Fiberglass Fabrication

Fiberglass fabrication is the process of combining thin glass fibers with different resins to produce a strong, light weight product. Since the introduction of fiberglass, it has been used as a reinforcing agent for plastics as well as insulation in buildings and appliances. Fiberglass is used in fabrication applications that demand light-weight material with high-strength and scratch-resistant qualities.

Quick Links to Fiberglass Fabrication Information

The History of Fiberglass Fabrication

The earliest form of fiberglass wasn't truly fiberglass as it is currently understood. While in modern industry fiberglass usually refers to fiberglass reinforced plastics, when originally created the term referred to mass produced glass wool.

Games Slayter invented the process for mass production of glass fiber in 1932, which he used to produce glass wool he called 'fiberglas' by trapping gas in glass fibers.

Modern plastic fiberglass composite came several years later in 1936, when du Pont used a combination of fiberglass and resin to create a product with the gas of glass wool replaced with plastic. This greatly reduced the insulation properties of fiberglass, but added significant structural strength such that the material might be used in construction.

By 1942, peroxide curing and polyester resins similar to those used in fiberglass fabrication today were being used in the production of fiberglass. The development of plastics over the last century has accordingly led to significant improvements in basic fiberglass, and the expansion to countless special varieties and configurations.

In modern parlance, fiberglass usually refers to the newer form of glass fiber composite made using plastics and glass fibers, but also encompasses various glass fiber composites such as low-density glass wool used in insulation.

Fiberglass Fabrication Process

Of the fiberglass fabrication processes, fiberglass molding is the most commonly used process in the creation of fiberglass reinforced plastic products. The fiberglass itself is made of molten glass extruded through ultra fine openings in a tool, resulting in thread-like formations that are then woven together to form a rough cloth or patch. These fibers are combined with plastic resin by heat treatment or pressing. This process is used to form many different fiberglass products, including panels, shells of racing cars, electric circuit boards, machinery support and an extensive variety of other products. Fiberglass does not expand or shrink with temperature change. It is not water absorbent, has a high strength-to-weight ratio, is nonflammable and chemical resistant and acts as an electric insulator. Fiberglass fabricators manufacture various types of fiberglass products. One prominent example is corrugated fiberglass, which is made up of two-layer fiberglass sheets and fiberglass panels and is used in building construction.

The three main methods of fiberglass fabricating are open molding, closed molding and centrifugal molding. In open molding fiberglass fabrication, a layer of gel coat is applied and cured in a one-piece mold or structure. After being layered into the mold, the fiberglass and sprayed resin are allowed to cure. Open molding releases more emissions than the other two processes. In closed molding, the initial gel coat is applied in a two-part mold. Fibers in the form of chopped fibers or laminated sheets are sprayed or placed in the female part of the mold on top of the gel coat. The part cures after being sealed in the mold by a vacuum and catalyzed resin is injected into the pressurized mold. In centrifugal molding, the gel coat is applied to the sides of a spinning cylindrical mold. Layer by layer, catalyzed resins saturated with short fibers are sprayed into the mold until desired thickness is reached. Centrifugal molding is used to form cylindrical products, such as pipes and tanks. In all processes, the end products are then demolded and trimmed. Corrugated fiberglass is perhaps the most widely used fiberglass product used today. It is strong, may be either a solid color (often green) or transparent for light transmission into buildings. It is mostly used in building construction to make siding or roofing, and it is often used to build greenhouses and sheds. Corrugated fiberglass is generally composed of two layers that are glued together. The outer layer is a hard, weather-resistant resin surface, while the other layers are made of fiberglass.

Fiberglass enclosures like fiberglass tanks and fiberglass boxes are other important fiberglass products. Other examples of fiberglass reinforced plastics include fiberglass pipes and fiberglass rods.

Fiberglass fabricating begins with one of three molding processes before continuing on the certain steps consistent across methods. These initial molding processes are open molding, closed molding, and centrifugal molding.

- Open Molding

- A one-piece structure or mold is used. A layer of gel coat is applied and cured, then fiberglass and resin layered in and allowed to cure. Notably released more emissions than alternative molding techniques.

- Closed Molding

- Uses a two-part structure in a more complex process than open molding. After the application of gel coat to the mold, glass fibers are added to one part of the mold as laminated sheets or small chopped pieces of glass fiber. The part is cured in a sealed vacuum and specially catalyzed resin is injected into the mold.

