. The molten glass is introduced to the float bath through the refractory spout which pours the liquid glass onto molten tin. The sheet glass is cooled slowly, creating a solid ribbon. The ribbon is inspected for impurities or surface anomalies. At this stage, any coatings that change the optical properties may be applied to the surface through the process of chemical vapor deposition (CVD). Annealing reduces the possibility of stress fractures during the cutting process. After the float glass ribbons have cooled, a diamond wheel trims off the selvedge which is pre-stressed to prevent cracking during processing. The ribbons are then cut to order for use as windows, mirror strips, and screens.

Annealing is also used to temper glass, making it 4 to 5 times stronger. Tempered glass, which has been heated and cooled to extremes, shatters entirely into oval pebbles when broken, eliminating sharp edges and shards. Tempered glass is considered a type of safety glass and is used in coffee carafes, oven windows, shower doors, computer screens, and construction applications. Spandrel glass is an architectural product that is used on the outside of buildings to cover underlying framework and provide a sleek, unbroken, exterior finish. These panels are usually opaque from the outside and may be reflective. The reflective coatings are generally applied during the annealing process.

Laminated glass, another form of safety glass, is made by placing plastic between glass layers, which are then annealed to seal them together. These laminate glass products are used in such things as windshields for cars. When they break, the shattered glass adheres to the plastic layers, remaining in one piece.

Glass Cutting

Glass cutting on a small scale is accomplished through the use of a hand held cutting wheel. The wheel scores the surface of the glass along the break line. In the case of a straight edge, pressure is then applied to the surface on either side of the score line, producing a clean break. Grozer pliers and grinders are used to make smooth lines and curves along the glass cuts. The score and break methods are generally used to scratch a straight line and snap sheet glass or small tubes.

Diamond saw cutting uses a power grinder with a diamond encrusted wheel or a band saw with a diamond encrusted blade to score and make precision glass cuts with tight tolerances.

CNC Machining

Complex glass cuts and shaping may be accomplished with the use of CNC machining. The computer numerical control (CNC) process allows the glass fabricator to use a computerized machine to make precision grinds or glass cuts. These are programmed into the machine to reproduce the desired results. Some of these services include boring, drilling, grooving, slotting, pocketing, grinding, polishing or engraving of the glass.

Thermal cutting, also known as hot cutting, is accomplished through the use of CNC machining. It uses controlled heating and cooling of the glass along a break line to produce the glass cut. Used to cut laminates, the heat seals the edges of the plastic layer as it cuts.

A water jet cutter utilizes a high-pressure stream of water, sometimes mixed with an abrasive medium to score, and cut glass. The water jet mimics natural erosion, eating away the glass along the pre-programmed glass cut line. This method can be used for nearly any required shaping of glass fabrications. Similarly, an air jet cutter may be used. Compressed air mixed with abrasive materials scores and cuts the piece of glass.

Choosing a glass manufacturer depends on customer needs and the capabilities of the manufacturer. A good commercial glass fabricator will have a facility that is well equipped and staffed with competent design consultants and craftsmen. It will have ready access to raw materials and the appropriate machinery to produce the desired results. A good manufacturing facility will operate with regard to its impact on the environment as well as the economy. The right manufacturer will understand what is required and will assist the client in engineering a satisfactory end product.

What Is Glass?

Glass is an inorganic, amorphous solid, meaning that it retains its rigid, brittle structure without crystallizing. Prehistoric people used blades of volcanic glass, or obsidian. Iron age man traded glass beads made from the slag of their primitive forging processes. Today, manufactured glass is found in architecture, transportation, technology, and a wide range of everyday products. It is heat resistant, chemical resistant, corrosion resistant, pressure resistant, and strong. It can be reflective or refractive. Glass takes on a surprising variety of forms. It may provide transparent, translucent, or opaque barriers. It may be fabricated into vessels of any shape, size, or color. It is ground into fine optical lenses, formed into laboratory instruments, or used to create delicate "objects d'arte". It may be spun into fibers, pressed or poured into molds, blown, blocked, and laminated. Glass fabrication is almost as diverse, depending largely on the desired end product.