- Centrifugal Molding

- A process used specifically in the production of cylindrical fiberglass products, such as pipes and fiberglass tanks. In this process, a rotating cylindrical mold has gel coat applied to the sides, then resins saturated with fibers are layered into the mold via sprayer until the cylinder reaches the desired thickness.

- Demolding

- All three molding processes come together. There are several potential approaches to demolding, offering different degrees of stress, speed, and convenience. These options include mechanical demolding, demolding by hand, and demolding via compressed air.

- Trimming

- After a fiberglass structure has been removed from its mold, it is then trimmed or cut using any number of specialty tools and systems. Depending on the end product and the fabricator's toolset, this may be a highly automated process using modeling software and high end mechanical automation, or a manual crafting process using hand-tools and simpler fiberglass cutting machines.

- Other Processes

- Some fiberglass products will require additional coatings and treatments after the trimming process to produce the final desired specifications. However, most forms of fiberglass can be fabricated with specific colors, resistances, and applications in mind, minimizing the need for post-processing relative to other fabricated materials.

Material Types for Glass Fabrication

There are a number of different types of fiberglass and resins used to make fiberglass materials and products with different strengths, aesthetics and applications. Fiberglass is classified into seven main types. E-glass is the most common glass reinforced plastic variety, A-glass is characterized by low boron oxide concentration, E-CR-glass has a high acid resistance, C-glass is used for glass staple fibers, D-glass features a high dielectric constant, R-glass is known for its exceptional mechanical properties and S-glass is known for its very high tensile strength. These fiberglass types are mixed with thermosetting resins, which are usually made of epoxy or polyester. Resins are used for molding, laminating and casting. Epoxy resin has a higher performance and therefore a higher cost, and it is used in weight-critical, high strength applications. Polyester resins are less expensive, more widely used and have good resistance to corrosion.

There are a few key descriptors used in identifying a particular type of fiberglass. The basic glass fiber material used in the fabrication process and the type of resin used has the most influence on the basic properties of the completed fiberglass product.

- Glass Classifications

- Traditionally assigned one of seven common classifications based on the material components and properties.

- E-Glass

- Standard glass-reinforced plastic fiberglass.

- A-Glass

- Specialty glass with a lowered concentration of boron oxide.

- E-CR-Glass

- Fiberglass produced for exceptionally high acid resistance.

- C-Glass

- Used to produce glass staple fibers.

- D-Glass

- Fiberglass characterized by a relatively high dielectric constant.

- R-Glass

- Fiberglass designed for high mechanical performance specs.

- S-Glass

- Fiberglass designed for an exceptionally high tensile strength.

- Resins

- In addition to the basic fiberglass material, most fiberglass products will also be characterized by the choice of thermosetting resins. While there are alternative resins, the vast majority of use cases will involve either polyester or epoxy based resin.

- Polyester Resin

- Inexpensive widely-used resins with a high resistance to corrosion resistant effects. The most common resin type for fiberglass fabrication.

- Epoxy Resin

- High-performance resin used in applications requiring exceptional strength-to-weight ratios. More expensive than polyester resin.

- Other Fiberglass Types

- Outside of the basic categories and classifications of fiberglass, you may also run into certain common terms when describing fiberglass for specific applications or specs.

- Fiberglass Pipe

- Piping made up of FRP, aka fiberglass reinforced plastic. Highly resistant to corrosion.

- Fibercast Pipe

- Refers to a specific popular family of fiberglass pipe products for chemical processing and handling.

- Fiberglass Reinforced Plastic

- Plastics combined via plastic thermoforming with extruded glass fibers. Often referred to simply as fiberglass, or as GRP (glass-fiber reinforced plastic). Usually, but not always, what is meant by the term 'fiberglass' in industry.

- Structural Fiberglass

- Rugged fiberglass shapes, plates, and components used in construction and other industrial production processes.

Fiberglass Fabrication Images, Diagrams and Visual Concepts

Fiberglass molding, a method for forming complex and intricate parts using fiberglass resin for reasons such as cost of the materials, ease of production, durability, and replicability.

Fiberglass molding, a method for forming complex and intricate parts using fiberglass resin for reasons such as cost of the materials, ease of production, durability, and replicability.

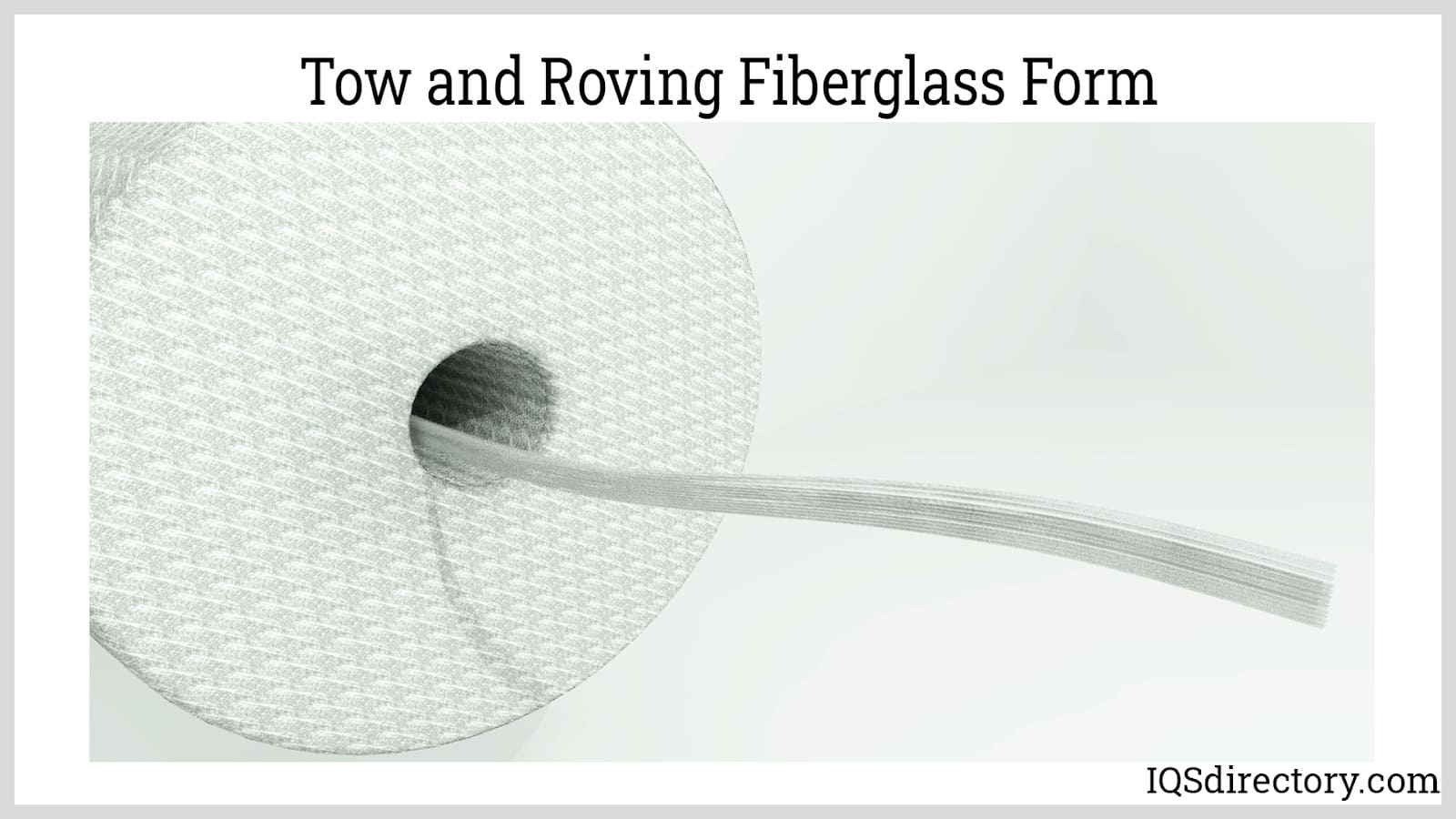

Tow and roving fiberglass, the form that has the highest properties of all fiberglass.

Tow and roving fiberglass, the form that has the highest properties of all fiberglass.