The properties of glass that allow for custom fabrication make it a valuable manufacturing commodity. Glass is made from one of the Earth's most abundant elements: silica, and is 100% recyclable. Introducing other elements into the manufacturing process changes the properties of the glass. Soda-lime glass is primarily used for bottles, jars, and float glass. As the name implies, it is made from silica, soda, and lime. Boron added to the silica makes borosilicate, which is expansive and heat resistant. Borosilicate glass is used in manufacturing cooking and laboratory vessels of Pyrex, which maintains accurate dimensions regardless of temperature. With the addition of phosphorus, it becomes electrically resistant borophosphosilicate, used in fabricating semiconductors. Alloyed with fluorite, the glass becomes fluorosilicate, used to make CD's and DVD's. Lead may be added to silica for the manufacture of optical glass, used in the making of eyewear lenses and optical scopes. Leaded glass is predictable and readily reproducible for consistent results.

Glass Cutting Terms

- Annealing

- The procedure of controlling the cooling of glass in the manufacturing of float glass; doing it in a lehr prevents residual pressures in the glass. Annealed glass from the manufacturer typically has a breaking strength of 500psi.

- Annealing Lehr

- An apparatus in the float glass production line subsequent to the tin bath and prior to the cooling conveyor, which controls the cooling and heating. It relieves pressure from the flat glass product to permit ordinary cold end-of-line processing.

- Anti-Walk Blocks

- Blocks of elastomer that restrict lateral movements of glass as it travels through the glazing channel caused by seismic, thermal, building movement, wind load effects or any other applicable force.

- Autoclave

- A container using heat and extreme pressure in the glass industry that creates a bond between glass and PVB or urethane sheet, resulting in laminated glass.

- Bent Glass

- A glass product that has been shaped from a flat shape into the desired curved shape during the molten state.

- Beveling

- The procedure of putting a bevel edge on finished cut glass.

- Bow/Warp

- An imperfection in flat glass that is a bend, curve or any other alteration.

- Bubbles

- Imperfections that occur in laminated glass as a pocket of air or gas between the interlayer and the glass. The parameter is any inclusion higher than .8 mm (1/32") in diameter in float glass.

- Chemically Strengthened Glass

- The strengthening of glass through ion-exchange to create a compressive pressure layer at the treated surface.

- Chipped Edge

- A flaw resulting from breakage of tiny pieces off of the edge of cut glass; typically, it is only significant for heat absorbing glass.

- Cullet

- Waste or broken glass. Can often be remolded for later use.

- Double Strength

- Float glass that measures approximately three mm thick (1/8").

- Flare

- A protrusion on the edge of a lite of glass.

- Flat Glass

- A general term that describes float glass, sheet glass, plate glass and rolled glass.

- Float Glass

- Glass formed on a bath of molten tin. The surface in contact with the tin is known as the tin surface or tin side. The top surface is known as the atmosphere surface or air side.

- Gob

- The portion of hot glass delivered by a feeder or gathered on a punty or a pipe.

- Heat Absorbing Glass

- Glass designed to absorb significant quantities of solar energy.

- Laminated Glass

- The bonding of two or more panes of glass (lites) with one or more interlayers; the interlayer is composed of plastic. The glass lites could be various colors and thicknesses, mirrored or stenciled, and the intermediary plastic material choices are many depending on the preferred effect.

- Lite

- An industry term for pane of glass, spelled differently to differentiate from perceptible light.

- Moil

- The left-over glass remaining on a punty or blowpipe after a piece has been completed and cut off.

- Polished Wired Glass

- Wire glass with both sides polished and ground.

- Punty

- A device to which ware is attached for holding during fire polishing or finishing.

- Quartz Glass

- Glass that is composed almost entirely of silica.

- Seam

- The mark on a glass surface resulting from joint of matching mold parts.

- Temper

- A reference to the degree of enduring stress found in annealed glass.