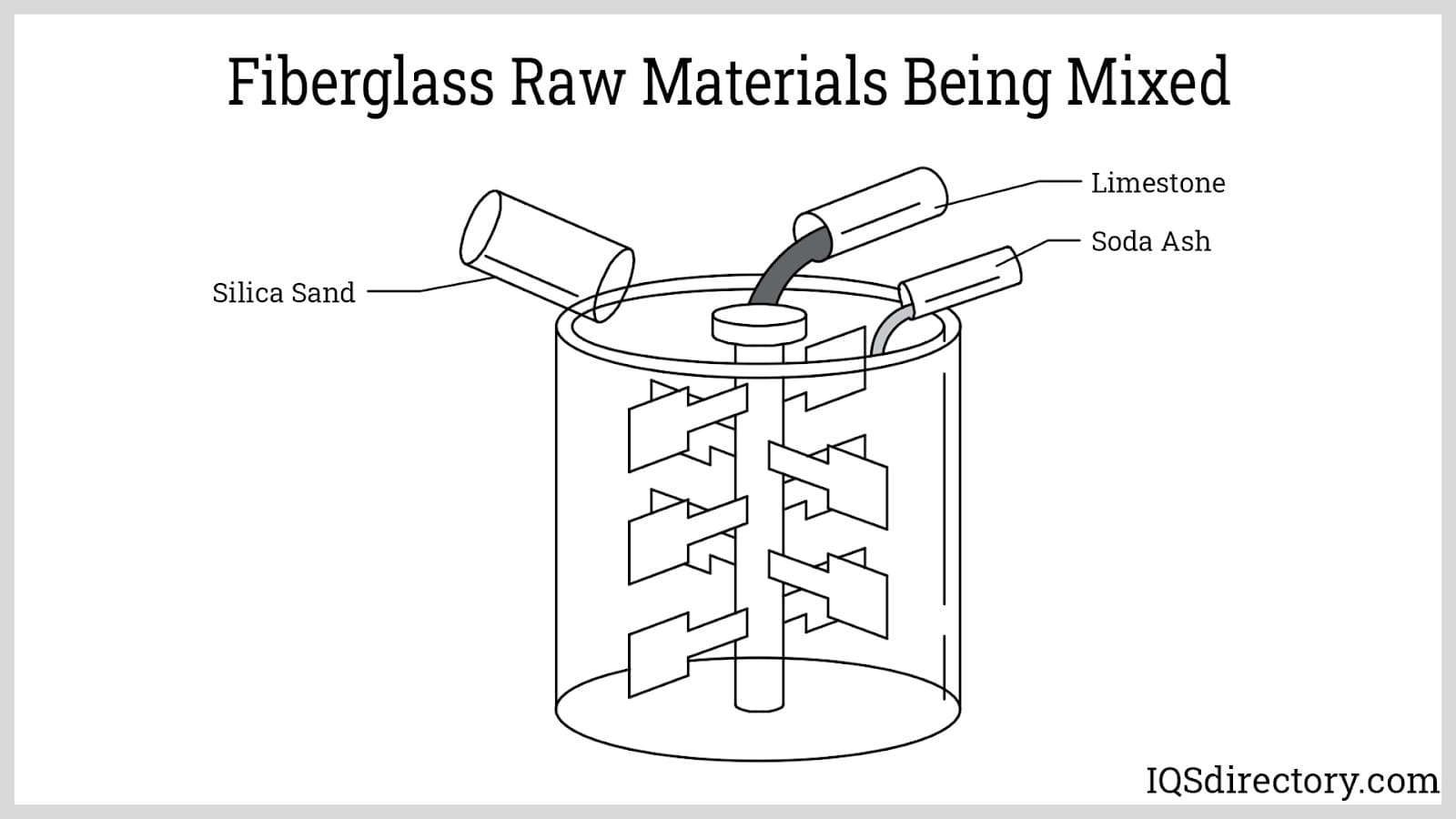

The ingredients for fiberglass include silica sand, limestone, and soda ash, which is carefully measured and mixed to form the batch.

The ingredients for fiberglass include silica sand, limestone, and soda ash, which is carefully measured and mixed to form the batch.

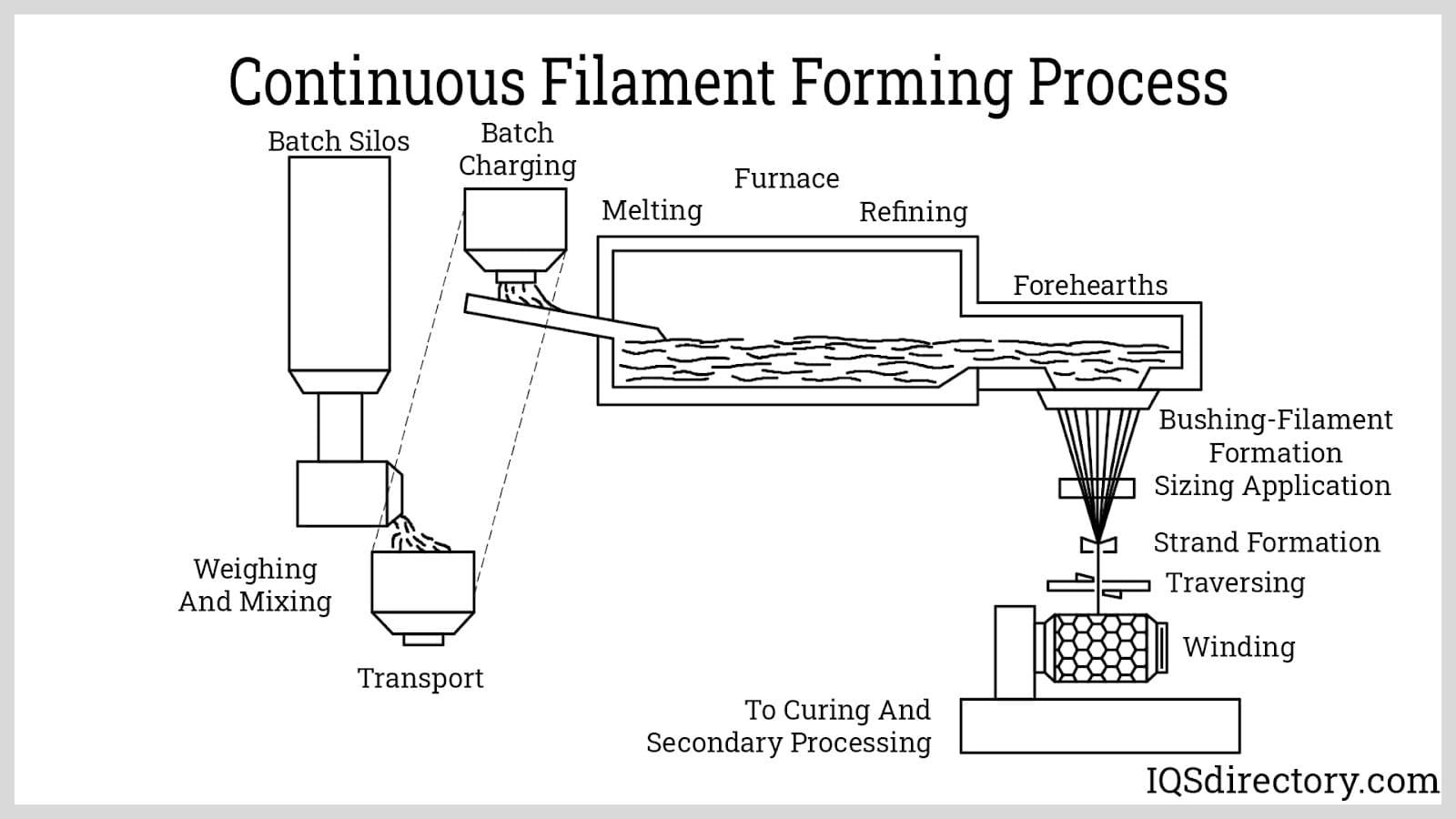

The process for melting the material to create fiberglass.

The process for melting the material to create fiberglass.

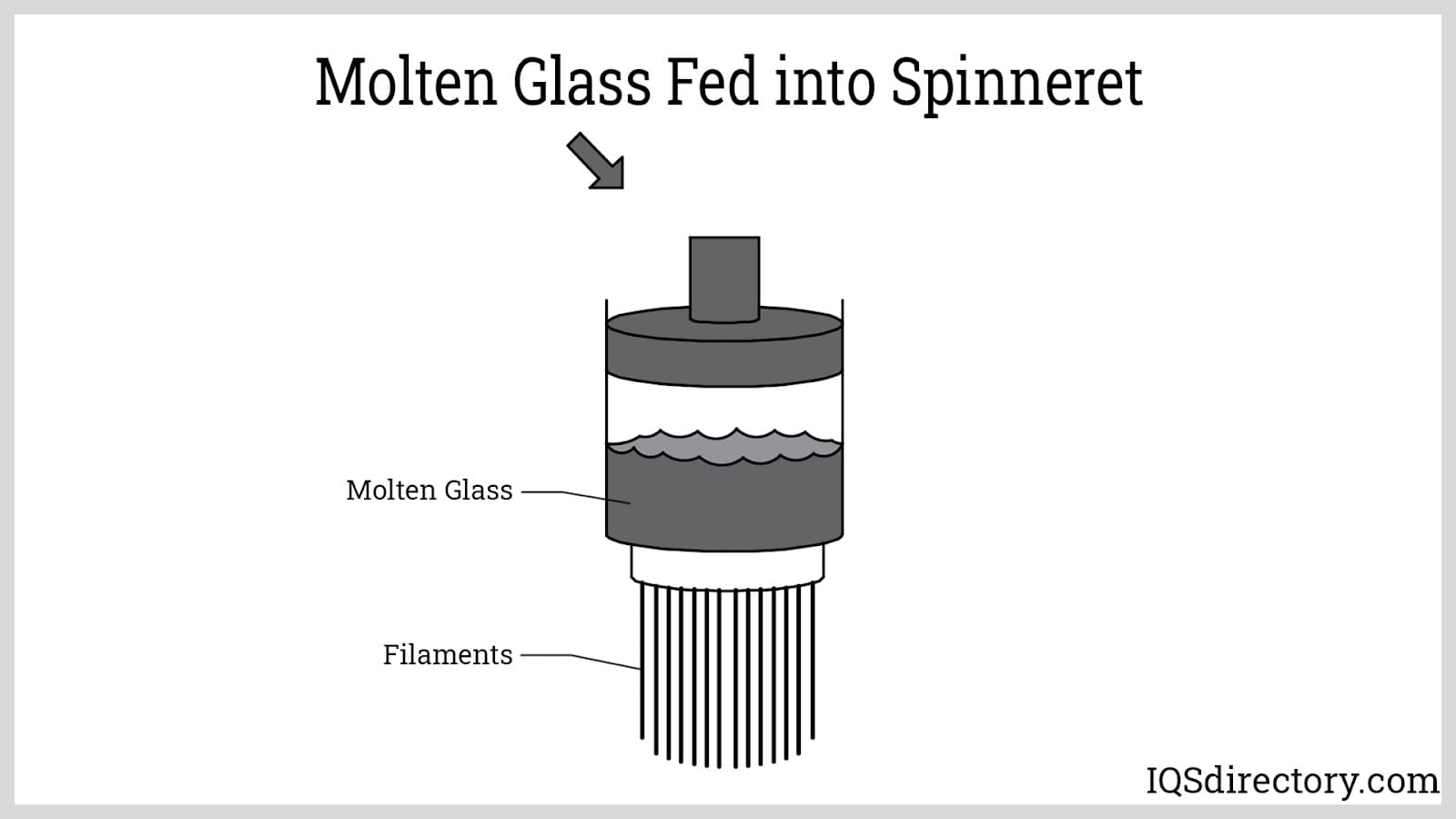

The molten glass is passed through fine filaments which creates the fiberglass.

The molten glass is passed through fine filaments which creates the fiberglass.

This process can yield a long and continuous fiber, fiberglass filaments are produced through this process.

This process can yield a long and continuous fiber, fiberglass filaments are produced through this process.

Types of Fiberglass Fabrication

- Corrugated Fiberglass Products

- Waved or ridged, two-layer fiberglass reinforced plastic sheets.

- Fiberglass Boxes

- Square or rectangular-shaped storage and transportation tools made of fiberglass reinforced plastic.

- Fiberglass Enclosures

- Tanks or storage areas fabricated of fiberglass. Food industries, chemical plants and water treatment facilities use fiberglass enclosures.

- Fiberglass Fabricators

- Companies that produce fiberglass reinforced plastic products as well as fiberglass for other applications like insulation.

- Fiberglass Grating

- Composed of a series of parallel and intersecting parallel lines of fiberglass.

- Fiberglass Molding

- Open, closed and centrifugal molding, shapes fiberglass products using a hollowed form. The mold from which the fiberglass is created is usually a metal.

- Fiberglass Panels

- Planes or sheets made of fiberglass reinforced plastic.

- Fiberglass Pipes

- Hollow channels made of fiberglass reinforced plastic.

- Fiberglass Products

- Made of a mix of glass fibers and resins.

- Fiberglass Reinforced Plastics

- Plastics that have been combined during a plastic thermoforming process with extruded glass fibers in order to improve the plastic's qualities of strength and durability.

- Fiberglass Rods

- Thin, often rounded shafts that are made of fiberglass reinforced plastic.

- Fiberglass Sheets

- Sheets made of a mix of fine filaments of glass and resins.

- Fiberglass Storage Boxes

- Heavy-duty, durable, waterproof units that are used to store such things as fishing tackle, pool equipment and paint and liquid products. Larger storage boxes may also double as seating.

- Fiberglass Tanks

- Fiberglass containers ranging in size that are used to store gases, liquids and sometimes solids. Many food plants and chemical plants will make use of fiberglass tanks.

Fiberglass Applications and Industries

The versatility of fiberglass lends it to applications across countless industries. It can serve in a huge number of structural roles where metals or pure plastics may otherwise be used, including but not limited to:

- Construction

- A common material for basic insulation in some forms and as a primary structural material in others.

- Vehicle Manufacture

- A popular material for the body of boats, cars, airplanes, and various other vehicles thanks to its strength-to-weight ratio.

- HVAC

- Used as a primary insulation material as solid panels and for seals and coatings in spray form. Sporting Equipment- Fiberglass has become a popular material for protective gear, equipment such as poles, hockey sticks, and bows, and many other items.

- Storage Tanks

- Many types of storage tanks can be produced using fiberglass as a primary material. Fiberglass tanks are most commonly used as chemical storage, septic tanks, and similar containers.

- Piping

- Fiberglass pipes offer a number of benefits over traditional plastic or metal piping, making fiberglass piping the ideal choice for certain applications.

- Medicine

- A key component in medicine for similar reasons to its presence in sporting equipment. Particularly common are fiberglass parts in orthopedic devices.

- Telecommunications

- Low RF permeability and low signal attenuation is used for shrouding antennas or to conceal equipment when signal permeability is non-desirable or a nonfactor.

Fabrication Machinery

While any number of typical industrial machines will be found at a fiberglass fabricator, there are two unique pieces of machinery crucial to the production of fiberglass products:

- Fiberglass Molds

- Each type of fiberglass molding process requires a unique mold designed to that standard. Any particular fabricating team may be equipped with some or all of the types of mold, depending on specialties and the size of the operation. A fabricator working exclusively with pipes, for example, may only need regular access to a centrifugal mold.

- Fiberglass Cutting Systems

- Regardless of the molding process used, fiberglass products will almost always require trimming and cutting to meet final specifications. This usually involved specialized fiberglass cutting machines, which can offer greater or less degrees of automation. More advanced assemblies may complete the entire cutting process without human input, while others may require step by step setting and manual adjustment.

Choosing a Custom Fiberglass Manufacturer

Choosing fiberglass fabricators for your project, ongoing supply requirements, or fiberglass repair can be difficult. Rather than trying to determine the best or cheapest fiberglass fabricators in your area, you instead should look for the one best suited to your custom needs.

- Specific Application

- It's always best to work with a fiberglass fabricator already familiar with your custom application requirements or similar projects. If you can get references from businesses which had similar needs, you can get a very clear picture of the type of service and final product you can expect.

- Fiberglass fabricators familiar with your specific industry or field's requirements can also assist you in maintaining compliance, meeting industry standards, and ensuring optimal results with a minimum of waste, miscommunication, and inefficiency.

- Manufacturing Scheduling

- Make your schedule needs clear when choosing a manufacturer, to make sure the turn-around and timing for your project will be what you need it to be. If you're going to have an erratic, unpredictable, or fluctuating need for fiberglass products, make sure you're working with a manufacturer that can adapt to your custom requirements without problems.

- Volume Requirements

- If you have larger volume requirements, make sure you're working with a manufacturer that can meet those requirements without compromising operations for other clients and customers. If you anticipate growth in the future, it's best to start with a manufacturer that can meet your future volume needs rather than trying to change fabricators down the line.

- Product Versatility

- A good fiberglass manufacturer wants to work with you to meet your custom fabrication needs as accurately as possible, rather than trying to force you into their lowest-cost solution with no regard for your needs. Versatility in products, shipping, and other considerations should always be a high priority in custom fiberglass fabrication.

Variations and Alternatives to Fiberglass

While there are any number of materials which may be used in specific applications instead of fiberglass, aluminum stands out as the most consistent alternative due to largely similar properties. Aluminum and fiberglass reinforced plastics offer similar densities and physical versatility, but with a few key differences. Different applications may make aluminum or fiberglass more desirable.

Fiberglass is often a superior material in comparison to many others, specifically aluminum, which is the main alternative to fiberglass. Pultruded fiberglass shapes have several advantages over comparable aluminum extruded shapes. Pultruded fiberglass has superior resistance to a wide variety of chemicals. Fiberglass shapes are about 70% of the weight of aluminum shapes but with the same density. Pultruded fiberglass is non-conductive with a high dielectric capability, while aluminum is a conductor. Fiberglass is a much better insulator than aluminum, as it has much lower thermal conductivity. Pigment added to the resins of fiberglass can provide color throughout the part, while aluminum requires prefinishing, anodic coatings or paint. Fiberglass is transparent to radio waves and EMI/RFI transmissions and is often used for radar and antennae enclosures and supports. Aluminum is highly reflective, making it inappropriate for such applications. Pultruded fiberglass shapes can be easily fabricated in the field with common carpenter tools and do not require torches or welding. Finally, the glass mat in pultruded fiberglass shapes evenly distributes the load of an impact, while aluminum easily deforms. Fiberglass reinforced plastic is an excellent construction material for an extensive range of products.

- Lighter Weight

- Compared to its primary alternative, aluminum, fiberglass tends to be about 70% of the weight at similar density and strength. The ratio also compares favorably to any number of other plastics, composites, and metals.

- Non-Reflective Properties

- While not a benefit in all applications, in many roles fiberglass non-reflective properties for light, radio, and other waves make it the ideal material.

- Even Distribution of Force

- One of the unique properties of fiberglass lay in the way it distributes force. While this may not be ideal in all applications, it's highly valuable in many cases.

- Easy Fabrication

- Relative to the fabrication process for aluminum and other comparable materials, fiberglass is extremely easy to fabricate and customize to your exact needs. This includes pigmentation, secondary coatings, and many other considerations.

- Superior Insulation

- The unique thermal properties of fiberglass make it a standout solution for insulation in a wide range of uses. It remains a primary insulation material in construction, HVAC, and similar industries.

Fiberglass Fabrication Terms

- Aspect Ratio

- Generally, the ratio of diameter to length. In composites, it is the ratio of the fiber or filler in the composite matrix.

- Bondable

- Capable of being secured or fastened using a bond or rope. Fiberglass is bondable because the resins and glass that are combined to create fiberglass are bond forming.

- Catenary

- The act of creating or maintaining equal tension in parallel fibers. Catenary also refers to having the property of this tension.

- Chopped Strand Mat

- A reinforcement of fiberglass that uses short strands of continuous rovings arranged in random order and held together with a binder.

- Composite

- A material, such as fiberglass reinforced plastic (FRP), composed of two or more distinct substances. They combine to form functional or structural characteristics not available with a single material.

- Compression

- The process of increasing density of materials. As with fiberglass laminates, compression results in the product becoming smaller and pressed together.

- Continuous Roving

- Sizing-coated parallel filaments drawn together into single or multiple strands and wound into a cylindrical package.

- Cupola

- Also referred to as a “dome,” it is an upside down-shaped cup made of fiberglass, which covers the tops of buildings, churches and other forms of architecture.

- Epoxy

- A common surface coating that forms a tight surface structure, is strongly adhesive and shrinks little, if at all.

- Fiber

- General term for a filamentary material whose length is at least 100 times its diameter. Fiber also refers to parts of a single unit of a substance that forms threads to be woven.

- Fiberglass Reinforcement

- Common material used to reinforce plastic.

- Filament

- The smallest unit of a fibrous material that is formed by spinning or drawing it into a single, long, continuous entity.

- Filament Wound Tubing

- Tubing that consists of finely spun fibers in a uniform structure.

- Filler

- An inorganic addition, especially particulate additives, to the composite matrix in order to improve the performance of the product, such as in shrinkage control, surface smoothness and water resistance.

- Glass

- Of a large class of materials with varying optical and mechanical properties that is generally hard, brittle and translucent or transparent and considered to be a super cooled liquid, as opposed to a solid. Glass fibers, when mixed with various resins, are the main ingredients in a fiberglass product.

- Glass to Resin Ratio

- The amount of glass compared to the amount of resin in a fiberglass product. Generally, the higher the concentration of glass, the greater the strength and durability.

- Laminate

- A thin fiberglass sheet or plate created by compression. Laminates sometimes consist of several thin layers.

- Polymer

- One of many synthetic and natural compounds of high molecular weight. They are composed of millions of repeating links, each considerably light and simple.

- Resin

- Any of numerous translucent yellow or brown to clear, semisolid or solid substances of plant origin, such as amber and copal. Resins are used in synthetic plastics, inks, lacquers, adhesives, etc.